Choosing the right tools for machining acetal can mean the difference between perfect parts and costly mistakes. While this versatile engineering plastic offers excellent machinability, using the wrong tools can lead to poor surface finish, dimensional inaccuracy, or even scrapped parts.

Successful acetal machining requires four key tool categories: cutting tools (including end mills and twist drills) for general material removal, specialized drilling tools with modified geometries, lathe tools for turning operations, and threading tools for producing threaded features. Each category is designed to address specific machining requirements while maintaining material integrity.

In this guide, we’ll explore each tool category in detail, explaining why they’re essential and how to choose the right ones for your application. You’ll learn how proper tool selection impacts your machining success from surface finish requirements to production efficiency.

Table of Contents

1. Cutting Tools

When machining acetal, your cutting tools are like the front-line soldiers in your toolbox. Just as a chef needs different knives for different ingredients, you need specific cutting tools to work with acetal effectively. These tools form the foundation of your machining operations, and selecting the right ones can mean the difference between smooth, efficient cuts and problematic results.

End Mills

End Mills are your primary workhorses for milling acetal. The polished finish isn’t just about appearance – it’s crucial for reducing friction during cutting and preventing material from sticking to the tool. When selecting end mills for acetal, look for positive rake angles to ensure clean cuts rather than pushing or tearing the material.

End Mill Characteristics Details Why It Matters

Polished Flutes Smooth, shiny surface Reduces friction, prevents sticking

Sharp Edges Precision-ground cutting edges Ensures clean cuts, better finish

Positive Rake Angles Forward-tilting cutting face Prevents material tearing

Twist Drills

Twist Drills require specific modifications for acetal machining. The key is having the right geometry to ensure clean cuts without material grabbing or deformation. Standard metal-cutting drills often need adjustments for optimal performance with acetal.

Drill Features Specifications Benefits

Modified Leading Edge Specialized geometry Prevents material grabbing

Relief Angles Higher than standard Reduces friction and heat

Point Angle Application-specific Clean hole entry and exit

HSS Tools

High-speed steel (HSS) tools offer excellent versatility and cost-effectiveness for acetal machining. These tools balance performance and value well, making them ideal for various operations when properly maintained and used with the correct parameters.

HSS Tool Features Specifications Benefits

Cutting Edges Sharp, well-maintained Clean cuts, good finish

Material High-speed steel Cost-effective, easy to resharpen

Application Range Wide variety of operations Versatile for different needs

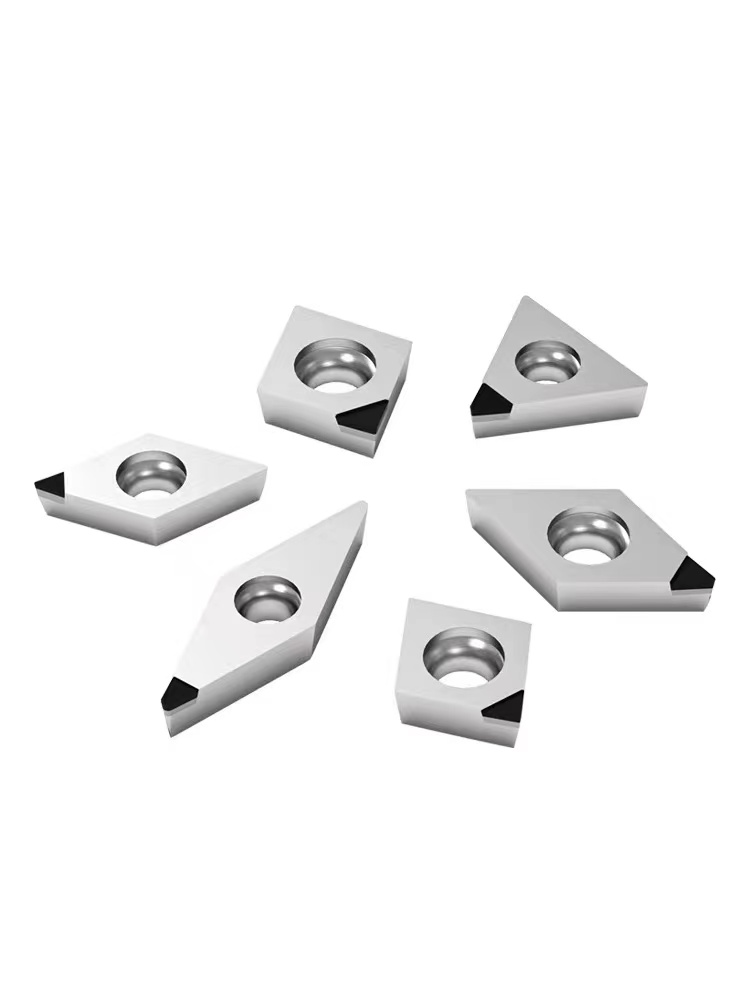

Carbide Inserts

Carbide inserts represent the premium choice for acetal machining, especially in production environments. While they have a higher initial cost, their superior performance and longevity often justify the investment for larger production runs.

Insert Features Specifications Benefits

Edge Quality Precision-ground Superior surface finish

Wear Resistance High durability Longer tool life

Heat Management Better heat dissipation Higher cutting speeds possible

Pro Tip: Always inspect your cutting tools before starting a new project. Even slight wear can affect the surface finish quality of an acetal. Think of it like writing with a sharp versus dull pencil – the difference is immediately noticeable in the results.

2. Drilling Tools

While standard drills can cut acetal, specialized drilling tools make a significant difference in hole quality and efficiency. Think of it like using a specialized bread knife instead of a general-purpose knife – the right tool makes the job both easier and more precise. Proper drilling tool selection can mean the difference between clean, accurate holes and scrapped parts.

Plastic-Specific Drills

Drilling tools designed specifically for plastics feature unique geometries that address the particular characteristics of acetal. These specialized drills prevent common issues like melting, chipping, and rough-hole surfaces. Unlike standard metal-cutting drills, plastic-specific drills are engineered to handle the lower melting point and different cutting characteristics of acetal.

The design differences aren’t just minor modifications – they represent a complete rethinking of how the tool interacts with the material. Plastic-specific drills feature special geometries that control heat generation, manage chip evacuation, and prevent the material from climbing up the flutes. This is particularly important with acetal, which can quickly soften and bind if heat isn’t properly managed.

Drill Features Specifications Benefits

Point Angle Modified for plastics Cleaner hole entry

Flute Design Enhanced chip evacuation Prevents heat buildup

Cutting Edge Special geometry Reduces material stress

Modified Tip Angles

The tip angle of your drill plays a crucial role in how it interacts with acetal. Unlike metal drilling, plastic drilling requires specific angles to prevent material grabbing and ensure clean cuts. The wrong tip angle can lead to a host of problems, from poor hole quality to complete part failure.

A properly modified tip angle helps control how the material flows away from the cutting edge, prevents grabbing and climbing, and ensures consistent hole quality throughout the drilling operation. This becomes especially important in deep holes or when working with thin-walled parts.

Angle Type Recommended Spec Purpose

Point Angle Typically broader than standard Better chip formation

Relief Angle Higher than metal drills Reduces friction

Helix Angle Modified for plastics Improves chip evacuation

Coolant Application

While acetal doesn’t always require coolant during high-speed drilling, proper cooling can significantly improve results and tool life. The decision to use coolant, and which type to use, depends on several factors including hole depth, cutting speed, and production requirements.

Coolant serves multiple purposes in acetal drilling operations. Beyond temperature control, it helps lubricate the cutting edge, assists in chip evacuation, and can help maintain dimensional stability in precision applications. The right cooling strategy can extend tool life, improve hole quality, and increase production efficiency.

When selecting a cooling method, consider your specific application requirements. Deep holes or high-speed operations may require more aggressive cooling, while shallow holes or light-duty work might need minimal or no coolant. Always consider the cleanup requirements and potential for contamination in your final application.

Cooling Method Application When to Use

Air Cooling Clean, dry operation Light-duty work

Coolant Mist Minimal residue Medium-duty drilling

Flood Coolant Maximum cooling Deep holes, heavy cuts

Pro Tip: Start with a slower speed when drilling acetal and increase gradually while monitoring chip formation. Clear, well-formed chips indicate proper cutting conditions. If chips become stringy or start to wrap around the tool, reduce speed or adjust your cooling method.

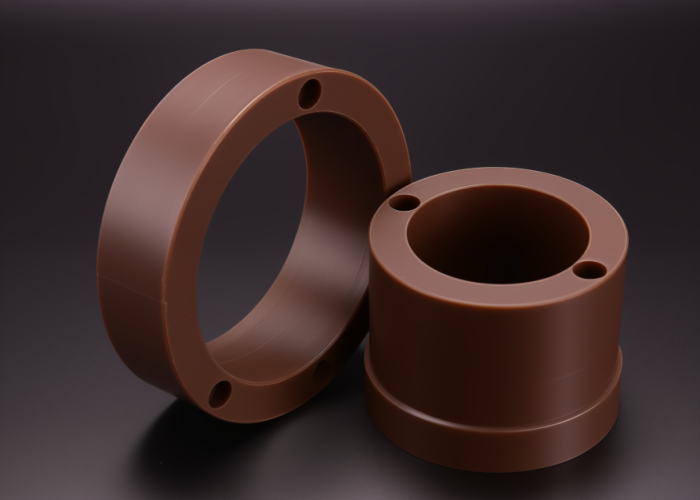

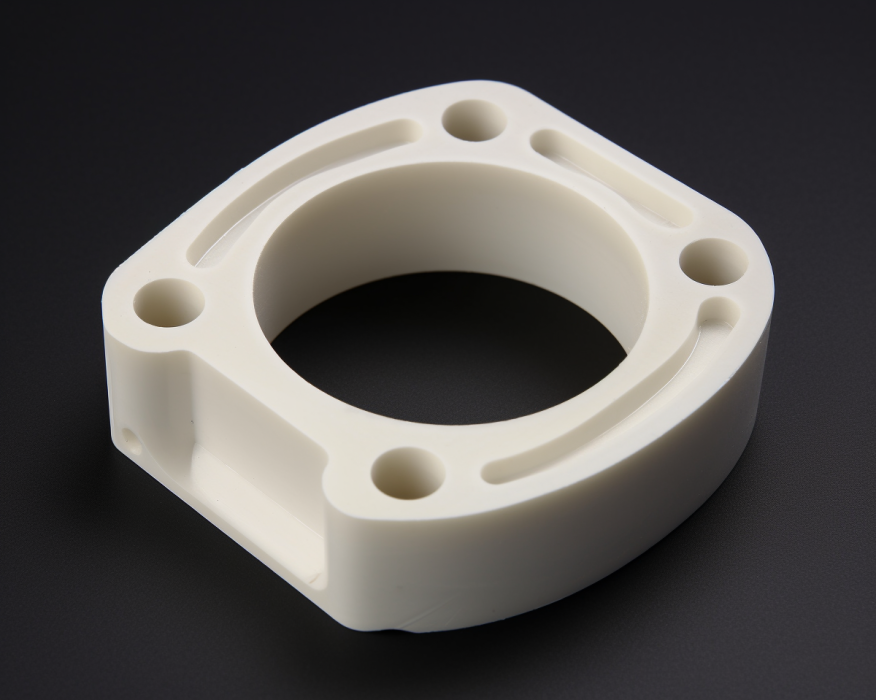

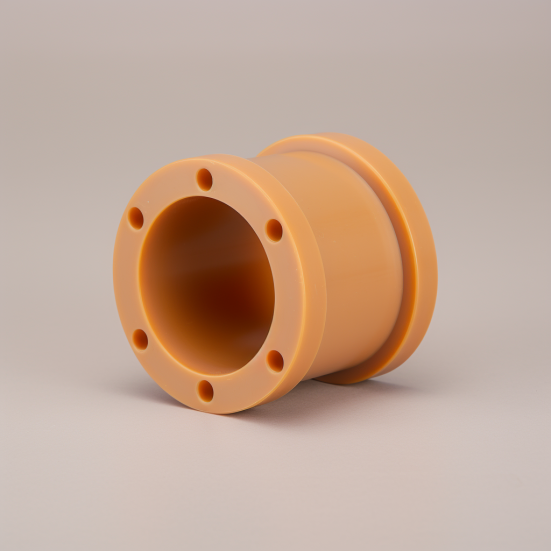

3. Lathe Tools

Lathe operations are crucial for creating precise cylindrical features in acetal parts. While acetal is generally easy to turn, using the correct lathe tools and techniques is essential for achieving the best results. Think of lathe tools as sculptors’ chisels – each type has its specific purpose and technique for optimal results.

Single-Point Cutting Tools

Single-point cutting tools are the workhorses of lathe operations for acetal. Their effectiveness depends greatly on both their geometry and how they’re used. The right tool geometry can differentiate between a smooth, precise cut and a rough, inaccurate surface.

Single-point tools require specific attention to their cutting edges and angles when working with acetal on a lathe. Unlike metalworking, where tool pressure and heat can be higher, acetal needs tools that cut cleanly without generating excessive heat. The tool’s rake angle, relief angle, and edge preparation all play crucial roles in achieving optimal results.

Tool Feature Specification Why It Matters

Rake Angle Positive, 5-15 degrees Reduces cutting forces

Relief Angle 10-15 degrees Prevents rubbing and heat

Edge Sharpness Very sharp, polished Ensures clean cutting

Thread Supports

Thread cutting in acetal requires special consideration due to the material’s flexibility and lower strength compared to metals. Proper thread support is crucial for achieving accurate, functional threads without damaging the material.

Support systems become even more critical when threading acetal because the material can flex under cutting pressure. Without proper support, you might end up with inconsistent thread geometry or, worse, damaged parts. This is especially important for longer or thinner parts where deflection is more likely to occur.

Support Type Application Benefits

Fixed Steady Long workpieces Prevents deflection

Following Rest External threading Maintains accuracy

Center Support Between-center work Ensures alignment

Surface Finish Considerations

The surface finish achieved during lathe operations can significantly impact the final part’s functionality and appearance. Acetal can achieve excellent surface finishes when proper techniques are used.

Understanding how different factors affect surface finish helps achieve consistent results. Speed, feed rate, tool geometry, and cooling all play interconnected roles in determining the final surface quality. Getting these factors right is essential for parts that need to meet specific finish requirements.

Factor Recommendation Impact

Cutting Speed Moderate to high Affects finish quality

Feed Rate Light for finishing Determines surface texture

Tool Condition Sharp and clean Critical for smooth finish

Pro Tip: When turning acetal, start with conservative speeds and gradually increase while monitoring surface finish quality. Look for a smooth, satin-like appearance without signs of melting or dragging.

4. Threading Tools

Threading acetal requires a different approach compared to metals due to the material’s unique properties. Like carving threads in wood versus metal, the softer, more flexible nature of acetal demands specific attention to tool selection and cutting parameters to achieve durable, accurate threads.

Conventional Threading Tools

Traditional threading tools can be used on acetal, but they need to be optimized for plastic machining. Success with these tools depends on understanding how acetal responds to the threading process and adjusting your approach accordingly.

The key to successful threading lies in how these tools engage with the material. Acetal’s tendency to flex and its lower heat resistance means that conventional threading tools must be used with modified techniques and parameters. This isn’t just about avoiding damage – it’s about creating threads that will maintain their strength and functionality over time.

Tool Type Characteristics Application Notes

Thread Mills Sharp cutting edges Best for larger threads

Taps Ground flutes Ideal for small holes

Dies Modified geometry External thread forming

Special Considerations for Acetal

Threading acetal successfully requires attention to several unique factors that differ from metal threading. These considerations directly impact thread quality and long-term performance.

Understanding these special requirements helps prevent common issues like stripped threads, dimensional inaccuracy, and premature wear. Acetal’s properties require specific adjustments to standard threading practices to ensure optimal results.

Factor Requirement Reason

Cutting Speed Lower than metals Prevents heat buildup

Thread Depth Slightly deeper Compensates for material flex

Lead Angle Modified for plastics Ensures clean cutting

Thread Quality Control

Maintaining consistent thread quality in acetal requires careful attention to both process and inspection. Quality control becomes especially important given acetal’s different wear characteristics compared to metals.

Regular monitoring and adjustment of threading parameters help maintain consistency across production runs. Understanding what to look for and how to measure thread quality is crucial for producing reliable threaded components.

Quality Aspect Check Method Acceptance Criteria

Thread Profile Thread gauges Clean, full profile

Surface Finish Visual/tactile Smooth, no tearing

Dimensional Go/No-Go gauges Within tolerance

Pro Tip: Always start with a pilot hole slightly larger than you would use for metal threading. This reduces stress on both the tool and the material, leading to better thread quality and longer tool life.

Conclusion

Selecting the right tools for machining acetal isn’t just about having the right equipment – it’s about understanding how each tool category contributes to successful part production. By mastering these four essential tool categories, you can achieve better results and avoid common machining problems.

Key Takeaways:

– Cutting tools need to be sharp and specifically designed for plastics

– Drilling tools require special geometries and proper cooling strategies

– Lathe tools must be optimized for acetal’s unique properties

– Threading tools need careful selection and application

Need help with your custom acetal parts? At okdor, our machining experts specialize in precision plastic components. Contact us to discuss your next project or learn more about our acetal machining capabilities.

Frequently Asked Questions

Sharpness is crucial. Tools designed specifically for plastics with sharp edges and proper geometries provide the best results. These features ensure clean cuts and proper chip formation.

Replace tools at the first signs of dulling or when surface finish quality begins to deteriorate. Regular inspection of cutting edges and monitoring of machining performance indicates when replacement is needed.

Standard metalworking tools often lack the optimal geometries for acetal, leading to poor surface finish, excess heat generation, and premature tool wear. Tools designed for plastics provide better results and longer service life.

Cooling requirements vary by operation. Light cuts might need only air cooling, while heavy machining benefits from flood coolant. The key is preventing heat buildup while maintaining material integrity.

Thread quality depends on tool geometry, cutting speed, pilot hole size, and cooling effectiveness. Proper parameters prevent material deformation and ensure thread strength.

Tool clogging typically results from improper chip evacuation, wrong speeds, and feeds, or inadequate cooling. Polished tool surfaces and proper machining parameters prevent material adhesion.