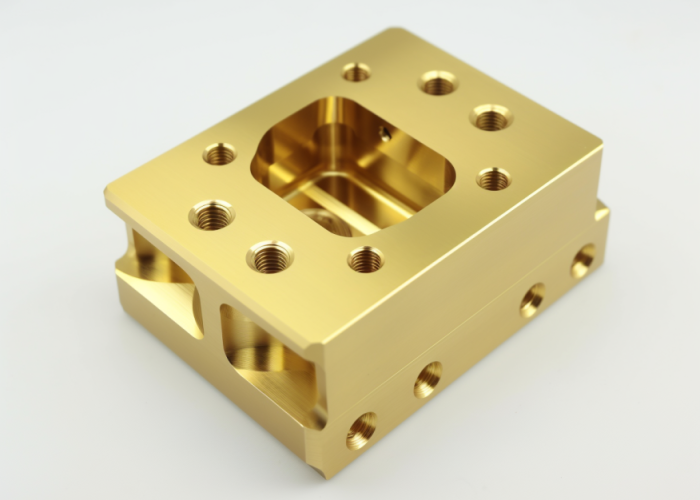

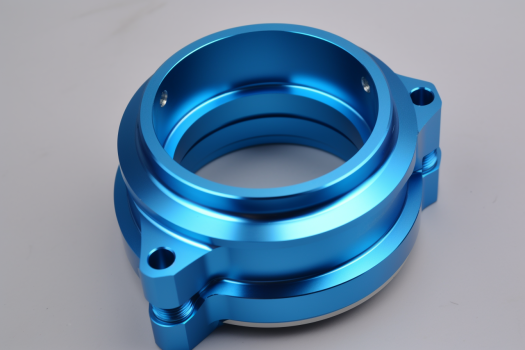

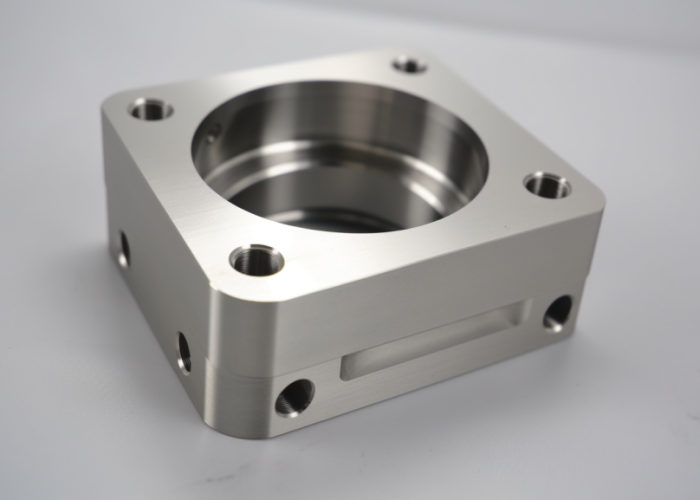

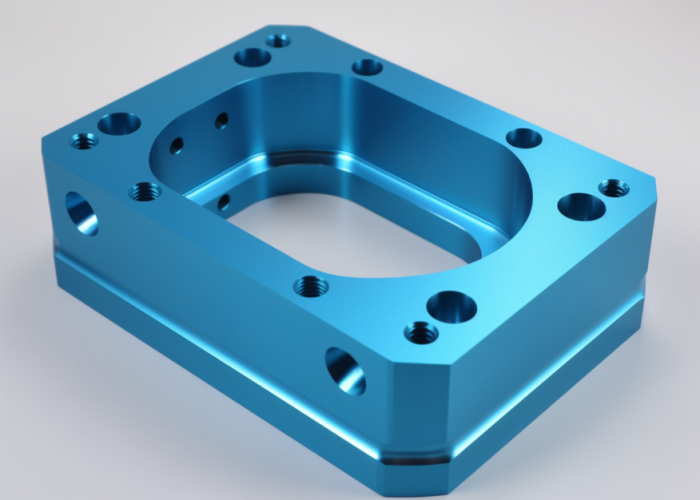

Choosing between blind holes and through holes isn’t just about geometry — it’s about balancing cost, functionality, and manufacturability. After machining thousands of precision parts for aerospace, medical, and audio applications, we’ve seen how this single design decision can impact everything from production cost to assembly complexity.

Use blind holes when you need hidden fasteners, maximum material strength, or sealed cavities. Choose through holes for lower cost, easier assembly access, and simpler inspection. Blind holes typically add 15-30% to machining cost but eliminate the need for plugs or caps in many applications.

We’re writing this guide to help engineers make informed hole design decisions that optimize both performance and manufacturing efficiency.

Table of Contents

When should I use blind holes vs through holes?

A blind hole only goes partway through your material, while a through hole goes completely through from one side to the other. Choose blind holes when you need hidden fasteners, maximum material strength, or sealed surfaces. Use through holes for lower cost, easier assembly, and when you need access from both sides.

Quick Decision Framework:

- Need clean external appearance? → Blind hole

- Using nuts and bolts? → Through hole

- Material under 3mm thick? → Through hole only

- Require sealed surface? → Blind hole

- Cost is primary concern? → Through hole

In precision enclosures, blind holes eliminate visible fastener heads while maintaining structural integrity. Medical device housings use blind holes to prevent contamination pathways, while mounting plates typically use through holes for hardware accessibility. Through holes simplify inspection since you can verify the complete hole geometry from both sides.

For regulated industries like aerospace and medical, blind holes often reduce documentation complexity since there are no exit burr concerns or backside finishing requirements. However, through holes remain standard for high-volume production where assembly speed and cost control are priorities.

Design Takeaway: Start with through holes as your default for cost efficiency, then switch to blind holes only when you specifically need hidden fasteners, sealed surfaces, or maximum material retention in your specific application.

Do blind holes cost more than through holes to machine?

Blind holes typically cost 15-30% more to machine than through holes due to specialized tooling, slower feed rates, and additional cycle time for depth control. For a typical aluminum bracket with 4 holes, expect blind holes to add $8-15 per part compared to through holes.

The cost difference comes from longer cycle times and programming complexity. Blind holes require peck drilling cycles and precise depth control, adding 20-40 seconds per hole depending on depth. Through holes can be drilled continuously at higher speeds with simpler programming. On high-volume runs (1000+ parts), this time difference typically narrows the cost gap to 10-15% as setup efficiencies improve.

However, blind holes can eliminate secondary costs. If your design would require plugs, caps, or backside finishing on through holes, blind holes often break even or save money. Medical enclosures and audio faceplates frequently benefit from this trade-off since cosmetic plugs can cost $5-20 per part.

For regulated industries, blind holes reduce inspection complexity since there are no exit burrs or breakthrough defects to document, potentially saving QA time and costs.

Design Takeaway: Budget 20-30% more machining cost for blind holes, but calculate total cost including any eliminated plugs, caps, or finishing operations that through holes would require.

What's the minimum wall thickness I need around a blind hole?

For common screw sizes, maintain these minimum wall thicknesses: M3 screws need 5mm walls, M4 screws need 6mm walls, M5 screws need 8mm walls. If your walls are thinner than these guidelines, use through holes instead.

Wall thickness directly affects both machining success and thread reliability. Insufficient material around blind holes leads to breakthrough during drilling, thread stripping under load, or part distortion during machining. We’ve seen 3mm walls consistently crack around M4 blind holes, especially in aluminum enclosures.

Material type affects these requirements. Harder materials like stainless steel need roughly 20% more wall thickness than aluminum due to higher cutting forces. Most electronic enclosures and thin-walled housings are only 2-4mm thick, making blind holes impractical for standard fasteners.

Corner locations require extra consideration. Blind holes within 8mm of part edges risk cracking during machining or use, especially in cast materials or plastics with internal stress.

Design Takeaway: Use the minimum wall guidelines above for initial sizing, then add 1-2mm safety margin for critical applications. When walls are too thin for blind holes, through holes are the safer choice.

What's the maximum depth for a blind hole in CNC machining?

The maximum practical depth for blind holes is 3-4 times the hole diameter in aluminum, or 2-3 times diameter in harder materials like stainless steel. Beyond these limits, expect drill breakage, poor surface finish, and 2-3x longer cycle times that significantly increase costs.

Quick depth check: Divide your hole depth by diameter. If the result is over 4 in aluminum or over 3 in steel, redesign is recommended to avoid production problems.

Exceeding depth limits creates expensive complications. Broken drills can add $50-100 in tooling costs per incident, plus machine downtime for tool changes. Deep holes also require slower feeds and multiple peck cycles, doubling or tripling machining time. We’ve seen 20mm deep holes in 4mm diameter take 10x longer than equivalent shallow holes.

When your design requires deeper holes, consider these alternatives: drill from both sides to meet in the middle (creates through-hole access), use larger diameter holes with stepped geometry, or split into multiple shorter holes connected by channels. Electronic enclosures often use this approach for cable routing.

Very deep holes beyond 5x diameter typically aren’t feasible on standard CNC equipment and may require specialized deep-hole drilling services that cost significantly more.

Design Takeaway: Keep blind holes under 3x diameter depth for standard production. If your design shows deeper holes, modify the geometry or switch to alternative solutions before quoting to avoid unexpected costs and delays.

What are standard blind hole sizes for CNC machining?

Stick to standard metric sizes: 2mm, 3mm, 4mm, 5mm, 6mm, 8mm, 10mm, 12mm for holes, and M2, M3, M4, M5, M6, M8, M10, M12 for threads. Custom sizes between these standards add 25% cost and 2-3 weeks lead time due to special tooling requirements.

Design modification strategy: If your CAD shows 6.5mm holes, change to either 6mm or 8mm and adjust surrounding geometry accordingly. Most functional requirements work fine with the nearest standard size – the cost savings usually outweigh minor design compromises.

Custom sizes become expensive quickly because machine shops must order special drill bits, reamers, or taps that may only be used for your project. A 7mm drill bit costs the same as a 6mm, but gets used once versus hundreds of times, making your parts absorb the full tooling cost.

For threaded holes, non-standard pitches (like M6x0.75 instead of standard M6x1.0) can add weeks to delivery since taps aren’t shelf stock. Standard coarse threads provide adequate strength for most applications and ensure reliable sourcing.

Small holes under 2mm become increasingly difficult and expensive, with practical minimum around 1mm diameter for reliable blind hole production in most materials.

Design Takeaway: Choose standard sizes whenever possible and modify your design around them rather than specifying custom dimensions. Reserve non-standard sizes only for critical functional requirements that standard options cannot meet, and budget extra time and cost accordingly.

Do blind holes trap chips and debris during machining?

Yes, blind holes trap chips during machining, but this only matters for certain applications. For structural parts like brackets and housings, residual chips rarely cause problems. For electronics, medical devices, or precision assemblies, specify “debris-free” finishing and budget an extra $5-15 per part for verified cleaning.

Simple decision check: Will metal chips in your holes cause short circuits, contamination, or functional problems? If no, standard machining is fine. If yes, specify cleaning requirements in your drawings.

Most mechanical applications tolerate minor chip residue without issues. Mounting brackets, structural components, and general hardware function normally with small amounts of debris. However, electronic enclosures need clean holes to prevent short circuits, and medical devices require verified cleanliness for regulatory compliance.

Material affects cleanup difficulty. Aluminum chips are easily removed with compressed air. Stainless steel creates stringy chips that may require ultrasonic cleaning or solvent washing. Always specify your cleanliness requirements upfront rather than discovering contamination issues during assembly.

Drawing callouts for clean holes: Note “Remove all chips and debris” or reference cleanliness standards like “MIL-STD-1246 Level A” for critical applications. This ensures your supplier includes proper cleaning in their quote rather than treating it as an unexpected extra.

Design Takeaway: For non-critical structural parts, don’t worry about chip residue. For electronics, medical, or precision applications, specify cleaning requirements early and budget accordingly to avoid surprise costs.

Do blind holes cause assembly problems in manufactured parts?

Blind holes can limit tool access and fastener options, but these challenges are manageable with proper design planning. Provide at least 15mm clearance around holes for standard tools, consider captive or thumb screws for easy assembly, and evaluate whether single-sided access benefits outweigh the constraints.

Key design decisions: Can your assembly team access the holes with standard tools? Do you need frequent disassembly? If tool access is severely limited or you need regular maintenance access, through holes may be more practical despite aesthetic compromises.

Tool clearance represents the biggest challenge. Socket wrenches and hex keys need adequate space around holes, especially in deep pockets. Design enclosures with sufficient clearance or plan for specialized bent tools that add assembly cost. Consumer electronics often use captive screws or quarter-turn fasteners to eliminate tool requirements entirely.

Fastener limitations also matter. Blind holes restrict you to screws only – no nuts, bolts, or washers. This may require larger screw diameters or higher-grade materials to achieve equivalent holding strength. Thread-locking compounds become essential since disassembly is more difficult.

However, blind holes excel in single-sided assembly operations and clean aesthetic applications. Audio equipment and medical devices benefit from invisible fasteners and simplified assembly sequences without coordinating front/back operations.

Design Takeaway: Plan assembly sequence early and design adequate tool clearance around blind holes. If your product requires frequent disassembly or maximum joint strength, through holes with appropriate hardware often provide better long-term functionality.

Conclusion

Choose blind holes for hidden fasteners and maximum strength, or through holes for lower cost and easier assembly. Most decisions come down to balancing aesthetics versus manufacturing efficiency. When specification challenges arise, consider through holes with plugs as a cost-effective alternative. Contact us to explore manufacturing solutions tailored to your hole design requirements.

Frequently Asked Questions

Yes, but keep thread depth under 1.5x the screw diameter and ensure adequate wall thickness around the hole. M4 threads need minimum 6mm wall thickness to prevent breakthrough. Use cutting fluids and proper tap drill sizes to reduce breakage risk. Tapping blind holes costs 10-15% more due to slower feeds and careful depth control.

Check three key ratios: depth should be under 3x diameter, wall thickness should exceed 1.5x diameter, and thread engagement should be at least 1x screw diameter. If any ratio exceeds these limits, consider design modifications or switch to through holes. Most CAD software can validate these automatically.

Blind holes eliminate visible fasteners but cost 15-30% more to machine. For cost-sensitive projects, through holes with decorative plugs or caps often provide similar aesthetics at lower total cost. Evaluate both options during design – the break-even point is typically around $10-15 in plug costs per part.

Blind holes typically provide 40-60% more material retention around the fastener, significantly improving local strength and pull-out resistance. This makes them ideal for high-stress applications like brackets and structural mounts. Through holes work fine for moderate loads but may require larger fasteners or reinforcement plates for equivalent strength.

For most CNC machined parts, ±0.05 mm is achievable with standard tooling and processes. Going tighter than ±0.01 mm often requires specialized fixturing or climate-controlled environments, which increases cost significantly. We recommend tolerancing only critical features tightly and keeping others at ISO 2768-m levels for cost efficiency.

Usually yes, since through holes require the same or less material thickness. However, you’ll need to address the newly exposed back side with finishing, plugs, or design modifications. Converting through holes to blind holes is much more difficult and often requires complete part redesign.