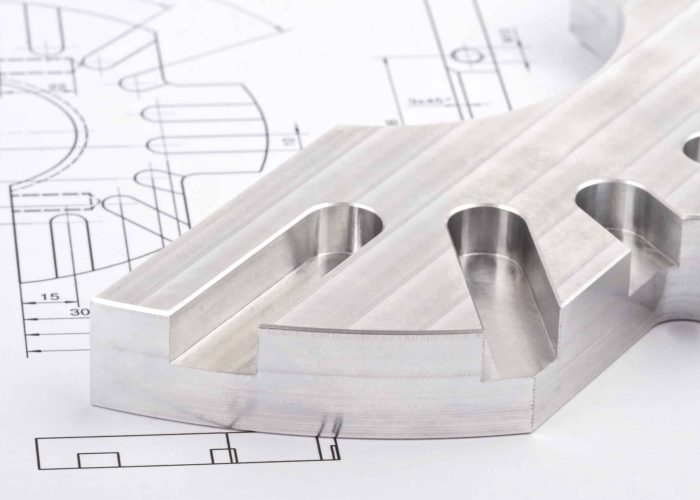

Product developers constantly balance performance with budget constraints when specifying CNC components. After working with hundreds of engineers across aerospace, medical, and audio industries, we’ve seen how small design adjustments can slash machining costs by 30-50% without compromising functionality.

Seven primary factors drive CNC machining costs: material selection, part complexity, machining time, production volume, machine type, secondary operations, and setup complexity. Understanding these variables helps engineers make smart trade-offs between cost, performance, and manufacturability during design.

Learn which design changes deliver the biggest cost savings and when tight tolerances justify the premium. Real production data from our shop floor included.

Table of Contents

How Can I Reduce CNC Costs Without Compromising Design?

Focus on geometry simplification, standard tooling compatibility, and tolerance optimization for non-critical features. The biggest cost reductions come from eliminating deep pockets, reducing setup changes, and using readily available end mills. These changes can cut machining time by 40-60% while maintaining part functionality and structural integrity.

We routinely see cost savings of $15-45 per part when engineers switch from custom 3mm end mills to standard ¼” tooling on aluminum housings. Eliminating undercuts that require secondary setups saves 2-3 hours per part—typically $120-180 in labor costs. Parts redesigned with 0.5mm minimum fillets instead of sharp corners reduce tool breakage and achieve ±0.05 mm tolerances without premium operations. One audio enclosure project dropped from $85 to $52 per part by standardizing pocket depths to 2x tool diameter and consolidating hole patterns.

Medical device housings see the biggest savings when sharp internal corners are replaced with manufacturability-friendly radii. Aerospace brackets benefit from consolidated setups using standard hole spacing. The key is identifying which geometric features actually affect assembly fit versus those added for aesthetics. ISO 2768-m general tolerances apply to non-critical dimensions, eliminating tight specifications on cosmetic surfaces that don’t impact function.

Design Takeaway: Prioritize simplification efforts on features that require multiple setups or custom tooling. Keep complexity only where it serves critical functions—everything else should use standard radii, common tool sizes, and consolidated operations.

What's the Cost Difference Between 3-Axis and 5-Axis Machining?

3-axis machining costs $45-65/hour while 5-axis runs $85-120/hour, but can reduce total project cost 20-40% by eliminating multiple setups. The decision comes down to part complexity—simple designs stay cheaper on 3-axis, while complex geometries often justify the 5-axis premium through reduced total cost.

A recent titanium bracket project cost $340 using 3-axis (6 setups) versus $195 on 5-axis (single setup). However, basic plastic enclosures with simple pockets stay 30-50% cheaper on 3-axis. 5-axis pays off when your part has angled holes, compound curves, or requires tight tolerances on multiple faces. If your current quote shows 4+ setups, 5-axis likely reduces total cost despite higher hourly rates.

The break-even point typically occurs around $200 total machining cost—below that, 3-axis wins. Above $200, evaluate setup count and geometric complexity. Most instrumentation housings and robotics components justify 5-axis investment, while simple brackets and plates don’t. Factor in your timeline too—5-axis often delivers faster since it eliminates fixture changes between setups.

Design Takeaway: Request quotes for both options when total machining cost exceeds $150. Choose 5-axis if your part requires 3+ setups on 3-axis or has angled features that complicate fixturing.

How Much Do Tight Tolerances Increase CNC Pricing?

Standard ±0.05 mm tolerances add minimal cost, while ±0.01 mm specifications increase pricing 40-80% through slower machining and mandatory inspection. Tolerances below ±0.005 mm can double costs. Budget impact depends on how many features need tight control—not every dimension requires precision.

We tracked one aerospace bracket where tightening all dimensions from ±0.05 mm to ±0.005 mm increased cost from $65 to $125 per part. The expensive part isn’t the machining—it’s the inspection time. CMM verification adds $15-30 per piece for documentation. Smart engineers specify tight tolerances only where function demands it: bearing seats, mating surfaces, and assembly-critical dimensions.

Hole location tolerances cost less than surface profile tolerances—a ±0.005 mm positioned hole adds $8-12 per part, while the same tolerance on a curved surface adds $25-40. Material choice amplifies the effect: stainless steel and titanium see higher tolerance premiums due to thermal expansion during machining.

Design Takeaway: Budget 50-80% cost increase when specifying ±0.01 mm tolerances. Use ISO 2768-m for non-critical dimensions and save tight specs for features that actually affect assembly or performance.

Which Materials Offer the Best Cost-Performance Balance?

6061-T6 aluminum delivers the best ROI for most applications—30-50% cheaper to machine than stainless steel while offering excellent strength-to-weight ratios. Material costs run $3-8/pound versus $8-15 for stainless grades. Unless your application specifically requires stainless properties, aluminum maximizes budget efficiency.

7075-T6 aluminum costs similarly to machine as 6061 but offers 40% higher strength—worth the 20% material premium when weight or space constraints matter. 304 stainless steel requires slower machining (adding $12-20 per part) but delivers corrosion resistance aluminum can’t match. For prototyping, aluminum alloys minimize both material waste and cycle time.

The business case is straightforward: start with 6061-T6 for cost optimization, upgrade to 7075-T6 when strength justifies the premium, choose stainless only when corrosion resistance is mandatory. PEEK and POM plastics machine fastest but limit design flexibility compared to metal options.

Design Takeaway: Default to 6061-T6 aluminum unless specific performance requirements force material upgrades. The machining cost difference often outweighs material cost savings from cheaper alternatives.

When Does Higher Volume Make CNC More Cost-Effective?

CNC economics flip around 25 pieces—what costs $95 as a prototype drops to $45 per part, with setup costs spreading across the batch. Single parts absorb the full $200-400 setup burden, while volume runs amortize this fixed cost. Your ROI calculation changes dramatically once you cross this threshold.

We tracked a medical device bracket that cost $120 for a single prototype but dropped to $48 per piece at 50 units—the customer saved $3,600 on their pilot production run versus ordering individually. The math is simple: setup time stays constant whether you make 1 part or 100 parts. Tooling optimization kicks in around 100+ pieces where dedicated fixtures justify their cost through cycle time reduction.

Most teams hit the sweet spot at 50-100 pieces for design validation—enough volume to capture savings without overcommitting to untested designs. Beyond 250 pieces, start evaluating injection molding or stamping as machining cost advantages plateau while alternative processes become competitive. Factor your cash flow too—volume orders require larger upfront investment but deliver better unit economics.

Design Takeaway: Plan your prototype-to-production transition around 25-50 piece volumes to maximize cost efficiency. Use these quantities for design validation runs when you’re confident in your design direction.

How Much Do Secondary Operations Add to Part Cost?

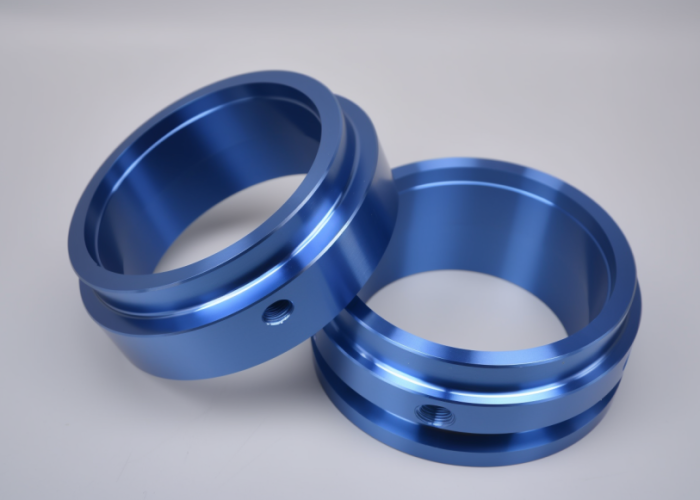

Secondary operations typically increase your total part cost by 40-90%, with anodizing running $12-20 per part and threading adding $5-15 per feature. The financial impact depends on your aesthetic and functional requirements—not every part needs premium finishing. Budget planning becomes crucial when multiple operations stack up.

Anodizing transforms raw aluminum into customer-ready components but costs $12-20 per piece—justified when appearance or corrosion resistance drives sales. Bead blasting delivers uniform texture for $8-15 per part, while powder coating adds $15-25 but provides superior durability. Threading operations cost $5-15 per hole depending on specification complexity. One robotics housing jumped from $65 base cost to $110 finished when customer specs required anodizing, laser marking, and precision tapping.

Smart procurement teams batch secondary operations across multiple part numbers to reduce per-piece costs. Small quantities under 10 pieces pay premium rates due to setup minimums—sometimes doubling the base machining cost. Consider your market positioning: consumer products often justify finishing costs while internal components may not.

Design Takeaway: Factor secondary operations into your initial budget planning rather than treating them as add-ons. Batch operations across part families when possible to optimize cost structure.

Conclusion

Smart CNC cost management starts with early design decisions—geometry simplification, appropriate tolerances, and volume planning deliver the biggest savings. Optimize material selection and secondary operations based on functional requirements, not assumptions. Contact us to explore manufacturing solutions tailored to your product requirements and unlock cost-effective precision machining strategies.

Frequently Asked Questions

5-axis pays off when your part requires 4+ setups on 3-axis equipment or total machining cost exceeds $200. Complex geometries with angled features typically justify the investment through reduced setup time.

Tolerances tighter than ±0.01 mm create the biggest cost impact—often doubling machining expenses through slower feeds, premium tooling, and mandatory CMM inspection requirements.

6061-T6 aluminum delivers optimal cost-performance balance for most applications, machining 30-50% cheaper than stainless steel while providing excellent strength-to-weight characteristics and anodizing compatibility.

Plan for 40-90% additional cost beyond base machining. Anodizing adds $12-20 per part, while threading operations cost $5-15 per feature. Batch multiple operations to reduce per-piece costs.

CNC remains cost-effective from 1-250 pieces for most applications. Below 25 pieces, expect prototype pricing. Above 250 pieces, evaluate injection molding or stamping for better unit economics.

Focus on tolerance optimization first—apply ±0.05 mm to non-critical dimensions and reserve tight tolerances for functional surfaces only. This single change can reduce costs 30-40% without geometric modifications.