Precision hole requirements can make or break critical engineering projects. As a CNC machining service provider, we regularly help engineers solve challenging hole-finishing problems across aerospace, audio, medical, and industrial applications. This post addresses key questions about when precision hole finishing justifies the investment and how to make smarter design decisions.

Reaming delivers six essential advantages: superior dimensional accuracy with tolerances up to ±0.002 inches, enhanced surface finish quality, cost-effective processing, straightforward operation, effective burr removal, and versatile material compatibility.

Learn how to specify the right tolerances, understand achievable capabilities, and discover when precision hole finishing delivers measurable ROI.

Table of Contents

What Tolerance Should I Specify for Precision Holes?

±0.005 mm is sufficient for most non-critical aluminum and steel components, while precision assemblies requiring tight fits typically need ±0.002 mm or tighter. Always reserve the tightest tolerances for functional features only, as each step tighter significantly increases machining cost and complexity.

Common tolerance applications:

- ±0.005 mm – General holes, mounting features, non-critical dimensions

- ±0.002 mm – Precision fits, bearing assemblies, alignment features

- ±0.001 mm – Critical assemblies, high-performance applications only

We routinely achieve ±0.002 mm on aluminum parts using controlled CNC setups with proper fixturing. For steel components, ±0.001 mm is achievable but requires additional verification and slower processing. Critical aerospace components often demand ±0.0005 mm, requiring specialized measurement and controlled environments.

In audio enclosures, ±0.005 mm provides adequate faceplate alignment without unnecessary cost. However, medical device housings frequently require ±0.002 mm to ensure proper sealing. Bearing bores and shaft fits typically need ±0.001 mm to prevent looseness while allowing smooth assembly.

Design Takeaway: Specify ±0.005 mm for general features, ±0.002 mm for precision fits, and ±0.001 mm only when absolutely required. Over-specifying tolerances can double machining costs without performance benefits.

What's the Tightest Tolerance CNC Machining Can Hold?

CNC reaming can achieve tolerances as tight as ±0.0002 inches under optimal conditions, though ±0.002 inches represents the practical limit for most production environments. These capabilities depend heavily on machine condition, environmental controls, and part geometry.

Tolerance capability breakdown:

- ±0.002″ – Standard production capability with quality CNC equipment

- ±0.001″ – Achievable with climate control and rigid setups

- ±0.0002″ – Maximum capability requiring specialized conditions

Machine precision, temperature changes, and workpiece material all directly impact achievable tolerances. High-precision machines in temperature-controlled environments can hold tighter tolerances, while standard shop conditions limit capability to ±0.002″. Aluminum’s thermal expansion makes climate control essential for tolerances below ±0.001″.

Industry standards classify these tolerances into precision grades, with the tightest grades reserved for critical applications like aerospace fuel systems and medical implants. Most precision manufacturing falls into the ±0.002″ range, which provides excellent performance for bearing assemblies and mechanical fits.

We’ve measured ±0.0005″ tolerances on titanium aerospace components using temperature-controlled machining and CMM verification. However, these extreme tolerances required 48-hour temperature stabilization and added 40% to production time.

Design Takeaway: Plan designs around ±0.002″ capability for reliable production results. Tolerances tighter than ±0.001″ require specialized equipment and controlled environments, significantly increasing cost and lead time.

How Does Hole Quality Affect Assembly Performance?

Poor hole quality directly impacts bearing life, seal effectiveness, and assembly reliability – often reducing component lifespan by 30-50% compared to properly finished holes. Surface finish and dimensional accuracy determine how well mating parts perform over time.

Performance impact areas:

- Bearing assemblies – Rough surfaces increase friction and wear rates

- Seal applications – Surface imperfections cause leakage paths

- Pin/shaft fits – Dimensional variation creates play or binding

Bearing manufacturers specify smooth surface finishes for optimal performance. Standard drilling produces rough surfaces, while reaming achieves the smooth finish bearings need. This surface improvement can extend bearing life from months to years in high-cycle applications.

For hydraulic seals, even minor surface irregularities create leak paths that compromise system pressure. We’ve seen medical device projects where poor hole finish caused seal failures during FDA testing, requiring complete redesign. Automotive applications depend on precise hole quality for vibration dampening and noise reduction.

A recent aerospace project required fuel system components with precise hole geometry. Initial drilling created surface irregularities that trapped contaminants, leading to flow restrictions. After switching to reamed holes, flow testing showed 15% improvement and eliminated contamination issues.

Design Takeaway: Invest in hole quality for any application involving seals, bearings, or critical fits. The cost of precision finishing is typically 5-10% of total component failure costs.

Is Precision Hole Machining Worth the Extra Cost?

Precision hole finishing typically adds 15-25% to machining costs but can prevent field failures costing 10-50x more than the initial investment. The ROI calculation depends on production volume, failure consequences, and assembly requirements.

Cost comparison breakdown:

- Standard drilling – Base cost, ±0.005″ tolerance capability

- Precision reaming – 15-25% premium, ±0.002″ tolerance capability

- Boring operations – 40-60% premium, custom sizing capability

For production volumes above 100 units, precision hole finishing typically pays for itself through reduced scrap rates and assembly issues. A recent automotive project showed 8% scrap reduction after switching from drilling to reaming, saving $12,000 annually on a $150,000 production run.

The hidden costs of poor hole quality include field service calls, warranty claims, and product recalls. We’ve seen medical device companies spend $200,000 on recalls due to seal failures that could have been prevented with $5,000 in precision hole finishing during initial production.

High-volume electronics manufacturing often justifies precision holes through improved assembly automation. Consistent hole geometry reduces pick-and-place errors and assembly line downtime. One client reduced assembly time by 12 seconds per unit, saving $48,000 annually in labor costs.

Design Takeaway: For critical assemblies or volumes above 50 units, precision hole finishing typically delivers positive ROI within 6-12 months through reduced failures, scrap, and assembly issues.

Which Hole Finishing Method Works Best for My Application?

Reaming works best for standard hole sizes requiring ±0.002″ tolerances in production quantities, while boring suits custom sizes or larger holes, and specialized methods serve ultra-precision applications. Your choice depends on hole size, tolerance requirements, and production volume.

Method selection guide:

- Reaming – Standard sizes, production quantities, cost-effective precision

- Boring – Custom diameters, larger holes, ultimate precision capability

- Other methods – Specialized applications requiring unique characteristics

For most product development projects, reaming offers the best balance of precision and lead time. Standard reaming operations typically deliver parts within 2-3 days, while custom boring may require additional setup time. Production quantities above 100 units strongly favor reaming due to consistent results and lower per-part costs.

Medical device applications often require custom hole sizes for specific seal requirements, making boring the preferred choice. Electronics products with standard mounting holes benefit from reaming’s speed and consistency. Aerospace components requiring both precision and high-volume production typically specify reaming for cost control.

Consider your assembly requirements when choosing methods. Tight-fitting components need the precision reaming provides, while loose-fitting applications may work fine with standard drilling. Volume also matters – prototype quantities work well with any method, but production runs favor reaming’s efficiency.

Design Takeaway: Choose reaming for standard hole sizes in production quantities, boring for custom applications requiring special dimensions, and discuss your specific requirements with your machining partner during design review to optimize both performance and cost.

What Materials Require Special Hole Machining Considerations?

Aluminum and mild steel work well with standard reaming parameters, while stainless steel, titanium, and exotic alloys require specialized tooling, reduced speeds, and enhanced cooling to achieve quality results. Material choice significantly impacts hole finishing cost, lead time, and achievable quality.

Material considerations:

- Aluminum (6061, 7075) – Excellent machinability, fast processing, standard tooling

- Steel (4140, 1018) – Good results with proper speeds, reliable tolerances

- Stainless (304, 316) – Requires slower speeds, specialized coatings, work hardening concerns

- Exotic alloys – Custom parameters, premium tooling, extended lead times

Medical device projects often specify 316 stainless steel for biocompatibility, requiring carbide reamers and reduced cutting speeds to prevent work hardening. Aerospace applications frequently use titanium alloys, which demand specialized tooling and precise temperature control to avoid material damage.

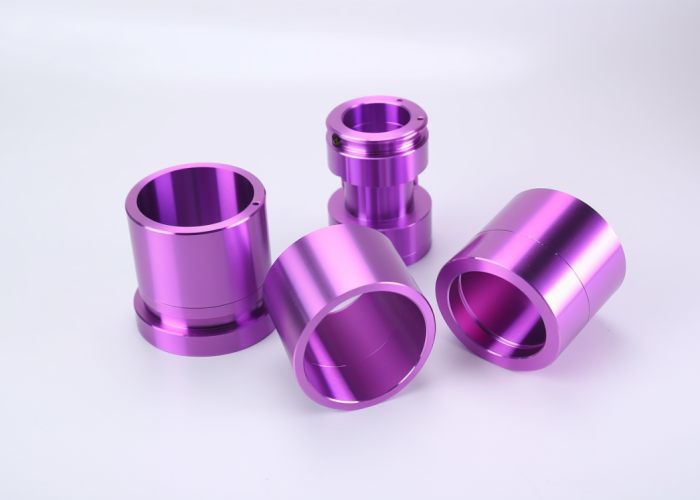

Audio equipment manufacturers typically choose aluminum for its excellent surface finish and cost-effectiveness. The material machines cleanly and accepts anodizing well, providing both functional and aesthetic benefits. Industrial applications often specify steel for strength requirements, though processing takes longer than aluminum.

Heat-resistant alloys like Inconel require premium tooling and extended machining time, potentially doubling production costs compared to aluminum. However, the superior performance in high-temperature applications justifies the investment for critical components.

Design Takeaway: Choose aluminum for cost-effective precision and fast turnaround, steel for strength requirements with moderate processing time, and exotic alloys only when performance demands justify the additional cost and lead time.

Conclusion

Reaming delivers superior hole precision with tolerances to ±0.002″ while remaining cost-effective for production volumes. Choose reaming for standard sizes requiring tight fits, and reserve exotic materials only when performance demands justify additional costs.

Contact us to explore precision hole manufacturing solutions tailored to your product requirements.

Frequently Asked Questions

Yes, for volumes above 50 units where hole quality affects assembly or performance. The precision benefit often justifies the cost even in prototyping when testing critical fits and functions.

Use reaming when your application requires tolerances tighter than ±0.005″, smooth surface finish for seals or bearings, or consistent hole quality across production runs. Standard drilling works fine for mounting holes and non-critical features.

Reaming typically adds 15-25% to hole machining costs compared to drilling alone. This investment usually pays for itself through reduced assembly issues and field failures.

: Consider tight tolerances (±0.002″ or better) for bearing seats, seal surfaces, precision pins, or any assembly requiring consistent fit across multiple parts. Loose fits can use standard drilling tolerances.

Aluminum 6061 and mild steel provide excellent results with standard tooling. Stainless steel requires specialized parameters but achieves similar quality with proper machining techniques.

Specify ±0.002″ for most bearing applications. This provides proper fit without excessive cost. Tighter tolerances like ±0.001″ are only needed for high-precision or high-speed applications.