In CNC machining of 304 parts, quality control is essential. With each part costing significant time and resources, implementing proper QC checkpoints helps prevent costly rejections and ensures consistent quality throughout production.

Eight critical quality checkpoints for 304 CNC parts:

- Material Verification

- Tool Condition Monitoring

- Dimensional Checks

- Surface Finish Assessment

- Tolerance Verification

- Process Monitoring

- Post-Machining Inspection

- Documentation Tracking

Let’s explore each checkpoint in detail to understand how they contribute to producing high-quality 304 parts while minimizing waste and ensuring customer satisfaction.

Table of Contents

1. Material Verification

Think of material verification as your quality control gatekeeper for 304 parts. Just like checking ingredients before cooking a gourmet meal, you need to ensure your base material is exactly what you ordered. Get this wrong, and everything that follows could be a costly mistake.

When verifying 304, we’re looking for specific characteristics that set it apart from its cousins in the stainless steel family. The key is its chemical makeup – it should have 18-20% chromium and 8-10.5% nickel content. This isn’t just about matching numbers; these percentages directly affect how your part will perform in the real world.

Material Verification Checklist:

Verification Point Method Critical Factors

Chemical Composition Certificate Review Cr, Ni content

Physical Properties Documentation Tensile strength, hardness

Material Grade Visual/PMI Testing Grade markings

Traceability Documentation Lot numbers, certifications

Material Condition Visual Inspection Surface defects, damage

Remember:

Material verification isn’t just paperwork – it’s your insurance policy against future problems. Always keep certificates organized and materials marked. When in doubt, verify again. It’s much cheaper to catch material issues before cutting than to scrap finished parts.

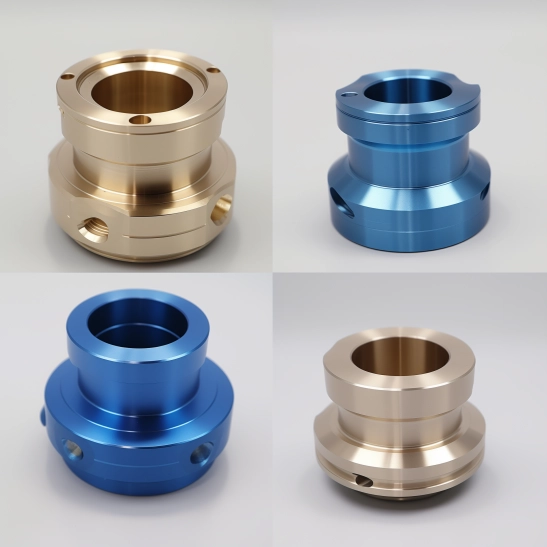

2. Tool Condition Monitoring

Poor tool condition is often the hidden culprit behind quality issues in 304 machining. Due to 304’s work-hardening properties, tool wear happens faster than with other materials, making consistent monitoring essential for quality control.

Effective tool monitoring involves systematic observation of multiple factors. While visual wear is obvious, subtle changes in performance often signal problems before they become visible. Changes in surface finish, cutting sound, or chip formation can all indicate developing tool issues.

Tool Condition Monitoring Guide:

Monitoring Point Warning Signs Action Required

Cutting Edge Visible wear/chips Replace tool

Surface Finish Roughness change Check wear patterns

Cutting Sound Unusual noise Immediate inspection

Chip Formation Color/shape change Adjust parameters

Tool Life Hours in use Preventive replacement

Key Monitoring Elements:

– Track tool usage hours

– Monitor cutting sounds

– Check chip formation

– Inspect surface finish quality

– Document tool performance

Regular tool monitoring isn’t just about preventing failures – it’s about maintaining consistent quality while optimizing tool life and reducing production costs.

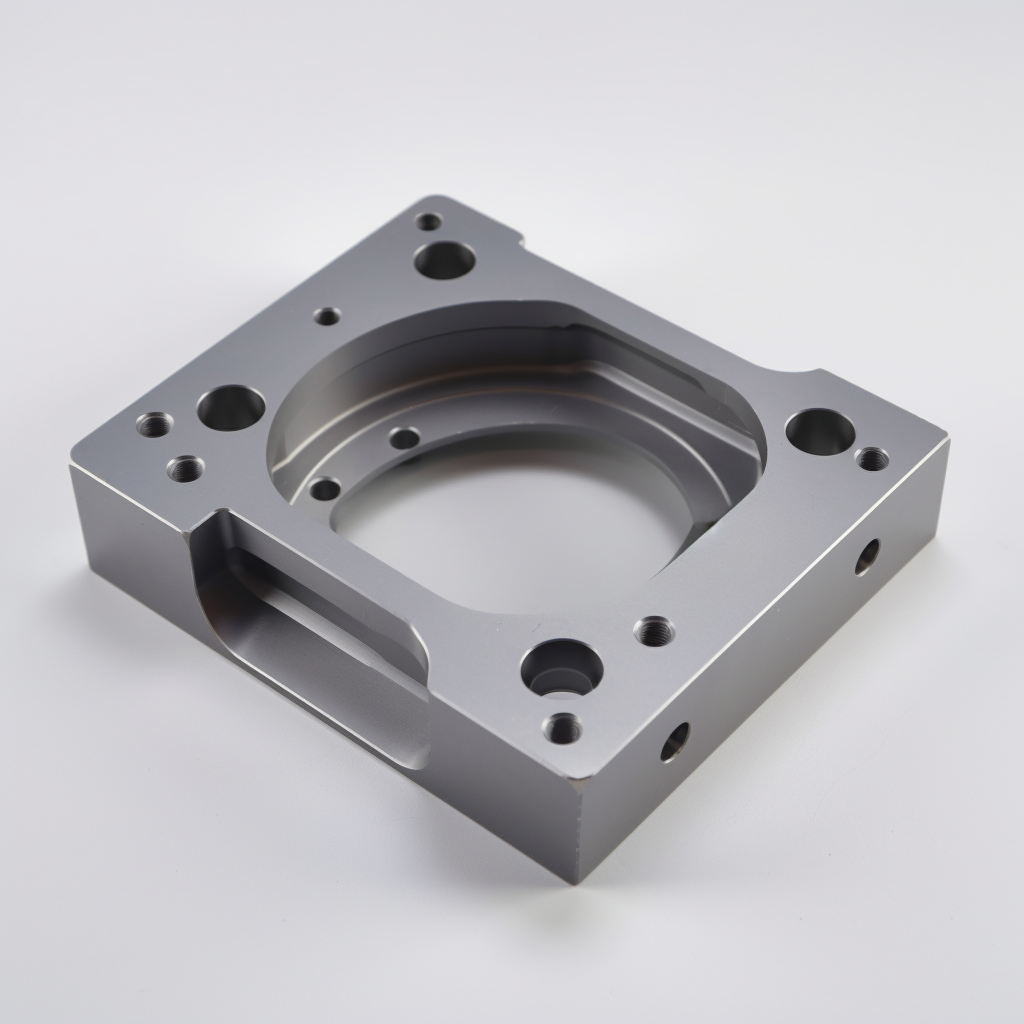

3. Dimensional Checks

Accurate dimensional verification serves as a critical quality checkpoint in 304 machining. With tight tolerances and complex geometries common in modern parts, systematic dimensional checking helps catch issues before they compound into costly problems.

Dimensional accuracy in 304 parts requires more than just occasional measurements. The material’s tendency to work harden and its thermal properties can affect dimensions during machining, making regular checks throughout the process essential for maintaining quality.

Dimensional Check Protocol:

Measurement Type Equipment Frequency

Critical Dimensions CMM/Micrometer Every part

Hole Diameters Bore Gauges First article/Sample

Depths Depth Micrometers Per setup

Thread Pitch Thread Gauges First article

General Dimensions Calipers Per batch

Essential Check Points:

– First article inspection

– In-process measurements

– Final verification

– Statistical sampling

– Documentation of results

A systematic approach to dimensional checking helps maintain consistent quality while identifying potential issues early in the production process. Regular measurement and documentation create a reliable quality control framework.

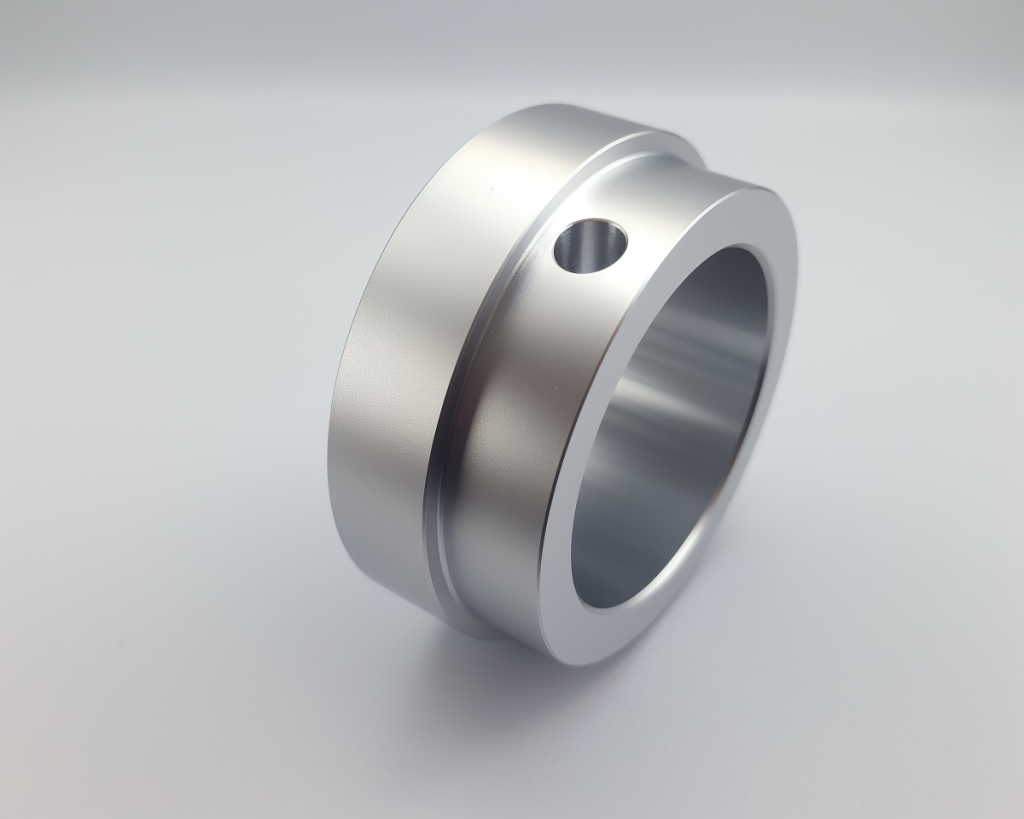

4. Surface Finish Assessment

Surface finish quality plays a crucial role in both the aesthetics and functionality of 304 parts. While standard machining can achieve Ra 1.6, achieving and verifying specific finish requirements demands careful assessment and measurement.

Surface assessment goes beyond visual inspection. What looks smooth to the eye might not meet technical requirements, and what appears rough might be within specifications. Systematic measurement and documentation ensure consistent quality across production runs.

Surface Assessment Guide:

Finish Type Measurement Method Typical Use

Standard (Ra 1.6) Visual + Profilometer General surfaces

Fine (Ra 0.8) Profilometer Sealing surfaces

Mirror (Ra 0.4) Optical comparison Cosmetic features

Custom Application-specific Special requirements

Pattern Visual + touch Non-critical areas

Key Assessment Points:

– Surface roughness measurement

– Pattern consistency check

– Defect inspection

– Finish uniformity

– Documentation of results

Remember:

Surface finish requirements should balance function with cost. Over-specifying finish requirements can significantly impact production costs without adding value to the part.

5. Tolerance Verification

Tolerance verification represents the crucial balance between design requirements and manufacturing capabilities in 304 parts. Each tolerance band directly impacts production cost and time, making accurate verification essential for both quality control and cost management.

Modern tolerance verification extends beyond simple dimensional checks. Geometric Dimensioning and Tolerancing (GD&T) requirements add layers of complexity, requiring systematic verification of form, orientation, and position tolerances in addition to basic dimensions.

Tolerance Verification Matrix:

Tolerance Type Verification Method Typical Range

Linear CMM/Calipers ±0.127mm standard

Geometric CMM/Height Gauge Per GD&T frame

Position CMM/Fixtures Location dependent

Roundness Dial Indicator 0.025mm typical

Flatness Surface Plate Application specific

Key Verification Points:

– Basic dimensions

– Geometric tolerances

– Feature relationships

– Critical interfaces

– Stack-up analysis

Modern manufacturing demands precise tolerance control. Understanding and verifying both dimensional and geometric tolerances ensures parts meet functional requirements while maintaining reasonable production costs.

6. Process Monitoring

Real-time process monitoring makes the difference between consistent quality and unpredictable results in 304 machining. Modern CNC machines provide valuable data about cutting parameters, but knowing what to monitor and when to act makes a real difference.

Process monitoring involves tracking multiple parameters simultaneously. From cutting speeds to coolant conditions, each element impacts part quality. Catching variations early prevents quality issues and reduces scrap rates.

Process Monitoring Parameters:

Parameter Monitor Point Action Trigger

Cutting Speed Machine display ±10% variation

Feed Rate Real-time data Abnormal loads

Spindle Load Power readings Excessive peaks

Temperature Thermal sensors Above normal range

Coolant Flow Flow indicators Below minimum

Critical Monitoring Areas:

– Machine parameters

– Tool performance

– Coolant conditions

– Power consumption

– Unusual vibrations

Active process monitoring helps maintain consistent quality while preventing issues before they affect parts. Regular data collection and analysis enable continuous process improvement.

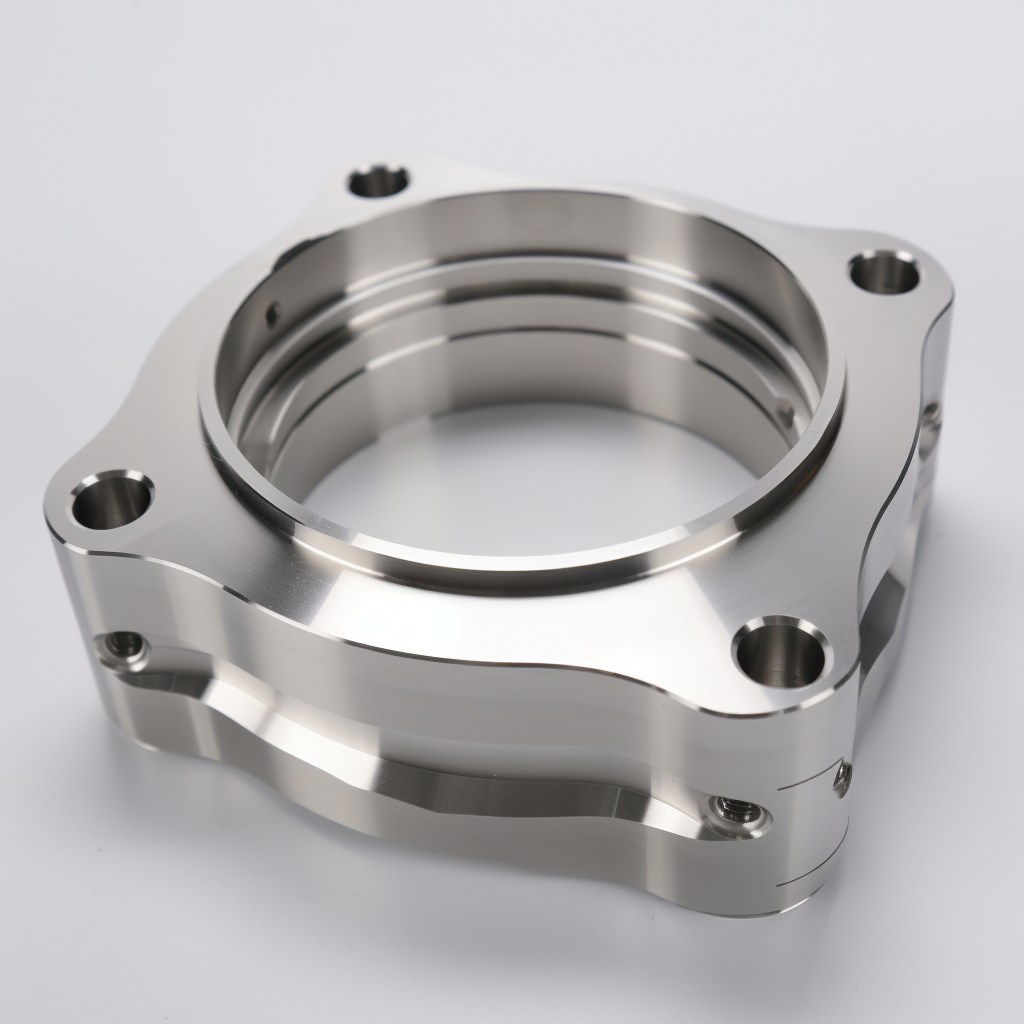

7. Post-Machining Inspection

Post-machining inspection serves as your final quality gateway before parts reach customers. This step catches any issues that might have slipped through earlier checkpoints and confirms that parts fully meet specifications.

A systematic post-machining inspection combines visual, dimensional, and functional checks. Each part receives thorough examination against drawing requirements and quality standards, ensuring complete conformance before release.

Final Inspection Checklist:

Inspection Type Method Focus Areas

Visual Direct observation Surface defects

Dimensional CMM/Gauges Critical features

Functional Fit checks Assembly points

Cleanliness Visual/Touch Surface contamination

Documentation Records review Certification requirements

Key Inspection Elements:

– Complete feature verification

– Surface finish confirmation

– Cleanliness check

– Deburring validation

– Documentation review

Thorough post-machining inspection provides the final quality assurance before parts leave the production. Proper documentation of inspection results ensures traceability and supports continuous improvement.

8. Documentation Tracking

Documentation tracking provides the backbone of quality control in 304 machining. Without proper records, even the best inspection processes lose their value. Good documentation proves part quality and helps trace any issues to their source.

Effective documentation goes beyond just filing paperwork. It creates a clear trail from material certification through final inspection, enabling quick response to quality issues and supporting continuous improvement efforts.

Documentation Requirements:

Document Type Content Purpose

Material Certs Chemical/Physical properties Material validation

Process Records Machine parameters Process control

Inspection Data Measurements/Results Quality verification

NCR Reports Non-conformance details Issue tracking

Final Reports Complete quality package Customer requirements

Essential Records:

– Material certifications

– Production data

– Inspection results

– Quality deviations

– Corrective actions

Complete documentation protects both the manufacturer and customer by providing clear evidence of quality control throughout the production process.

Conclusion

Implementing these 8 critical QC checkpoints ensures consistent quality in 304 CNC machining. From initial material verification to final documentation, each checkpoint plays a vital role in producing parts that meet specifications and customer requirements.

Essential Benefits:

– Prevents quality issues before they occur

– Reduces scrap and rework

– Ensures consistent part quality

– Maintains production efficiency

– Supports continuous improvement

Remember: Quality control in 304 machining isn’t just about inspection – it’s about maintaining a systematic approach throughout the entire production process.

Frequently Asked Questions

Surface finish is verified using profilometers for numerical measurements (Ra values) and visual/tactile inspection for consistency. Standard machining typically achieves Ra 1.6.

Documentation provides traceability, helps identify the root causes of any issues, and serves as proof of quality for customers. It’s essential for ISO compliance and quality system requirements.

Tool condition should be monitored continuously through parameters like surface finish quality and cutting sounds, with physical inspections at regular intervals based on tool life data.

Material verification is typically most critical as it affects all subsequent operations. Using incorrect material can cause issues that no amount of process control can fix.

First article inspection is essential for new setups, followed by regular in-process checks. The frequency depends on part complexity and requirements but typically includes sampling every few parts for key dimensions.

Standard tolerances of ±0.127mm are readily achievable, with tighter tolerances of ±0.025mm possible for critical features. However, tighter tolerances increase cost and production time.