What To Consider When Choosing Black Oxide?

Choosing black oxide for machined steel parts requires balancing appearance, dimensional precision, and actual protection needs. From our experience finishing components across industrial and precision applications, the decision often comes down to specific performance requirements versus cost. Consider black oxide when you need minimal thickness buildup (0.0001-0.0003″), dark appearance, and can accept limited corrosion protection. […]

Bead Blasting vs. Sandblasting: Which Finish Is Right for Your Precision Parts?

Choosing between bead blasting and sandblasting can determine whether your precision parts meet spec or get scrapped. The wrong surface finish can blow out tolerances, damage thin walls, or ruin coating adhesion—making this decision critical for part quality and project budgets. For most precision parts, bead blasting is the safer choice because it preserves tight […]

5 Reasons Black Oxide Wears Off and Prevention Tips

Black oxide coatings are crucial for protecting metal parts, but they can wear off under certain conditions. Understanding why this happens is essential for engineers and product developers who rely on this surface treatment. Let’s explore the five main reasons for black oxide wear and how to prevent them. Black oxide coatings wear off primarily […]

5 Surface Treatments More Durable Than Black Oxide

When durability matters in metal manufacturing, black oxide often falls short despite its popularity. While it provides basic corrosion resistance, modern engineering demands more robust solutions. From aerospace components to outdoor machinery, these five surface treatments offer significantly better protection and longevity than traditional black oxide processes. Black oxide provides moderate protection but wears quickly, […]

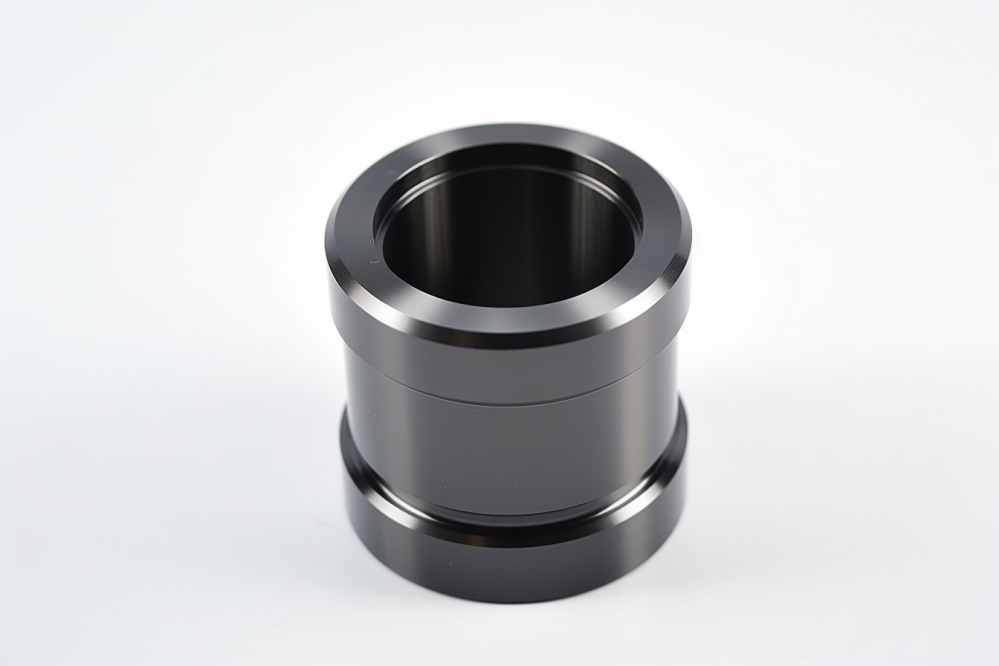

What Is The Surface Hardness of Type 3 Anodizing?

When it comes to protecting aluminum surfaces, Type III anodizing stands out as a powerhouse in the metal finishing industry. This hard-coat anodizing process creates a surface that rivals the hardness of case-hardened steel, making it a crucial treatment for demanding industrial applications. Type III anodizing significantly enhances the hardness of aluminum surfaces, achieving a […]

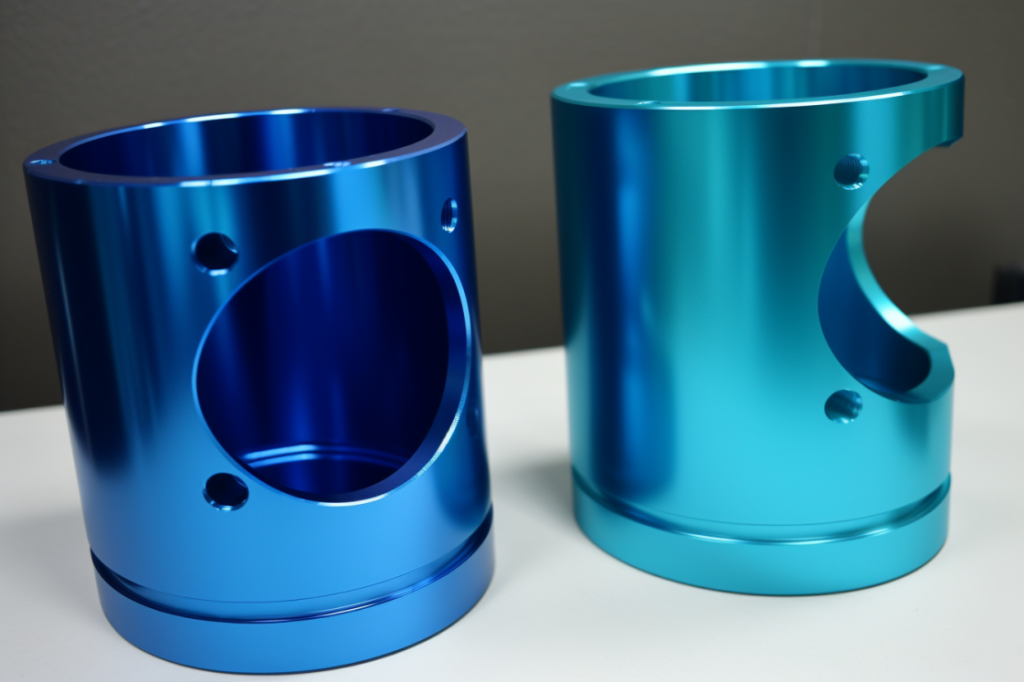

When Is Type III Anodizing the Right Choice?

Choosing between Type II and Type III anodizing isn’t just about thicker coatings — it’s about understanding when that extra thickness justifies the higher cost and dimensional impact. With experience manufacturing parts across aerospace, medical, and industrial applications, the wrong anodizing choice can mean premature failure or unnecessary expense. Type III anodizing is the right […]

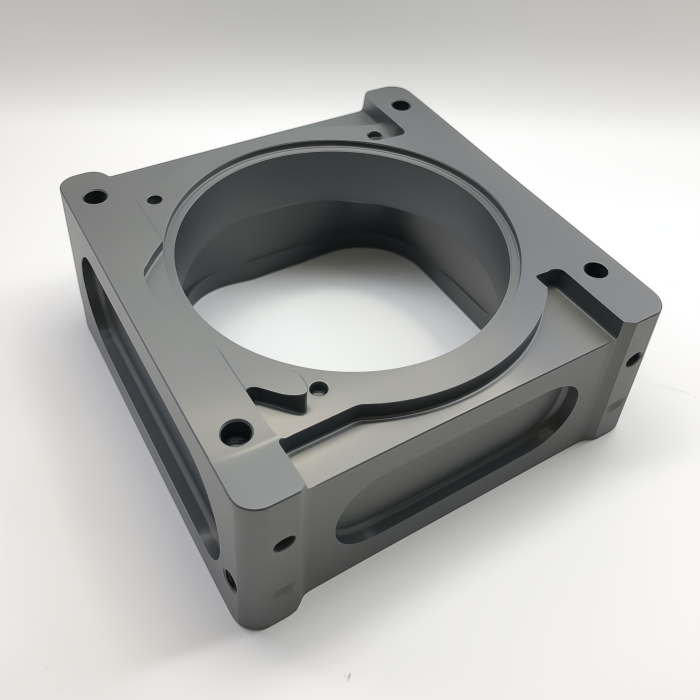

5 Key Facts About Material Compatibility for Type III Anodizing

Type III anodizing, also known as hard coat anodizing, is a specialized process that transforms the properties of aluminum and its alloys. For engineers and product developers, understanding material compatibility is crucial for achieving optimal performance and durability in their applications. Material compatibility for Type III anodizing primarily depends on five key factors: base material […]

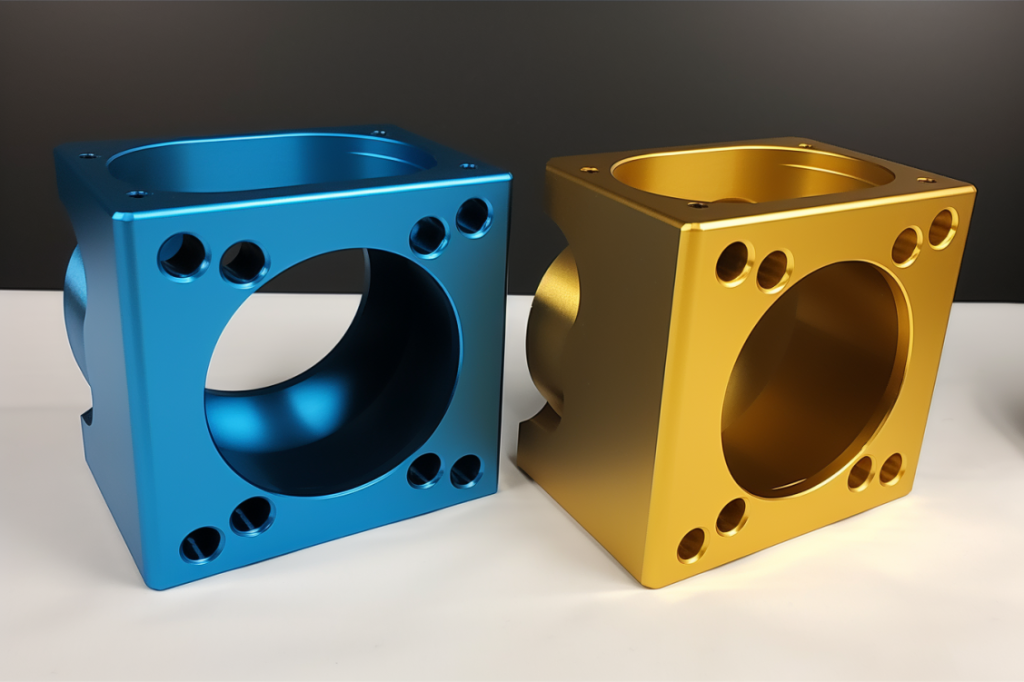

5 Factors That Make Type III Anodizing Ideal for Precision Parts

Precision CNC machining demands more than just tight tolerances — it requires surface finishes that can withstand demanding environments without compromising dimensional accuracy. At Okdor, we regularly consult with engineers who need parts that perform reliably in aerospace, medical, and industrial applications where standard finishes simply aren’t enough. Type III anodizing delivers exceptional hardness comparable […]

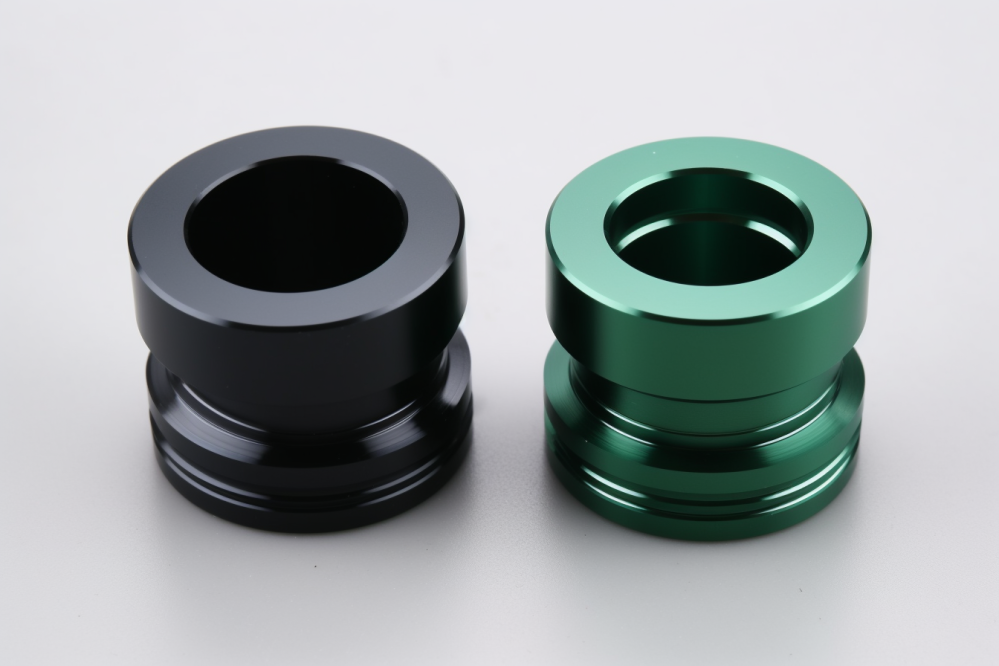

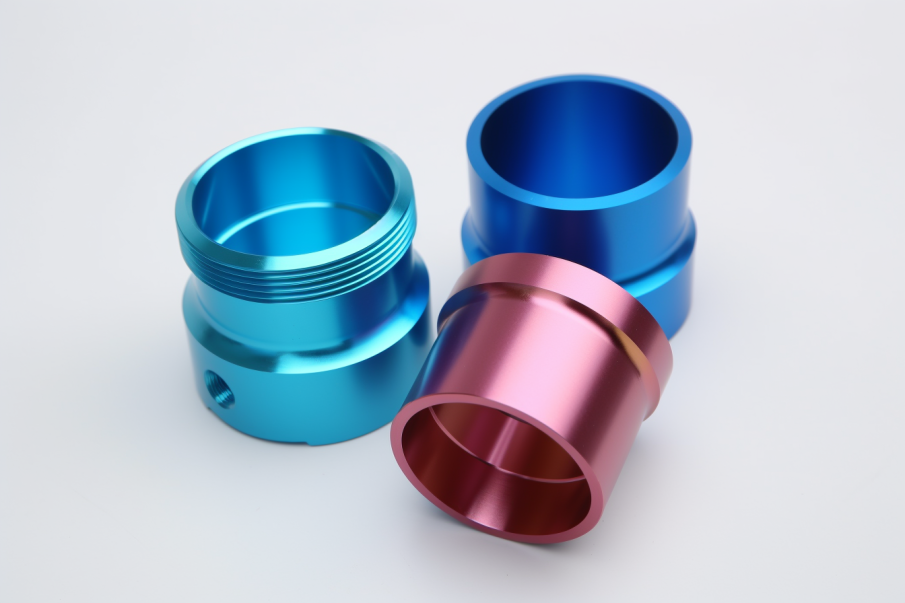

7 Design Choices to Reduce Anodizing Costs

Anodizing decisions made during the design phase can cut finishing costs by 40-60% without sacrificing corrosion resistance or appearance quality. With decades of experience processing precision aluminum parts for aerospace, medical, and audio applications, small design modifications consistently reduce both labor time and per-part expenses while maintaining tight tolerances. Choose 6061 over 7075 aluminum, simplify […]

7 Ways Anodizing Costs Affect Your Budget

Anodizing aluminum parts seems straightforward until you see the quote—then cost factors you never considered start affecting your budget. A few specification decisions made during design can double or triple your finishing costs without improving functionality. Anodizing costs impact budgets through seven key decisions: process type selection, part geometry, tolerance requirements, color choices, quality levels, […]