A quote that’s half the price often means half the review. Many shops send fast numbers without reading your drawing or checking tolerances — they’re guessing, not quoting.

The real reason for cheap quotes? They skip setup, inspection, or finish prep that quality shops include. That “great deal” usually becomes rework, delay, or rejection.

Read on to see what those missing line items really mean, how to verify if a shop’s capable, and when paying more actually protects your schedule.

Table of Contents

Did They Actually Read My Drawing—or Just Guess?

Most “instant” low quotes come from shops that never reviewed your drawing at all. Many small CNC job shops price only by size and material, skipping tolerance and feature checks. That’s how $800 quotes appear next to $1,200 ones — they’re not quoting the same job.

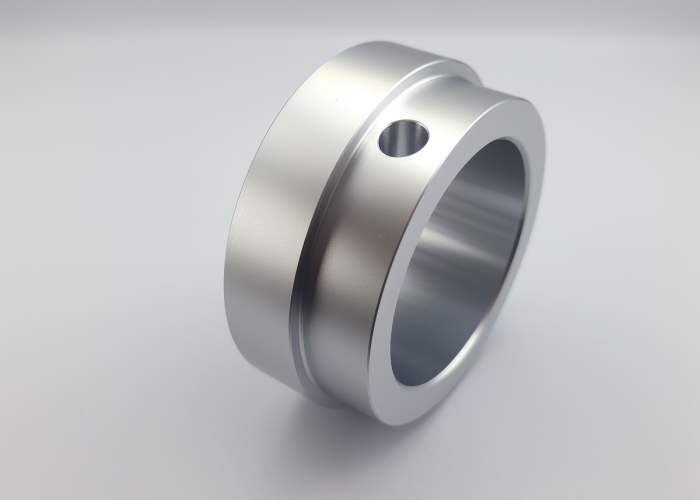

A shop may assume ±0.1 mm general tolerance when your drawing calls for ±0.02 mm. That difference can mean one quick setup versus precision fixturing and CMM inspection — easily 40 % of total cost. Ignoring that step makes their quote cheaper but also makes out-of-spec parts far more likely.

We review every drawing line by line before quoting. Our estimators check tolerances, finishes, and threads against real machine capabilities and flag risks before sending a price. This prevents the “price first, questions later” trap that causes weeks of rework.

Each drawing is validated to ISO 2768 with inspection and setup confirmed before quoting. That’s how we keep quotes accurate and production on schedule.

Supplier Checkpoint: If a quote arrived suspiciously fast, ask what tolerances or inspection steps were assumed. Upload your drawing — we’ll verify those assumptions and return a confirmed quote within 24 hours.

Are They Holding My Tolerances—or Just Ignoring Them?

A low quote often hides a quiet assumption: the shop doesn’t plan to hold your specified tolerances. Many quote based on what they usually hold, not what’s on your print.

For example, a shop might price your ±0.02 mm bore as if it were ±0.1 mm. That saves them fixture time and inspection cost — until the part fails fit testing or needs rework. The “savings” quickly disappear when 30 % of the batch ends up scrapped.

We quote only what we can actually hold. Our team routinely achieves ±0.01 mm on precision fits using calibrated CMMs and temperature-controlled inspection. The cost reflects full compliance with your tolerance stack-up, not a “best effort” guess.

Every order includes traceable inspection reports and measurement photos before shipment — proof that the tolerances you paid for were met.

Supplier Checkpoint: When a quote looks unusually low, confirm which tolerances they priced for. If they can’t specify, the quote isn’t a savings — it’s a future failure.

What’s Actually Different Between an $800 and a $1,200 CNC Quote?

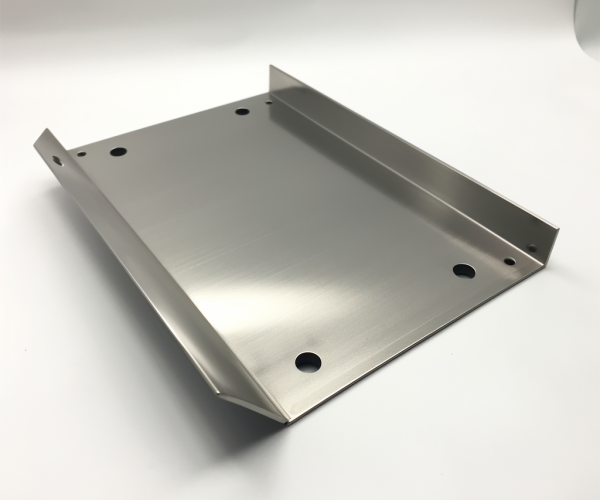

When quotes vary this much, they’re not pricing the same job. The lower number usually cuts setup hours, finish prep, or inspection detail to appear competitive. The higher one often reflects the full work required to meet your print — and to deliver parts that actually assemble.

A shop quoting $800 may assume one-side machining and hand-held gauging; a $1,200 quote might include two setups, verified bore alignment, and bead-blast prep. That “extra” $400 buys control, consistency, and a week saved on post-rework.

We price the entire process, not the ideal scenario. Our estimates cover setup, machining, finishing, and inspection matched to tolerance class — whether that’s plug-gauging for ±0.05 mm or optical verification for tighter features. That’s how we prevent scope creep and mid-project revisions.

Each quote breaks down labor hours and operations so you can compare real scope, not just totals.

Supplier Checkpoint: When two quotes differ sharply, ask what’s included in each stage. If a shop can’t specify setups, finish steps, or inspection tools, the lower price isn’t efficiency — it’s omission waiting to surface after week one.

Get a Verified Quote Before Production Stalls

Upload your drawing for a full tolerance and process check — response within 24 hours.

What’s Missing From This Quote — Setup, Finishing, or Inspection?

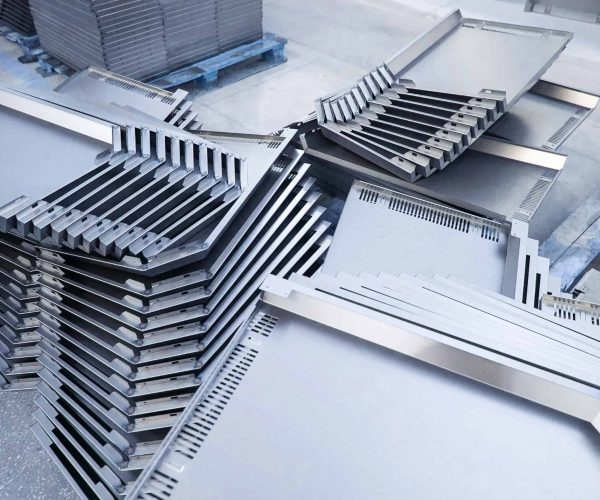

Low quotes often hide what’s left out. Skipped setup or finishing turns a quick win into a two-week delay. Suppliers frequently exclude deburring, bead-blast prep, or final verification so the first price looks lean — then add charges once parts fail review.

That “TBD” line means you’ll absorb the risk. When setup or finish isn’t costed, you’re likely to see chatter on visible faces or tolerance drift that forces rework. A one-day review before quoting is always cheaper than a week of correction later.

We quote every required stage up front. Setup labor, machining, surface finishing, and final inspection are bundled into one verified price. Depending on tolerance, inspection may use bore gauges, height gauges, or optical comparators — escalating only when geometry demands it. That balance keeps prices honest without over-engineering the cost.

Every quote itemizes critical operations with aligned lead-time ranges so there’s no room for mid-build surprises.

Supplier Checkpoint: Before approving any quote, verify who’s handling setup, finishing, and inspection. If those rows are blank, expect new costs mid-production — and likely another missed delivery.

How Can You Tell If a Shop’s Actually Equipped for Your Part?

A cheap quote can mean they’re quoting optimism, not capability. Some shops price complex parts assuming they’ll outsource high-precision cuts or borrow fixtures later. That gamble always costs the buyer time.

Watch for vague replies about machine size limits, hole depth, or tolerance control. Shops lacking rigid spindles, stable fixtures, or precision gauges often quote fast, hoping your tolerances “run fine.” When that guess fails, your lead time collapses.

We quote only from proven setups. Each part is matched to verified equipment and inspection suited to its tolerance range — from in-process probing for tight fits to manual gauging for standard dimensions. Tooling and fixtures are confirmed before pricing, so feasibility is built in, not assumed.

That readiness eliminates subcontract delays and keeps timelines predictable.

Supplier Checkpoint: Before choosing the cheapest option, ask which machines, fixtures, and measurement tools will be used. If the answer sounds uncertain, the shop’s quoting hope — and you’ll pay for it in weeks, not dollars.

How Does a “Great Deal” Turn Into an 8-Week Nightmare?

A bargain quote often buys you a delay, not a discount. The initial price looks great—until the supplier calls mid-production to say “we didn’t expect this much setup time.” What follows is re-programming, missed deadlines, and a scramble for updates.

Low-margin shops rely on quick turnarounds to survive. When an underestimated job overruns setup or tool life, they push it behind higher-profit orders. The part that was “two weeks” becomes eight while they balance the backlog. The cost difference disappears in expedited shipping and emergency rework.

We build lead-time accuracy into the quote itself. Each project is timed using real machine capacity and operator availability—not assumptions. We confirm fixture readiness, tool wear allowance, and finishing queue before committing to a delivery window. If the job risks delay, you’ll know before approval, not after week three.

Progress is tracked daily so potential slips are visible within hours, not days.

Supplier Checkpoint: Before approving any “fast & cheap” quote, ask how the shop calculated its lead time and what happens if setup takes longer. If they can’t show a workload schedule, the timeline is wishful thinking—and you’ll be the one explaining the delay to your team.

What Quote Red Flags Predict Out-of-Spec Parts?

Some quotes tell you failure is coming—you just have to know where to look. The most dangerous red flags aren’t the numbers but the omissions: no tolerance references, no inspection plan, and “TBD” on finish.

A quote without dimensional accountability often means the shop intends to machine “by feel.” When they don’t specify inspection tools or sample frequency, the first full batch becomes the inspection trial. That’s how tolerance drift or mismatched fits appear after hundreds of parts.

We prevent that by defining quality before cutting material. Every quote includes the inspection frequency, tool type, and sampling plan aligned to tolerance class. Whether that’s micrometer checks every batch or full dimensional reports for precision fits, quality is structured, not guessed.

Our internal rule: if we can’t measure it, we don’t quote it. That principle protects both schedule and trust.

Supplier Checkpoint: Scan any quote for red flags—no inspection notes, vague tolerances, or incomplete finish detail. If those blanks exist, expect deviation reports later. A transparent quote today saves you from rejected parts tomorrow.

What Questions Should You Ask Before Accepting the Lowest Quote?

The cheapest quote isn’t the real decision—it’s a test of what you’re willing to risk. Before saying yes, confirm whether the low-cost supplier actually read, planned, and equipped for your part.

Ask five questions that expose hidden gaps:

- What tolerance and surface finish did you price for?

- What machine and fixture will you use?

- Is inspection in-house or outsourced?

- What’s included in setup and finishing?

- What happens if the part doesn’t pass first article?

Shops confident in their process answer these easily; those guessing around the details will stall.

We welcome those questions before every order. Our quoting notes specify tolerance assumptions, inspection scope, and delivery schedule so you can validate capability line by line. That openness prevents costly surprises later.

Supplier Checkpoint: Never accept a low quote without proof of how it’ll be achieved. The right questions reveal who’s quoting from readiness—and who’s quoting from hope.

When Should You Pay More for the Supplier Who’ll Actually Deliver?

Paying more once is cheaper than paying twice for failure. The lowest quote feels smart until production stalls or parts fail inspection. At that point, the real cost isn’t the quote—it’s the lost time, missed shipment, and damage to your credibility with your own customer.

Low-margin shops survive by chasing fast wins. When a job overruns setup time or tooling costs, they move it behind higher-profit work. A “two-week” promise turns into an eight-week headache while your schedule burns. That short-term saving can erase ten times its value in missed delivery penalties or idle assembly lines.

We quote for delivery certainty, not illusion. Every price we give already includes setup validation, inspection suited to tolerance, and confirmed machine availability before commitment. That’s how we prevent those “we’re still running it” calls and keep programs moving without delay.

Projects that look 20 % cheaper often run 40 % longer. One verified quote that delivers on time always beats two cheap ones that collapse mid-build.

Supplier Checkpoint: If your deadlines drive your success, choose the supplier who proves readiness before taking the order. Pay once for reliability—not twice for recovery. Upload your drawing for a verified price and lead-time confirmation within 24 hours.

Conclusion

Most low quotes hide skipped steps that lead to rework, delays, or failed inspections. Okdor solves these sourcing risks by quoting complete, verified processes and delivering on the timelines others miss. Upload your rejected or uncertain drawings today—get a full manufacturability review and accurate quote within 24 hours.

Frequently Asked Questions

Standard parts usually start within 2–3 days after quote approval. For urgent projects, we allocate available machine capacity immediately upon purchase order confirmation and provide milestone updates every 48 hours.

We accept STEP, STP, IGES, DWG, and PDF drawings. Files can include dimensional callouts, surface finish, or tolerance notes. Uploading both 3D and 2D versions ensures accurate cost and lead-time estimation.

Yes. For precision or production-critical parts, we can provide a full First Article Inspection (FAI) report or dimensional summary before bulk machining. This helps confirm part accuracy before committing to full-batch production.

Yes. We can review incomplete drawings and highlight missing dimensions or tolerances that might trigger supplier rejections. You’ll receive manufacturability feedback within 24 hours, so your team can finalize prints confidently before sending full RFQs.

We can review the competing quote line by line to identify what’s missing — setup, finishing, or inspection steps. If both quotes cover identical scope and standards, we’ll match or explain the cost difference transparently.

We can assess partial progress and complete the remaining machining or finishing steps. Send your latest parts and drawings — we’ll evaluate remaining work, verify tolerances, and issue a revised quote and delivery timeline within 48 hours.