Standard plastics lack strength while metals add unwanted weight and cost. Glass-filled POM offers a compelling solution, but requires understanding unique machining challenges for successful implementation.

Glass-filled POM delivers 70% higher tensile strength than standard POM but increases machining costs by 30-50% due to specialized tooling requirements and 2-3x higher tool wear rates.

Learn when glass-filled POM justifies the extra cost, how to budget for machining, and what design changes ensure manufacturing success.

Table of Contents

When Does Glass-Filled POM Justify the Extra Cost?

Glass-filled POM justifies its 30-50% machining cost premium when parts require strength exceeding standard plastics, typically at 50+ unit volumes where performance gains outweigh additional tooling costs. The material delivers 70% higher tensile strength while remaining 60% lighter than aluminum equivalents.

Key justification scenarios:

- High-load applications requiring 70% more strength than standard POM

- Weight-critical designs where aluminum adds unacceptable mass

- Thermal cycling environments up to 155°C requiring dimensional stability

- Vibration-sensitive assemblies needing superior damping properties

- Production volumes above 50 units where cost premium becomes economical

We achieve ±0.1% dimensional stability up to 155°C versus ±0.3% for standard POM. For prototypes (1-25 parts), expect $15-40 additional cost per part. Production runs above 100 units reduce this to $8-15 per part as tooling costs distribute.

Glass-filled POM excels in audio equipment requiring vibration damping without aluminum’s resonance issues, medical devices needing sterilization cycle stability, and aerospace components where weight reduction is critical. Compared to glass-filled nylon, POM offers superior dimensional stability. Carbon fiber costs 3-4x more with limited machinability.

Design Takeaway: Choose glass-filled POM when applications need performance beyond standard plastics but metal weight creates design constraints. Cost-effectiveness begins at 50+ unit volumes where performance requirements justify the machining premium.

How Much Should You Budget for Glass-Filled POM Machining?

Expect to budget 30-50% more for glass-filled POM machining compared to standard POM, with costs ranging from $15-40 per part for prototypes and $8-15 per part for production runs above 100 units. The premium reflects increased machining time and more frequent tool changes required for this abrasive material.

Cost breakdown factors:

- Prototype runs (1-25 parts): $15-40 premium per part

- Production runs (100+ parts): $8-15 premium per part

- Machining time increases 30-40% due to reduced cutting speeds

- Tool replacement frequency doubles compared to standard POM

- Setup costs higher due to specialized fixturing requirements

For volume planning, injection molding becomes more economical than CNC machining at approximately 500+ units for simple geometries. However, CNC remains cost-effective for prototyping and low-volume production where injection molding tooling costs become prohibitive. In our experience with medical device housings, the crossover point often shifts higher due to tolerance requirements that favor CNC precision.

Secondary finishing operations add 20-30% to base machining costs when smooth surfaces are required, but many applications accept the natural Ra 0.8-1.6 μm finish with visible fiber patterns.

Design Takeaway: Plan machining budgets with 40% buffer over standard POM costs for prototype phases. Production cost premiums decrease significantly with volume, making glass-filled POM manufacturing economically viable for runs above 50 units where performance justifies the investment.

What Design Guidelines Should I Follow for Glass-Filled POM?

Design glass-filled POM parts with minimum 2mm wall thickness, corner radii ≥0.5mm, and consolidated setups to minimize tool stress and reduce machining complexity caused by abrasive glass fibers. Following these guidelines prevents tool breakage, reduces scrap rates, and maintains cost control.

Critical design rules:

- Minimum wall thickness: 2mm (thinner walls cause tool deflection and breakage)

- Corner radii: ≥0.5mm to reduce tool stress and improve surface finish

- Avoid deep pockets >5:1 depth-to-width ratios that trap chips and heat

- Design for 3-axis machining when possible to minimize complex setups

- Thread engagement: limit to 1.5x diameter to prevent tap breakage

Deep hole drilling becomes problematic beyond 8:1 depth-to-diameter ratios due to chip evacuation challenges unique to glass-filled materials. Thread cutting requires pilot holes 0.1mm larger than standard to accommodate material spring-back—a lesson learned from aerospace bracket production where initial tap failures taught us this adjustment.

Feature consolidation significantly impacts manufacturability since glass-filled POM’s abrasive nature makes frequent repositioning challenging for both fixtures and operators. Single-setup designs reduce handling complexity and improve dimensional consistency across features.

Design Takeaway: Prioritize geometric simplicity and generous features over complex thin-wall designs. Every design decision should consider tool accessibility and chip evacuation to optimize glass-filled POM manufacturing efficiency.

What Manufacturing Requirements Should I Expect?

Glass-filled POM manufacturing typically requires 2-3 weeks lead time for prototypes and 3-4 weeks for production runs, with surface finishes of Ra 0.8-1.6 μm and visible fiber patterns that may require additional finishing for cosmetic applications. Understanding these timeline and quality expectations helps with project planning.

Manufacturing specifications:

- Lead times: 2-3 weeks prototypes, 3-4 weeks production (vs 1-2 weeks standard POM)

- Surface finish: Ra 0.8-1.6 μm typical with visible fiber patterns

- Cutting speeds: 300-600 ft/min (reduced from standard 500-1000 ft/min)

- Tool requirements: Carbide or diamond-coated for fiber-reinforced plastics

- Tolerance capability: ±0.1% achievable due to enhanced thermal stability

Quality verification involves more frequent dimensional checks using coordinate measuring machines, particularly for parts destined for regulated industries where documentation requirements exceed standard commercial applications. High-pressure coolant systems and specialized chip evacuation maintain consistent results, though cycle times extend compared to standard POM machining.

For applications requiring smooth surfaces, secondary finishing operations can achieve Ra 0.4-0.8 μm finishes but extend delivery timelines by 3-5 days. Most industrial applications accept the natural surface texture without additional processing, particularly in audio equipment where slight texture can actually improve grip and handling.

Design Takeaway: Plan project timelines with additional buffer for glass-filled POM manufacturing lead times. The material’s enhanced thermal properties enable tighter tolerances, but surface finish expectations should account for inherent fiber visibility in standard machining processes.

Which Applications Benefit Most from Glass-Filled POM?

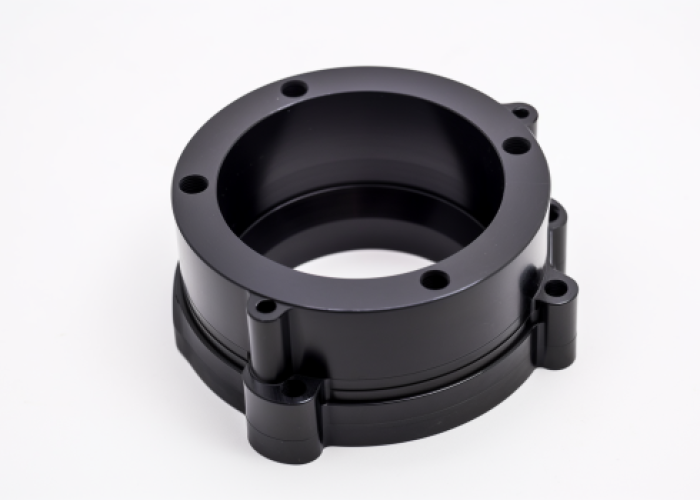

Glass-filled POM excels in audio equipment housings, medical device enclosures, aerospace brackets, and precision instrumentation where regulatory compliance, thermal cycling, or specialized performance requirements exceed standard plastic capabilities. These applications justify the machining cost premium through functionality that cannot be achieved with alternative materials.

Primary application areas:

- Audio equipment: Professional studio monitors and turntable components requiring acoustic precision

- Medical devices: Diagnostic equipment housings requiring FDA biocompatibility documentation

- Aerospace: Non-structural components needing AS9100 material traceability

- Precision instruments: Measurement devices operating across wide temperature ranges

- Industrial automation: Components exposed to continuous thermal cycling environments

Professional audio manufacturers specify glass-filled POM for critical acoustic components where even minor resonance affects sound reproduction quality. The material’s consistent performance eliminates the need for complex damping solutions required with metal alternatives.

Medical device applications focus on equipment housings that must maintain dimensional accuracy through repeated sterilization protocols while meeting biocompatibility standards for patient-contact applications. The material’s stability prevents seal degradation that could compromise sterile barriers.

Aerospace and instrumentation applications prioritize the material’s thermal stability for components operating in environments with significant temperature fluctuations, where dimensional consistency directly impacts calibration accuracy and operational reliability.

Conclusion

Glass-filled POM delivers exceptional strength and thermal stability but requires specialized machining expertise to manage 30-50% cost premiums effectively. Proper design optimization minimizes tool wear while maximizing performance benefits. Contact us to explore manufacturing solutions tailored to your glass-filled POM requirements.

Frequently Asked Questions

Optimal cutting speeds range from 300-600 ft/min, significantly slower than the 500-1000 ft/min used for standard POM. Faster speeds cause excessive tool wear and poor surface finish due to heat buildup from glass fiber friction.

CNC machining remains cost-effective for volumes under 500 units for simple parts or 1,000 units for complex geometries. Above these thresholds, injection molding becomes more economical despite higher upfront tooling costs, especially for parts with consistent wall thickness.

Design with minimum 2mm wall thickness to prevent tool deflection and breakage during machining. Thinner walls increase scrap risk and drive up costs due to the material’s abrasive glass fiber content. For critical features, consider 2.5mm minimum to ensure dimensional stability.

Glass-filled POM provides 70% higher strength than standard POM while weighing 60% less than aluminum. It works well for non-structural components, vibration-sensitive assemblies, and parts requiring thermal stability. However, aluminum remains necessary for primary load-bearing structural applications.

Glass-filled POM maintains dimensional stability up to 155°C compared to 110°C for standard POM, with thermal expansion reduced to ±0.1% versus ±0.3%. This enables tighter tolerances in applications with temperature cycling, such as automotive or industrial equipment.

Glass-filled POM typically costs 30-50% more to machine due to increased tool wear and slower cutting speeds. For prototypes, expect $15-40 additional cost per part. Production runs above 100 units reduce this premium to $8-15 per part as setup costs distribute across larger quantities.