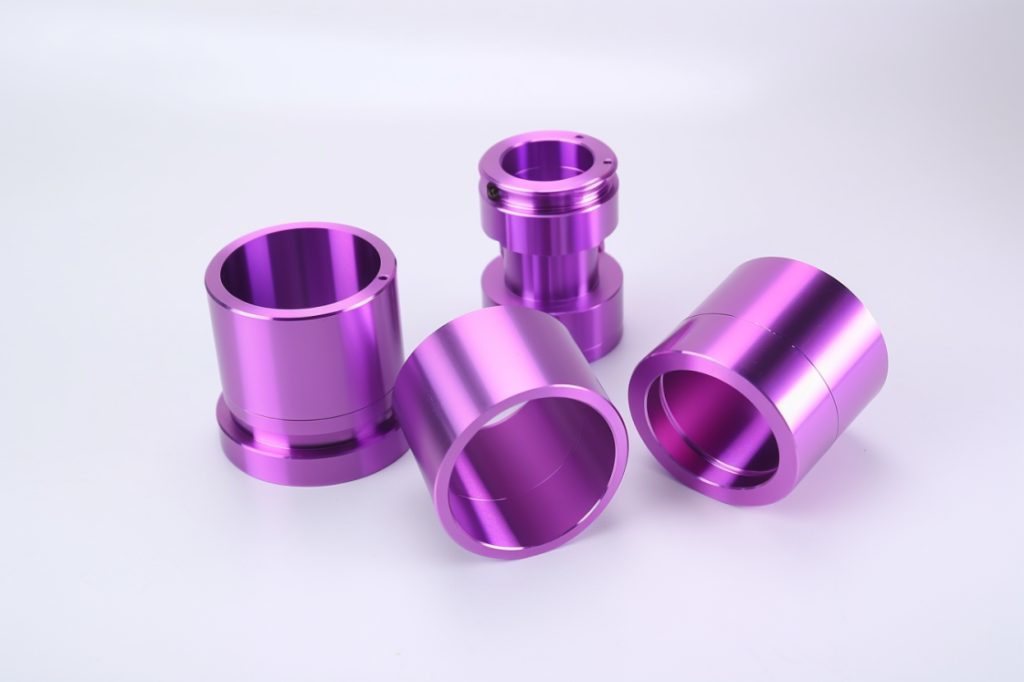

Are My Default Tolerances Slowing Down Every Quote?

Your drawing looks simple, but every quote drags. The real slowdown often isn’t workload — it’s your default tolerances. Many shops see ±0.01 mm callouts or tight general tolerances and pause before committing. A slow quote usually means the shop isn’t confident it can hold your specs without risk. Generic job shops hesitate when tolerances […]

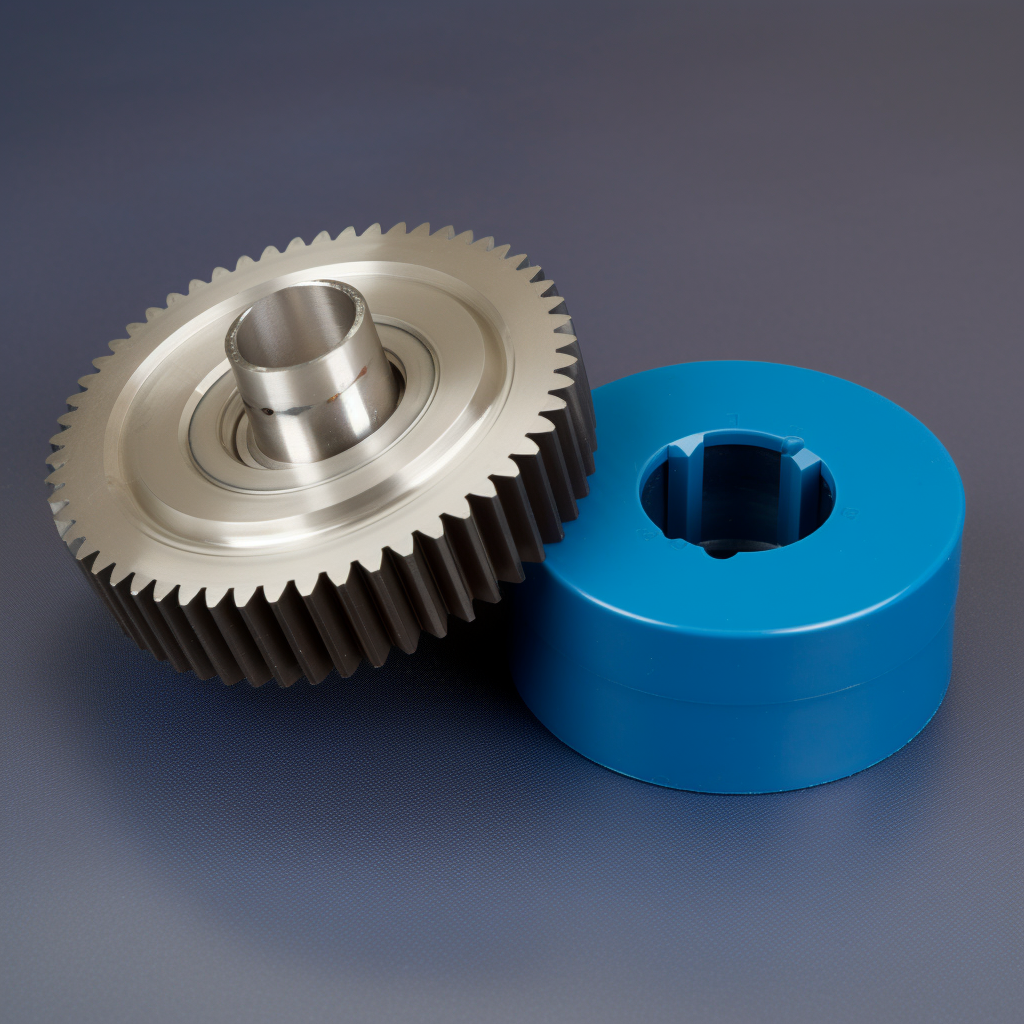

Why Does My Quiet Gear Design Become Noisy After Machining?

Your gear design ran quietly in simulation — but after machining, it buzzes or hums. The supplier blames “tolerance sensitivity,” even though everything passed inspection. That noise appeared after production, not in your design. In most cases, noise reveals poor process control — tool wear, runout, or weak fixturing — not design error. A CMM […]

Why CNC Parts Come Back Warped — and How to Fix It?

Your part was drawn flat but arrived twisted. The shop blames “material stress.” In most cases, that excuse hides poor fixturing, uneven cuts, or skipped stress relief — not a design issue. Every warped batch costs you time, assemblies, and credibility with your team. Warpage exposes weak process control, not bad drawings. Reliable CNC suppliers […]

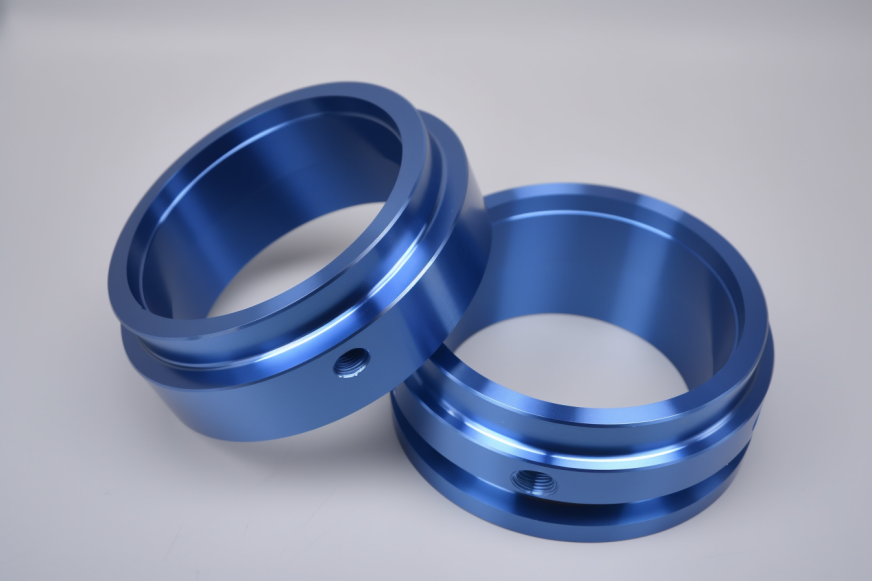

Why CNC Shops Reject Stainless Steel Parts as Too Difficult?

Your CNC supplier just said your stainless-steel parts are “too difficult.” No explanation, just a rejection — and now your schedule is slipping, It’s one of the most common sourcing frustrations: parts get rejected not because they can’t be made, but because the shop lacks stainless-specific capability. Most rejections come from shop limitations, not design […]