Hardened steel machining presents unique challenges that can derail product timelines and budgets if not properly planned. With over 15 years of precision CNC experience serving aerospace, medical, and industrial sectors, Okdor frequently helps engineers navigate the critical decisions that determine project success when working with hardened materials.

Five key factors determine success in hardened material machining: achieving realistic tolerances (±0.01-0.02 mm), understanding hardness effects on tool selection, avoiding problematic geometries, timing machining versus heat treatment, and controlling cost drivers like specialized tooling and setup complexity.

Discover tolerance limits, design tips, and cost strategies for hardened steel—plus when to machine before or after heat treatment for best results.

Table of Contents

What Tolerances Can CNC Hold on Hardened Steel?

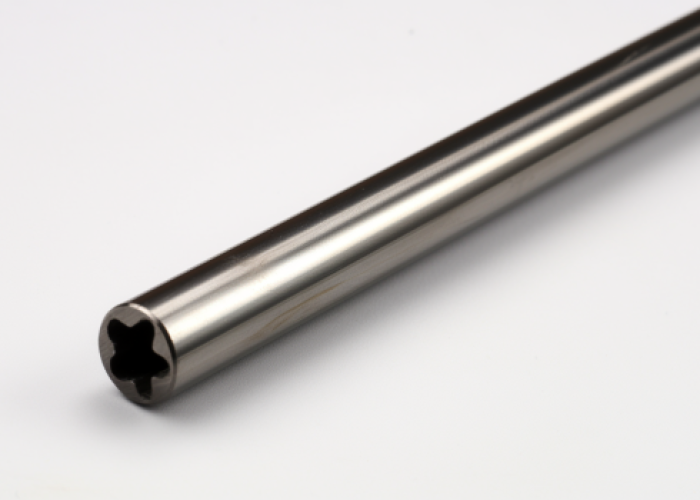

±0.01-0.02 mm tolerances are achievable on hardened steel with proper CBN tooling and rigid machine setup. Standard tolerances for steel alloys typically range ±0.08 mm under normal conditions, while tight tolerances like ±0.001 inches (±0.025 mm) require advanced techniques and skilled operators. CBN grades are largely used for finish turning hardened steels with hardness over 45 HRC.

Typical hardened steel tolerance ranges:

- General features: ±0.05-0.08 mm standard machining

- Functional surfaces: ±0.01-0.02 mm with CBN/ceramic tools

- Critical fits: ±0.01 mm using climate-controlled setup

- Complex geometries: ±0.02-0.03 mm due to tool access limitations

Manufacturing plants using hard turning can consistently hold dimensional tolerances to ±0.01 mm (±0.0004 inch) or better over long production runs. CBN tools can process steel up to 70 HRC and are suitable for hardened steel between 50-68 HRC. Specialized measurement tools like CMMs are essential for accurately assessing tight tolerances.

CBN inserts are designed for about 50 HRC to 68 HRC materials and produce fine finishes with tight tolerances, while ceramic inserts work well for hardened steel but CBN may have a slight edge for extremely high hardness levels. Moving from ±0.05 mm to ±0.01 mm tolerance can increase production costs by 45% due to specialized equipment and enhanced quality control requirements.

ISO 2768 provides general tolerance standards, while CMM inspection is necessary for parts with limited tolerances due to precision requirements.

Design Takeaway: Specify tighter tolerances only for features that directly impact part functionality or assembly fit. Reserve ±0.01 mm specifications for critical mating surfaces, bearing fits, and seal grooves. Use standard tolerances elsewhere to minimize machining complexity, tool costs, and inspection time.

How Does Steel Hardness Affect CNC Machining Performance?

Harder materials require cutting speeds 50-70% lower than soft materials to prevent excessive tool wear. Hard materials like steel use spindle speeds around 500-1500 RPM, while soft materials like aluminum use 3000-6000 RPM. Parameter values reduce as hardness increases, with hardness taken as the defining factor for ductile materials.

Steel hardness cutting speed guidelines:

- Soft steel (<30 HRC): 80-120 m/min cutting speed

- Medium hardness (30-45 HRC): 50-80 m/min cutting speed

- Hardened steel (45-65 HRC): 20-50 m/min cutting speed

- Ultra-hard steel (>65 HRC): CBN tools required, <20 m/min

Machining of hardened steels having hardness in the range of 45-65 HRC is considered hard machining. Tool wear rate increases exponentially with material hardness, with harder materials showing 2.65 times more tool erosion than ductile materials. Cutting forces are substantially higher with hardened materials, requiring adequate spindle power and high machine stiffness for close tolerance work. Dynamic stiffness becomes critical as high forces can excite vibrations leading to abrasive wear and early tool failure.

Effects of improper speeds and feeds are more visible on harder materials like titanium or Inconel because there is limited room for error. Medical device housings in 440C stainless require specialized cooling strategies to prevent work hardening that makes subsequent passes more difficult. Each cutting pass produces a work-hardened layer that affects subsequent operations, causing accumulated hardness increases and higher cutting forces. Aerospace components often specify multiple hardness zones within single parts, requiring parameter adjustments during machining.

Most operators agree on baseline cutting speeds: steel machining between 80-120 m/min, aluminum between 600-800 m/min. Material certification and hardness testing ensure consistent machining parameters across production runs.

Design Takeaway: Plan for 2-3x longer cycle times when specifying materials above 45 HRC. Consider material hardness impact on tooling costs and lead times during material selection phase, as tool replacement frequency increases significantly with harder materials.

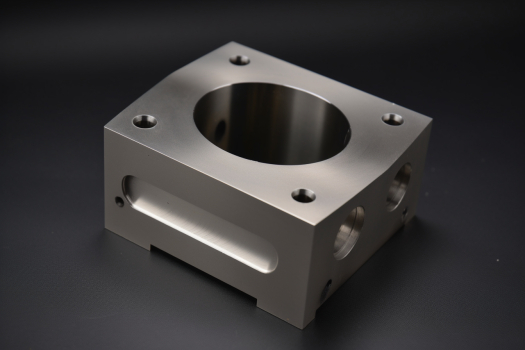

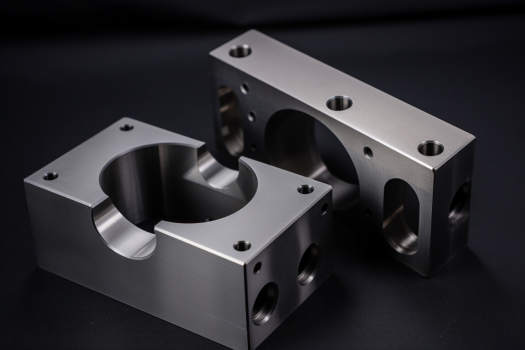

What Part Geometries Should You Avoid in Hardened Steel Machining?

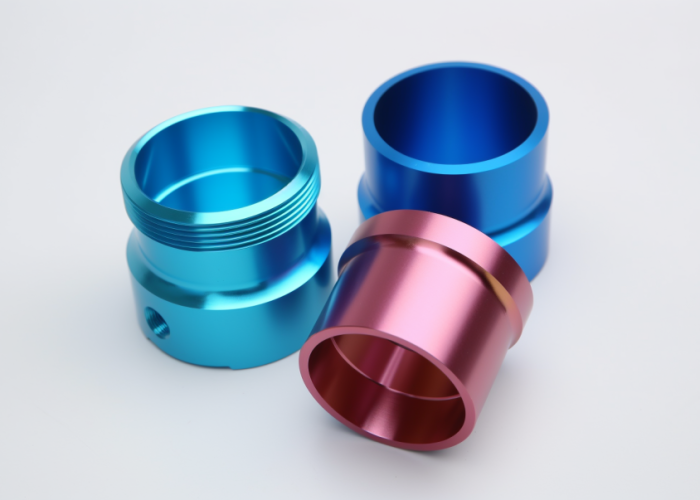

Thin walls below 0.5 mm thickness and deep pockets with high aspect ratios create tool deflection and machining difficulties. Thin walls of 0.020 in. (0.508mm) or less are subject to breaking during machining and may flex or warp afterwards. Complex shapes and sharp section changes generate stress and distortion during hardening processes.

Problematic geometries for hardened steel:

- Wall thickness <0.5 mm (deflection and breakage risk)

- Aspect ratios >3:1 for deep features (tool access limitations)

- Sharp internal corners <0.2 mm radius (stress concentration points)

- Undercuts requiring 5-axis setups (increased complexity and cost)

Tool runout from diameter inconsistencies makes corner radii inaccurate during radial cuts, especially problematic in hardened materials where tool deflection is amplified. A good width-to-height ratio for walls is 3:1, with maximum practical height of 2 in. (51mm) for adequate rigidity. Cutting tools spinning at 10,000-15,000 RPM create significant forces that can cause thin features to vibrate or break.

Aerospace bracket applications often require complex internal geometries, but over-designing tight corner radii to 0.1 mm increases machining time by 60% with minimal functional benefit. Medical device housings benefit from generous 0.5 mm radii for proper sealing while maintaining manufacturability. Adding 1-3 degree draft angles to walls makes machining easier and leaves less leftover material to remove. Avoid designing features requiring unnecessary material removal, as this adds significant machining time and production costs.

If complex features are unavoidable, select high-hardenability steel for slower cooling rates to minimize distortion risk. DFM guidelines recommend eliminating sharp corners and abrupt section changes through careful component design.

Design Takeaway: Optimize geometries for standard 3-axis machining with generous radii (minimum 0.2 mm) and adequate wall thickness ratios above 3:1. Eliminate unnecessary complex features that require specialized setups, extended cycle times, or increase scrap risk due to part deflection during machining.

Should You Machine Before or After Heat Treatment?

Pre-hardening machining offers easier cutting and faster cycle times, while post-hardening ensures tight tolerances and eliminates distortion effects. Heat treatment after machining adds cost and lead time but provides better dimensional control. With modern machines, cutting tools, and CAD/CAM, it’s often more cost effective to machine hardened bar in one shot.

Machining timing decision factors:

- Part tolerances: Tight specs require post-hardening machining

- Material removal: Heavy cuts favor pre-hardening approach

- Distortion risk: Complex geometries require careful timing planning

- Production volume: High volumes may justify pre-hardened material costs

Heat treating material before CNC machining can save overall production time but adds cost to the machining process due to harder materials taking longer to machine and wearing down tooling faster. Many parts come through shop doors pre-heat treated, meaning they have been heat treated prior to arrival for maintaining highest accuracy and tightest tolerances possible. Parts with tight tolerance are machined a little bit oversized then ground to size, with warpage varying by steel type and process.

Heat treating can impart varying levels of distortion depending on size, shape, material, heat treat process, and target hardness. Aerospace applications often require leaving 0.100″ on all surfaces prior to heat treatment to accommodate distortion. Heat treating after machining can cause parts to warp or otherwise deform, affecting tight tolerances achieved during machining. Medical device components frequently use a hybrid approach: rough machining, heat treatment, then final finishing.

ASME Y14.5 provides geometric dimensioning standards for heat-treated parts, while ISO 9001 requires documented heat treatment procedures for quality control. Process certification ensures repeatability across production runs.

Design Takeaway: Choose pre-hardening for heavy material removal and looser tolerances, or post-hardening for critical dimensions and precision fits. Plan adequate stock allowances when heat treating between operations, typically 0.05-0.10mm for finishing passes after hardening.

What Increases Cost in Hardened Steel Machining?

Specialized tooling, reduced cutting speeds, and increased setup complexity drive costs significantly higher than standard steel machining. Hard-to-machine materials like hardened steel require specialized tools and longer machining times compared to softer materials. HSS or standard carbide tooling cannot be used when milling hardened steel above 50 HRC.

Primary cost drivers for hardened steel:

- Tool costs: CBN/ceramic tools cost 4-5x more than carbide

- Cycle time: 2-3x longer machining time vs. soft materials

- Setup complexity: Specialized fixturing and alignment requirements

- Quality control: CMM inspection and documentation needs

Industries such as medical, aerospace, and defense require high-strength parts from materials like hardened steel, necessitating tools with higher hardness that are understandably more expensive. Hardened materials need stronger CNC machines and more expensive cutting tools, resulting in higher costs. Tool changeover time becomes significant, with poorly setup changes easily requiring 30 minutes of spindle non-running time.

Medical device housings in 440C stainless require specialized cooling strategies and precise parameter control, increasing both setup time and inspection requirements. Managing temperature control becomes critical when machining hardened steel due to high cutting temperatures that reduce optimal performance. Higher tolerances necessitate more advanced machinery and longer machining times, increasing costs and reject rates if not managed properly.

Custom CNC fabrications often require specific tool bits, with clients bearing portion of machine tool costs due to wear during production. Quality control requirements add inspection time and certification costs.

ISO 9001 requires documented cost accounting procedures for tooling expenses, while industry standards specify tool life tracking methodologies for accurate project costing.

Design Takeaway: Minimize hardened steel usage to critical areas only, specify standard tolerances where possible, and consider design modifications that reduce setup complexity. Plan for 3-4x higher tooling costs and extended lead times compared to standard steel projects.

Conclusion

Mastering hardened steel machining requires balancing tolerance requirements, material timing decisions, geometry optimization, and cost factors for project success. Consider pre-hardening for heavy cuts or post-hardening for precision fits based on your specific application needs. Contact us to explore manufacturing solutions tailored to your hardened steel product requirements.

Frequently Asked Questions

Expect 2-3x longer machining cycles due to reduced cutting speeds (20-50 m/min vs 80-120 m/min for soft steel) plus additional time for specialized tooling setup and enhanced quality control verification.

Deep pockets, thin walls below 0.5 mm, and tight internal radii present challenges due to tool deflection and access limitations. Simplify geometries where possible or consider multi-setup strategies for complex features.

Hardened steel justifies higher costs when component durability, wear resistance, or precision retention directly impacts product performance. Evaluate total lifecycle cost including reduced maintenance and replacement frequency versus initial manufacturing expense.

Choose hardened steel when your application requires wear resistance, high strength, or precision retention under load above 45 HRC. Consider heat-treated standard steel alternatives if only moderate hardness increases are needed for cost optimization.

Use generous radii (≥0.2 mm), maintain wall thickness ratios above 3:1, eliminate sharp corners and undercuts, and plan adequate stock allowances if heat treating between operations to accommodate distortion.

Minimize hardened areas to critical surfaces only, use standard tolerances where functionally acceptable, and optimize geometry for 3-axis machining. Consider machining before heat treatment for non-critical features to reduce specialized tooling costs.