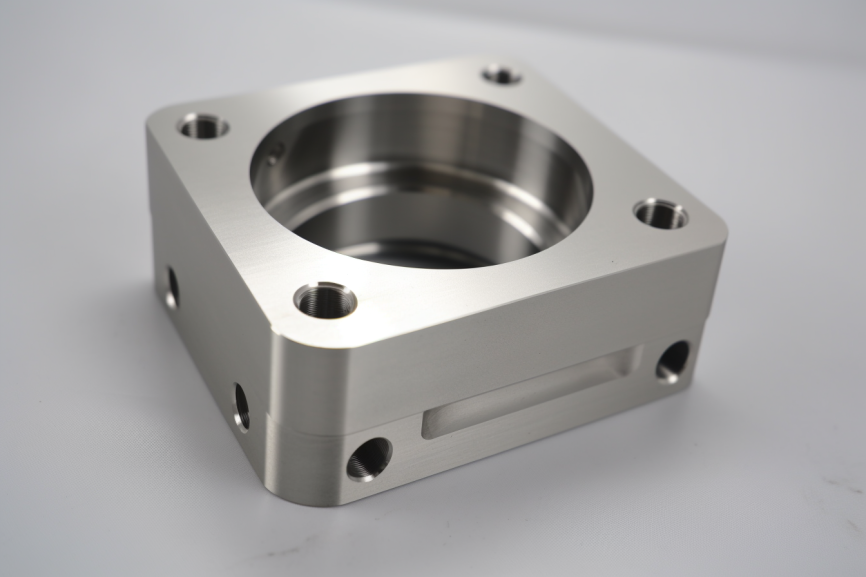

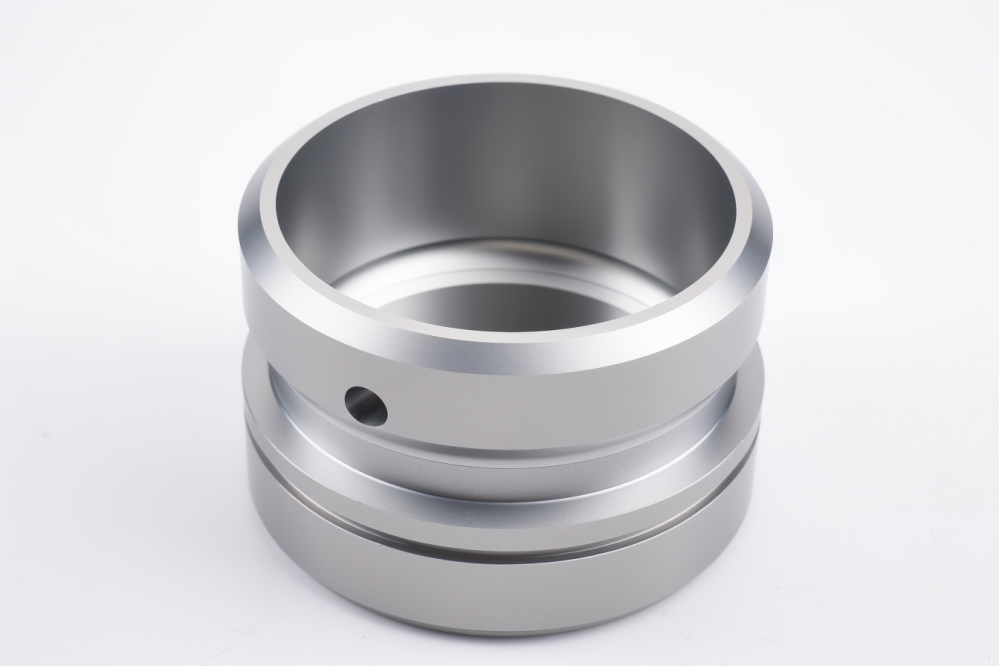

In precision manufacturing, selecting the right metal for CNC machined prototypes can make or break your project’s success. Whether you’re developing aerospace components or medical devices, the metal you choose impacts not just durability, but also cost-effectiveness, machinability, and overall performance.

The five best metals for CNC machined prototypes are aluminum alloys, titanium alloys, stainless steel, carbon steel, and magnesium alloys. Each offers unique advantages: aluminum for versatility, titanium for strength, stainless steel for corrosion resistance, carbon steel for durability, and magnesium for lightweight applications.

Dive deeper with us as we explore each metal’s specific properties, compare their real-world applications, and uncover the critical factors that will help you make an informed decision for your next prototyping project.

Table of Contents

#1 Aluminum Alloys

When balancing performance requirements with practical manufacturing needs, aluminum alloys stand out as a foundational choice for CNC machined prototypes. Their unique combination of machinability, strength, and corrosion resistance makes them invaluable across diverse industries.

Aluminum 6061

Your Reliable First Choice This versatile alloy is widely favored in prototype development due to its comprehensive benefits:

- Exceptional machinability that reduces manufacturing time and tool wear

- Outstanding strength-to-weight ratio, ideal for lightweight yet durable components

- Built-in corrosion resistance without requiring additional treatments

- Well-suited for a broad range of applications from automotive parts to structural components

- Maintains consistent properties across different machining conditions

- Readily available and cost-effective for prototype development

Aluminum 7075

The High-Performance Specialist When your prototype demands superior mechanical properties:

- Significantly higher strength than 6061, making it ideal for critical components

- Particularly valued in aerospace applications where performance is paramount

- Heat-treatment capabilities allow for enhanced hardness and strength

- Excellent fatigue resistance for components under repeated stress

- Superior stress tolerance in high-performance applications

- Maintains dimensional stability under demanding conditions

Aluminum 5083

The Marine Environment Expert Specifically engineered for challenging environments:

- Exceptional resistance to saltwater corrosion

- Superior mechanical properties in marine conditions

- Combines excellent machinability with high strength

- Particularly effective for marine applications and outdoor equipment

- Maintains structural integrity in harsh chemical environments

- Offers excellent weldability for complex prototype assemblies

Selection Considerations

- Environmental Exposure: Consider the operating environment – 5083 excels in corrosive conditions

- Strength Requirements: For high-stress applications, 7075 provides superior mechanical properties

- Manufacturing Complexity: 6061 offers the best machinability for intricate designs

- Performance Needs: Match the alloy’s properties to your prototype’s specific performance requirements

#2 Titanium Alloys

Titanium alloys represent the high-end spectrum of CNC machined prototypes, offering exceptional strength-to-weight ratios and corrosion resistance. While they may require more specialized machining expertise, their outstanding properties make them indispensable for demanding applications.

Ti-6Al4V (Grade 5 Titanium)

The Aerospace and Medical Standard This premium titanium alloy sets the bar for high-performance applications:

- Exceptional strength-to-weight ratio surpassing most metals

- Superior corrosion resistance in aggressive environments

- High temperature tolerance for demanding conditions

- Particularly valued in aerospace, military, and biomedical applications

- Biocompatible properties make it ideal for medical implants

- Maintains strength at elevated temperatures

- More challenging to machine compared to aluminum, requiring specialized expertise

Grade 2 Titanium

The Workhorse Pure Titanium Known as “commercially pure” titanium, Grade 2 offers a balanced profile:

- Excellent balance of strength and ductility

- Widely used in medical and aerospace industries

- Superior corrosion resistance compared to many other metals

- Good weldability for complex assemblies

- More cost-effective than Grade 5 while maintaining key titanium properties

- Components requiring high corrosion resistance

- Ideal for prototypes that prioritize chemical resistance over maximum strength

Selection Considerations

- Machining Requirements: Both grades require specific cutting speeds and tooling

- Cost Implications: Factor in higher material and machining costs compared to aluminum

- Performance Needs: Grade 5 for maximum strength, Grade 2 for better corrosion resistance

- Application Environment: Consider temperature, chemical exposure, and stress requirements

#3 Stainless Steel

Stainless steel alloys stand out in the world of CNC machined prototypes for their exceptional durability and resistance to corrosion. These metals offer a perfect balance of strength, longevity, and versatility, making them crucial for specific industrial applications.

Stainless Steel 304

Stainless Steel 304: The Industry Standard Often referred to as the most common stainless steel grade in machining:

- Outstanding corrosion resistance against most environmental conditions

- Excellent mechanical properties for diverse applications

- Non-magnetic properties make it ideal for electronic components

- Maintains structural integrity across a wide temperature range

- Good machinability despite its hardness

- Widely available and well-understood by machinists

- Perfect for food processing equipment, chemical containers, and medical devices

Duplex Stainless Steel 316/2205

The Heavy-Duty Performer When standard stainless steel isn’t enough:

- Superior corrosion resistance in extreme environments

- Particularly effective in marine and chemical processing applications

- Enhanced resistance to pitting and crevice corrosion

- Higher strength than standard 304 grade

- Excellent for parts exposed to harsh chemicals or saltwater

- Exceptional strength and toughness combination

- 2205 variety offers even higher strength for demanding applications

Selection Considerations

- Environmental Factors: Choose 316/2205 for marine or highly corrosive environments

- Strength Requirements: Consider load-bearing needs and stress exposure

- Cost Efficiency: 304 offers good performance at a lower cost than duplex grades

- Application Specifics: Match the grade to your specific corrosion resistance needs

#4 Carbon Steel

When durability and wear resistance take center stage in prototype development, carbon steel alloys prove their worth. These metals offer exceptional strength and hardness, making them ideal for components that need to withstand significant wear and tear.

Carbon Steel 1045

The Versatile Performer Known for its reliable performance in mechanical applications:

- High strength and good machinability balance

- Ideal for gears, shafts, and mechanical components

- Excellent wear resistance for moving parts

- Cost-effective for high-strength requirements

- Responds well to heat treatment

- Suitable for parts requiring durability

- Maintains dimensional stability under load

D2 Tool Steel

The Wear-Resistant Specialist When exceptional hardness and wear resistance are crucial:

- Superior resistance to wear and abrasion

- Excellent hardness after heat treatment

- Ideal for cutting tools and dies

- High carbon and chromium content for enhanced properties

- Maintains edge retention under heavy use

- Perfect for tooling applications

- Excellent choice for high-stress mechanical components

Selection Considerations

- Wear Requirements: Match the grade to expected wear conditions

- Machining Complexity: Consider that D2 is more challenging to machine than 1045

- Heat Treatment Needs: Both grades respond well to heat treatment for enhanced properties

- Application Demands: Consider load-bearing requirements and wear patterns

#5 Magnesium Alloys

When weight reduction becomes the primary goal in prototyping, magnesium alloys emerge as a compelling solution. These metals offer remarkable weight savings while maintaining respectable strength properties, making them particularly valuable for aerospace and high-performance applications.

Magnesium AZ31

The Weight-Saving Champion This lightweight alloy presents a unique combination of properties:

- Superior strength-to-weight ratio compared to aluminum

- Ideal for weight-critical aerospace components

- Excellent machinability for precise prototyping

- Good balance of strength and formability

- Perfect for components where weight savings are crucial

- Suitable for structural applications

- Cost-effective when weight reduction justifies the investment

Distinctive Advantages:

- Significantly lighter than aluminum while maintaining structural integrity

- Excellent vibration damping characteristics

- Good thermal conductivity

- Suitable for thin-walled components

- Valuable for portable and handheld devices

- High dimensional stability

- Recyclable material for sustainable design

Selection Considerations

- Cost Analysis: Higher material cost offset by weight savings benefits

- Design Requirements: Consider thin wall capabilities and structural needs

- Environmental Factors: Evaluate corrosion protection requirements

- Application Specifics: Balance weight reduction goals with performance needs

Conclusion

Each metal option brings unique advantages to your prototyping journey: aluminum alloys for versatility and cost-effectiveness, titanium for premium strength and biocompatibility, stainless steel for corrosion resistance, carbon steel for durability, and magnesium for lightweight applications. Success in prototype development comes down to carefully evaluating your specific needs – considering factors like mechanical properties, corrosion resistance, machinability, and cost efficiency. By understanding these options, you can make an informed decision that best serves your project requirements.

Frequently Asked Questions

Aluminum 6061 is the easiest to machine, offering excellent machinability with standard cutting tools and faster production times compared to other metals.

Aluminum 6061 is the most cost-effective metal for general prototyping due to its excellent machinability, good strength, and lower material costs compared to other options.

Ti-6Al4V (Grade 5 Titanium) is the best choice for medical device prototypes due to its biocompatibility, high strength, and corrosion resistance properties.

For saltwater exposure, either Aluminum 5083 or Duplex Stainless Steel 316 should be used, with 316 being the superior choice for long-term exposure to marine environments.

Ti-6Al4V (Grade 5 Titanium) offers the highest strength-to-weight ratio among all options, making it ideal for aerospace and high-performance applications.

D2 Tool Steel is the best choice for cutting tool prototypes due to its exceptional hardness, wear resistance, and edge retention properties.