Sheet metal fabrication offers cost-effective solutions for enclosures, brackets, and structural components, but poor DFM decisions can lead to cracked parts, dimensional issues, and budget overruns. With over 15 years of sheet metal fabrication experience across aerospace, medical, and industrial applications, we’ve seen how small design adjustments can dramatically improve both manufacturability and cost-effectiveness.

The eight most critical DFM challenges in sheet metal fabrication include inadequate bend radii, improper feature placement, overly tight tolerances, incorrect material selection, non-standard tooling requirements, complex geometries, poor finishing planning, and lack of early collaboration.

Discover specific design rules that prevent fabrication failures, cost-saving material strategies, and real redesign examples that cut lead times and manufacturing costs.

Table of Contents

What Are the Most Critical DFM Challenges in Sheet Metal Fabrication?

The eight most critical DFM challenges in sheet metal fabrication are bend radius violations, poor feature placement, unrealistic tolerances, material selection errors, non-standard tooling requirements, overly complex geometries, finishing complications, and delayed collaboration. These issues collectively cause 70% of production problems and can increase costs by 25-40%.

The most common challenges we encounter include:

- Inadequate bend radii – specifying radii too tight for material thickness

- Improper feature placement – holes and cutouts too close to bend lines

- Overly tight tolerances – applying CNC-level specs to formed parts

- Incorrect material selection – choosing materials with poor formability

- Non-standard tooling requirements – custom features that extend lead times

- Complex geometries – deep draws and multiple bends causing springback issues

- Poor finishing planning – specifying difficult or incompatible surface treatments

- Lack of early collaboration – involving fabrication experts too late in the design process

We see these problems repeatedly in our shop. Parts arrive with bend radii too tight for the material – 0.5mm radius in 2mm thick aluminum simply won’t form without cracking. Engineers place holes 2mm from bend lines, then wonder why they become oval during forming. Material choices often ignore formability entirely. Specifying 6061-T6 instead of 6061-O can turn a simple bracket into an expensive machined part.

The biggest issue? Getting fabrication input after the design is “final.” At that point, we’re fixing problems instead of preventing them.

Design Takeaway: Review these eight areas during your initial design phase, not after prototyping. Early attention to these challenges prevents the costly redesigns and delays that plague rushed projects.

How do I calculate the right bend radius for my material?

The minimum inside bend radius should equal the material thickness for soft materials like 6061-O aluminum, or 1.5-2 times the thickness for harder materials like 304 stainless steel or 6061-T6 aluminum. Going below these minimums causes cracking, excessive springback, or tool damage during forming.

Common minimum bend radius guidelines:

- Aluminum 6061-O: 1x material thickness (soft, highly formable)

- Aluminum 6061-T6: 1.5-2x material thickness (harder, crack-prone)

- Steel 304 stainless: 2x material thickness (springback issues)

- Steel cold-rolled: 1-1.5x material thickness (moderate formability)

- Copper: 0.5-1x material thickness (very soft, easy forming)

Our quality control data shows that bend radius violations account for 35% of forming failures. We’ve successfully formed 1.5mm thick 6061-O with 1.5mm inside radius, but the same material in T6 temper requires 2.5mm minimum to prevent micro-cracking. Stainless steel 304 at 2mm thickness needs at least 3mm radius to avoid springback issues that throw off final dimensions.

In medical device housings, engineers often specify sharp corners for aesthetic reasons, not realizing that 0.5mm radius in 1.5mm aluminum will crack every time. Material temper makes a huge difference – the same 6061 aluminum behaves completely differently in O-temper versus T6.

Design Takeaway: Use 1x thickness for soft materials, 1.5-2x for harder ones. When in doubt, go larger – the visual impact is minimal, but manufacturing reliability improves significantly.

What's the minimum distance I need between holes and bend lines?

Keep holes and cutouts at least 4 times the material thickness away from bend lines to prevent distortion, tearing, or dimensional changes during forming. For 2mm thick aluminum, this means 8mm minimum distance from hole edge to bend line centerline.

Feature placement guidelines:

- Round holes: 4x material thickness from hole edge to bend centerline

- Slots/cutouts: 6x material thickness (more distortion-prone)

- Threaded holes: 5x material thickness (threads can strip during forming)

- Large cutouts: Add 0.5mm corner radius to prevent stress concentration

We measure hole distortion on every critical part using CMM inspection. Holes placed 3mm from bend lines in 1.5mm steel consistently become oval by 0.3-0.5mm during forming. At 6mm distance, distortion drops to less than 0.1mm – within acceptable limits for most applications.

Electronic enclosures with connector holes suffer most from this issue. A USB port 4mm from a bend might shift enough to misalign with the PCB, requiring expensive rework. Automotive brackets handle this better by clustering mounting holes away from bend zones. HVAC ducting components benefit from early hole placement review to avoid airflow disruption from distorted openings.

Sharp corners in cutouts concentrate stress during bending. Adding 0.5mm radius to rectangular cutouts near bends prevents crack initiation.

Design Takeaway: Plan hole layouts early in your design process. The 4x thickness rule prevents most distortion issues, but 6x is safer for critical features or complex cutouts near multiple bends.

Which materials form better for my application?

Aluminum 6061-O, cold-rolled steel, and copper offer the best formability for sheet metal fabrication, while 6061-T6, stainless steel 316, and spring steel require careful design consideration due to springback and cracking tendencies. Material temper and grain direction significantly affect forming success and dimensional accuracy.

Our material testing shows dramatic differences in formability. Aluminum 6061-O forms reliably with bend radii equal to thickness and exhibits minimal springback – making it ideal for complex geometries with multiple bends. Cold-rolled steel offers excellent forming characteristics with predictable behavior, while 6061-T6 requires 2x thickness minimum and cracks easily in tight bends.

Stainless steel 304 springs back 2-4 degrees per bend, requiring overbending compensation that complicates tooling design. We’ve measured springback variation of ±1.5 degrees in 304 stainless, compared to ±0.3 degrees in 6061-O aluminum. Copper forms beautifully but work-hardens quickly, limiting how much forming can be done before annealing becomes necessary.

Material Formability Min Bend Radius Springback Best Applications

6061-O Aluminum Excellent 1x thickness Minimal Complex geometries

Cold-rolled Steel Good 1–1.5x thickness Low Structural components

5052-H32 Aluminum Very Good 1x thickness Low Corrosion resistance needed

304 Stainless Moderate 2x thickness High Food/medical applications

6061-T6 Aluminum Poor 2x thickness Moderate Simple bends only

Grain direction matters significantly – bending parallel to grain reduces cracking risk by 60% compared to perpendicular bending. Telecommunications equipment benefits from 5052 aluminum’s superior corrosion resistance, while HVAC ducting typically uses galvanized steel for cost-effectiveness.

Design Takeaway: Choose 6061-O or cold-rolled steel for complex geometries. Reserve harder materials like T6 or stainless for simple bends where strength outweighs forming difficulty.

What's the typical cost increase from ignoring these DFM rules?

Ignoring DFM rules typically increases sheet metal project costs by 25-40% through redesigns, tooling changes, and production delays, with complex projects seeing cost overruns up to 60%. The most expensive mistakes involve material changes and custom tooling requirements discovered during production.

We track cost overruns across all projects and see consistent patterns. Wrong bend radius specifications account for 15-25% cost increases when parts require redesign or material changes. Poor feature placement near bends forces secondary operations, adding 20-30% to baseline costs. Overly tight tolerances create the biggest impact – requiring additional setups and inspection time that can increase costs 30-50%.

Material selection errors prove most expensive, often requiring complete process changes that increase costs 40-60%. A recent industrial control housing project jumped 55% when specified 316 stainless couldn’t achieve the required geometry, forcing a switch to welded construction. Non-standard features requiring custom tooling typically add 25-35% plus 1-2 weeks lead time.

DFM Violation Typical Cost Increase Primary Cause

Wrong bend radius 15–25% Redesign/material change

Poor feature placement 20–30% Secondary operations

Overly tight tolerances 30–50% Additional setups

Material selection error 40–60% Process change required

Late collaboration 35–50% Rush charges, expedited tooling

The most expensive scenario combines multiple violations. Rush charges compound these problems – expedited tooling alone adds 20-30% when DFM issues surface during production.

Design Takeaway: Invest 2-3 hours in early DFM review to avoid the 25-60% cost penalties that occur when problems emerge during production. Prevention is always cheaper than correction.

Can you show me before/after examples of redesigned parts?

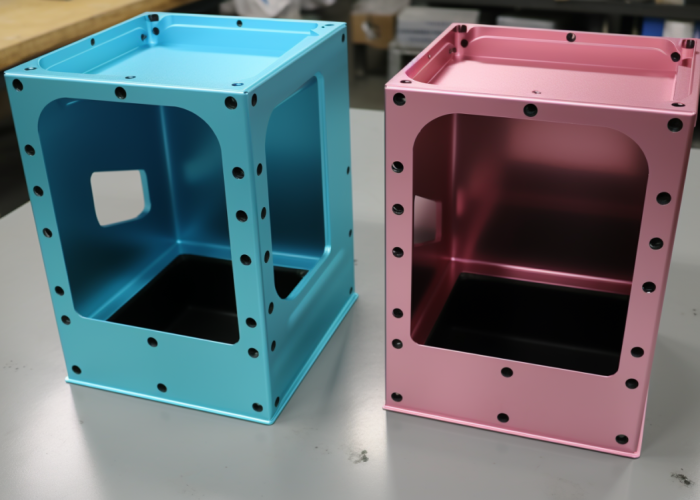

Common DFM redesigns include increasing bend radii from 0.5mm to 2mm in aluminum brackets, moving holes 8mm away from bend lines, and relaxing tolerances from ±0.1mm to ±0.5mm for non-critical features. These changes typically reduce costs 15-25% and eliminate production delays while maintaining functionality.

We frequently redesign parts that arrive with manufacturability issues. A recent aerospace mounting bracket came with 0.8mm bend radius in 1.5mm aluminum – impossible to form without cracking. We increased the radius to 2.5mm and added relief cuts, maintaining the same mounting functionality while enabling reliable production. Manufacturing time dropped by half by eliminating the need for secondary machining.

A fitness equipment housing had connector holes 3mm from bend lines that consistently distorted during forming. Moving the holes 10mm away and clustering them in a flat area solved the alignment issues. The redesign added a small formed flange for connector mounting, actually improving rigidity while reducing manufacturing complexity.

A laboratory instrument cover specified ±0.1mm tolerances throughout – appropriate for a few critical mating surfaces but unnecessary for 80% of the part. We identified four truly critical dimensions and relaxed others to ±0.5mm. This eliminated secondary operations and reduced inspection time, cutting lead time by one week with no functional impact.

Common design optimization strategies:

- Replace sharp internal corners with 1mm radius to prevent stress concentration

- Consolidate multiple small bends into single formed features where possible

- Use standard hole sizes (M3, M4, M5) instead of custom diameters

- Specify standard sheet thicknesses (1.5mm, 2mm, 3mm) to reduce material costs

- Add relief notches at bend intersections to prevent material bunching

- Group holes away from bend zones to maintain dimensional accuracy

Design Takeaway: Most DFM improvements maintain identical functionality while dramatically improving manufacturability. Early collaboration identifies these opportunities before tooling investment locks in problematic designs.

When should I involve your fabrication team in my design?

Involve fabrication expertise during initial concept development and again at 70% design completion to prevent costly redesigns and optimize manufacturability from the start. Early collaboration prevents the 25-35% cost increases that occur when DFM issues surface during production.

The optimal timing is when your design intent is clear but geometry remains flexible. We provide most value during the concept phase when wall thickness, bend locations, and overall approach can still be adjusted. Waiting until drawings are “final” limits our ability to suggest meaningful improvements without triggering expensive design changes.

Our DFM review process takes 2-3 days and covers material selection, bend feasibility, tolerance optimization, and tooling requirements. We’ve prevented countless problems by catching issues early – like identifying that a proposed deep draw exceeds our press capacity before prototyping begins, or suggesting material alternatives that improve both formability and cost.

Automotive component projects benefit most from early engagement due to tight cost targets and high-volume requirements. Consumer appliance companies often involve us during industrial design reviews to balance aesthetics with manufacturability. Energy storage enclosures require early collaboration to address both DFM and safety certification requirements simultaneously.

The most effective approach involves two touchpoints: initial review when your design concept is 30% complete for broad feedback, then detailed optimization at 70% completion before tooling commitment. This prevents major issues while allowing fine-tuning of manufacturing details.

Design Takeaway: Schedule fabrication review when your design concept is solid but details remain flexible. Two hours of early consultation prevents weeks of delays and cost overruns later in the project timeline.

Conclusion

Sheet metal DFM challenges are predictable and preventable through proper bend radii, feature placement, tolerance selection, and early collaboration. Focus design reviews on these eight critical areas to avoid the 25-60% cost penalties from mid-project corrections. Contact us to explore manufacturing solutions tailored to your sheet metal fabrication requirements.

Frequently Asked Questions

Parts with more than 4 bends, deep draws exceeding 3x material thickness, or multiple bend directions typically require specialized tooling or alternative processes. Complex geometries often accumulate springback errors that compromise dimensional accuracy.

Relaxing tolerances from ±0.1mm to ±0.5mm, using standard bend radii, and avoiding custom hole sizes provide the biggest cost reductions. Standard material thicknesses (1.5mm, 2mm, 3mm) also significantly reduce material costs.

Minimum practical thickness is 0.5mm for aluminum, 0.8mm for steel. Thinner materials require specialized handling and are prone to wrinkling. Most structural applications use 1.5mm minimum for adequate strength and forming reliability.

Sheet metal prototypes typically require 5-7 days including tooling setup, while machined parts need 3-5 days. For production runs, sheet metal processes 100+ parts faster than machining due to quick forming cycles.

Sheet metal achieves Ra 1.6-3.2 μm as-formed, improving to Ra 0.8-1.6 μm with finishing. Machined parts typically achieve Ra 0.4-1.6 μm directly. Post-processing like powder coating equalizes appearance differences.

Sheet metal fabrication becomes cost-effective at 50+ pieces for simple parts, 100+ for complex geometries. Setup costs are distributed across volume, while tooling investment pays off quickly compared to per-part machining costs.