Your supplier’s quote doubled—and all you changed were a few tighter tolerances. This happens constantly: engineers apply tight limits everywhere to “be safe,” and shops respond with inflated pricing or quiet rejections.

Use tight tolerances only where fit, function, or alignment require them.

For most CNC parts, ±0.05 mm is standard, while ±0.01 mm should be limited to mating or precision features. Applying it across every dimension multiplies setup, inspection, and scrap costs without improving performance.

Learn how supplier behavior exposes tolerance risks, when to relax limits safely, and how Okdor delivers 24-hour precision quotes without overpaying.

Table of Contents

Why Your Quote Doubled: The Hidden Tolerance Trap?

When quotes suddenly spike, it’s rarely a design flaw—it’s a tolerance communication issue.

A blanket ±0.01 mm spec tells the shop every feature demands micrometer-level control. That forces slower feeds, extra QC steps, and higher scrap risk—all of which show up directly in the quote. The part didn’t get harder; it just became unprofitable to run like that.

Most 3-axis CNC centers can reliably hold ±0.05 mm under ISO 2768-m. Only select features—bearing bores, sealing faces, or mating fits—truly need ±0.01 mm or better. Extending those limits across the print inflates machining cost by 20–50 % and inspection time by hours, even when function doesn’t change.

We review tolerance distribution before cutting metal, keeping tight control only where it affects assembly fit. This approach stabilizes pricing and reduces setup complexity while protecting functional accuracy.

Capability Aspect | Typical Job Shop | Precision-Controlled Setup |

Practical Tolerance Range | ±0.05 mm | ±0.01 mm |

Quote Turnaround | 3–5 days | 24–48 hours |

Inspection Method | Calipers / Micrometer | Full CMM verification |

Lead Time (prototype) | 2–3 weeks | 5–10 days |

If your quote doubled overnight, review the tolerance callouts before re-sourcing.

Relaxing just three or four unnecessary ±0.01 mm dimensions often restores pricing within a day—and can recover one to two days from the quote cycle when timelines are tight.

Why Shops Quote High Instead of Saying “We Can’t”?

A steep quote is often a soft refusal, not greed.

When a supplier lacks the tools or process control to meet your spec, they rarely reject outright—they price high enough that you move on. It’s a defensive response to uncertainty.

Most open-floor job shops maintain ±0.03–0.05 mm stability. Achieving tighter limits requires temperature-controlled environments, in-process probing, or precision grinding—all costly for one-off runs. So, rather than admit “we can’t,” many simply quote beyond budget to avoid rejection risk.

Our process starts by confirming feasibility before quoting. If a feature truly needs ±0.01 mm, it’s scheduled on controlled-spindle equipment or fine-finish operations designed for that range. That transparency keeps pricing aligned with capability and avoids hidden risk.

Supplier Behavior Signal | What It Usually Means | How to Respond |

Quote 2–3× higher than peers | Capability limit or tolerance beyond setup range | Ask for achievable tolerance band |

“We’ll try but no guarantee” | Unstable process or manual measurement | Request proof of past precision runs |

No questions before quoting | Possible lack of DFM review | Seek a shop that validates before pricing |

If pricing looks inflated, treat it as a diagnostic tool.

A short conversation about which dimensions drive cost can reveal whether the problem is equipment, process control, or tolerance strategy—and help you find a capable supplier faster, before deadlines slip.

When Suppliers Should Ask Questions (and What It Means If They Don’t)?

Silence before quoting isn’t efficiency—it’s risk.

Reliable suppliers always ask questions about datums, surface finishes, or tolerance priorities. When they don’t, it means they’re either auto-quoting or making assumptions that often lead to cost inflation or mid-project delays.

Inconsistent quoting behavior stems from unverified assumptions. Shops that quote “as is” without clarification usually protect margins with extra inspection hours or wider scrap allowances—raising prices by 15–30 %. Others under-quote, then stop production once “not machinable” surfaces appear.

We use pre-quote clarification as process control, not pushback. One five-minute exchange on feature order or tolerance function often prevents two full days of re-quoting or drawing revisions.

Supplier Behavior | What It Signals | Expected Outcome |

Asks detailed datum / setup questions | Strong process planning | Stable cost & timeline |

Sends quote without questions | Low engagement | Price swings, later re-quote |

Flags tolerance conflicts early | Quality-driven review | Predictable lead time |

If your supplier never asks, assume they’re guessing.

Engaged pre-quote dialogue consistently cuts cost variance by 20 % + and stabilizes delivery commitments—because precision starts before the first chip, not after.

Your supplier called it “impossible”?

Don’t redesign yet. Upload your rejected drawing and get a verified tolerance review from our engineers—free within 24 hours.

What to Do When Your Supplier Calls Your Tolerances “Impossible”?

“Impossible” often translates to “not profitable for our setup.”

Most rejections come from machine or inspection limits, not physics. General-purpose VMCs drift beyond ±0.02 mm over long toolpaths; thin-wall parts distort under cutting load; hole positions shift without CMM feedback.

That doesn’t make the print wrong—it means the shop lacks environmental control, probing, or fixturing precision to hold those numbers economically.

The fix isn’t surrendering accuracy but isolating which dimensions truly need micrometer control. Once intent is clear, alternate strategies—split tolerances, finish ream, or controlled passes—restore feasibility without compromising function.

Common “Impossible” Case | Real Cause | Practical Adjustment |

Long bore ±0.01 mm | Tool deflection over depth | Split tolerance or finish ream |

Thin-wall flatness ≤ 0.05 mm | Thermal distortion | Add fixturing + light passes |

We see this weekly—clarifying functional zones converts 80 % + of “rejected” parts into approved quotes within 24 hours.

When a shop says “impossible,” ask why.

That single question turns rejection into diagnosis and saves days that would otherwise be lost waiting for another quote.

How to Tell When a Tight Tolerance Actually Matters?

Not every decimal justifies its cost.

A well-performing assembly depends on a handful of precision features, not every cut surface. Tight tolerance should protect fit or motion, not appear everywhere for safety.

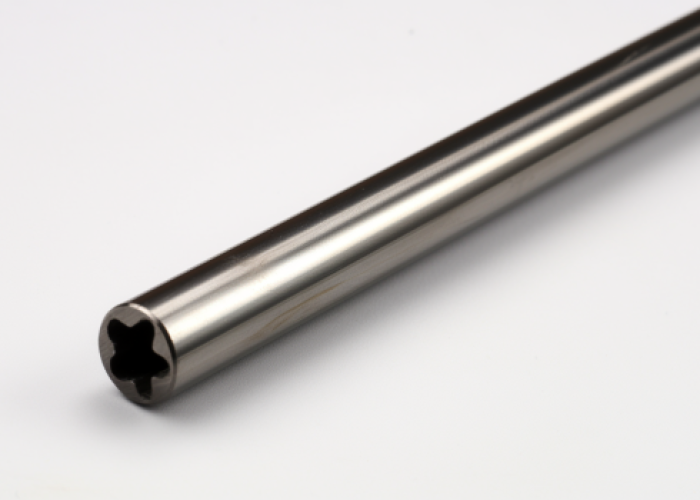

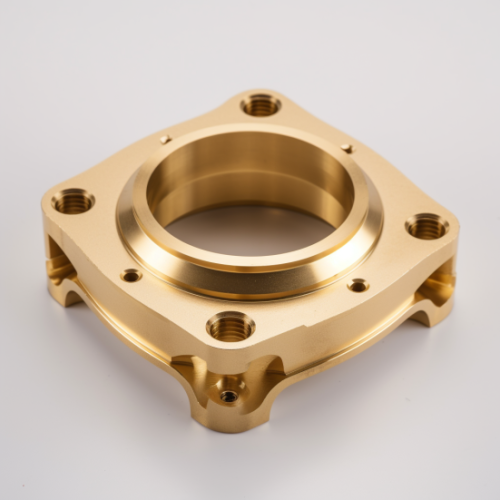

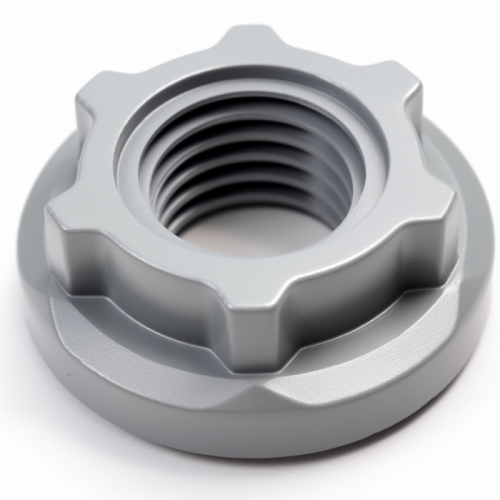

Critical fits—like bearing bores or sealing diameters—need ±0.01 mm (H7 / h6 range).

Sliding interfaces or shafts typically run fine at ±0.02–0.03 mm.

Mounting holes and covers hold alignment easily at ±0.05–0.10 mm.

Anything cosmetic or non-functional can relax to ±0.10 mm + without consequence.

Evaluating drawings this way helps suppliers quote realistically. It also accelerates manufacturing: focusing precision where it matters often cuts machining time by 25–40 % and reduces inspection load by half.

If you’re not sure which dimensions drive performance, start from the assembly function.

Identify three to five critical dimensions per part—enough to ensure fit and reliability. This simple exercise speeds quoting by a full day and eliminates the cycle of “tight-everywhere” revisions that stall sourcing.

When ±0.01 mm Becomes a Cost Multiplier, Not a Precision Need?

Every extra decimal adds hours you never see on the quote.

A ±0.01 mm callout may seem harmless on paper, but it forces the machinist to slow feeds, verify after every pass, and treat scrap as inevitable. That single tolerance can turn a two-hour cycle into four, and it’s rarely the feature’s performance that demands it—it’s the drawing.

For most machined parts, ±0.05 mm meets 90 % of fit and function needs under ISO 2768-m. When designers tighten beyond that across the board, they pay for microscopic precision where none is needed. Tool wear rises, setup time doubles, and inspection shifts from batch-check to full-piece verification.

We’ve helped customers who applied ±0.01 mm blanketly across non-critical faces. By identifying only five features that actually needed it, total part cost fell 35 % and inspection time dropped from eight hours to three. The part still assembled perfectly—but at half the quote.

What this means for you:

If a quote suddenly spikes after minor tolerance edits, don’t assume greed—ask which dimensions drive it. The shops that can pinpoint exactly why are process-driven; the ones that can’t are quoting defensively. That question alone tells you who’s worth keeping in your vendor list.

The Tolerance Stack-Up Problem That Breaks Perfect Designs

Perfect single parts don’t guarantee a perfect assembly.

When ten “on-spec” parts stack together, even ±0.05 mm per piece can cause a 0.5 mm interference fit—enough to jam slides, misalign shafts, or force field rework. This is tolerance stack-up, and it’s the hidden reason many “precision” builds fail after approval.

Most shops check single-part accuracy only. Without datum correlation or 3D chain analysis, small drifts compound across multiple components. The problem doesn’t appear until final fit, when everything technically measures “good” but nothing aligns.

A five-minute stack-up review before quoting can prevent days of rebuilds. We routinely catch these issues early—like one enclosure job where three linked flatness callouts created a cumulative 0.4 mm bow. Clarifying primary datums and tolerance flow avoided a full fixture redesign and recovered an entire production week.

Supplier-evaluation step:

Ask if your supplier validates tolerance chains or runs multi-part CMM checks before machining. If not, they’re machining in isolation—hoping the parts fit later. Shops that verify stack-ups before cutting demonstrate genuine process control, not guesswork. Those are the ones you can trust for critical assemblies where every hour and alignment point matters.

What Tolerances Shops Can Actually Hold vs. What They Claim?

Brochure tolerances and production tolerances are two different worlds.

The glossy spec that says ±0.005 mm usually comes from a single lab test under perfect temperature control. On the shop floor, heat, tool wear, and fixturing reality widen that band fast. Understanding the real numbers separates capable partners from marketing noise.

In continuous production, typical ranges look like this:

- 3-axis CNCs: ±0.05 mm stable, ±0.03 mm with careful setup.

- 4-/5-axis precision machines: ±0.01–0.02 mm under climate control.

- Grinding or jig-boring: ±0.005 mm—but with longer lead times.

We’ve stabilized repeat runs that other shops lost control of at ±0.02 mm simply by verifying machine warm-up and probing routines. Across 20-part batches, holding ±0.01 mm consistently matters more than hitting ±0.005 mm once. That’s real capability.

Before trusting a quoted tolerance, ask three questions:

- What’s your repeatable tolerance band over ten consecutive parts?

- What environment maintains that stability—open floor or temperature-controlled?

- How often are key dimensions verified mid-run?

Suppliers who answer with measured data, not adjectives like “tight” or “precise,” are the ones who’ll still deliver your parts on time and within spec—without surprises or excuses.

Should You Relax Tolerances—or Find a Shop That Can Hold Them?

Loosening tolerances isn’t always the fix—sometimes the shop is the limit.

When your supplier says “we can’t hold ±0.01 mm,” the instinct is to relax the spec. But that decision can hide process instability instead of solving it. The question isn’t “Is my print too tight?” It’s “Is my supplier capable enough to hold it consistently?”

Functional tolerances—press fits, bearing seats, linear rails—exist for performance. Relaxing them risks clearance loss or vibration. But when tight bands appear on brackets, covers, or purely aesthetic surfaces, they add cost without value. The key is knowing which group you’re in before touching the drawing.

We’ve seen this play out many times: one client loosened all critical fits after a supplier complained, then re-tightened them months later when the assembly failed in testing. The re-quote cycle cost more than the original machining. In contrast, switching to a precision shop that could sustain ±0.01 mm over 20-piece runs solved the issue within a week.

Sourcing cue:

If your supplier can’t explain how they’ll hold a tolerance—fixturing, probing, or environment—they can’t hold it reliably. Keep functional tolerances firm, relax only the decorative ones, and partner with shops that can prove repeatability with inspection data. Clear capability beats cautious compromises every time.

How to Mark Up Drawings So Suppliers Stop Guessing

Suppliers don’t reject drawings—they reject uncertainty.

Every missing datum or vague finish note forces assumptions that turn into quote inflation. A clear drawing doesn’t just speed quoting; it shows control. When intent is obvious, suppliers stop padding time or hiding behind “not manufacturable.”

Group dimensions by function instead of geometry:

- Box and tag critical fits as functional.

- Use ISO 2768-m for reference dimensions.

- Note purpose directly: “flatness for gasket seal,” “slot aligns sensor.”

We’ve seen quoting cycles drop from five days to under 24 hours after engineers clarified just a few of these. One recent example: an RFQ for a tight-fit aluminum housing kept stalling until the client labeled the sealing face as “functional” and marked side walls “cosmetic.” Pricing stabilized immediately, and first article shipped two weeks earlier.

Supplier-evaluation cue:

Good suppliers respond to clear drawings with follow-up questions, not silence. If your vendor quotes instantly without asking about tagged zones, they’re assuming risk you’ll pay for later.

Before you send your next RFQ, scan your drawing like a supplier. If you’d hesitate for even one feature, rewrite it. Clear mark-ups typically cut quoting time by 1–2 days and prevent inflated “safety” pricing. Precision starts long before machining—it begins with drawings that leave nothing to interpretation.

Conclusion

When quotes double or suppliers call your tolerances “impossible,” it’s not your design—it’s their process control. At Okdor, we specialize in rescuing these stalled projects. Upload your rejected drawings today for an immediate tolerance assessment and a precise, 24-hour quote that gets your production moving agai

Frequently Asked Questions

Yes—if the feature truly needs it. We isolate critical fits, apply hybrid tolerance zones, and use in-process probing or grinding only where function demands it. That approach holds precision where it matters while cutting unnecessary cost by 20–40 %.

Ask what repeatable tolerance band they achieve over ten parts and in what environment. If they can’t answer with data, they’re estimating risk. We quote from verified process control records, not best-case claims—so pricing reflects reality, not guesswork.

“Impossible” usually means “uneconomical for our setup.” Ask what process or fixturing limitation causes the issue. We translate those limits into workable solutions—splitting tolerances, reaming, or adjusting finish operations—to keep your part functional and on schedule.

Upload your drawing and inspection notes—our engineering team provides a tolerance feasibility review and a new quote within 24 hours. We’ll identify which dimensions can stay tight, which can relax safely, and deliver a clear path to approval without delay.

CAD shows geometry, not process capability. Many suppliers can’t maintain ±0.01 mm across production due to tool wear or temperature drift. We verify both design intent and machining stability before quoting—so the tolerance you call out is the tolerance we can hold consistently.

Confirm datum flow and alignment zones during quoting. We run pre-quote tolerance-chain checks that flag interference before machining starts—saving days of fixture rework and avoiding finger-pointing once assemblies fail.