Product developers often wonder what 5-axis CNC machining can actually accomplish for their projects beyond the marketing claims. With over 15 years of precision CNC experience serving engineers across aerospace, audio, and medical sectors, we help teams understand the real capabilities and limitations of 5-axis technology. This post answers what 5-axis can do for your specific design challenges, timeline pressures, and budget constraints.

5-axis CNC machining can cut deep cavities, undercuts, and compound angles in one setup, reduce cycle times by 30-50%, and achieve ±0.01 mm tolerances on complex geometries that require multiple setups or design compromises on 3-axis machines.

Explore how 5-axis machining boosts speed, quality, and design flexibility—with data on setup reduction and when it adds real value to your project.

Table of Contents

Can 5-Axis Handle Your Complex Part Design?

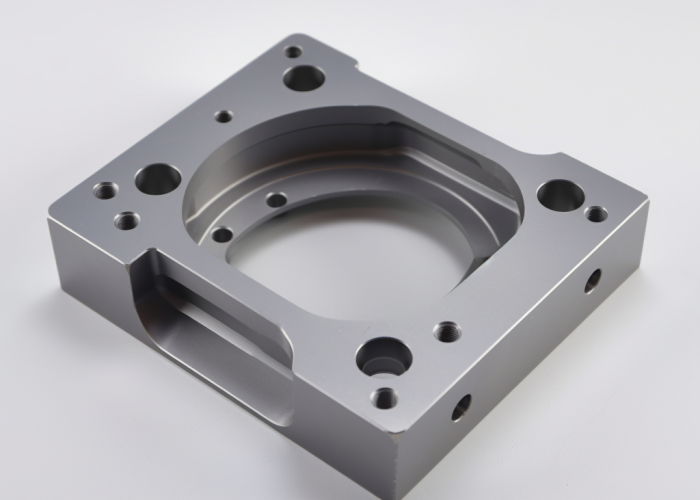

Yes, 5-axis CNC machining can handle deep cavities, undercuts, compound angles, and intricate contours that are impossible or require costly workarounds on 3-axis equipment. The simultaneous five-axis movement allows cutting tools to approach workpieces from virtually any angle without repositioning, enabling complex geometries in single setups.

Key complex geometries 5-axis can handle:

- Deep cavities with depth-to-width ratios exceeding 4:1

- Undercuts requiring angled tool access

- Compound curved surfaces and twisted geometries

- Multi-directional features in single setups

- Internal channels and cooling passages

We routinely machine parts with cavity depth-to-width ratios exceeding 4:1, undercuts requiring specialized tool access, and compound curved surfaces on aerospace components. For example, turbine blade cooling channels with internal geometries that would require multiple setups and custom fixtures on 3-axis machines are completed in one operation on our 5-axis centers.

Complex parts like medical instrument housings with deep pockets, angled bores, and curved surfaces benefit significantly from 5-axis capabilities. Audio equipment faceplates requiring precise compound angles for aesthetic and functional requirements are another ideal application where 3-axis limitations would force design compromises or increase manufacturing complexity.

According to ISO 2768-m standards, we maintain general tolerances while accessing geometries that challenge conventional machining approaches. Parts requiring multi-directional tool access—such as impeller blades with twisted surfaces or enclosures with internal features—showcase 5-axis advantages most clearly.

Design Takeaway: Reserve 5-axis for parts with deep cavities (depth-to-width >4:1), undercuts, compound angles, or multi-directional features that would require multiple 3-axis setups. Simple flat-surfaced components remain more economical on 3-axis equipment.

Will 5-Axis Give You More Design Freedom?

Yes, 5-axis CNC machining eliminates many design constraints imposed by 3-axis limitations, allowing engineers to optimize parts for function rather than manufacturability. You can design complex curved surfaces, eliminate draft angles, and create features that would otherwise require assembly of multiple components.

Design freedoms 5-axis enables:

- Curved surfaces without step marks or witness lines

- Zero-draft vertical walls and undercuts

- Internal features accessible from multiple angles

- Elimination of parting lines and assembly joints

- Organic shapes following functional requirements

Traditional 3-axis machining forces design compromises like adding draft angles for tool access, splitting complex parts into multiple components, or accepting step marks on curved surfaces. We’ve helped clients redesign audio equipment faceplates to eliminate visible parting lines, and aerospace engineers create lighter structural brackets by removing material in areas previously inaccessible to 3-axis tooling.

Complex geometries like helical cooling channels, twisted impeller blades, and organic shapes become manufacturable without design modifications. One medical device client reduced their assembly from five components to a single 5-axis machined housing, improving both reliability and aesthetics while cutting assembly time by 60%.

Engineers can focus on optimal part performance—such as aerodynamic efficiency or stress distribution—rather than working around manufacturing constraints. Weight reduction through optimized geometry becomes achievable when manufacturing limitations no longer dictate design decisions.

Design Takeaway: Leverage 5-axis when your part’s optimal design includes curves, undercuts, or complex angles that would require compromises on 3-axis equipment. The investment pays off when design freedom translates to improved part performance or weight reduction.

Can 5-Axis Achieve Better Quality Than 3-Axis?

Yes, 5-axis CNC machining consistently delivers superior quality through continuous tool engagement, reduced vibration, and optimal cutting angles throughout the operation. We achieve ±0.01 mm tolerances on complex features while maintaining Ra 0.8 μm surface finishes on contoured geometries.

Quality advantages of 5-axis:

- Tighter tolerances (±0.01 mm achievable on complex features)

- Superior surface finishes (Ra 0.8-1.6 μm on curves)

- Reduced vibration through optimal cutting angles

- Consistent tool engagement across complex surfaces

- Better dimensional stability on thin-walled features

Continuous tool engagement eliminates the quality variations that occur when parts are repositioned multiple times. Our Mitutoyo CMM verification with ±0.005 mm accuracy consistently shows better dimensional accuracy on intricate features compared to multi-operation approaches, particularly on aerospace components where ISO 2768-m general tolerances must be maintained alongside critical-to-function dimensions.

Surface finish quality improves significantly on curved and angled features because 5-axis maintains optimal cutting angles throughout the operation. Medical implants requiring ISO 13485-compliant surface quality and precision optical components benefit from this continuous engagement capability without the witness marks typical of 3-axis step-over patterns.

The reduced vibration from optimal tool positioning also extends tool life and maintains consistent cutting forces, resulting in more predictable surface finishes and dimensional accuracy across production runs. Thin-walled parts prone to deflection show improved dimensional stability when cutting forces remain perpendicular to surfaces.

Design Takeaway: Specify 5-axis when your part requires tight tolerances (≤±0.02 mm) on complex features or superior surface finishes on curved geometries. The quality improvements often justify the higher machining costs for critical applications.

Will 5-Axis Speed Up Your Delivery Timeline?

Yes, 5-axis CNC machining can reduce total production time by 30-50% through faster cutting speeds, optimized tool paths, and elimination of manual handling between operations. Complex parts complete in continuous operations rather than stop-start cycles with repositioning delays.

Timeline advantages of 5-axis:

- 30-50% faster completion on complex geometries

- Continuous cutting without repositioning interruptions

- Higher material removal rates through optimal approach angles

- Reduced manual handling and operator intervention

- Faster programming for single-operation parts

Higher cutting speeds become possible because 5-axis maintains optimal chip load and cutting angles throughout the operation. We’ve seen material removal rates increase by 25-40% on aluminum aerospace brackets compared to 3-axis operations that must compromise cutting parameters for tool access limitations.

Recent projects demonstrate these gains: a titanium medical instrument housing that required 18 hours across four 3-axis setups completed in 11 hours on our 5-axis centers. Programming time also dropped from 12 hours to 6 hours since we developed single continuous toolpaths rather than coordinating multiple fixture orientations.

Prototype development accelerates significantly because design iterations require only toolpath modifications rather than new fixture setups. Rush orders benefit from immediate production start without fixture preparation time, often saving 1-2 days on complex prototypes.

Design Takeaway: Choose 5-axis when project deadlines are critical and your part geometry involves complex features. The time savings are most significant on parts where 3-axis would require multiple operations or compromise cutting parameters for access.

Can 5-Axis Cut Your Project Budget?

Yes, 5-axis CNC machining often reduces total project costs by 20-40% through lower scrap rates, eliminated fixtures, and reduced setup labor—despite higher hourly machine rates. The key is fewer operations, less handling, and dramatically reduced fixture complexity.

Cost advantages of 5-axis:

- 20-40% reduction in total project costs on complex parts

- Elimination of specialized fixtures and custom tooling

- Lower scrap rates through single-setup accuracy

- Reduced setup labor and programming time

- Fewer inspection checkpoints and rework cycles

Custom fixtures represent a major expense on complex 3-axis projects. We recently completed an aerospace housing that would have required elaborate multi-axis fixtures on 3-axis equipment, but ran in standard vises on our 5-axis centers. The client avoided significant tooling investments while maintaining their tight delivery schedule.

Material waste decreases substantially when parts stay in one setup throughout machining. Complex titanium components show notably lower scrap rates because positioning errors between multiple setups are eliminated. This becomes especially important when raw material costs are high.

Programming efficiency improves since engineers develop single continuous toolpaths rather than coordinating multiple fixture orientations. Operators also spend less time on part handling and setup verification between operations, reducing overall labor hours per component.

The real advantage appears on parts that would otherwise require multiple setups with complex fixturing. Simple parts requiring only basic operations remain more economical on 3-axis equipment regardless of other factors.

Design Takeaway: Calculate total project costs including fixtures, setup labor, and scrap risk—not just machine hourly rates. 5-axis typically pays off when your part would require 3+ setups or expensive custom fixtures on 3-axis equipment.

Is 5-Axis Good for Small or Large Production Quantities?

Yes, 5-axis excels at both prototype/low-volume production (1-100 pieces) and medium-volume runs (100-1,000 pieces), with setup advantages becoming more valuable as complexity increases rather than volume. The technology suits parts where geometry complexity justifies the higher machine costs.

Volume advantages of 5-axis:

- Prototype efficiency: immediate production without fixture investment

- Low-volume ideal range: 1-100 pieces with complex features

- Medium-volume capability: 100-1,000 pieces with consistent quality

- Setup time amortization improves with complexity, not just quantity

- Reduced per-piece costs on intricate geometries

For prototypes and short runs, 5-axis eliminates the fixture development time that can add 2-4 weeks to 3-axis projects. We regularly start complex prototype production within 24-48 hours using standard workholding, while equivalent 3-axis setups require custom fixture design and fabrication.

Medium-volume production benefits from consistent quality across runs since parts never leave the machine coordinate system. Aerospace brackets in 200-piece quantities show improved dimensional consistency compared to multi-setup 3-axis production where tolerance stackup varies between runs.

The economic crossover point depends more on part complexity than volume. Simple parts remain more economical on 3-axis regardless of quantity, while complex geometries justify 5-axis even for single prototypes. We’ve seen 5-axis pay off on single $50,000 titanium aerospace components and 500-piece aluminum medical housings equally.

Design Takeaway: Choose 5-axis for complex parts in any quantity from prototypes to medium production. Simple geometries should stay on 3-axis equipment regardless of volume to optimize costs.

Conclusion

5-axis CNC machining delivers measurable value through reduced cycle times, eliminated fixtures, superior quality on complex geometries, and expanded design freedom—justifying higher machine costs when parts require multiple 3-axis setups. Simple geometries remain more economical on 3-axis equipment. Contact us to explore 5-axis manufacturing solutions tailored to your complex part requirements.

Frequently Asked Questions

STEP or IGES files with complete 3D geometry work best. 2D drawings require additional programming time since 5-axis toolpaths depend on full surface definitions for optimal cutting angles.

All CNC-compatible materials work on 5-axis equipment. Titanium, aluminum, and stainless steel show the greatest advantages due to improved cutting angles and reduced vibration on complex geometries.

5-axis reduces lead times 30-50% on complex parts by eliminating fixture design time and multiple setups. Simple parts may have similar lead times regardless of machine type.

5-axis hourly rates are 40-60% higher, but total project costs often decrease 20-40% on complex parts through setup elimination, reduced scrap rates, and fixture savings.

Parts requiring 3+ setups on 3-axis equipment or featuring deep cavities (depth-to-width >4:1), undercuts, and compound angles typically justify 5-axis investment through reduced cycle times and fixture elimination.

Yes, 5-axis maintains ±0.01 mm tolerances on complex features while achieving superior results on curved surfaces and angled features compared to multi-setup 3-axis operations.