Choosing between Alodine and anodizing for CNC aluminum parts affects electrical performance, dimensional accuracy, and processing cost. We help engineers make this critical surface treatment decision based on functionality requirements.

Choose Alodine for electrically conductive and tight-tolerance parts with 0.00001-0.0004 inch thickness. Choose anodizing for maximum corrosion protection and cosmetic appearance, accepting 0.0002-0.003 inch dimensional impact.

Compare performance, cost, and application tips to choose the best aluminum treatment—based on real CNC production experience.

Table of Contents

What's the Key Difference Between Alodine and Anodizing?

Alodine creates a thin chemical conversion layer that maintains electrical conductivity, while anodizing builds a thick insulating oxide barrier for maximum corrosion protection. This fundamental difference drives every other decision about which treatment to specify for your aluminum CNC parts.

When we process Alodine coating, we’re essentially converting the aluminum surface through a room-temperature chromate bath in 5-30 minutes. The resulting layer measures just 0.00001-0.0004 inches thick and preserves the metal’s natural conductivity. Anodizing works completely differently – it uses an electrochemical process to grow aluminum oxide from the base material itself, creating layers 0.0002-0.003 inches thick that act as electrical insulators.

We see this difference play out constantly in real applications. Electronics housing projects almost always specify Alodine because the chassis needs to maintain grounding paths between components. Meanwhile, outdoor equipment manufacturers choose anodizing for the superior weather protection, even though it means designing around the thicker, non-conductive surface. The processing difference also affects lead times – Alodine can be completed the same day, while anodizing requires specialized equipment and longer processing cycles.

Design Takeaway: Choose Alodine when you need electrical continuity and tight dimensional control. Specify anodizing when corrosion resistance and appearance matter more than conductivity, and you can accommodate the dimensional impact in your design.

Which Treatment Maintains Electrical Conductivity?

Alodine coating preserves electrical conductivity, making it ideal for grounding applications, while anodizing creates an insulating barrier that blocks electrical current. For electronics enclosures, EMI shielding, and any application requiring electrical continuity, this difference is critical to functionality.

Alodine’s chromate conversion layer allows electrons to flow through the coating, maintaining the aluminum’s natural conductive properties. We regularly measure less than 0.1 ohm resistance across Alodine-treated surfaces, which easily satisfies grounding requirements for most electronic applications. Anodized aluminum acts as an electrical insulator with megohm-level resistance – essentially creating an open circuit that breaks electrical paths.

This conductivity difference drives real design decisions across regulated industries. Audio equipment manufacturers specify Alodine for chassis components because circuit boards need reliable grounding paths to meet EMI compliance. Defense contractors choose Alodine on radar enclosures where maintaining conductivity is required for proper shielding performance. Medical devices sometimes intentionally select anodizing for its insulating properties when electrical isolation between components is needed for patient safety compliance.

Design Takeaway: Always specify Alodine when electrical continuity is required between aluminum components. Use anodizing only when electrical isolation is desired or when conductivity isn’t a design requirement.

How Do Coating Thicknesses Compare for Tight Tolerances?

Alodine adds 0.00001-0.0004 inches per surface, while anodizing adds 0.0002-0.003 inches – a difference that can make or break tight-tolerance designs. For precision CNC parts with ±0.005 inch tolerances, this thickness variation determines which coating is feasible.

When programming precision components, we build coating thickness into the nominal dimensions from the start. Alodine’s minimal buildup rarely affects parts machined to standard tolerances – we can machine to print and apply the coating without dimensional concerns. Anodizing requires careful planning since a typical 0.001 inch coating layer consumes 0.002 inches of total tolerance on diameter features. For threaded holes, we often machine oversize to maintain proper thread engagement after the thicker anodized layer is applied.

The thickness impact becomes critical in assemblies where multiple surfaces must mate precisely. Precision instrument housings often specify Alodine to avoid secondary machining operations on critical surfaces after coating. Medical device projects requiring FDA validation choose Alodine when maintaining exact sealing surface dimensions is essential for regulatory compliance.

Design Takeaway: Use Alodine for parts with tolerances tighter than ±0.010 inches or when multiple coated surfaces must maintain precise fits. Reserve anodizing for applications where the dimensional impact can be planned into the design.

Which Offers Better Corrosion Protection?

Anodizing provides superior corrosion resistance with its thick aluminum oxide barrier, while Alodine offers moderate protection that’s adequate for most controlled environments. The choice depends on your operating environment and expected service life requirements.

Anodizing creates a dense aluminum oxide layer that acts as a physical barrier against moisture, salt, and chemical exposure. Parts we’ve anodized consistently pass ASTM B117 salt spray testing for 1000+ hours, demonstrating excellent long-term protection in harsh environments. Alodine’s chromate conversion layer provides chemical corrosion resistance through passivation rather than barrier protection – effective for indoor applications but not designed for severe outdoor exposure.

The protection difference becomes critical in demanding applications. Offshore drilling equipment specifies anodizing for aluminum components that face constant saltwater exposure and temperature cycling. Food processing machinery uses anodizing to resist cleaning chemicals and maintain sanitary surfaces. Meanwhile, laboratory instrumentation typically chooses Alodine because the controlled environment doesn’t require maximum barrier protection, and other performance factors like dimensional stability take priority.

Design Takeaway: Choose anodizing for outdoor applications, harsh chemical environments, or when maximum corrosion protection is required. Specify Alodine for controlled indoor environments where moderate protection is sufficient and other factors like conductivity take priority.

What Are the Appearance and Color Options?

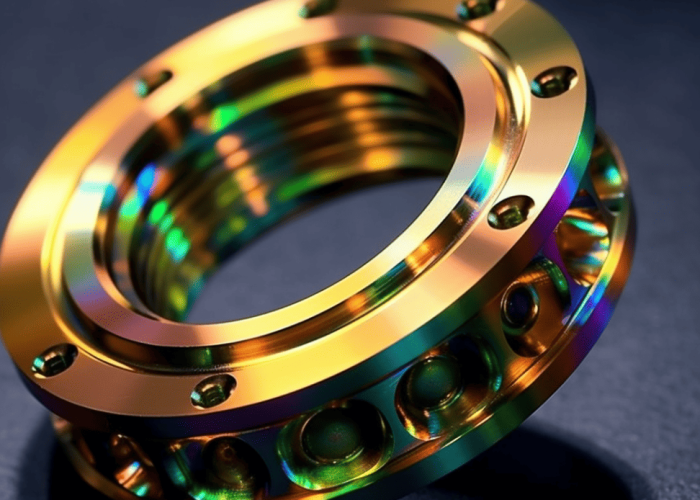

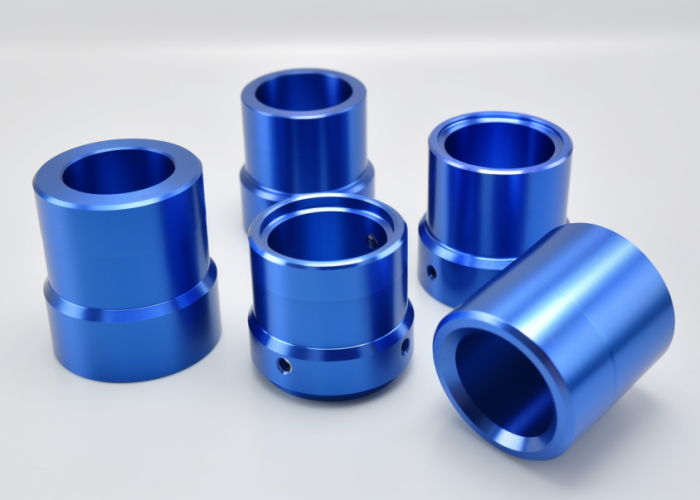

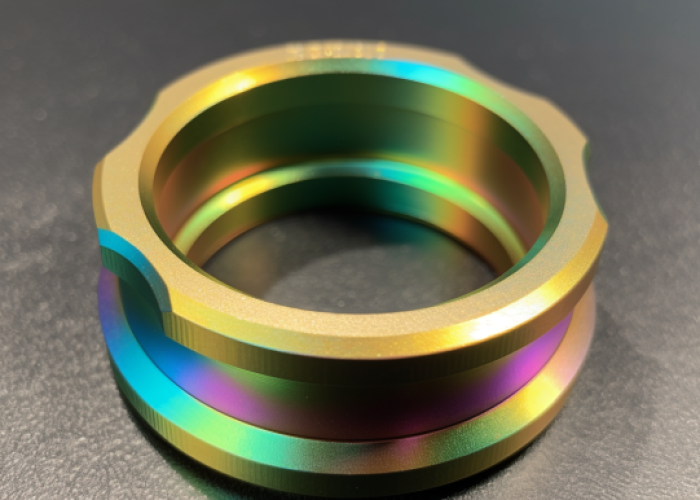

Anodizing offers extensive color options from clear to black with consistent, attractive finishes, while Alodine provides limited clear or gold-brown appearance primarily for functional protection. For parts where aesthetics matter, this difference often drives the coating decision.

Anodizing produces uniform, durable colors through controlled dye absorption in the porous oxide layer. We regularly achieve consistent color matching across production batches using ASTM D2244 color measurement standards, with options including clear, black, red, blue, and custom colors. The resulting finish provides a smooth, professional appearance ideal for visible components. Alodine typically produces a clear to light gold-brown appearance that varies with aluminum alloy composition – 6061 remains nearly clear while 7075 develops more pronounced golden tones.

The aesthetic difference impacts product positioning significantly. Architectural hardware manufacturers choose bronze or black anodizing to match building design requirements while maintaining weather resistance. Test equipment enclosures often specify clear anodizing to achieve a clean, professional appearance without compromising functionality. Research instruments typically use Alodine because technical performance outweighs cosmetic considerations, and the slight color variation doesn’t affect laboratory operations.

Design Takeaway: Select anodizing when consistent color, premium appearance, or specific aesthetic requirements are important to your product. Choose Alodine when function takes priority over appearance and the natural aluminum look is acceptable.

What Are the Cost and Lead Time Differences?

Alodine coating costs significantly less and processes faster due to simpler equipment requirements, while anodizing requires specialized facilities with higher operational costs. For budget-conscious projects and tight deadlines, this economic difference often determines the coating choice.

Alodine treatment uses standard chemical tanks without requiring electrical systems, heating equipment, or complex waste treatment facilities. Most machine shops can add Alodine capability without major capital investment, keeping processing costs low and availability high. Anodizing demands rectifiers capable of handling hundreds of amps, precise temperature control systems, and extensive environmental compliance measures – infrastructure that only dedicated facilities can justify economically.

The cost structure affects different project types distinctively. Government contractors often specify Alodine for cost-effective protection that meets defense requirements without premium anodizing expenses. High-volume consumer electronics manufacturers build anodizing costs into their pricing models because the premium appearance commands higher selling prices in competitive markets. Small-batch custom fabricators typically offer Alodine in-house while outsourcing anodizing to maintain competitive pricing on quick-turn projects.

Design Takeaway: Choose Alodine when minimizing surface treatment costs and lead times is essential for project success. Select anodizing when the performance and aesthetic benefits justify higher processing investments and longer cycles

When Should I Choose Alodine vs Anodizing?

The decision framework starts with your most critical requirement: electrical performance drives you toward Alodine, while maximum durability points toward anodizing. Secondary factors like cost, appearance, and schedule then confirm or modify this initial direction.

Technical requirements typically eliminate one option immediately. Applications requiring grounding paths, EMI shielding, or static dissipation must use Alodine since anodizing breaks electrical continuity. Conversely, marine hardware, outdoor signage, or architectural elements need anodizing’s barrier protection to survive environmental exposure. When both coatings could technically work, the decision shifts to optimizing cost, appearance, and manufacturing constraints.

The selection process becomes clearer with specific application contexts. Medical device manufacturers often choose Alodine for internal components where dimensional precision and conductivity matter more than cosmetic appearance. Aerospace suppliers specify anodizing for structural components requiring both corrosion protection and visual inspection capability per industry standards. Telecommunications equipment manufacturers select Alodine for rack-mounted hardware where EMC compliance requires maintained conductivity between chassis components.

Design Takeaway: Identify your non-negotiable requirement first – this usually determines the coating choice. Use secondary factors like budget and schedule to validate the decision rather than compromise critical performance needs.

Conclusion

Alodine maintains electrical conductivity with minimal dimensional impact, while anodizing provides superior corrosion protection and appearance options. Choose based on your primary requirement – conductivity points to Alodine, maximum durability to anodizing. Contact us to explore manufacturing solutions tailored to your aluminum surface treatment requirements.

Frequently Asked Questions

Alodine provides moderate corrosion protection suitable for controlled indoor environments. For outdoor exposure, marine applications, or harsh chemical environments, anodizing offers significantly better long-term protection.

Minimal impact. Alodine’s thin layer rarely affects thread engagement or press-fit tolerances. Unlike anodizing, you typically don’t need to adjust tap sizes or interference fits when specifying Alodine coating.

Call out “Alodine per MIL-DTL-5541” for chemical conversion coating or “Anodize per MIL-A-8625 Type II” for standard anodizing. Include class specifications and mask critical dimensions that cannot accommodate coating thickness.

Alodine typically costs 50-70% less than anodizing for small batches due to simpler processing and wider supplier availability. The cost gap narrows on high-volume orders where anodizing setup costs are distributed.

Alodine is your only choice for maintaining conductivity. If more corrosion protection is needed, consider design modifications like conformal coatings over Alodine or switching to corrosion-resistant aluminum alloys rather than compromising electrical performance.

Yes. Since Alodine adds only 0.00001-0.0004 inches versus anodizing’s 0.0002-0.003 inches, switching to Alodine typically eliminates dimensional concerns and may allow tighter machining tolerances without redesign.