Did you get sticker shock from your black anodizing quote? You’re not alone. While black anodizing might seem expensive at first glance, there’s more to the story than just the price tag. Understanding what drives these costs can help you make smarter finishing decisions – and save some money.

Black anodizing costs typically range from $0.50-$5.00 per square foot, varying based on six key factors: part geometry, processing requirements, volume, customization needs, timeline demands, and long-term durability requirements. Type II (standard) black anodizing averages $0.50-$2.00 per square foot, while Type III (hard) costs $2.00-$5.00 per square foot. Additional factors like complex geometry, special processing, or rush orders can increase these base prices by 25-50%.

Let’s break down six key factors that impact your bottom line – and reveal some industry insights that might help you optimize your spending. Whether you’re dealing with prototype parts or production runs, these insights could save you more than just money.

Table of Contents

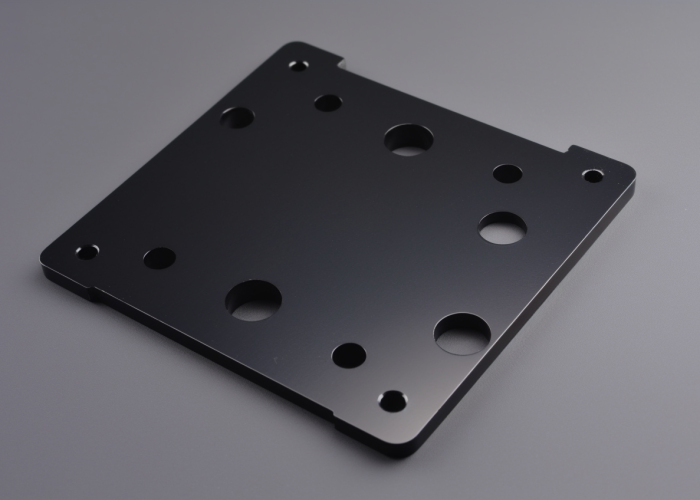

1. Part Geometry Impact

Think complex parts mean complex costs? You’re right. Let’s break down how your part’s design directly impacts your wallet – and what you can do about it.

Cost Impact by Design Features

Feature Cost Impact Why It Matters

Deep Recesses +20-30% Requires special racking

Blind Holes +15-25% Extra processing time

Sharp Corners +10-20% Quality control challenges

Multiple Faces +25-35% Increased handling needs

Your part’s geometry affects more than just machining – it’s a major cost driver in anodizing. Complex shapes require special handling, custom racking solutions, and often more processing time.

Think of it like painting a house – a simple ranch style is straightforward, but a Victorian with lots of trim and hard-to-reach areas? That’s going to cost you.

Here’s what this means for your budget:

- Simple shapes cost less to process

- Minimize deep recesses when possible

- Consider rack point locations

- Design with anodizing in mind

[Key Takeaway]

Want to control anodizing costs? Start with smart design choices. Like planning a road trip, the straightest path isn’t always possible – but knowing the terrain helps you plan better routes.

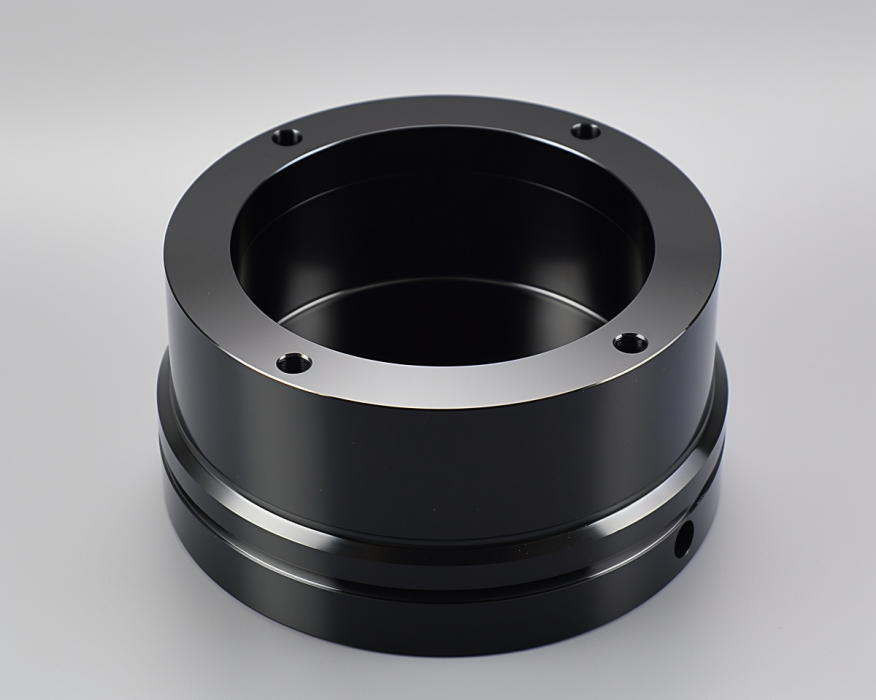

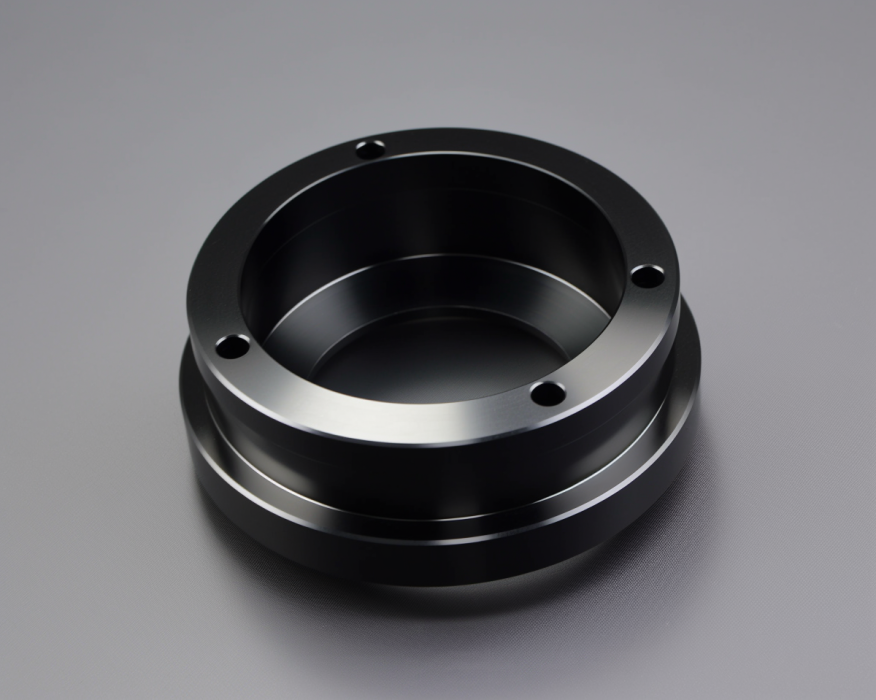

2. Processing Requirements

You might think that all black anodizing processes are the same. However, your specific requirements may change the final cost significantly.

Processing Cost Comparison

Process Type Base Cost/ft² Additional Requirements

Type I (Chromic) $0.75-$2.50 Specialized handling

Type II Standard $0.50-$2.00 Specialized handling

Type III Hard $2.00-$5.00 Enhanced controls

Special Processing +25-50% Custom procedures

Masking +$0.25-$1.00/area Extra labor

Beyond the basic process, each special requirement adds complexity – and cost. It’s like ordering a coffee: basic black is one price, but start adding extras and watch that price climb.

While Type I offers excellent corrosion resistance, it’s often more expensive due to specialized chemical handling and environmental requirements.

Here’s what this means for your budget:

- Type I costs more but offers better corrosion resistance

- Type II provides best value for most applications

- Type III costs more but lasts longer

- Special processing and masking add significant costs

[Key Takeaway]

Understanding process requirements helps you balance cost and performance. Sometimes spending more on the right process saves money in the long run – like buying quality shoes instead of replacing cheap ones every few months.

3. Volume Considerations

It’s common knowledge that buying in bulk usually saves you money, and the same holds true for black anodizing.

Volume Price Breaks

Quantity (pieces) Cost Reduction Setup Impact

1-25 Base price Full setup cost

26-100 -10-15% Setup cost shared

101-500 -20-25% Better efficiency

500+ -30-35% Optimized process

The anodizing world has its version of economies of scale. Think of it like baking cookies – whether you’re making a dozen or a hundred, you still have to preheat the oven. The more cookies you bake at once, the less energy you spend per cookie.

Here’s what this means for your budget:

- Minimum order quantities affect unit cost

- Setup costs get distributed across volume

- Larger batches mean better efficiency

- Regular orders can lock in better rates

[Key Takeaway]

Smart volume planning can significantly reduce your per-piece cost. But remember – like buying in bulk at the grocery store, it only saves money if you need that many parts.

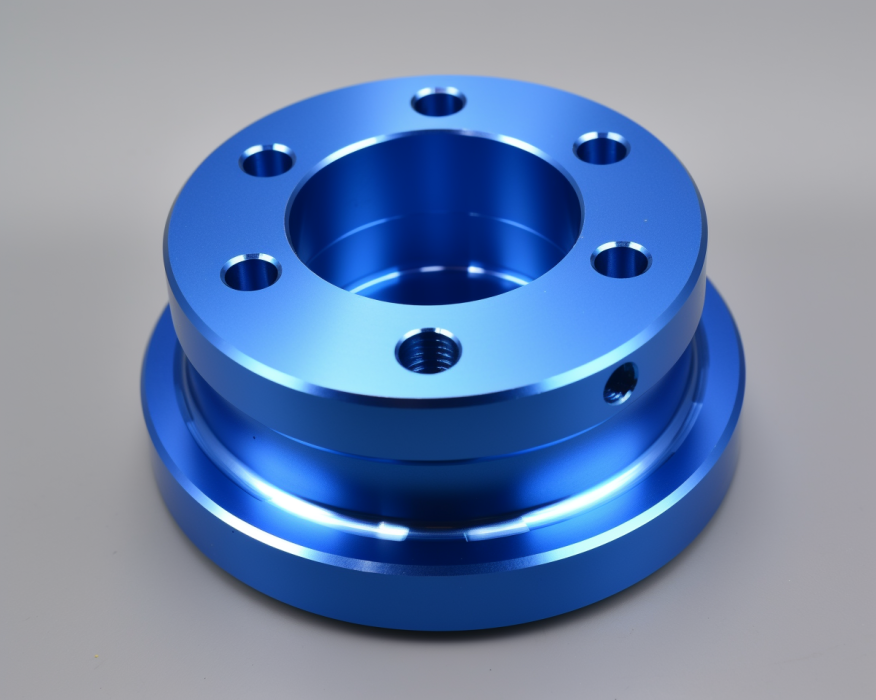

4. Customization Needs

You don’t have to pick black or any other color. Special requirements come with their own price, like ordering a custom suit instead of buying off the rack.

Customization Cost Impact

Finish Type Cost Premium Process Time

Standard Black Base cost Standard

Custom Black Shade +15-25% +1-2 days

Special Finish +25-35% +2-3 days

Multiple Specs +35-50% +3-5 days

Just like a restaurant charging extra for special orders, customization in anodizing adds complexity to the process. Each special requirement means additional steps, more monitoring, and stricter quality control.

Here’s what this means for your budget:

- Standard finishes cost less

- Special colors need extra processing

- Multiple specifications increase complexity

- Custom requirements need more QC

[Key Takeaway]

Need something special? Just remember – every customization adds to your bottom line. Choose custom options where they add real value, not just because they’re available.

5. Timeline Demands

In anodizing, “time is money” can have a different meaning. Rush orders aren’t just more expensive, they can affect quality and may not meet your deadline.

Timeline Cost Impact

Service Level Lead Time Cost Premium

Standard 5-7 days Base price

Priority 3-4 days +25-35%

Rush 1-2 days +50-75%

Same Day <24 hours +100%+

It’s like shipping packages – sure, overnight delivery is possible, but you’ll pay a premium for it. In anodizing, rushing isn’t just about working faster; it means rearranging production schedules and possibly disrupting other jobs.

Here’s what this means for your budget:

- Standard timing offers best value

- Rush orders command premium pricing

- Emergency service costs significantly more

- Planning ahead saves money

[Key Takeaway]

Want to keep costs down? Plan ahead. Like booking airline tickets, the early bird usually gets both the better price and the better service.

6. Long-term Durability Requirements

Numbers don’t lie, but sometimes they don’t tell the whole story. Let’s look at the real value of black anodizing over time – because cheaper isn’t always less expensive in the long run.

Long-term Cost Comparison

Feature Black Anodize Other Finishes

Initial Cost Higher Lower

Lifespan 20+ years 5-10 years

Maintenance Minimal Regular

Replacement Rarely needed More frequent

Think of it like buying a quality tool versus a cheap one. The good one costs more upfront but saves money (and headaches) over time. Black anodizing follows the same principle.

Here’s what this means for your budget:

- Higher upfront cost but longer life

- Reduced maintenance expenses

- Fewer replacements needed

- Better resale value

[Key Takeaway]

Sometimes spending more now saves money later. Black anodizing might cost more upfront, but its durability and low maintenance requirements often make it the more economical choice in the long run.

7. Making Cost-Smart Decisions

Want to get the most value from your anodizing investment? Here’s your practical guide to making budget-wise choices without compromising quality.

Smart Decision Guide

Decision Point Cost Impact Best Practice

Part Geometry -20-30% Design simple, accessible features

Processing Type -15-25% Match process to actual needs

Volume Planning -15-35% Optimize batch sizes

Customization -10-25% Stick to standard when possible

Timeline -25-50% Plan ahead, avoid rush fees

Long-term Value -20-40% Consider lifetime costs

Think of this like building a house – good planning before you start saves way more money than trying to fix things later. Here’s how to make the smartest decisions at each stage.

Here’s what this means for your budget:

- Start with anodizing in mind during the design

- Choose the right process level for your needs

- Combine orders to hit volume breaks

- Avoid unnecessary customization

- Build realistic timelines

- Consider total lifecycle costs

[Key Takeaway]

The best cost savings come from smart planning. Like a good chess player, think several moves ahead – your budget will thank you.

Conclusion

After exploring these crucial cost factors, one thing is clear:

managing anodizing costs isn’t just about finding the lowest price – it’s about making informed choices for your needs. From part design to production planning, understanding these factors helps optimize your investment without compromising quality.

Do you need help making cost-smart decisions for your anodizing project? Our team at okdor specializes in helping clients optimize their surface finishing processes. Let’s discuss your specific needs.

Frequently Asked Questions

Key cost-saving strategies include designing parts with anodizing in mind, ordering in larger volumes (500+ pieces can save 30-35%), avoiding rush orders, minimizing special requirements, and planning ahead to get standard lead times.

With proper care, black anodizing typically lasts 20+ years outdoors and 30+ years indoors. While the initial cost is higher than some alternatives, longer lifespan and minimal maintenance requirements often make it more cost-effective long-term.

Type II ($0.50-$2.00/ft²) is suitable for most decorative and light-duty applications. Type III ($2.00-$5.00/ft²) is recommended for high-wear applications or harsh environments. The choice depends on your specific durability requirements.

Standard processing takes 5-7 days. Rush orders (1-2 days) cost 50-75% more, while same-day service can double the price. Complex geometries, special requirements, and customization also extend lead times.

6061 and 6063 aluminum alloys typically provide the most cost-effective anodizing results with consistent quality. Some alloys like 2000 series or die cast aluminum can require special processing, increasing costs.

Type II (standard) black anodizing costs $0.50-$2.00 per square foot, while Type III (hard) costs $2.00-$5.00 per square foot. Complex geometries, special requirements, or rush orders can add 25-50% to these base prices.