Sheet metal fabrication isn’t just about getting parts made — it’s about designing parts that perform reliably while staying within budget. With experience fabricating enclosures, brackets, and chassis for audio, medical, and industrial equipment, small design adjustments during CAD can prevent expensive redesigns and production delays.

Seven key DFM optimizations can dramatically improve your sheet metal project: prevent bend cracking through thickness selection, optimize bend radii, position holes to avoid distortion, evaluate part vs assembly trade-offs, specify functional tolerances, choose cost-effective edge treatments, and plan for coating thickness effects. These upfront design decisions control both manufacturing cost and product performance.

Learn to design crack-free flanges, place features to prevent distortion, and set tolerances that matter—plus cost-saving tips from real fabrication work.

Table of Contents

How do I choose sheet thickness to avoid bend cracking in my design?

Start with your application requirements: consumer electronics need 16-20 gauge aluminum (0.040-0.063″), while industrial chassis require 10-14 gauge steel (0.060-0.135″) for structural integrity. 16-gauge aluminum measures 0.062″ thick, while 16-gauge steel is 0.059″ thick — these gauge differences directly impact your bend geometry and assembly clearances during design.

In design reviews, we see product developers choose thickness based purely on strength calculations, then discover bend cracking during prototyping. The key decision point is balancing your functional requirements against forming constraints during the CAD stage. For example, specifying 0.025″ aluminum for weight savings often leads to cracking at 90-degree corners, requiring design changes to 18-gauge (0.040″) material or alternative approaches like adding relief cuts.

Your design complexity drives thickness selection more than load requirements:

Application Type Aluminum Gauge (inches) Steel Gauge (inches) When to Consider Alternatives / Design Advice

Consumer electronics 18 – 16 GA (0.040-0.063″) 20 – 18 GA (0.036-0.048″) Use ribs if weight is critical

Medical housings 16 – 14 GA (0.063-0.080″) 18 – 16 GA (0.048-0.060″) Consider part splitting for complex bends

Industrial chassis 14 – 12 GA (0.080-0.105″) 16 – 14 GA (0.060-0.075″) Add gussets instead of thicker material

Material selection also affects formability: 6061-T6 aluminum is stronger than 5052, but not as formable. Choose 5052 for complex bend patterns, 6061 for strength-critical applications with simpler geometry.

Design Takeaway: Make thickness decisions during concept design based on bend count and geometry complexity. If your design has 3+ sharp bends in sequence, either specify thicker material or redesign with relief features, split parts, or reinforcing ribs instead of fighting the forming process.

What bend radius prevents flange cracking without oversizing my part?

Start with radius equal to your material thickness as the baseline, then adjust based on your design priorities: tighter for space constraints, larger for smooth appearance. Most fabricators recommend minimum bend radius of 1t (1x thickness) for reliable forming, but your aesthetic and envelope requirements often drive the final choice.

Engineers often encounter specify minimum radius to save space without considering visual impact. In a recent consumer electronics project, tight 0.030″ radii created sharp bend lines that clashed with the smooth industrial design intent. Stepping up to 2x material thickness radius eliminated the aesthetic issue while adding only minimal envelope space — often an acceptable trade-off discovered during design review.

Your design priorities determine the optimal approach during CAD work. Using 2-3T radius minimum provides optimal forming results while maintaining clean appearance. Here’s how to balance the trade-offs:

Design Priority Radius Choice Design Impact

Space-critical 1x thickness (minimum) Sharp visual lines, tight envelope

Appearance-focused 2-3x thickness Smooth transitions, larger envelope

Mixed requirements Vary by visibility Large radius where visible, minimum radius where hidden

When space is genuinely tight, redesign the geometry rather than forcing radius constraints. Add mounting tabs that extend beyond tight areas, use living hinges for seamless transitions, or split complex parts into simpler bent pieces.

Design Takeaway: Plan your part envelope around realistic bend requirements during initial concept work. If smooth appearance matters, allocate space for larger radii early in design development rather than forcing tight radii that compromise aesthetics.

How close can I place holes to bends without causing distortion?

Keep holes at least 2-3x material thickness from bend lines, but when space is tight, redesign with mounting solutions that avoid the constraint entirely. Industry guidelines recommend 2.5T + bend radius spacing for holes, but smart design alternatives often work better than fighting close spacing.

Design teams frequently need connector holes near corners where spacing creates conflicts. In an audio equipment project, precision connector holes were initially placed too close to corner bends, requiring design revision to relocate mounting features. The solution was adding small mounting tabs that extended beyond the bend zone — providing proper spacing without enlarging the main part envelope.

The recommended minimum distance is three times sheet thickness plus bend radius, but practical design solutions can eliminate spacing conflicts:

Hole placement solutions by constraint:

- Extended tabs: Add small tabs beyond bend zones for mounting

- Relief cutouts: Use shaped cutouts instead of drilled holes near corners

- Hardware inserts: Plan for PEM nuts installed after forming

- Strategic redesign: Move critical features to flat sections

Hole size affects required spacing: Large holes (>0.125″) need more clearance and often work better as shaped cutouts rather than drilled features. For threaded connections in thin materials, hardware inserts provide better engagement than drilled-and-tapped holes.

Design Takeaway: Plan mounting locations during initial CAD layout using the 2-3x spacing guideline. When conflicts arise, choose mounting solutions that work with forming constraints — extended tabs and cutouts often provide better assembly results than compromised hole placement.

Should I design one complex part or split into multiple pieces?

Complex parts with 4+ bends or tight feature spacing often cost more and take longer than designing separate pieces joined with fasteners. The decision depends on your assembly time tolerance, part count preferences, and manufacturing volume — but consider hidden costs like additional fasteners, assembly labor, and part inventory management.

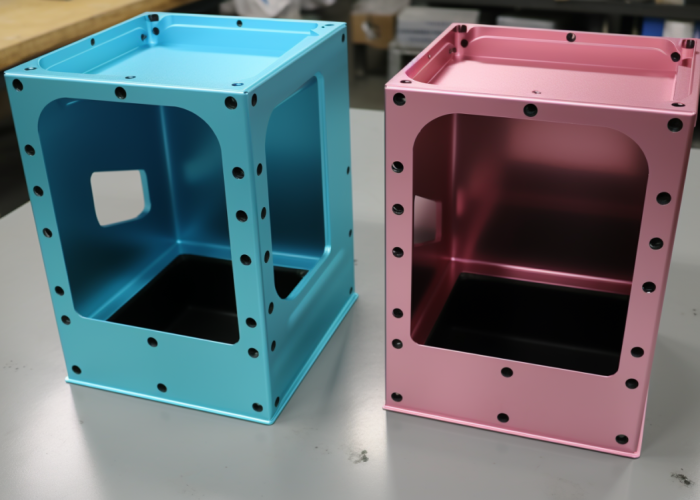

A typical design challenge is to assume single parts are simpler, but complex geometry creates manufacturing constraints. In a medical housing project, a 6-bend part with holes near corners required expensive secondary operations. Breaking it into 3 simpler pieces reduced forming cost but added 8 fasteners and 15 minutes assembly time — the right trade-off for low-volume production but questionable for high-volume manufacturing.

Decision framework with real implementation factors:

Design Scenario Single Part Approach Split Design Approach

1-2 simple bends Usually optimal Adds cost: extra fasteners, assembly time

3-4 bends, features >3x thickness Good for volumes >100 units Better for prototypes, easier secondary operations

5+ bends or features near corners Only if welded permanently Recommended: easier manufacturing, service access

Mixed thickness requirements Not possible Optimize each piece independently

Joining method selection for split designs:

- Removable fasteners: Use when access needed for service or assembly sequence

- Welding: Best for high-volume, permanent assemblies (eliminates fastener cost)

- Tabs and slots: Self-locating assembly, good for alignment without fasteners

- Bent flanges: Create integral mounting features during forming

Design guidelines for proper split alignment:

- Overlap joints: Minimum 2x material thickness overlap for rigid connection

- Pilot holes: Use different sized holes for self-alignment during assembly

- Datum features: Design one part with registration bosses, mating part with clearance slots

Design Takeaway: Calculate total cost including fasteners, assembly labor, and inventory complexity. For volumes under 100 units, split designs usually win. Above 500 units, consider welded assemblies. Plan joining method during initial CAD work, not as an afterthought.

How do I specify tolerances that actually control my assembly fit?

Start with standard sheet metal tolerances (±0.030″) everywhere, then tighten only the 3-5 dimensions that directly control your assembly function. Tighter tolerances raise manufacturing cost significantly, and most sheet metal features don’t need precision beyond standard forming capabilities.

Product developers often copy machined part tolerances onto sheet metal, creating unnecessarily expensive parts. A chassis design had 24 dimensions at ±0.005″ when only hole patterns for critical alignment actually needed that precision. Using standard ±0.030″ on non-critical dimensions while keeping ±0.010″ on 4 hole locations reduced cost 25% with identical function.

Practical tolerance selection by specific feature:

Feature Type Standard Tolerance When to Tighten Realistic Limit

Overall part size ±0.030″ Envelope constraints ±0.015″

Hole diameters ±0.005″ Tight bearing fits ±0.002″

Hole-to-hole spacing ±0.015″ Alignment-critical fasteners ±0.005″

Bend angles ±1° Mating part interfaces ±0.5°

Flange dimensions ±0.030″ Sealing surfaces only ±0.010″

Sheet metal tolerance stackup considerations:

- Multiple bends accumulate error: Each bend adds ±0.5-1.0° variation

- Material thickness variation: ±0.007″ standard thickness tolerance affects bend calculations

- Forming vs machined features: Punched holes hold ±0.005″, machined holes ±0.002″

GD&T callouts that actually help sheet metal:

- Position tolerance: Use for hole patterns instead of tight coordinate dimensions

- Profile tolerance: Control bent flange shape and orientation together

- Parallelism: Control opposite flanges for mating part fit

Design Takeaway: Identify your 3-5 most critical assembly interfaces first, then tolerance only those features. Use position callouts for hole patterns, profile for bent shapes, and standard tolerances everywhere else. Design clearances 2-3x larger than your tightest tolerance to accommodate real-world variation.

What's the most cost-effective way to eliminate sharp edges?

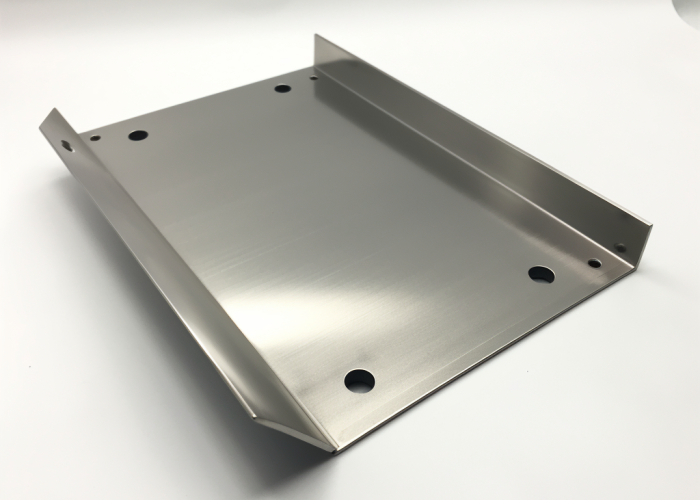

For most applications, specify 0.005-0.015″ chamfers on cut edges during design rather than adding secondary deburring operations. This approach eliminates sharp edges while maintaining precise dimensions, but the optimal method depends on your cutting process and volume requirements.

Design teams frequently overlook edge finishing during CAD work, then discover sharp edges create safety or assembly issues during prototyping. In an enclosure project, laser-cut edges were too sharp for safe handling, but adding tumble deburring removed dimensional control on mating surfaces. Redesigning with 0.010″ × 45° chamfers on all exterior edges solved safety issues while preserving assembly tolerances — the key was distinguishing which edges actually needed treatment.

Edge finishing approach by cutting method and volume:

Cutting Method Low Volume (<100) High Volume (>500) CAD Callout

Laser cutting 0.005 – 0.010″ chamfers Tumble deburring 0.010 × 45° TYP

Punch cutting Break sharp edges only Tumble + media finishing BREAK SHARP EDGES

Shearing 0.015″ chamfers required Always deburr 0.015 × 45° ALL EDGES

Which edges actually need finishing:

- Exterior/handled edges: Always finish for safety

- Interior assembly edges: Only if interference risk

- Hidden structural edges: Usually skip unless sharp burrs present

- Mating surfaces: Chamfer lightly to prevent assembly damage

CAD specification methods:

- Individual callouts: “0.010 × 45°” on specific edges in drawings

- General notes: “BREAK SHARP EDGES 0.005 MAX” for overall safety

- Edge symbols: Use standard chamfer symbols on drawing views

- Finish specifications: “DEBURR AND BREAK SHARP EDGES” in notes section

Volume-based decision rules:

- Under 50 parts: Design chamfers, avoid secondary operations

- 50-200 parts: Mix of designed chamfers and light deburring

- Over 500 parts: Tumble deburring becomes cost-effective for uniform finish

Design Takeaway: Add chamfer callouts to your drawings during initial design for exterior and handled edges. Use “BREAK SHARP EDGES” notes for interior features. Reserve post-process deburring for high-volume production where uniform appearance justifies the cost and tolerance impact.

How will powder coating thickness affect my critical clearances?

Plan for 0.002-0.005″ coating thickness on each surface when designing clearances, but thickness varies significantly by application method and part geometry. Standard powder coating thickness typically ranges between 2 to 5 mils (0.002-0.005″), so create design solutions that accommodate coating variation rather than trying to control it through specifications.

Engineers often encounter assembly problems when minimal clearances meet coating thickness reality. A connector housing had 0.012″ clearance for cable entry, but powder coating reduced it to 0.004″ — too tight for field assembly. Redesigning with 0.025″ clearance plus chamfered lead-ins accommodated coating variation while maintaining clean appearance and reliable assembly across production batches.

Coating thickness by application method and finish:

Application Method Typical Thickness Thickness Range Design Consideration

Electrostatic spray 0.002 – 0.004″ 0.001 – 0.010″ Most common, good control; standard colors

Standard colors 0.003 – 0.004″ ±0.001″ Most predictable thickness

Thick build applications 0.004 – 0.010″ ±0.003″ Higher variation range

Fluidized bed dipping 0.007 – 0.040″ Wide range Thickest application method

Masking capabilities and limitations:

- Threaded holes >¼”: Can be masked, tap after coating if needed

- Small holes (<0.125″): Difficult to mask, design oversize then drill

- Mating surfaces: Maskable but adds cost, design clearance instead

- Internal cavities: Usually fully coated, plan accordingly

Alternative finish thickness comparison:

- Anodizing (Type II): 0.0002-0.0012″ — minimal clearance impact

- Anodizing (Type III): 0.001-0.002“ — moderate clearance impact

- Electroplating: 0.0002-0.0005″ — good for tight clearances

- Powder coating: 0.002-0.005″ — requires design accommodation

Clearance design strategies:

- Assembly clearances: Add 0.010-0.015″ total (both surfaces coated)

- Threaded connections: Design holes 0.005″ oversize, tap after coating

- Sliding interfaces: Use anodizing instead of powder coating

- Press fits: Plan assembly before coating or design compression allowance

Design Takeaway: Choose your finish early in design and size clearances accordingly. For tight-clearance assemblies, consider anodizing over powder coating. When powder coating is required, design generous clearances with chamfered lead-ins rather than trying to control coating thickness through specifications.

Conclusion

Smart sheet metal design decisions during CAD work prevent costly manufacturing revisions later. Focus on material thickness for your application, design realistic bend radii, plan proper hole spacing, evaluate part complexity trade-offs, tolerance only critical features, specify edge finishing upfront, and accommodate coating thickness in clearances. Contact us to explore manufacturing solutions tailored to your sheet metal fabrication requirements.

Frequently Asked Questions

Use different hole sizes for alignment—pilot holes (0.250″) with clearance holes (0.281″) create natural registration during assembly. Bent tabs with slots, stepped flanges, or corner registration features also provide positive location without requiring fixtures. Design one part with bosses, the mating part with clearance slots.

Design bends in the same direction when possible and keep bend angles consistent across the part. Sharp bends (less than 45°) have more springback variation than gentle bends. If you need multiple bend directions, group similar angles together and avoid alternating between sharp and gentle bends on the same part.

Welding becomes cost-effective above 500 units for permanent assemblies, especially when you can eliminate 6+ fasteners per assembly. Consider welding for structural joints that don’t need disassembly, but use fasteners when service access or mixed materials are required. Welded assemblies also eliminate fastener inventory and assembly labor.

For coastal or high-corrosion environments, specify Type III anodizing or marine-grade powder coatings with 10+ year UV resistance ratings. Standard powder coating works for most climates but avoid textured finishes in high-pollution areas where cleaning is difficult. Galvanized steel with powder topcoat offers excellent corrosion protection for structural applications.

Use position tolerances for hole patterns instead of coordinate dimensions, and profile tolerances for bent flanges that need to mate with other parts. For example, specify “⌖ 0.010 Ⓐ|Ⓑ|Ⓒ” for mounting holes rather than tight X-Y coordinates. This gives fabricators flexibility while controlling what actually matters for assembly fit.

Separate dissimilar metals with non-conductive gaskets or isolating hardware, or choose metals close together on the galvanic series (like aluminum and stainless steel). When mixing steel and aluminum, use stainless fasteners with isolation washers rather than steel bolts directly into aluminum. Anodized aluminum provides natural electrical isolation.