Product developers struggle with tolerance decisions that impact both cost and performance. At Okdor, we guide engineers through these critical choices, preventing over-specification while ensuring functional requirements are met.

Use ISO 2768 standard tolerances for non-critical features and general dimensions, while specifying custom tolerances only for assembly-critical surfaces like mating features and seal interfaces. Reserve ±0.01mm custom tolerances for functional requirements that justify the additional cost.

Discover feature-specific tolerance guidelines, real cost implications, and practical strategies for collaborating with CNC manufacturers on tolerance optimization.

Table of Contents

When Should I Use ISO 2768 vs Specify Custom Tolerances?

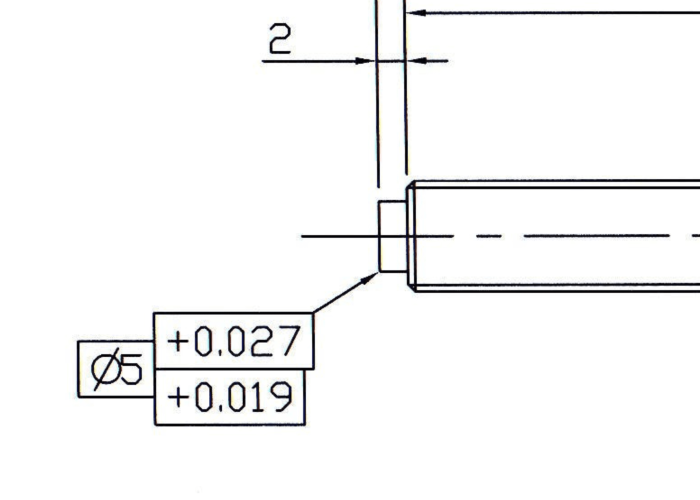

For most CNC aluminum parts, ISO 2768-m provides sufficient accuracy at ±0.1mm for general dimensions and non-critical features. Custom tolerances become necessary when parts require assembly fit, sealing surfaces, or functional precision that standard tolerances cannot achieve.

When Custom Tolerances Are Necessary:

- Mating surfaces and assembly interfaces

- Bearing seats and shaft housings requiring tight fits

- Sealing surfaces for fluid or pressure containment

- Threaded features with specific engagement requirements

ISO 2768 works effectively for structural components, mounting brackets, and enclosures where dimensional variation within ±0.1mm doesn’t affect performance. We routinely apply ISO 2768-m to audio equipment chassis, where aesthetic gaps and mounting holes function properly within standard tolerance bands. Custom tolerances of ±0.01mm are essential for precision assemblies like shaft housings, bearing seats, and threaded interfaces where tight fits prevent wobble or leakage.

Medical device housings often require custom tolerances for sealing surfaces to maintain sterile barriers, while aerospace components need verified dimensional control for weight distribution and structural integrity. Standard ISO 2768 tolerances apply to less critical features on the same parts, reducing overall machining costs.

Design Takeaway: Apply ISO 2768 to all non-critical dimensions and specify custom tolerances only for features affecting assembly, function, or safety—typically less than 20% of part dimensions require custom control.

How Do I Choose Tolerances During the Design Phase?

Establish a tolerance hierarchy during CAD modeling by categorizing features as critical, important, or standard based on assembly requirements and operating conditions. This systematic approach prevents over-specification while ensuring functional performance.

Design Phase Tolerance Workflow:

- Start with ISO 2768-m as baseline for all dimensions

- Identify critical dimensions through assembly analysis

- Calculate tolerance stack-ups for mating parts

- Document tolerance rationale for manufacturing reviews

Begin tolerance planning during concept development, not drawing finalization. Create a tolerance matrix that maps each dimension to its functional importance—critical dimensions affecting fit or safety, important dimensions for appearance or secondary function, and standard dimensions with no assembly impact. This prevents the common mistake of applying uniform tight tolerances across entire parts.

Thermal analysis influences tolerance decisions for assemblies spanning temperature ranges. A 200mm aluminum housing experiences ±0.46mm dimensional change across a 40°C operating range, requiring compensation in tolerance calculations for permanent assemblies. Early thermal modeling prevents interference issues during temperature cycling.

Prototype testing validates tolerance requirements before production release. Build assemblies using worst-case tolerance combinations to verify fit and function. Digital tolerance analysis software can simulate stack-ups, but physical validation confirms real-world performance and identifies overlooked interactions.

Design Takeaway: Create tolerance categories early in CAD—assign each dimension to “critical,” “important,” or “standard” groups to maintain design intent while controlling manufacturing costs.

Which Product Features Actually Need Tight Tolerances?

Only specify tight tolerances for dimensions that directly control mechanical function, environmental sealing, or electrical contact integrity. Decorative features, clearance dimensions, and structural elements typically perform adequately with standard tolerance control.

Functional Features Requiring Precision:

- Press-fit assemblies and interference connections

- Dynamic sealing surfaces (O-rings, gaskets)

- Electrical contact areas and connector interfaces

- Load-bearing surfaces with stress concentration

Mounting holes, external profiles, and cosmetic features consume unnecessary precision budgets. Standard ±0.1mm tolerance accommodates typical fastener clearances, paint thickness variations, and handling damage without functional impact. Reserve ±0.025mm control for rotating assemblies where bearing clearances affect performance and longevity.

Connector housings illustrate selective tolerance application effectively. Pin receptacles require ±0.01mm positional accuracy for reliable electrical contact, while the housing exterior functions properly with ±0.2mm variation. This targeted approach reduces machining costs by 40% compared to uniform tight tolerancing.

Environmental exposure drives tolerance requirements for outdoor equipment. UV degradation and thermal cycling cause polymer components to shift dimensionally over time, requiring initial tight tolerances to maintain sealing integrity throughout product lifetime. Metal components resist environmental effects and can accept looser initial tolerances.

Design Takeaway: Justify each tight tolerance by identifying the specific failure mode it prevents—if dimensional variation doesn’t cause malfunction, use standard tolerances to reduce costs.

How Much Do Custom Tolerances Increase Manufacturing Costs?

Custom tolerances dramatically increase CNC costs—specifying ±0.01mm instead of standard ±0.1mm typically doubles or triples part pricing. The tightest tolerances of ±0.005mm can cost 5-10 times more than standard machining, making tolerance selection a major budget decision.

Cost Impact by Tolerance Level:

- Standard ±0.1mm (ISO 2768): Baseline pricing

- Tight ±0.05mm: 50-100% cost increase

- Precision ±0.01mm: 200-300% cost increase

- Ultra-precision ±0.005mm: 500-1000% cost increase

These cost jumps result from slower machining speeds, specialized tooling, and extended quality control processes. A simple aluminum bracket might cost $50 with standard tolerances but $200 with ±0.01mm requirements across critical dimensions. Volume helps reduce the impact—high-quantity orders spread setup costs across more parts.

Smart tolerance strategy balances performance needs with budget reality. Apply tight tolerances only to the 2-3 most critical dimensions per part while using ISO 2768 elsewhere. This selective approach delivers functional performance at manageable cost increases of 20-50% rather than wholesale part price doubling.

Temperature-controlled machining environments and premium inspection equipment drive much of the cost premium for precision work. These overhead factors affect small quantities more severely than production runs, making prototype costs particularly sensitive to tolerance specifications.

Design Takeaway: Budget custom tolerances carefully during design—each ±0.01mm specification potentially doubles that feature’s cost contribution to overall part pricing.

How Do I Select the Right ISO 2768 Tolerance Class (f, m, c, v)?

Use ISO 2768-m (medium) for most product development projects—it provides ±0.1mm control suitable for typical assemblies while maintaining reasonable costs. Reserve fine (f) class for precision products requiring visual perfection or tight component interfaces.

Practical Class Selection Guide:

- Fine (f): Consumer electronics, optical products, precision instruments

- Medium (m): General products, prototypes, electronic enclosures

- Coarse (c): Industrial equipment, structural components

- Very Coarse (v): Heavy-duty applications, welded structures

Medium class works for approximately 85% of product development needs including smartphone cases, drone components, and laboratory equipment. Fine class becomes necessary when visible gaps between parts matter for brand perception or when components must align precisely for optical or measurement functions.

Choose coarse class when function outweighs appearance and manufacturing speed matters more than precision. Industrial control panels and equipment mounting brackets perform adequately with looser tolerances while reducing production time and cost.

Product category often determines appropriate class selection. Consumer-facing products typically require fine or medium class for aesthetic reasons, while internal components can accept coarse tolerances. Medical device housings use fine class for professional appearance, while internal mounting hardware uses medium class for cost control.

Design Takeaway: Start with ISO 2768-m as your default choice—upgrade to fine class only when customer-facing aesthetics or precision assembly clearly justify the additional cost.

How Do I Work with CNC Manufacturers on Tolerance Decisions?

Request tolerance capability assessments and cost estimates during the RFQ process to understand each manufacturer’s precision limits and pricing structure. This upfront evaluation prevents mismatched expectations and ensures your project aligns with supplier capabilities.

Manufacturer Evaluation Process:

- Request sample tolerance charts and capability statements

- Ask for cost breakdowns showing standard vs custom tolerance pricing

- Verify inspection equipment capabilities for your precision requirements

- Establish communication protocols for design questions during production

Focus discussions on manufacturing constraints rather than design theory. Ask specific questions like “What’s your tightest achievable bore tolerance on aluminum?” or “How does batch size affect your ±0.01mm pricing?” These practical conversations reveal real capabilities versus marketing claims.

Establish tolerance contingency plans before production begins. Identify which dimensions have flexibility if manufacturing issues arise, and which tolerances are absolutely non-negotiable. This preparation prevents project delays when unexpected machining challenges occur.

Professional manufacturers often suggest tolerance optimizations based on their equipment capabilities. A shop with wire EDM capabilities might recommend tighter slot tolerances, while another with precision turning centers could optimize cylindrical features more economically.

Design Takeaway: Evaluate manufacturers based on tolerance capabilities and communication quality—technical competence matters more than lowest initial pricing for precision work.

What Are the Best Practices for Tolerance Specification?

Document tolerance decisions with clear rationale to prevent specification creep and ensure consistent application across product variants. Systematic tolerance management reduces design errors and maintains cost control throughout product development cycles.

Tolerance Documentation Best Practices:

- Create tolerance decision matrices linking specifications to functional requirements

- Establish company-wide tolerance standards for common features

- Review tolerance specifications during formal design checkpoints

- Track tolerance-related costs and manufacturing feedback for future projects

Implement tolerance standardization across product families to leverage manufacturing learning curves. Develop standard specifications for common features like mounting holes, connector interfaces, and housing joints. This consistency reduces supplier qualification time and enables volume pricing benefits.

Avoid tolerance inheritance from legacy designs without functional validation. Copying specifications from previous projects often perpetuates unnecessary precision requirements that no longer serve current design goals. Each new product should justify its tolerance requirements based on specific functional needs.

Monitor tolerance-related manufacturing feedback to improve future specifications. Track which tolerances cause production delays, quality issues, or cost overruns. This data builds institutional knowledge for future projects.

Design Takeaway: Treat tolerance specification as a systematic engineering process with documentation and standards—not ad-hoc decisions made during drawing creation.

Conclusion

Tolerance decisions directly impact both product performance and manufacturing costs. ISO 2768 standards provide cost-effective control for most features, while custom tolerances should target only assembly-critical dimensions. Strategic tolerance specification reduces production costs by 20-40% without compromising functionality. Contact us to explore manufacturing solutions tailored to your tolerance specification requirements.

Frequently Asked Questions

ISO 2768-m provides general tolerances of ±0.1mm for dimensions up to 30mm and ±0.2mm for larger features. It’s the most common standard for CNC aluminum parts, covering dimensions without specific tolerance callouts on drawings.

Use ±0.01mm only for assembly-critical features like bearing fits, sealing surfaces, or mating interfaces where standard tolerances cause functional problems. Most dimensions work fine with ISO 2768 standard control.

Custom ±0.01mm tolerances typically cost 200-400% more than ISO 2768 standard tolerances. Ultra-tight ±0.005mm tolerances can cost 500-1000% more due to specialized equipment and extended machining time.

Yes, ISO 2768 works excellently for prototypes. Use ISO 2768-m for general prototyping and upgrade to ISO 2768-f only if your prototype requires precision assembly or visual alignment testing.

ISO 2768-1 covers dimensional tolerances (length, diameter, angles), while ISO 2768-2 addresses geometric tolerances (flatness, straightness, perpendicularity). Most CNC applications use both standards together via “ISO 2768-mK” notation.

Specify “ISO 2768-m” in your drawing title block for standard tolerances, then add custom callouts only where tighter control is needed. Include tolerance rationale to help manufacturers understand functional requirements and suggest optimizations.