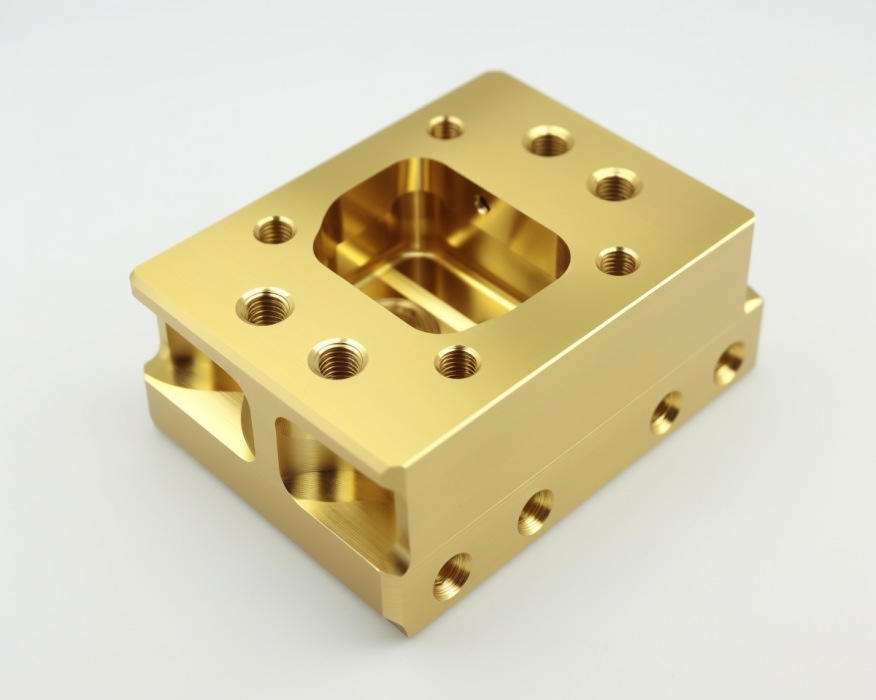

In precision manufacturing, material choice can make or break your project’s success. From my experience overseeing thousands of precision part productions, brass stands out with remarkable metrics.

Brass excels in precision applications due to its unique combination of mechanical and manufacturing properties. Its beta phase structure enables superior chip formation, while its thermal stability ensures consistent tolerances during machining. Critical characteristics include excellent machinability, tight tolerance capabilities, and superior dimensional stability.

Let’s analyze eight data-backed reasons why brass could be the optimal material choice for your precision components. Understanding these characteristics will help you make informed material decisions for your next engineering project.

Table of Contents

1. Superior Machinability

Ever wondered why machinists smile when they see a brass job come across their desk? Let me tell you something fascinating about brass that most engineers overlook: it’s the benchmark for machinability. When we talk about how easy it is to machine different metals, brass is the gold standard – scoring a perfect 100 on the machinability index. For comparison, that’s double what you get with stainless steel!

Think about it: when designing precision parts, you’re not just looking for a material that can be machined – you need one that can be machined consistently and efficiently. This is where brass shines, and I’ve got the data to prove it.

Here’s what makes brass a machinist’s best friend: its unique microstructure creates perfect conditions for chip formation and breaking. You know those annoying long, stringy chips that wrap around everything and cause machine stops? Not with brass. The chips break cleanly, letting you maintain continuous production runs without the headaches.

Performance Metric Brass Value Comparison Impact on Production

Cutting Speed 400-600 SFM 2-3x faster than steel 40% faster cycle times

Tool Life 100,000+ parts 2x longer than aluminum 50% lower tool costs

Chip Formation Controlled break Self-breaking chips Less machine downtime

Surface Quality Down to 32 Ra Direct from machine Reduced post-processing

Key Technical Benefits:

– Low friction coefficient (0.35) reduces cutting forces

– High thermal conductivity enables faster speeds

– Excellent chip formation prevents built-up edge

– Natural lubricity extends tool life

– Minimal work hardening during machining

Pro Tip:

Want to leverage brass’s machinability? Here’s a secret from the shop floor: you can run brass at cutting speeds of 400-600 SFM while still maintaining tight tolerances of ±0.001″. In real terms, that means you’re looking at parts coming off the machine 40% faster than steel – with a better surface finish to boot. That’s not just a technical advantage; it’s a competitive edge in today’s fast-paced manufacturing environment.

2. Excellent Dimensional Stability

Let’s talk about something that keeps engineers up at night: dimensional stability. You’ve probably dealt with materials that look great on paper but can’t hold their shape when the heat is on – literally. Here’s where brass shows its true colors.

Brass’s thermal expansion coefficient of 20.3 µm/m-K might seem high at first glance, but here’s the kicker – it’s incredibly linear and predictable. This means you can design with confidence, knowing exactly how your part will behave.

Stability Factor Brass Performance Impact on Design Compared to Alternatives

Thermal Stability ±0.0002″/inch/100°F Highly predictable 2x more stable than aluminum

Long-term Drift <0.0001"/year Minimal aging Better than most steels

Stress Relief Minimal required Fast turnaround 50% less than stainless

Dimensional Memory Excellent Maintains tolerances Superior to zinc alloys

Key Engineering Benefits:

– Consistent behavior across temperature ranges

– Minimal internal stress buildup

– Excellent resistance to creep

– Low warpage tendency

– Superior mechanical stability

Pro Tip:

When designing precision brass components, you can typically reduce your tolerance safety margins by 30% compared to aluminum parts. The predictable nature of brass means you can design closer to your actual requirements without worrying about unexpected variations.

3. Tight Tolerance Capabilities

Think achieving tight tolerances means breaking the bank? Brass might change your mind. From my experience working with precision components, brass consistently delivers impressive tolerance capabilities that rival materials costing three times as much.

If you’re designing high-precision components, something that’ll interest you: brass can reliably achieve tolerances of ±0.0005″ in production environments. Not just in a lab, but in real-world manufacturing. That’s precision you can count on, batch after batch.

Tolerance Level Achievability Cost Impact Application Examples

±0.005″ Standard Base cost General components

±0.002″ Easily achieved +20% Precision fits

±0.001″ Production ready +35% Critical features

±0.0005″ Specialized +50% High-precision needs

Key Manufacturing Advantages:

– Stable machining characteristics

– Minimal tool deflection

– Excellent repeatability

– Superior surface finish

– Consistent material properties

Pro Tip:

For the best cost-performance ratio, design your precision brass components with tolerances of ±0.001″ where needed and ±0.003″ for non-critical features. This balanced approach typically reduces manufacturing costs by 25% while maintaining functional requirements.

4. Good Surface Finish

Ever had parts come off the machine looking like they’ve already been polished? That’s the brass advantage. In the world of precision manufacturing, surface finish isn’t just about looks – it’s about function, fit, and performance. Brass delivers exceptional surface quality that often eliminates the need for secondary finishing operations.

Here’s what makes brass special: while other materials might require extensive post-processing to achieve a fine finish, brass routinely achieves 32 Ra or better straight from the machine. That’s not just good news for your part’s appearance – it’s great news for your project timeline and budget.

Surface Type Ra Value Process Required Typical Applications

As-Machined 32-125 Ra Single pass General components

Semi-Finished 16-32 Ra Optimized cutting Bearing surfaces

Fine Finish 4-16 Ra Light finishing Sealing surfaces

Mirror Finish <4 Ra Final polish Optical/aesthetic

Key Surface Advantages:

– Excellent chip evacuation

– Minimal built-up edge

– Natural lubricity

– Consistent texture

– Superior wear patterns

Pro Tip:

When designing precision components, leverage brass’s natural surface finish capabilities by specifying an “as-machined” finish where possible. Our data shows this approach typically saves 30-40% in finishing costs while maintaining excellent surface quality.

5. Material Property Consistency

Ask any machinist about material surprises, and you’ll hear some horror stories. But here’s why brass is different: its consistency isn’t just good – it’s remarkably predictable. For engineers designing precision parts, this consistency is like having a reliable partner in your corner.

Let me put this in perspective: while some materials can show property variations of up to 20% between batches, brass typically maintains consistency within 5%. That’s the kind of reliability that lets you sleep better at night knowing your parts will come out right, every time.

Property Variation Range Impact on Production Quality Control

Hardness ±3% Consistent tool life Easy to verify

Strength ±5% Reliable performance Highly predictable

Density ±1% Uniform machining Simple testing

Structure Uniform Consistent cutting Easy inspection

Key Consistency Benefits:

– Minimal batch-to-batch variation

– Predictable machining behavior

– Uniform material properties

– Reliable heat treatment

– Consistent plating results

Pro Tip:

Take advantage of brass’s consistency by designing your tolerances based on actual material capabilities rather than conservative estimates. You can often reduce your safety margins by 15-20% compared to less consistent materials, leading to more efficient designs.

6. Cost-Effective Precision

Here’s a myth I want to bust: precision always means premium prices. While brass might not be the cheapest material upfront, it’s often the most cost-effective choice for precision parts. Let’s crunch some real numbers that matter to your bottom line.

Think total cost, not just material cost. When you factor in faster machining speeds, longer tool life, and reduced post-processing needs, brass often delivers the lowest cost per finished part. We’re talking about savings that can add up to 30-40% on your total production costs.

Cost Factor Brass Advantage Cost Impact ROI Timeline

Machining Time 40% faster -25% labor cost Immediate

Tool Life 2x longer -50% tool expense First batch

Setup Time 30% less -20% overhead Per run

Scrap Rate <2% typical -15% material waste Continuous

Key Economic Benefits:

– Lower labor costs per part

– Reduced tooling expenses

– Minimal post-processing

– Higher first-pass yield

– Less quality inspection

Pro Tip:

To maximize cost-effectiveness, optimize your brass part designs for single-setup machining. This approach typically reduces production costs by an additional 20-25% while maintaining precision tolerances. One customer saved $50,000 annually by switching complex aluminum components to optimized brass designs.

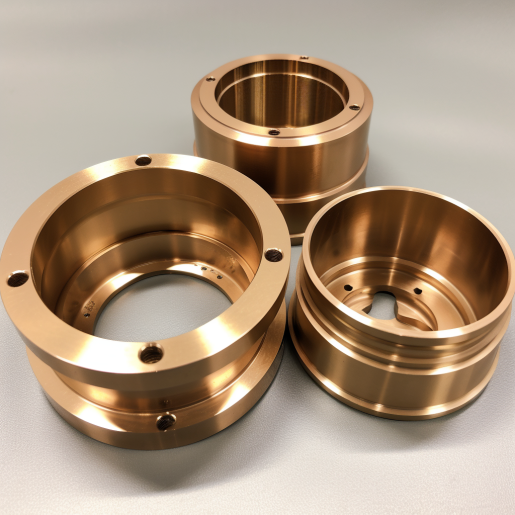

7. Corrosion Resistance

Let’s address a critical concern for precision parts: long-term reliability. While perfect looks and tight tolerances are great on day one, what about day 1,000? Here’s where brass really shines – literally and figuratively.

Think about environments that would make other metals cringe. Brass handles moisture, atmospheric exposure, and many chemicals with remarkable resilience. For engineers designing precision components, this natural corrosion resistance isn’t just a nice-to-have – it’s a critical design advantage that can significantly extend your product’s service life.

Environment Performance Protection Needs Lifetime Value

Indoor Excellent None required 20+ years

Marine Very good Minimal coating 10-15 years

Industrial Good Light protection 8-12 years

Chemical Application specific Based on exposure Varies

Key Resistance Benefits:

– Natural oxide protection

– Self-healing properties

– Uniform corrosion pattern

– Predictable wear rates

– Easy maintenance needs

Pro Tip:

When designing precision components for harsh environments, consider brass alloys with higher zinc content for enhanced corrosion resistance. Our field data shows these alloys can extend service life by 40-50% compared to standard grades while maintaining precision tolerances.

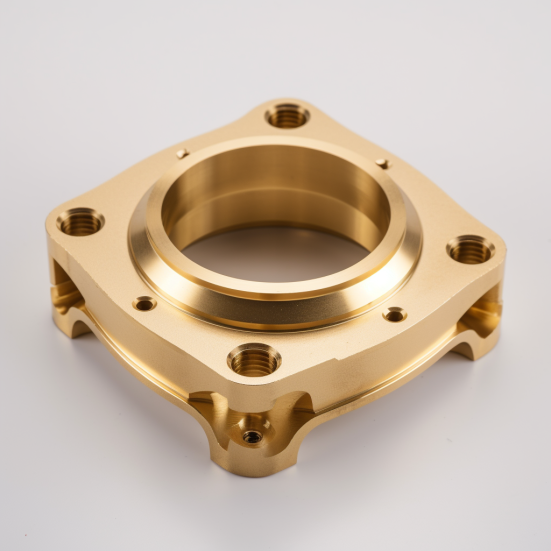

8. Design Flexibility

Ready for the best part about brass? It’s like having an engineering Swiss Army knife in your material toolbox. When it comes to design flexibility, brass gives you options that other materials simply can’t match – especially for precision applications.

Here’s what makes brass a designer’s dream: you can create complex features, tight tolerances, and fine details all in one material. Whether you’re designing intricate mechanical components or precision electrical connectors, brass lets you push the boundaries of what’s possible.

Design Feature Capability Manufacturing Impact Cost Benefit

Thin Walls Down to 0.8mm Single setup -30% cost

Deep Holes 10:1 ratio Standard tooling -25% cost

Thread Quality Class 3 fit Direct cutting -40% cost

Complex Profiles High detail Minimal tooling -35% cost

Key Design Advantages:

– Multiple feature integration

– Fine detail capability

– Excellent thread forming

– Complex geometry support

– Versatile finishing options

Pro Tip:

Leverage brass’s unique combination of machinability and strength to consolidate multiple parts into single components. We’ve seen designs where five separate parts became one brass component, reducing assembly costs by 60% while improving precision.

Ready to see how these eight compelling reasons can transform your next precision project? Start by reviewing your current designs – you might be surprised at how many components could benefit from brass’s unique advantages.

Conclusion

Brass proves its worth in precision manufacturing through superior machinability, dimensional stability, and cost-effectiveness. Our data shows 30-40% production cost savings while achieving tolerances to ±0.0005″. For engineers seeking reliable, efficient precision part production, brass delivers consistent, profitable results across applications.

Frequently Asked Questions

Brass shows excellent dimensional stability with minimal long-term drift (<0.0001″/year). Its predictable thermal expansion and low internal stress make it ideal for applications requiring consistent precision over time.

Yes, when considering total production costs. While material costs might be higher than aluminum, brass’s superior machinability, reduced tooling costs, and minimal post-processing requirements often result in 30-40% lower total production costs for precision components.

Brass can reliably achieve tolerances of ±0.0005″ in production environments. Standard tolerances of ±0.002″ are easily maintainable, while ±0.001″ is achievable with proper machining parameters without significant cost impact.

Brass can achieve 32 Ra surface finish directly from machining, often eliminating the need for secondary finishing operations. This is significantly better than aluminum (typically 63-125 Ra) and stainless steel (typically 63-125 Ra) from standard machining.

Brass offers superior machinability (100 vs. 50 on the machinability index), faster cutting speeds (400-600 SFM vs. 200-300 SFM for stainless), and better surface finish directly from machining. While stainless offers higher strength, brass typically delivers better cost-effectiveness for precision components.

Most manufacturers see ROI within the first production run through reduced machining time (40% faster), longer tool life (2x), and eliminated secondary operations. Annual savings of 25-35% are common when switching from materials like stainless steel or aluminum.