8 Reasons Why Is Brass Perfect for Precision Parts?

In precision manufacturing, material choice can make or break your project’s success. From my experience overseeing thousands of precision part productions, brass stands out with

In precision manufacturing, material choice can make or break your project’s success. From my experience overseeing thousands of precision part productions, brass stands out with

Think anodizing is just dipping aluminum in a tank and running some electricity through it? If only it were that simple. Even experienced manufacturers can

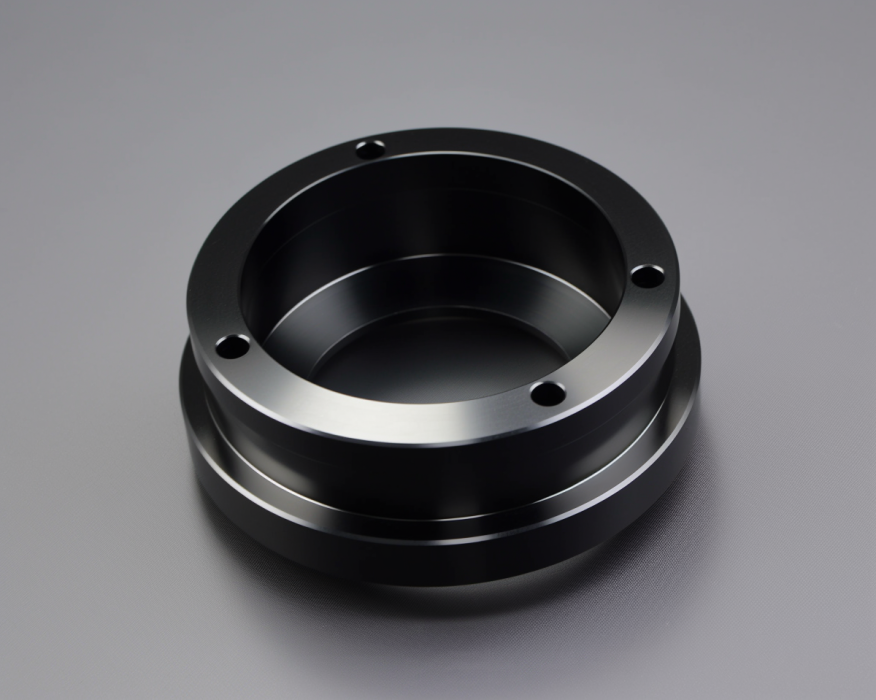

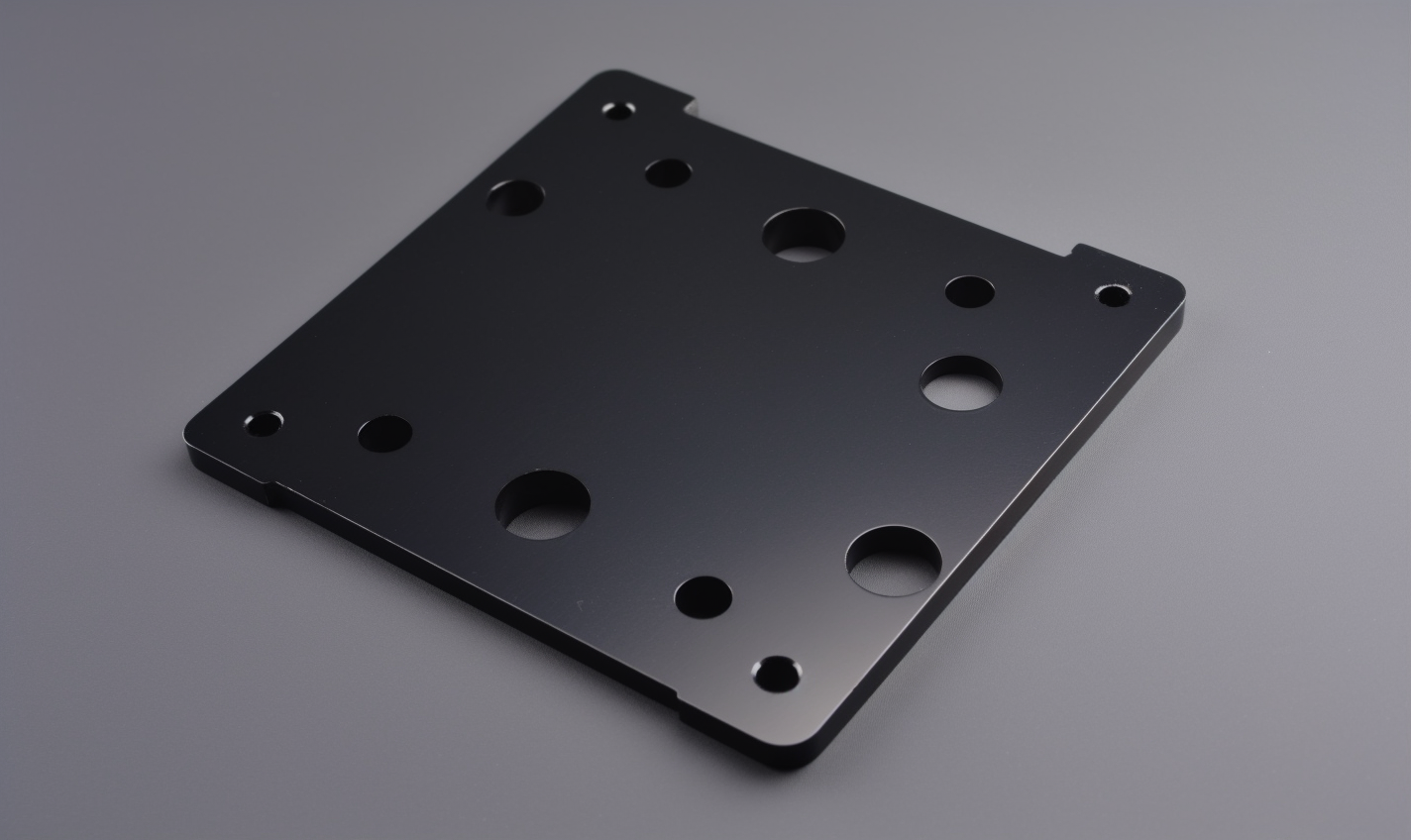

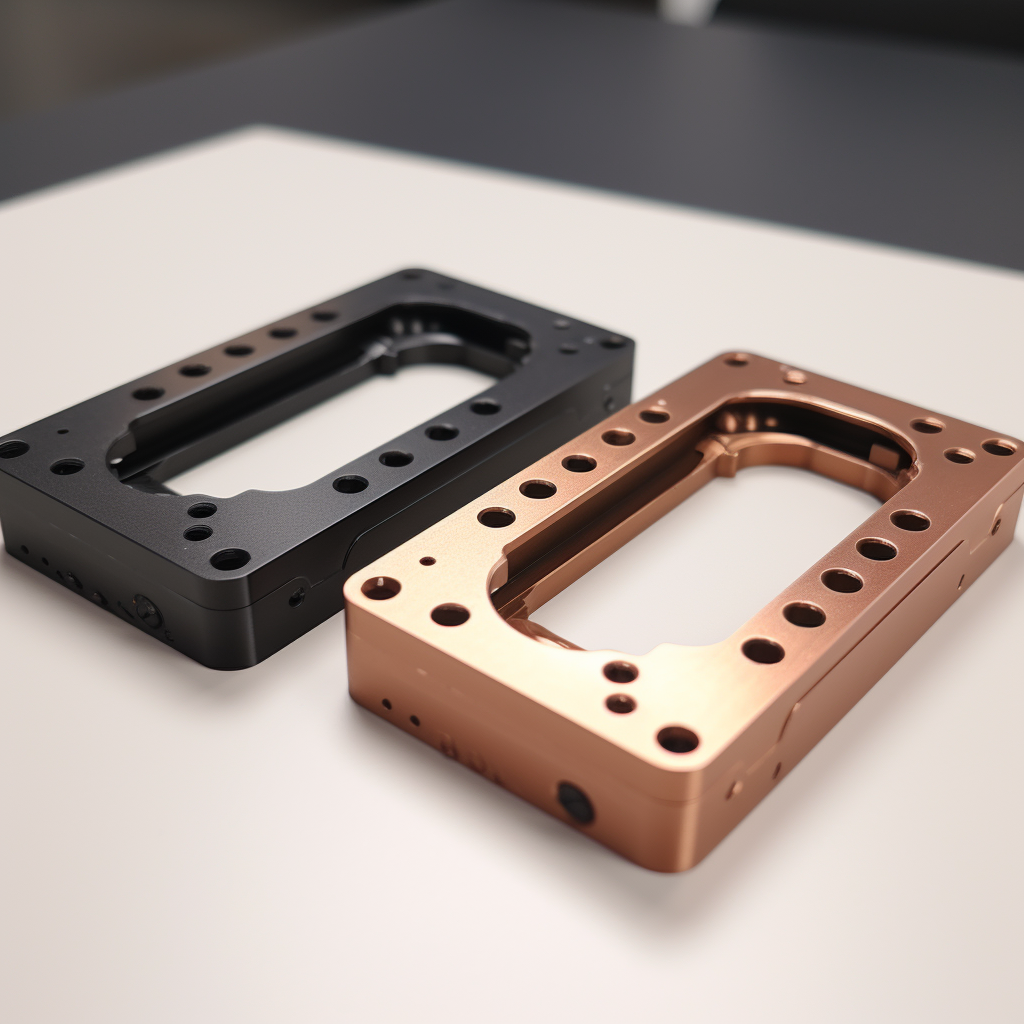

Engineers designing precision aluminum components often ask us: Will black anodizing affect my ±0.01 mm tolerances? Which alloy ensures consistent color? How do I prevent

Did you get sticker shock from your black anodizing quote? You’re not alone. While black anodizing might seem expensive at first glance, there’s more to

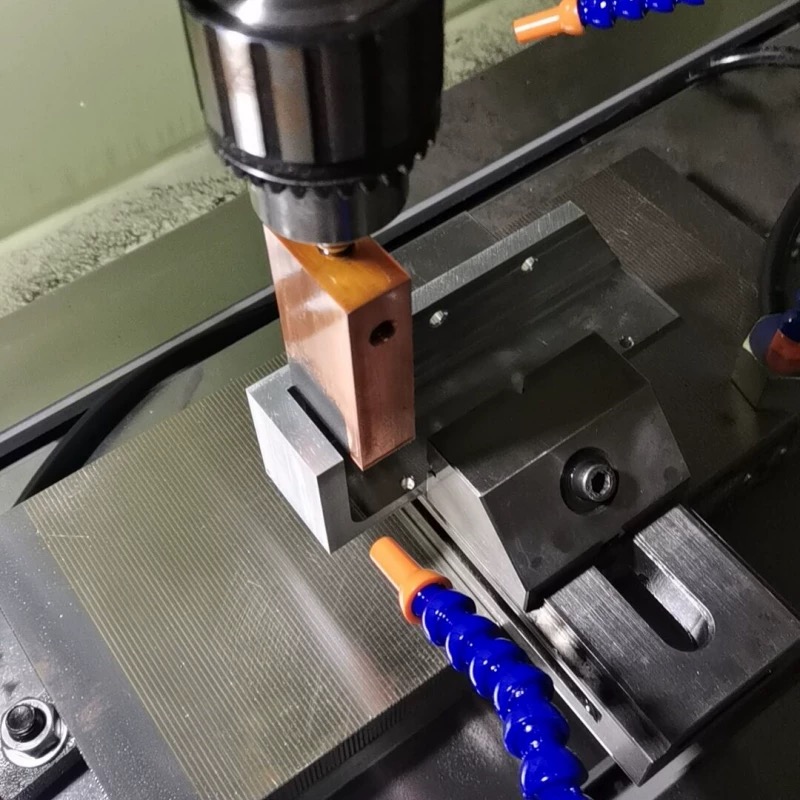

Exotic alloys offer superior performance, but Wire EDM compatibility isn’t guaranteed. With experience cutting Inconel aerospace brackets and titanium medical housings, material selection often determines

As a precision CNC machining service provider, we regularly help engineers and product developers navigate one critical decision: when does anodizing transform aluminum parts from

Designing complex parts often means facing a choice: compromise your geometry for CNC machining limitations, or explore alternatives that can deliver the precision and features

Everyone in manufacturing loves to brag about their cutting-edge technology (pun intended). After years in the manufacturing game, we’ve discovered there’s a lot more to

Manufacturing precision parts often means facing seemingly impossible challenges in material hardness, accuracy, and complexity. Whenever conventional machining methods do not meet manufacturers’ needs, they

Choosing the right EDM process isn’t just about what’s technically possible—it’s about matching your design requirements to the most cost-effective manufacturing approach. With extensive experience

The complete guide to custom manufacturing

Everything about custom manufacturing.

Collection of materials properties

Helpful tips and Advice

In a fast, efficient, and cost-effective manner, we provide services to product developers and engineers worldwide who are bringing new ideas to market.

why choose us

Order flow, from quote to deliver

How do we quote and deliver parts so fast

How we deliver consistent quality

Our team works with hundreds of specialized manufacturers so you don’t have to. Quality is guaranteed even on the most complex prototypes and parts.