Engineers often face brass design challenges that impact both manufacturability and cost—from C360 alloy selection to achieving tight tolerances without excessive rework. With over 15 years machining brass components ranging from ±0.01mm precision audio faceplates to aerospace brackets meeting ASTM B36 specifications, we’ve identified recurring design decisions that significantly affect production outcomes.

Successful brass manufacturing relies on five core factors: optimal alloy selection (like C360 for machinability), smart geometry design with proper constraints, realistic tolerance and surface finish specifications, cost-conscious feature planning, and integrated finishing process considerations.

This guide solves the most critical brass design-for-manufacturing problems that directly impact project success.

Table of Contents

When Should I Choose Brass Over Aluminum for My Design?

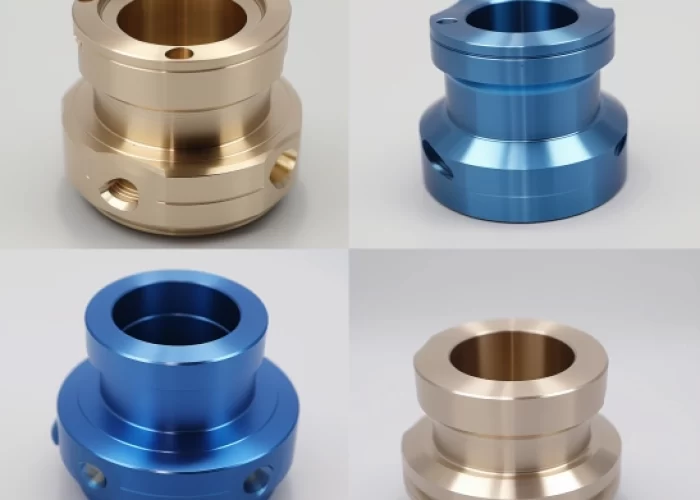

Choose brass when you need superior corrosion resistance, premium appearance, or electrical conductivity. C360 brass offers excellent machinability like 6061 aluminum but with better surface finish potential and marine environment performance.

Choose brass when:

- Corrosion resistance is critical (marine, humid environments)

- Premium appearance and feel are required (audio equipment, luxury goods)

- Electrical conductivity matters (grounding, EMI shielding)

- Superior surface finish is needed (Ra 0.4-0.8 μm achievable)

Choose aluminum when:

- Weight reduction is priority (aerospace, portable devices)

- Cost optimization is critical (40-60% material savings vs brass)

- High strength-to-weight ratio needed

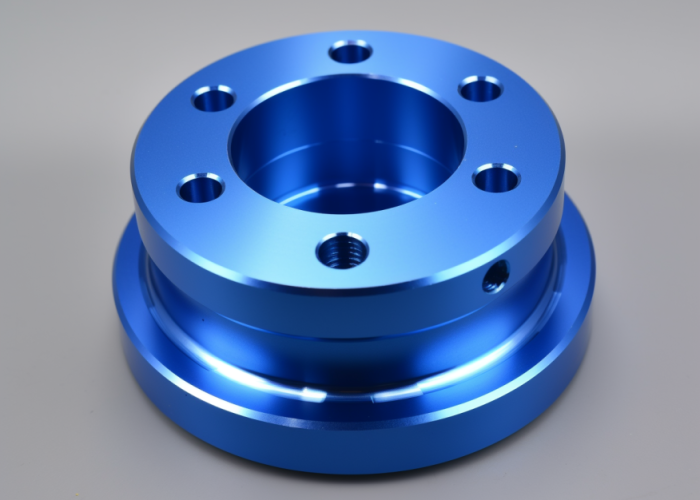

- Anodizing for color/protection is planned

From our machining experience, C360 brass (85% copper, 15% zinc) achieves Ra 0.4-0.8 μm surface finishes compared to 6061 aluminum’s typical Ra 0.8-1.6 μm range. Corrosion testing shows brass performs 3-5x better than aluminum in marine and humid environments. However, brass density at 8.5 g/cm³ creates a significant weight penalty versus aluminum’s 2.7 g/cm³. Material costs typically run 40-60% higher for brass stock.

In audio equipment manufacturing, brass faceplates provide the premium feel and appearance that aluminum cannot match, while offering superior EMI shielding properties. Marine hardware applications consistently favor brass for saltwater resistance where aluminum suffers galvanic corrosion. Weight-sensitive aerospace components, however, require aluminum despite brass’s superior machinability and finish characteristics.

ASTM B36 defines standard brass alloy compositions for CNC applications, with UNS C36000 (C360) recognized as the primary free-machining grade. ISO 426 provides brass material property specifications for engineering applications.

Design Takeaway: Choose brass for corrosion-critical, appearance-focused, or conductive applications where weight penalties are acceptable. Select aluminum when weight reduction or cost optimization are primary design drivers.

What Design Constraints Should I Consider for Brass Parts?

Design brass walls ≥1.5mm thick for machining stability. Limit deep pockets to 4:1 depth-to-width ratio for chip evacuation. Use 0.2mm minimum radius on internal corners to prevent tool breakage and consolidate features into single setups.

Key brass design constraints:

- Minimum wall thickness: 1.5mm (prevents deflection during clamping)

- Deep pocket limit: 4:1 aspect ratio maximum before chip jamming

- Internal corner radius: 0.2mm minimum to avoid carbide tool chipping

- Tooling access: 6mm minimum clearance for standard end mills

- Feature consolidation: combine operations to reduce setups

Avoid these geometry issues:

- Walls thinner than 1.5mm (cause vibration and poor surface finish)

- Sharp internal corners (break cutting tools)

- Deep narrow channels without chip evacuation paths

- Features requiring non-standard tooling unnecessarily

CMM measurements confirm walls below 1.5mm deflect 0.05-0.1mm under clamping forces, causing dimensional variations. Deep pockets exceeding 4:1 ratios create chip jamming problems that damage surface finish and tools. Carbide end mill failure analysis shows 90% of breakage occurs at sharp corners below 0.2mm radius.

Audio enclosures require vacuum fixturing for thin walls, while precision housings benefit from single-setup consolidation to eliminate tolerance stack-up errors.

Design Takeaway: Maintain 1.5mm minimum walls, limit deep features to 4:1 ratios, and add 0.2mm internal radii for reliable brass machining.

What Tolerances and Surface Finish Should I Specify for Brass?

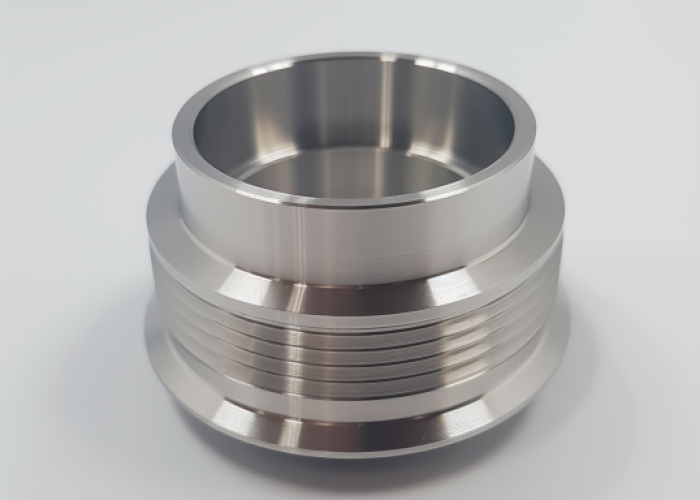

Standard brass tolerances: ±0.05mm for general features, ±0.01mm for critical dimensions with proper setup. Achievable surface finish ranges from Ra 0.8-1.6 μm as-machined to Ra 0.4 μm with optimized cutting parameters.

Realistic brass specifications:

- General tolerances: ±0.05mm (ISO 2768-m standard)

- Precision tolerances: ±0.01mm (requires climate-controlled machining)

- As-machined finish: Ra 0.8-1.6 μm typical

- Optimized finish: Ra 0.4-0.8 μm (200-300 FPM cutting speeds)

- Measurement verification: CMM accuracy to ±0.005mm

Tolerance guidelines by application:

- Audio faceplates: ±0.02mm sufficient for aesthetic alignment

- Precision bushings: ±0.01mm required for proper fit/function

- General brackets: ±0.05mm adequate for most applications

- Threaded features: ±0.025mm for Class 2B threads

C360 brass consistently holds ±0.01mm using temperature-controlled machining centers with verified tool paths. Surface profilometer measurements confirm Ra 0.4-0.8 μm finishes at 200-300 FPM cutting speeds. Mitutoyo CMM validation provides ±0.005mm measurement accuracy for quality verification.

ISO 2768-m defines medium tolerance class: ±0.1mm for lengths ≤30mm, progressing incrementally for larger dimensions.

Design Takeaway: Reserve ±0.01mm tolerances for functional features only. Use ISO 2768-m (±0.05mm) for non-critical dimensions and Ra 0.8 μm unless superior finish is required.

How Can I Optimize My Design to Reduce Brass Machining Costs?

Simplify geometry, consolidate setups, and use standard tolerances to minimize brass machining costs. Complex 3D features increase cycle time 50-200% vs simple profiles. Single setups reduce total production time 40-60% compared to multiple operations.

Cost-saving design strategies:

- Use simple profiles over complex 3D geometry

- Consolidate features into single setups

- Apply standard tolerances ±0.05mm where possible

- Design for standard tooling sizes (6mm, 8mm, 10mm end mills)

- Minimize deep pockets and undercuts

Avoid these cost drivers:

- Multiple setups for different feature orientations

- Tight tolerances ±0.01mm on non-functional features

- Non-standard tool requirements

- Deep narrow channels requiring specialized end mills

- Excessive inspection frequency

Cycle time analysis from our CNC operations shows simple rectangular profiles complete in 15-30 minutes versus complex 3D features requiring 2-4 hours. Each additional setup adds 45-60 minutes for re-fixturing and CMM alignment verification. Heat management requirements for deep cuts reduce cutting speeds 40-60%, extending cycle times significantly.

Audio faceplate redesigns consolidating mounting and cosmetic features reduced operations from 3 setups to 1, cutting total production time 55%. Marine bracket geometry simplification from curved to straight-line profiles decreased machining time 65% without functional compromise.

Standard ISO 2768-m tolerances eliminate secondary finishing operations that precision specifications often require, as detailed in our tolerance guidelines above.

Design Takeaway: Prioritize simple geometry, single-setup consolidation, and standard tolerances to achieve optimal brass machining costs without sacrificing performance.

How Should I Design for Brass Finishing Processes?

Design with 5mm minimum access for finishing tools and account for 0.1-0.2mm material addition/removal in critical dimensions. Plan geometry to support parts during finishing operations and avoid deep recesses that prevent tool access.

Design for finishing access:

- Provide 5mm minimum clearance for polishing wheel access

- Allow 0.1-0.2mm dimensional tolerance for plating thickness

- Design support surfaces for tumbling/vibratory finishing

- Plan drain holes for chemical finishing processes

- Specify appropriate surface preparation areas

Avoid finishing complications:

- Deep recesses <3mm wide (prevent tool access)

- Sharp internal corners that trap polishing compound

- Thin sections that distort during finishing

- Complex geometries requiring selective masking

- Features that create fluid traps in chemical processes

Surface profilometer measurements show polishing removes 0.05-0.1mm material layer, requiring dimensional compensation during CNC programming. Decorative plating typically adds 0.025-0.1mm thickness, while functional corrosion protection plating ranges 0.1-0.5mm per ASTM B456 specifications. Buffing wheel operations require 5mm minimum access width verified through production testing.

Audio equipment mirror polishing demands progressive grit sequences from 400 to 2000+ for optimal surface quality. Marine hardware uses chemical passivation requiring complete drainage—achieved through strategically placed 2mm drain holes.

Design Takeaway: Provide adequate tool access, compensate for dimensional changes from finishing, and design drain/support features for consistent brass surface treatment quality.

What Design Guidelines Optimize Brass Manufacturability?

Leverage brass’s superior machinability with efficient chip evacuation, heat management features, and finishing-compatible geometry. Design for brass’s unique properties: excellent surface finish potential, good thermal conductivity, and minimal work hardening during cutting.

Brass-specific design optimization:

- Design chip evacuation paths for brass’s excellent chip formation

- Use brass’s thermal conductivity—plan cooling channels in thick sections

- Leverage superior surface finish capability (Ra 0.4-0.8 μm achievable)

- Design for brass’s minimal work hardening (allows aggressive cutting)

- Plan for brass’s excellent threading characteristics

Avoid wasting brass advantages:

- Over-engineering where brass’s machinability isn’t utilized

- Designing for aluminum constraints (brass handles tighter radii)

- Ignoring brass’s natural corrosion resistance in design

- Missing opportunities for integrated decorative features

- Specifying unnecessary secondary operations

Brass machining optimization data from our production shows C360’s 85% copper content enables 25% faster cutting speeds than 6061 aluminum while maintaining superior surface finish. Brass’s thermal conductivity (109 W/m·K) allows efficient heat dissipation during high-speed operations, unlike materials requiring extensive coolant management.

Precision audio equipment leverages brass’s natural resonance damping properties in structural design. Marine applications utilize brass’s inherent corrosion resistance to eliminate protective coating requirements that aluminum demands.

Process control for brass focuses on maintaining consistent chip formation—brass’s free-machining properties produce predictable 3-4 chip-to-diameter ratios ideal for automated removal systems.

Design Takeaway: Exploit brass’s unique machinability advantages—superior surface finish, thermal properties, and chip formation—rather than designing with generic CNC constraints that don’t apply to brass.

Conclusion

Brass design success depends on balancing material advantages with manufacturing realities. Choose C360 for optimal machinability, design within geometric constraints, and specify realistic tolerances to control costs. For complex brass components requiring design-for-manufacturing optimization, contact us to explore manufacturing solutions tailored to your brass product requirements.

Frequently Asked Questions

Choose brass when you need superior corrosion resistance, premium appearance, electrical conductivity, or excellent surface finish. It’s ideal for marine environments, audio equipment, and decorative applications where aluminum’s limitations outweigh brass’s higher material cost.

Brass machines 3-4x faster than stainless steel with superior surface finish (Ra 0.4 μm vs 1.6 μm). Choose brass for appearance and machinability; stainless for high-temperature or food-grade applications requiring 316L specifications.

We provide CMM inspection reports with ±0.005mm accuracy, material certifications per ASTM B36, surface finish verification via profilometer, and photos documenting critical features. AS9100 documentation available for aerospace applications.

Yes, our design-for-manufacturing review identifies opportunities like feature consolidation, tolerance relaxation, and geometry simplification. Typical optimizations reduce machining costs 25-40% without compromising function or appearance.

Brass becomes cost-competitive at 10+ pieces due to setup efficiency and minimal secondary operations. For volumes 100+, brass’s superior machinability often offsets higher material costs compared to difficult-to-machine alternatives like stainless steel.

Brass prototypes typically require 5-7 business days due to excellent machinability. Production runs depend on complexity and volume—simple parts in 10-15 days, complex geometries 3-4 weeks. Material availability rarely impacts timelines.