Why Shop No-Quote Deep Cavities or Narrow Pockets?

You send out your deep-pocket drawing and get silence—or a quote three times higher than expected. It’s rarely your design at fault. Most shops avoid deep cavities and narrow pockets because they lack the tooling reach, rigidity, or setup experience to cut them profitably. “No-quotes” usually come from tool deflection risk, chatter, and time-consuming setups, […]

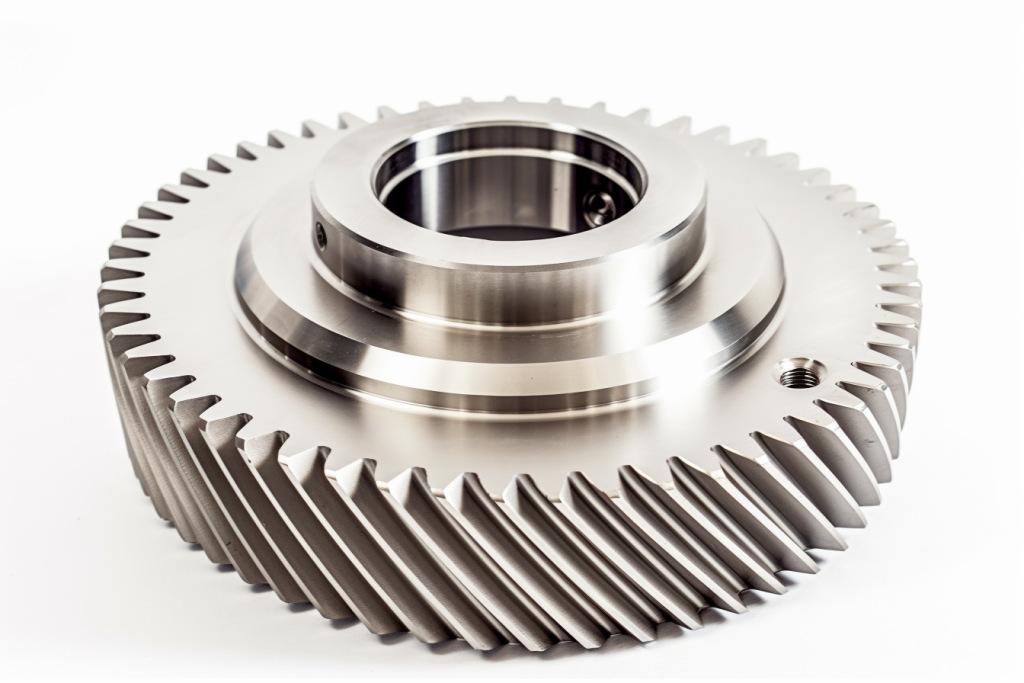

Am I over-specifying gear quality and paying too much?

Quotes come back slow or overpriced. Some shops decline. Others say your tolerances look “too tight.” You start wondering—are you paying for precision that doesn’t matter? Yes, many engineers over-specify gear quality and end up funding inspection time, tooling setups, and risk buffers that add no performance gain. Most shops price uncertainty, not capability. Matching […]

Why do my helical gears still make noise after grinding?

You expected grinding to make your helical gears run quiet — yet they still whine under load. It’s rarely a design flaw. Most often, the issue lies in supplier process control, where setup or alignment drift goes unchecked until the gears are already finished and delivered. Post-grind noise usually comes from lead, helix, or contact […]