Heat treatment distortion can turn an in-tolerance CNC part into scrap overnight — holes shrink or drift, faces warp, flatness disappears, and suddenly your supplier claims your drawing is the real problem. When this happens mid-project, cost, schedule, and credibility are all at risk.

Most heat-treat tolerance failures can be recovered with post-heat-treat machining, CMM-guided re-fixturing, and selective surface correction — but some distortion requires a clean remake to avoid cascading errors down the assembly. Knowing the difference early prevents wasted time and money.

Read on to see which issues are fixable, what proof you need before accepting blame, and when switching to a heat-treat-capable machining partner protects your deadline.

Table of Contents

Which heat-treatment tolerance issues are repairable vs. non-repairable?

If distortion is localized and machining allowance remains, rescue machining is normally faster and cheaper. Full re-manufacture is only required when distortion breaks functional geometry or removes too much material to re-establish datums.

Most suppliers call every failure “scrap” because they don’t have CMM feedback + post-heat-treat machining. The truth: shrinkage of bores by 0.02–0.08 mm, flatness drift up to 0.1 mm, and parallelism shifts under 0.05 mm are routinely recoverable by re-fixturing and selective correction — without touching unaffected features.

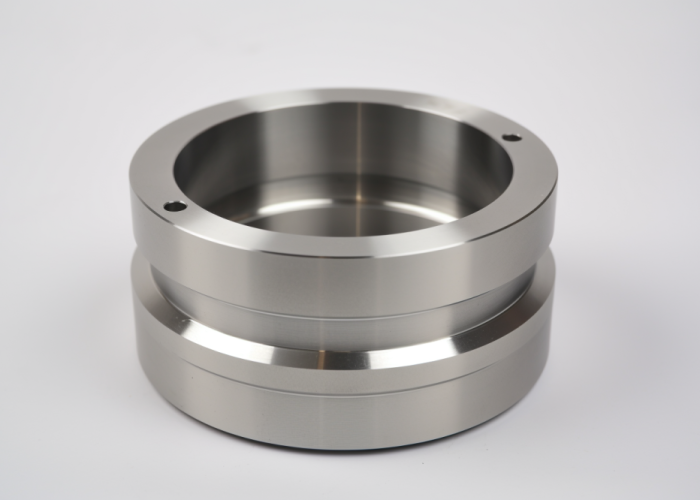

Example: We recently recovered 8 hardened steel housings where two bores shifted 0.06 mm off-position after heat treat. Re-datuming and line-boring saved the lot in 3 days vs 3–4 weeks to remake — and prevented a full assembly slip.

Quick decision framework:

- Machining stock still available? → Usually salvage

- Distortion isolated, not systemic? → High recovery success

- Datums still identifiable? → Minimal risk to restart geometry

Staying with a supplier who has already said “scrap” typically means lost weeks, another PO, and another risk roll.

Action Step: Send the CMM report or measured deviations — we’ll tell you within 24 hours whether parts go into rescue machining or if a clean restart protects the schedule you can’t afford to extend.

How can warped holes and bores be recovered after heat treatment?

Bores that distort during heat treat can usually be restored by re-establishing hardened-state datums and correcting roundness/position with line boring, honing, or bore grinding — all guided by CMM inspection.

The real failure is often process planning: shops reference soft-state datums pre-heat-treat, so when distortion shifts those relationships, they quit instead of correcting them. A capability gap — not a reason to restart.

Our typical heat-treat rescue sequence:

1️⃣ Probe hardened part — redefine datums based on actual form

2️⃣ Fixture for post-heat-treat relationships (not original blueprint assumptions)

3️⃣ Remove only what distortion created — preserving all other tolerances

4️⃣ Verify true position and diameter live during correction

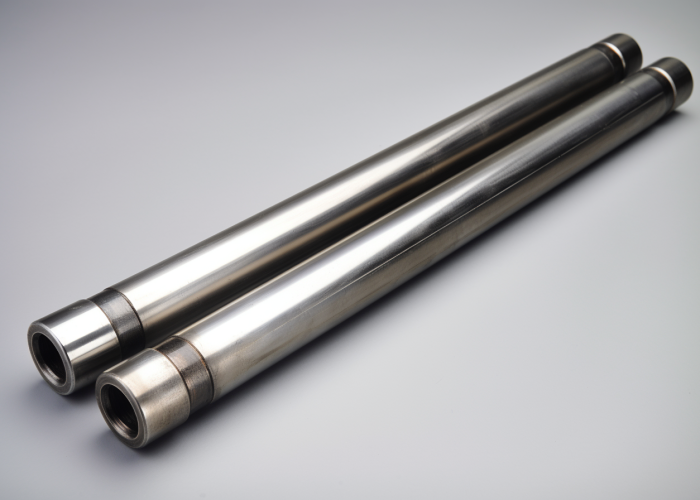

Example: 4140 shaft bores shrank 0.04 mm after nitriding. Supplier wanted to scrap the batch. We honed + re-qualified true position in 48 hours, assembly passed without a drawing change.

Fast timeline comparison:

Option | Typical Time | Project Risk |

Bore salvage machining | 1–4 days | Minimal — known geometry |

Full remake after scrap | 2–4 weeks | High — new heat-treat, new risk |

If your supplier didn’t propose second-operation alignment machining, they likely can’t do it.

Action Step: Share the drawing + bore deviations — we’ll confirm whether correction gets installation back on track this week instead of next month.

How do you handle supplier payment disputes over out-of-spec heat-treated parts?

Do not pay until an independent measurement confirms whether the failure is supplier-induced. Most heat-treat tolerance issues are created by fixturing or missed checks — not the drawing.

When a supplier demands full payment before proving cause, that’s a red flag.

If they cannot provide hardened-state CMM data tied to functional datums, they are asking you to fund their process failure. Every day spent arguing increases the risk that your assembly milestone slips.

Typical outcomes:

- You wait longer while they “look into it”

- You lose leverage once you pay

- They propose costly redesign instead of correction

We see this weekly: bore or flatness shifts blamed on design…

then recovered within 48–72 hours once a capable shop takes over.

Action Step: Hold payment until you have real measurements — send us the drawing + whatever data exists. We’ll confirm salvage vs. remake in 24 hours so you protect both your budget and your schedule before it collapses.

Supplier Can’t Fix Your Heat-Treat Distortion? We Can!

Upload your drawing for a 24-hour salvage feasibility check — before more scrap or delays stack up

What inspection evidence do you need before a supplier blames your drawing?

You need a CMM report that verifies critical features using hardened-state datums and functional relationships — not just single-feature checks.

Suppliers often measure only what failed, not why it failed.

Without a validated inspection plan:

- GD&T may have been interpreted incorrectly

- Fixturing errors go unnoticed

- Heat-treat distortion direction is ignored

A functional check must answer:

- Did datums shift during heat treat?

- Did true position move relative to mating features?

- Does the distortion follow the fixture orientation? (supplier error)

Case example: A batch of housings failed flatness by 0.12 mm.

CMM results showed repeatable distortion matching clamp support — we re-supported, finish-cut 0.07 mm, and brought them back inside tolerance without a drawing change.

Action Step: If your supplier is blaming the print without valid inspection logic, send us the CMM plots or even phone photos — we’ll tell you who is actually responsible so you stop losing days to the wrong argument.

How do you tell if flatness or parallelism failures come from design or supplier error?

If distortion aligns with fixture direction, it’s supplier-induced. If it’s uniform and within salvage range, it’s still recoverable — just needs finish machining after heat treat.

General job shops call planarity failures “thermal behavior” and hand the problem back to you.

But we’ve recovered flatness up to 0.15 mm and parallelism drift up to 0.1 mm in hardened steels using:

- CMM-guided re-datum

- Floating clamp compensation

- Minimal selective material removal

Quick fault test:

Distortion Pattern | Likely Cause | Response |

Directional & repeated | Holding/fixture error | Supplier-induced → salvage |

Symmetric but small | Internal stress | Salvage + future fixture change |

Systemically high & no stock | Design allowance insufficient | Redesign discussion |

If your supplier already called them scrap, you’re on the fastest path to delay — because they cannot recover what they failed to plan for.

Action Step: Email the flatness/parallelism deviations (orientation included) — we’ll map distortion to root cause and tell you today whether finish-cutting saves the lot and your assembly deadline.

Should you switch materials or find a supplier who can hold tolerances post-heat-treat?

Switching suppliers is the first and fastest recovery path. Switching materials is only necessary when distortion repeats even with proper post-heat-treat machining and fixturing.

Most job shops tell you to change the material because they can’t hold tolerances after heat treat — not because the alloy is wrong.

For 4140, 17-4PH, and tool steels, we routinely control bore and flatness movement post-treat as long as machining stock remains.

Material change should only be considered when:

- The part is thin-wall and heat-treat strength is still required

- Distortion forces geometric redesign

- There’s no allowance left for finish machining

But changing material triggers:

- New qualification tests

- New heat-treat curve

- New lead time (weeks, not days)

Fixing the process capability gap is almost always faster than changing the part.

Action Step: Before anyone rewrites the print, send the drawing and distortion pattern — we’ll confirm if a different supplier (not a different alloy) gets you back on schedule this week instead of next month.

When does re-fixturing unlock tolerances that looked impossible after heat treat?

If distortion direction is consistent, re-fixturing and re-establishing datums after heat treat can recover features that initially appear beyond tolerance.

A single setup shift before or during heat treat can move:

- Bore centerlines

- True position

- Flatness and parallelism planes

General shops scrap these parts because they can’t re-datum in the hardened state.

But if distortion is predictable, we can clamp and reference what the part has become — not what CAD assumed — and correct only where the movement occurred.

Example: Precision bracket holes drifted 0.09 mm. Supplier said “no recoverable stock.”

After re-support and CMM-guided probe-and-cut, position error dropped to 0.02 mm in 2 days — assembly saved.

Simple test:

- Repeatable deviation → high re-fixturing success

- Random deviation → deeper process issue → check heat-treat uniformity

Skipping this step typically costs a full remake cycle you didn’t plan for.

Action Step: Upload a CMM plot or even manual measurements — if deviation direction is clear, we’ll start hard-state fixturing review immediately so you avoid another week of standstill.

Which surfaces can be reground after heat treatment without breaking geometry or fit?

Any surface with remaining machining allowance that does not control functional relationships can be reground — including flats, datum pads, and sealing faces. Critical stack-up features must be corrected with CMM guidance to avoid new failures.

Problem arises when grinding removes:

- Datum integrity

- Fit dimensions

- Parallel or perpendicular relationships

- Thickness required for stiffness or sealing

Smart salvage focuses on:

- Non-datum surfaces first

- Selective removal where distortion occurred

- Protecting critical mating faces

Typical recoverable conditions:

- Flatness out 0.05–0.15 mm

- Parallelism drift under 0.1 mm

- Local waviness or quench marks

We see this weekly: case-hardened housings where top planes warped 0.1 mm — after re-datum + targeted grind, the parts cleared 0.03 mm flatness and passed leak testing 48 hours later.

If your shop is proposing full re-cuts or complete remakes, they’re avoiding the critical step: geometrically safe grinding.

Action Step: Send photos/CMM notes marking affected surfaces — we’ll identify which faces can be corrected within days, keeping your build on track and avoiding catastrophic assembly delay.

When is it better to remake parts than continue salvage machining?

You should stop salvage machining and restart when recovery would take longer than a controlled remake, or when distortion has already compromised functional datums and tolerance stack-ups.

If every correction introduces new variation or uncertainty, salvage becomes a time sink. The biggest danger is losing time twice: first on failed salvage attempts, then on a restart you could have initiated days earlier.

A capable shop sets the decision point early: after verifying remaining machining allowance and whether functional geometry can be re-established, the part either proceeds directly into finish correction — or a restart begins that same day. The goal is schedule protection, not “maybe this works” experiments.

Waiting too long to restart can push assembly milestones past fixed dates, turning a supplier mistake into a program-level credibility issue.

Action Step: Before one more hour is spent on uncertain rework, send the drawing and distortion evidence — we’ll tell you today whether recovery is clean or if a restart saves your build plan.

Don’t Approve Rework Until You Know It Will Work

Get a fix-or-restart verdict backed by heat-treated machining experience — protect your schedule, budget, and reputation

What if your supplier asks to relax tolerances after heat treat failure?

If a supplier asks to relax tolerances after heat treat, it means they cannot restore the original specification, so approving the change transfers their process failure into your assembly performance risk.

Relaxing tolerances may seem faster — until it causes fit issues, sealing failures, or unexpected noise downstream. Once tolerance integrity is compromised, you own the fallout, not the supplier who failed the process.

A proper rescue process restores the original drawing intent. Only when machining allowance is fully consumed and functional relationships are unrecoverable should tolerance changes even be discussed — and that conversation should be driven by your engineering priorities, not a supplier’s limitations.

Accepting relaxed tolerances just to move forward often leads to another, more expensive delay later when the assembly fails final testing.

Action Step: If a supplier is asking you to weaken your print, share the failed dimensions — we’ll confirm if the original specs are still achievable and keep your performance targets intact.

When is redesign necessary vs. switching to a heat-treat-capable shop?

Redesign is only necessary when machining allowance is insufficient and distortion repeats even with proper post-heat-treat machining; otherwise switching to a supplier who can hold tolerances after heat treat is faster and safer.

General shops recommend redesign first because they cannot recover hardened geometry. But in most cases, the part design is sound — it’s the process control that failed: no in-process checks, soft-state datum reliance, or uneven quench support.

Switching to a capable shop avoids unnecessary design changes that trigger:

- New validation work

- Updated models and tooling

- Approval cycles that take weeks, not days

Redesign should always be a last resort, never a reaction to someone else’s capability gap.

Action Step: Before opening a design change notice, send the drawing and failure mode — we’ll confirm if a process-capable partner solves the problem without altering your engineering intent or schedule.

When should you switch suppliers instead of absorbing ongoing scrap costs?

It’s smarter to switch suppliers immediately when the current shop shows no clear recovery plan, repeats the same errors, or continues invoicing while delays grow.

Once a supplier has demonstrated they cannot recover hardened geometry, every additional day they touch the parts increases:

- Schedule risk

- Scrap accumulation

- Cost you may never recover

The decision to switch becomes urgent when:

- You have no salvage timeline from the current supplier

- They propose compromises instead of solutions

- Their process caused the failure in the first place

Switching to a heat-treat-capable machining supplier eliminates repeat failure potential and returns control of your delivery date.

Action Step: If you’re still being asked to wait or pay, share your drawing and timeline requirement — we’ll tell you exactly how fast your project can be recovered and prevent a second round of failure.

Conclusion

Heat-treated parts that fail tolerance inspection don’t need to derail your build. Most can be recovered quickly with the right post-treat machining and inspection. Send your drawing and failure data — we’ll confirm salvage vs. restart within 24 hours so your delivery date stays intact.

Frequently Asked Questions

Within 24 hours of receiving the drawing and inspection data.

No. We selectively remove minimal stock from distortion-affected areas only, preserving strength and case depth.

Start with measurement data. Ship parts only if salvage is confirmed — saves time and cost.

We give a clear “restart now” recommendation before more schedule slips — with a fast remake plan.

We restart from hardened-state datums. Many “failed” salvage attempts are recoverable with proper fixturing and CMM feedback.

Yes. If machining allowance and functional datums remain, we restore original specs — no tolerance compromise.