CNC Turning Service

At okdor your parts can be produced within 24 hours. Upload your parts for a quote today.

All uploads are secure and confidential

CNC Turning Service

Upload your parts for a quote today.

CNC Turning is one of the machining processes of shaping workpieces on both outside and inside to produce tubular components for various geometries. At okdor your parts can be produced within 24 hours. Upload your parts for a quote today.

All uploads are secure and confidential

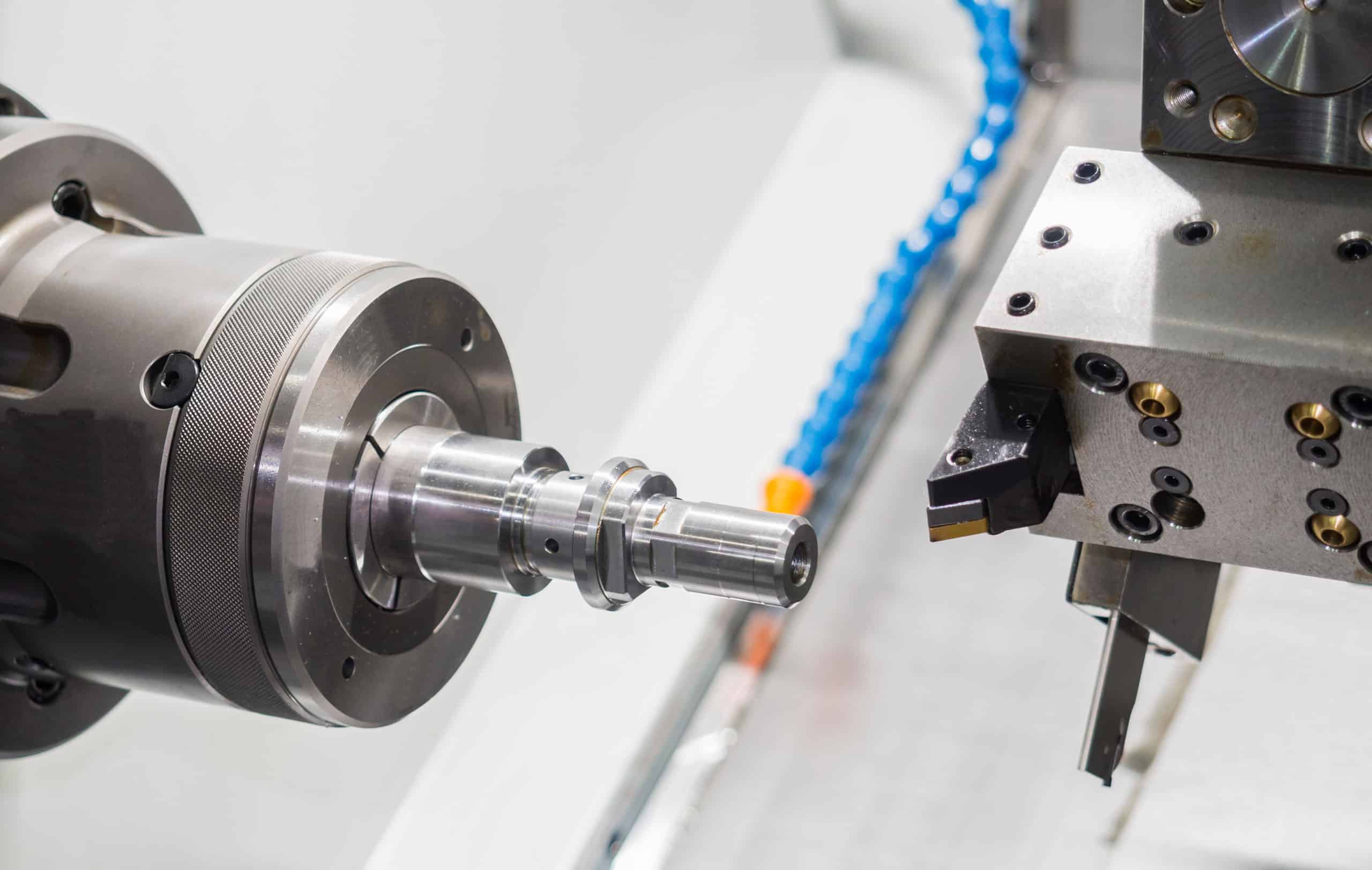

What is CNC Turning?

In CNC turning, material is held in a chuck and rotated by using tooling attached to a turret. Furthermore, the tool moves to the raw bar of material to remove material. The process is also known as “subtraction machining” since the material is removed. A center that has tuning and milling capabilities, such as the one pictured above, can be slowed so that other shapes can be milled out.

How CNC Turning Work?

From prototyping to full-scale production. High-quality parts can be produced with our CNC lathes and turning centers to meet even the strictest requirements.

Standard Materials for CNC Milling

Hundred of commercial-grade metal and plastic materials are suitable for both prototyping and production.

CNC Metals

| Aluminum | StainlessSteel | Steel | Other Metals |

| 2017 | 301 | 1018 | Brass C230 |

| 2021 | 303 | 1045 | Brass C360 |

| 2024 | 303L | 1095 | Copper C110 |

| 5052 | 304 | 4130 | Titanium Alloy |

| 6061 | 316 | 4140 | |

| 6063 | 316L | 4340 | |

| 6082 | 410 | SKD Series | |

| 7075 | 416 | SKH Series | |

| A380 | 420 | SUS Series |

CNC Plastics

| Plastics | Reinforced Plastic |

| ABS | PP 30%GF |

| Acetal | NylOn 30%GF |

| Delrin | |

| HEPD | |

| PVC | |

| PET | |

| PTFE | |

| PEEL | |

| Acrylic |

Machinable size for CNC Turning

General machinable size for CNC machining at our site. If a custom size is required please contact sales@okdor.com

| Size | Metals | Plastics |

| Maximal machined size | 800*800*600mm | 600*600*300mm |

| Minimal machined size | 0.050mm | 0.10mm |

Standard tolerance for CNC Turning

The below table is a general tolerance for the different CNC Turning processes. If a custom tolerance is required please contact sales@okdor.com

| Size Range | Metals | Plastics |

| 0.5mm – 30mm | 0.020mm | 0.050mm |

| 30mm – 120mm | 0.050mm | 0.10mm |

| 120mm – 300mm | 0.10mm | 0.150mm |

| 300mm – 600mm | 0.20mm | 0.30mm |

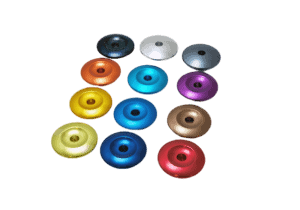

CNC Machined Surface

Available Surface Finishing for CNC Turning

Surface Finishing generally applies after assemble which not only changes the appearance but also provides much chemical resistance to the fine products.

| Treatment | Material | Thickness | Color |

| Anodizing | Aluminum | 0.8-12 μm | RAL code, Pantone number |

| Nickel | All metals | 5-30μm | Silver appearance |

| Passivation | SS steel and Carbon Steel | 9~100 Å | Clear |

| Black oxide | Ferrous materials | 0.8μm | Black |

| Bead blasting | All metals | #100, #120 | Yellow or clear Iridescent |

| Powder Coating | All metals | 10-80μm | RAL code, Pantone number |

| Zinc-Nickel | All metals | 5-25 μm | Clear, Black , Iridescent |

| Chromate coating | Steel and Aluminum | 0.25-1.0μm | Yellow or clear Iridescent |

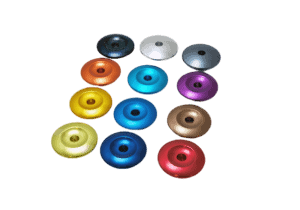

Anodizing

Anodizing treatment provides an aluminum oxide layer for metal parts, which protects against corrosion & adding an optional color surface.

Specifications:

RoHS compliant

Type two ( color)

Class 1 (clear)

Class 2 (black)

Black oxide

Black oxide produces a magnetite layer on the surface for ferrous, non-ferrous, and powdered metals to Add Mild corrosion resistance and minimize light reflection.

Specifications:

RoHS compliant

Hot black oxide

Mid-temperature black oxide

Cold black oxide

Chromate coating

Chromate coating is a type of conversion coating, which by producing a thin coating on the nonferrous surface, such as zinc, aluminum, and tin plate to improve paint adherence.

Specifications:

Type two, RoHS compliant

Class1A: For max protection against corrosion, painted or unpainted

Class 3: For max protection against corrosion where low electrical resistance is required

Tempering

Tempering is a process of not only increasing metal hardness levels to obtain tougher and more durable properties but also dissolving solute-rich precipitates.

Specifications:

Quenched and tempered

Conditioning

HRC 10 to HRC 65

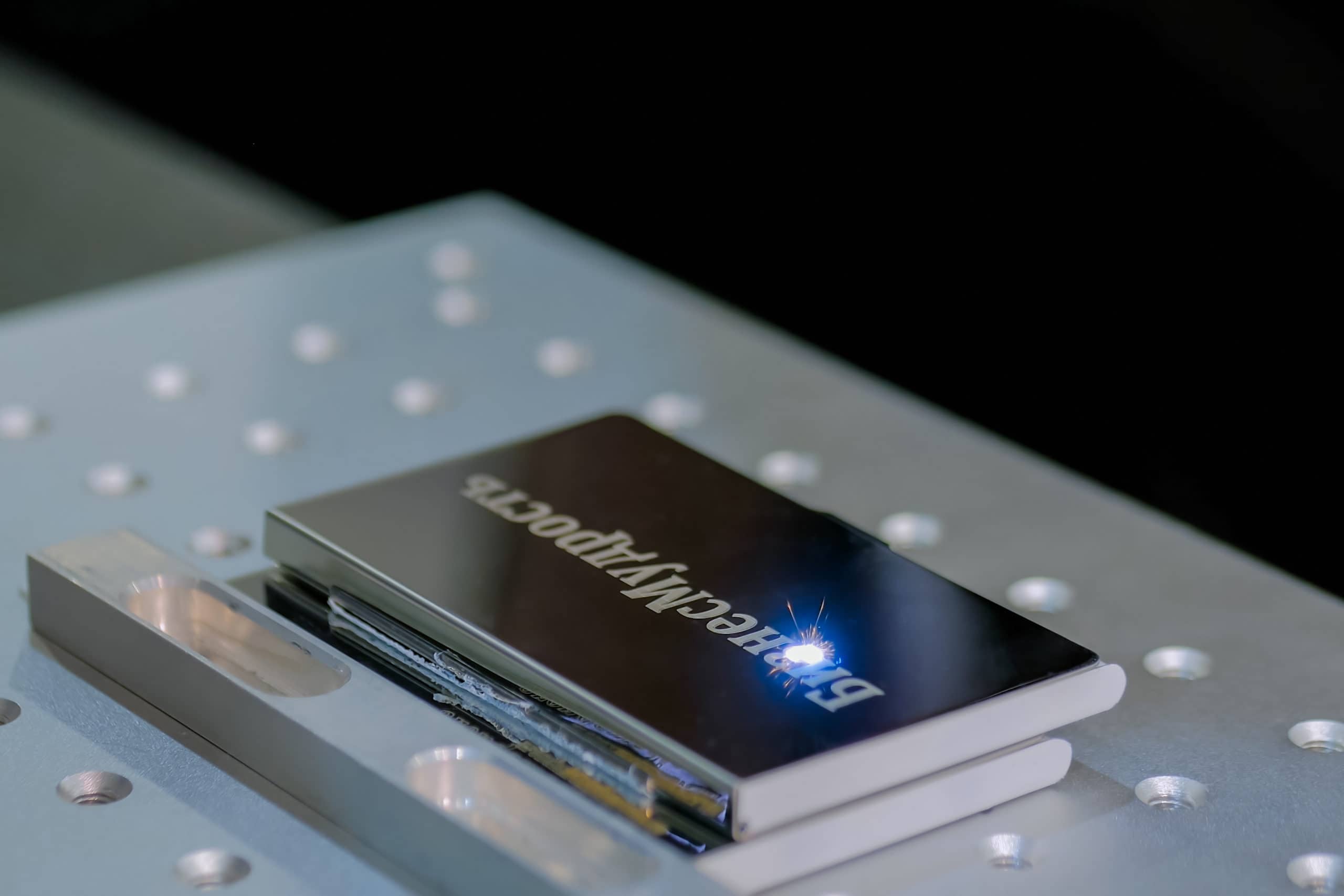

Part marking

Part marking is a process of marking parts with product info, such as serial numbers, part numbers, and logos, which allow the tracking of parts across the full product life circle.

Specifications:

Laser engraving

Silk printing

CNC Marking

0.05 to 3.0MM depth

Anodizing

Anodizing treatment provides an aluminum oxide layer for metal parts, which protects against corrosion & adding an optional color surface.

Specifications:

RoHS compliant

Type two ( color)

Class 1 (clear)

Class 2 (black)

Black oxide

Black oxide produces a magnetite layer on the surface for ferrous, non-ferrous, and powdered metals to Add Mild corrosion resistance and minimize light reflection.

Specifications:

RoHS compliant

Hot black oxide

Mid-temperature black oxide

Cold black oxide

Chromate coating

Chromate coating is a type of conversion coating, which by producing a thin coating on the nonferrous surface, such as zinc, aluminum, and tin plate to improve paint adherence.

Specifications:

Type two, RoHS compliant

Class1A: For max protection against corrosion, painted or unpainted

Class 3: For max protection against corrosion where low electrical resistance is required

Tempering

Tempering is a process of not only increasing metal hardness levels to obtain tougher and more durable properties but also dissolving solute-rich precipitates.

Specifications:

Quenched and tempered

Conditioning

HRC 10 to HRC 65

Part marking

Part marking is a process of marking parts with product info, such as serial numbers, part numbers, and logos, which allow the tracking of parts across the full product life circle.

Specifications:

Laser engraving

Silk printing

CNC Marking

0.05 to 3.0MM depth

Applications of CNC Machining

Lead Screw

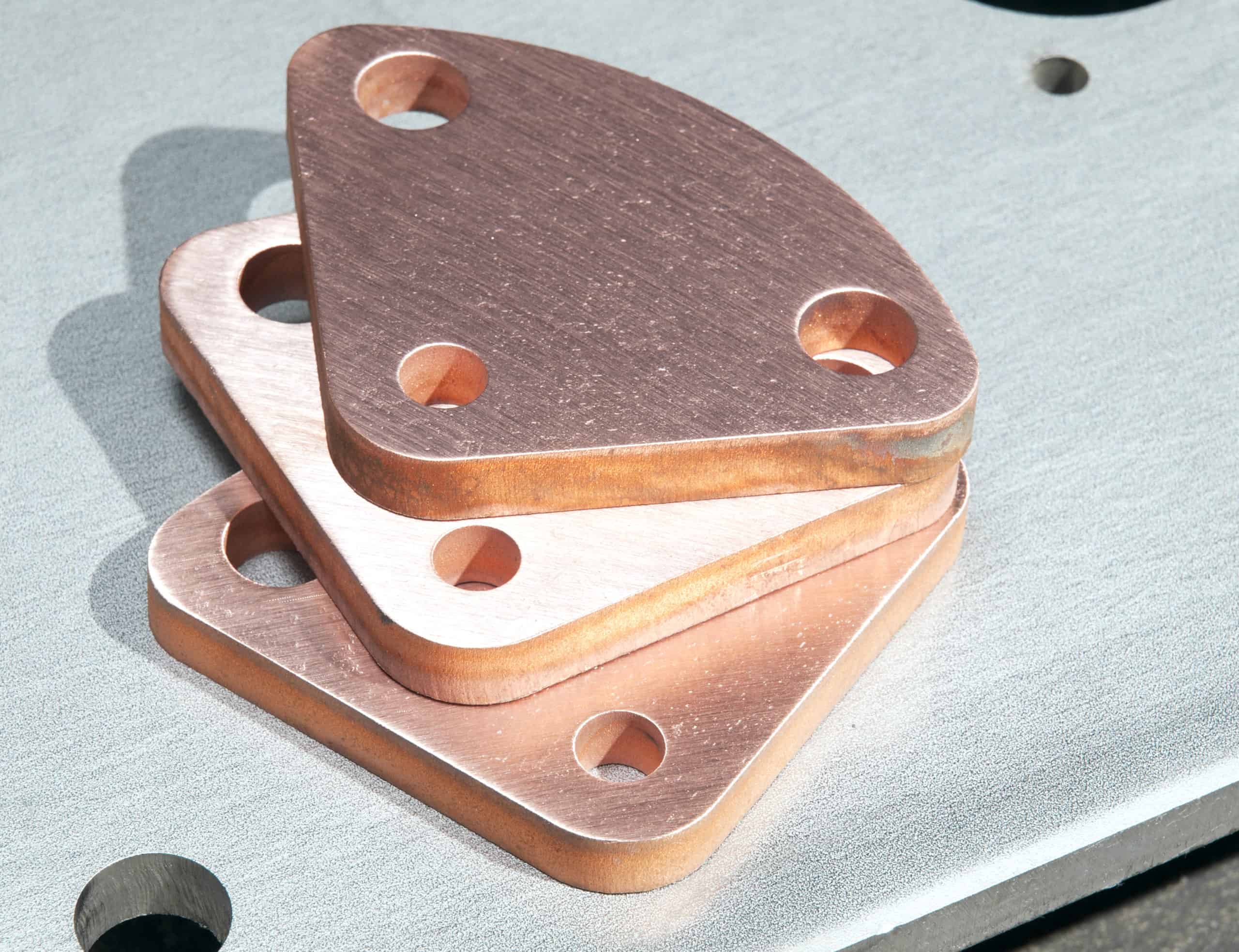

Stainless Steel Housing

Bronze CNC Screw Set

Need Part marking service?

FAQ's

Simply upload a CAD model to our site to get a quote for all of our services. You’ll get an interactive quote within hours. Or contact us directly at sales@okdor.com

It depends on specific case, we will do what we can.

It’s determined by your custom part’s geometry. the fast turnover for CNC custom parts are 48 hours.

The process uses less energy and strength while providing a high-quality surface finish.

When it comes to CNC machining, we can achieve a tolerance of +/- 0.005mm for parts less than 50MM in size. We will come to a mutual agreement before production regarding tighter tolerances if needed.

Currently, we offer CNC Machining, sheet metal fabrication, and metal stamping services. Your quote will include the necessary quote if your custom parts are within our range.

We offer FAIS on machined and sheet metal parts to ensure sizes are correct before sending out.

Machining Resources for engineers

CNC Machine Broke Down Before Deadline? What to Do Next

Your CNC supplier tells you a machine broke down, and your delivery is already close. At this stage, the explanation

CNC Supplier Outsourced Without Telling You — Parts Arrived Defective

Your CNC parts arrive defective, and only afterward do you discover the supplier outsourced the work without telling you. At

When a CNC Supplier Goes Silent After a Deadline Change, What Now?

You told your CNC supplier the deadline changed. They acknowledged it—but responses slowed, updates became vague, and progress stopped moving.