Choosing between anodizing and other coating options is like selecting the right protection for your smartphone – each option has its strengths. Understanding these key questions helps you make the right choice for your application.

Seven critical questions guide the choice between anodizing and other coatings: performance requirements, aesthetic finish, weight considerations, coating lifespan, environmental impact, budget constraints, and maintenance needs. Each question helps evaluate which finish best suits your specific needs.

Let’s explore each of these questions in detail to help you make an informed decision about your finishing choice.

Table of Contents

1. How Will It Perform?

Performance requirements in surface finishing are like choosing armor for different battle conditions – each type of protection serves different purposes. When selecting between anodizing and other coatings, understanding your performance needs is crucial because it directly affects product longevity and reliability. The wrong choice could lead to premature failure or unnecessary costs.

Durability Requirements

Durability in surface finishing refers to how well the coating withstands physical contact, environmental stress, and daily use. Think of it like choosing between a regular paint job and a protective car coating – while both make the car look good, their ability to handle scratches, stone chips, and weather varies significantly.

Anodizing creates a hard, integrated layer that becomes part of the aluminum surface, while powder coating forms a separate protective layer bonded to the surface. This fundamental difference affects how each performs under various conditions.

Performance Comparison:

Requirement Anodizing Powder Coating Real-World Application

Wear Resistance Extremely hard surface (9 on Mohs scale) Moderate hardness (6-7 on Mohs scale) High-traffic handrails

Corrosion Protection Excellent for atmospheric exposure Superior for chemical exposure Outdoor equipment

UV Stability No color fade for Type II, III May fade over time Building facades

Impact Resistance Moderate Excellent Industrial equipment

Resistance Needs

Environmental resistance means protecting against specific threats that your part will face during its service life. Just as different climates require different types of clothing, different operating environments demand specific types of protection.

Environmental Challenges:

Marine Environments:

- Anodizing excels in salt spray resistance

- Maintains appearance longer

- Prevents underlying corrosion

- Suitable for boat components

Industrial Settings:

- Chemical exposure resistance varies

- Temperature fluctuation handling

- Abrasion resistance needs

- Maintenance requirements

Environmental Exposure

The operating environment determines which coating will perform best over time. Like choosing between different types of outdoor gear, your coating needs to match the specific challenges it will face:

Temperature Considerations:

- Anodizing stable up to 1000°F

- Powder coating typically limited to 400°F

- Thermal cycling effects

- Color retention at temperature

Exposure Impact Analysis:

Environment Anodizing Performance Powder Coating Performance Deciding Factor

Indoor Excellent Excellent Aesthetic preference

Coastal Very Good Good (with proper primer) Salt resistance

Industrial Good Very Good Chemical exposure

High Heat Excellent Fair Temperature resistance

Pro Tip: Document all environmental conditions your part will face, including unexpected exposure scenarios. This comprehensive approach helps prevent premature coating failure.

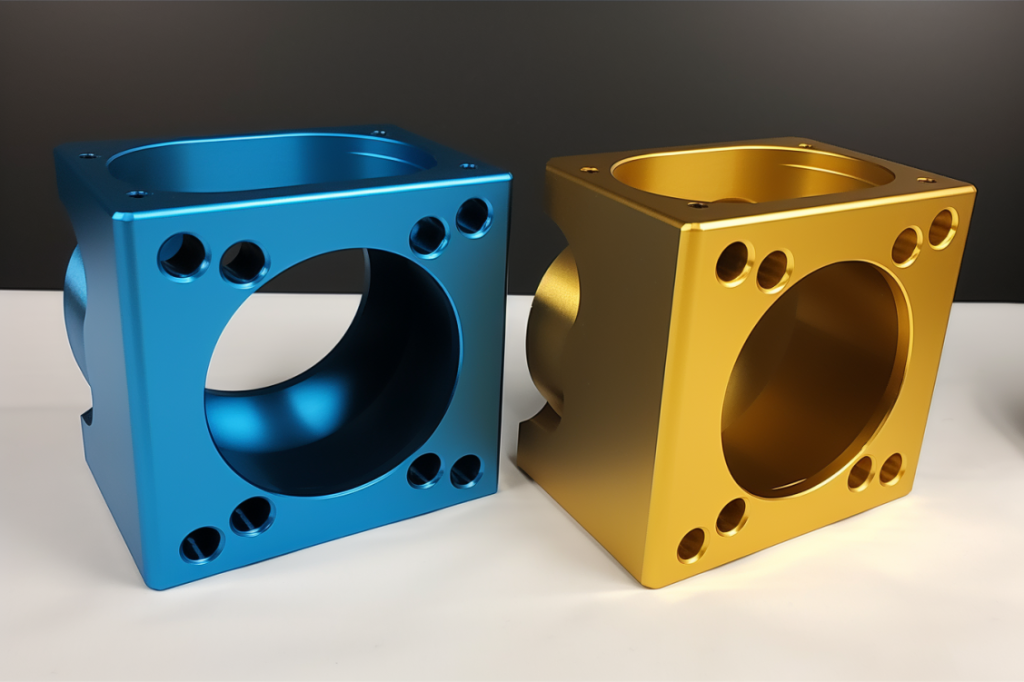

2. What Look Are You After?

Aesthetic considerations in surface finishing go beyond mere appearance – they affect both visual appeal and functional performance. Like choosing between matte and glossy finishes on a smartphone, different finishes create different impressions and serve different purposes. Understanding aesthetic options helps balance visual requirements with practical performance.

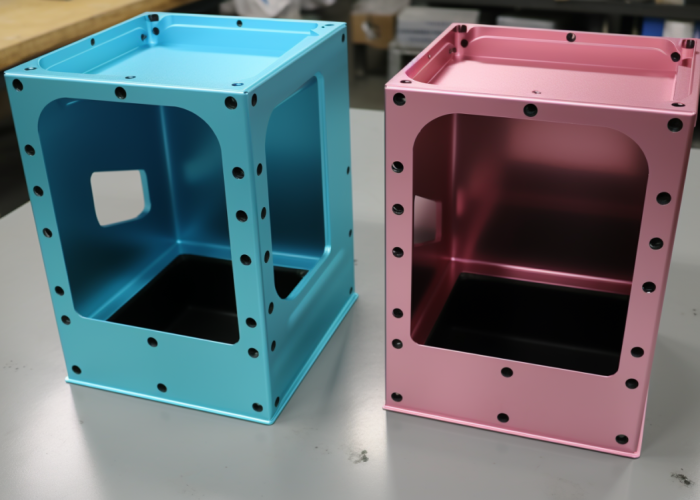

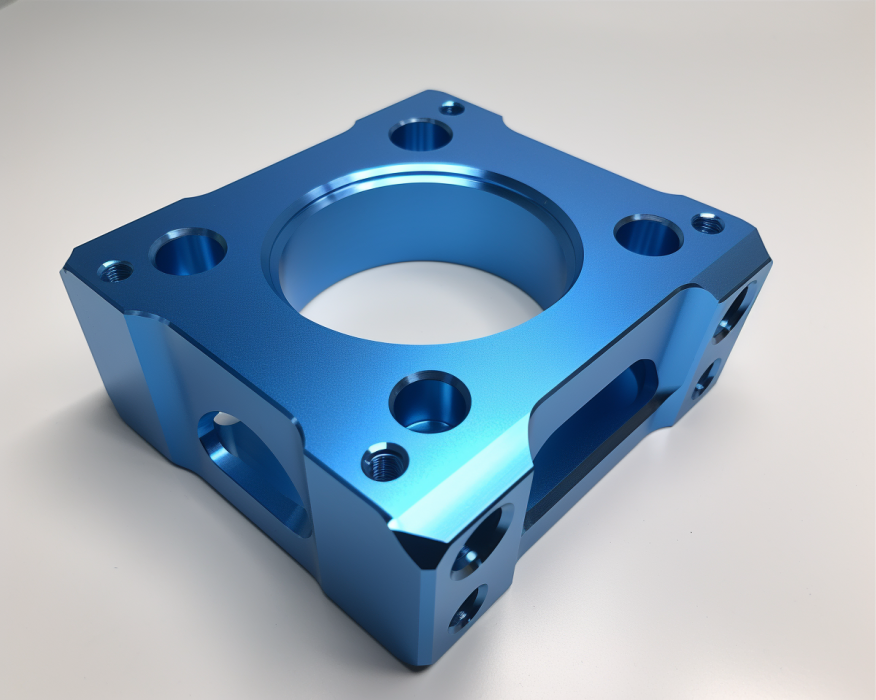

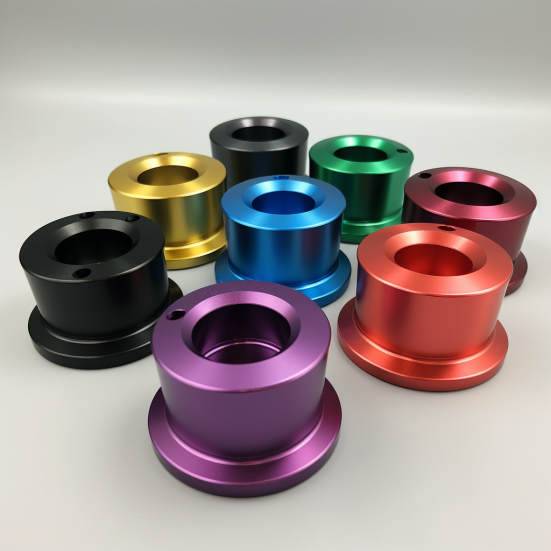

Color Options

Color selection in surface treatments significantly impacts both aesthetics and cost. Anodizing and powder coating offer distinctly different color possibilities, each with their own advantages and limitations.

Color Capability Comparison:

Color Type Anodizing Powder Coating Cost Impact

Natural Metallics Excellent Limited Base cost

Bright Colors Limited range Unlimited +10-30%

Black Very consistent Many variations Base cost

Custom Colors Challenging Easily achieved +20-50%

Detail Applications:

- Architectural uses require color consistency

- Consumer products need attractive finishes

- Industrial applications focus on durability

- Medical devices demand specific colors

Texture Choices

Surface texture affects both appearance and functionality. The choice between smooth, matte, or textured finishes impacts:

Finish Type Anodizing Powder Coating Best Application

Smooth Natural metal feel Paint-like Consumer products

Matte Subtle, uniform Can be inconsistent Professional equipment

Textured Limited options Many choices Industrial uses

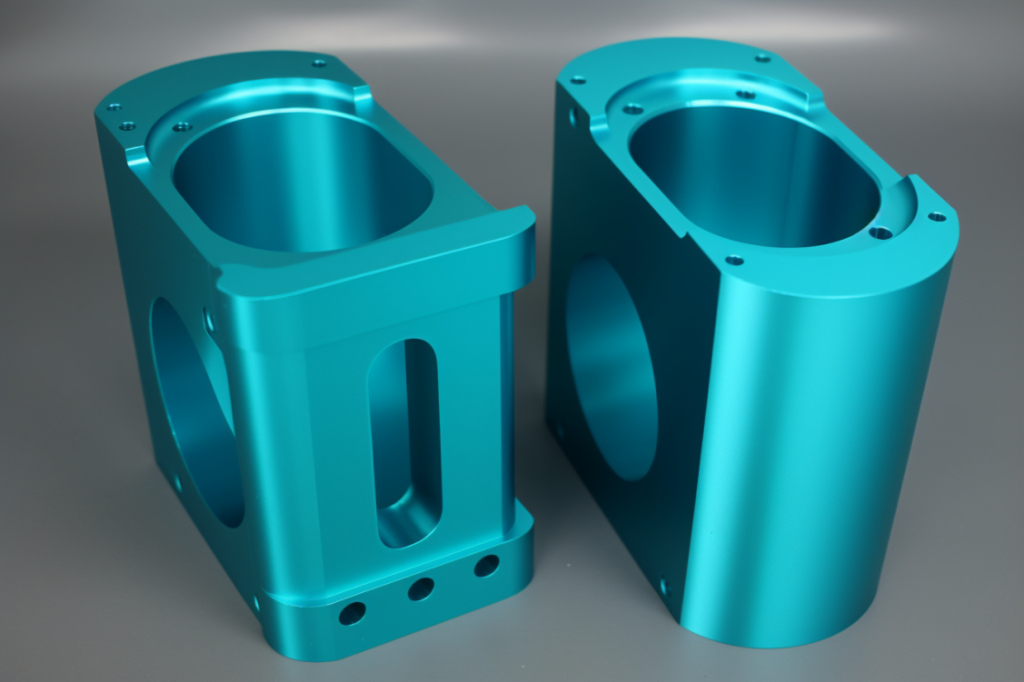

Finish Appearance

The final appearance goes beyond color and texture – it includes factors like:

Light Interaction:

- Anodized finishes maintain metallic look

- Powder coating provides solid color appearance

- Different light reflection properties

- Gloss level variations

Pro Tip: Request samples of different finishes under actual lighting conditions. Appearance can vary significantly between artificial and natural light.

3. Does Weight Matter?

Weight considerations in surface finishing directly impact product performance and cost. Like choosing between a leather or carbon fiber case for a laptop, the coating weight affects both functionality and usability. Understanding weight implications helps ensure your finished product meets design specifications.

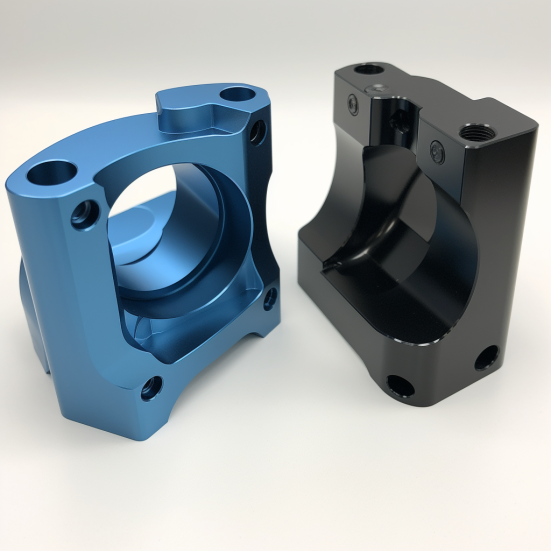

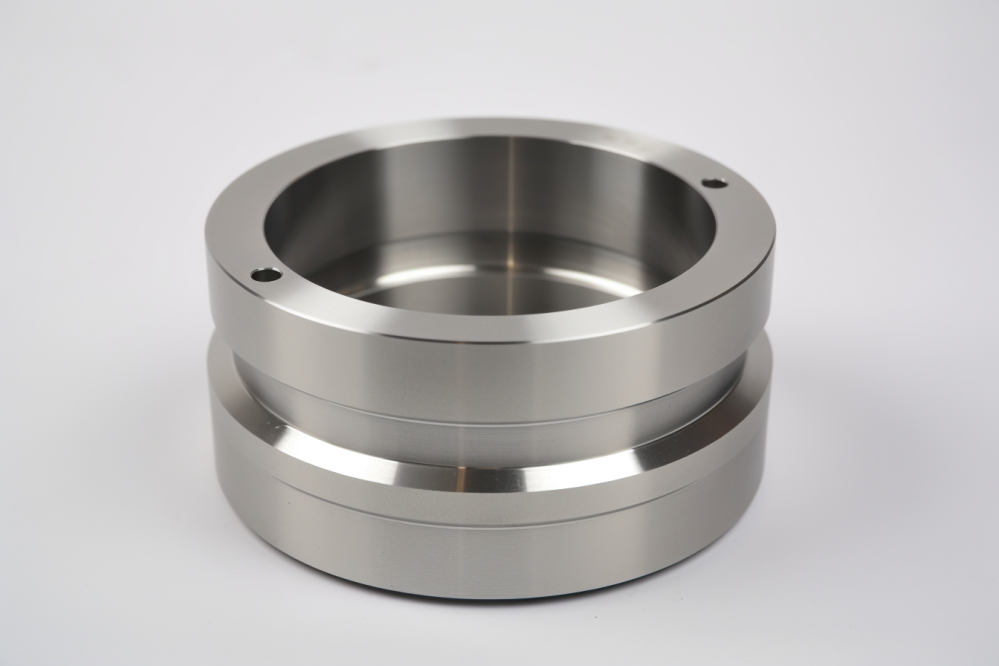

Coating Thickness

Coating thickness is a critical factor that affects both weight and dimensional tolerances. Different processes create significantly different coating thicknesses:

Thickness Comparison:

Process Type Typical Thickness Weight Impact Dimensional Change

Type II Anodize 0.4-0.8 mils Minimal <0.0002"

Type III Anodize 1.0-4.0 mils Low 0.0003-0.0005″

Powder Coating 2.0-6.0 mils Moderate 0.004-0.012″

Heavy Powder 6.0-12.0 mils Significant >0.012″

Dimensional Impacts

Surface treatment thickness affects part fit and function in ways that must be carefully considered during design. Like tailoring a suit, every fraction of an inch matters for proper fit and function. This dimensional change can significantly impact assembly and performance.

Dimensional Considerations by Feature:

Feature Type Anodizing Impact Powder Impact Design Considerations

Threaded Holes 0.0002″ per side 0.002-0.004″ per side Thread engagement, tap drill size

Press Fits Predictable growth Inconsistent build Interference calculations

Sliding Surfaces Maintains clearance May require machining Friction, clearance

Mating Parts Minor adjustment Significant allowance Assembly tolerances

Understanding Growth Patterns:

- Anodizing grows 50% outward, 50% inward

- Powder coating builds 100% outward

- Surface roughness affects actual dimensions

- Temperature impacts final dimensions

Weight Restrictions

Weight sensitivity in surface finishing varies dramatically by application, like how weight matters more for a racing bicycle than a street bike. Understanding weight implications helps ensure the coating choice aligns with product requirements

Application-Specific Considerations

Aerospace Applications: Weight impact in aerospace goes beyond simple measurements. Every additional gram affects operational costs and performance. Aircraft components must meet strict weight requirements while maintaining protection against harsh environments. For example, a commercial aircraft’s surface coating can add hundreds of pounds to total weight, directly impacting fuel consumption and operating costs.

Consumer Products: The weight impact on consumer products affects both practical and perceived value. In shipping, even small weight increases can significantly impact costs, especially in high-volume production. A product that’s too heavy may face higher shipping rates, affecting profit margins. Additionally, consumer perception of quality often relates to weight – while some products benefit from feeling substantial, others need to feel light and portable.

Medical Equipment: Medical device weight considerations balance durability with usability. Equipment often needs to be moved between rooms or facilities, making weight a critical factor. A portable X-ray machine, for instance, requires protective coating that won’t significantly increase weight and impair mobility. The coating must also maintain cleanliness standards while withstanding regular sanitization.

4. How Long Should It Last?

Coating lifespan directly impacts both initial investment and long-term maintenance costs. Like choosing between temporary and permanent home improvements, understanding service life expectations helps balance immediate costs against long-term value. This consideration becomes crucial when calculating total ownership costs.

Service Life Expectations

Service life in surface finishing refers to how long the coating maintains its protective and aesthetic properties under specified conditions. Different environments and uses demand different performance longevity.

Lifespan Comparison:

Environment Anodizing Powder Coating Determining Factors

Indoor 20+ years 15-20 years UV exposure, wear

Outdoor 15-20 years 10-15 years Weather exposure

Coastal 10-15 years 8-12 years Salt spray, humidity

Industrial 8-12 years 5-8 years Chemical exposure

Wear Characteristics

Each coating type ages differently under various conditions. Understanding these patterns helps predict maintenance needs and replacement timing.

Aging Behavior Analysis:

- Anodizing maintains consistent protection throughout its life, with gradual wear in high-contact areas

- Powder coating offers excellent initial protection but may show more noticeable aging through color fading and potential chipping

- Environmental factors can accelerate aging for both finishes

Environmental Durability

Coastal Environments: The combination of salt spray, high humidity, and UV exposure creates particularly challenging conditions. Anodized surfaces typically maintain their protective properties longer in these environments, while powder coatings may require more frequent maintenance or replacement.

Industrial Settings: Chemical exposure, temperature variations, and physical wear create complex durability requirements. The choice between anodizing and powder coating often depends on specific chemical resistance needs and temperature ranges.

Urban Locations: Air pollution, acid rain, and varying weather conditions affect coating performance. Both finishes can provide adequate protection, but maintenance requirements may differ:

Protection Performance:

Condition Anodizing Response Powder Coating Response Maintenance Needs

UV Exposure Minimal change Gradual fading Color restoration

Acid Rain Excellent resistance Good with proper primer Regular cleaning

Temperature Changes Stable May show stress Inspection routine

Pro Tip: Document expected environmental conditions and required service life early in the design process. This helps specify the most cost-effective coating system for your application.

5. What About Environmental Impact?

Environmental considerations in surface finishing extend beyond regulatory compliance into sustainable manufacturing practices. Like choosing between disposable and reusable products, the environmental impact of finishing processes affects both current operations and future sustainability. Understanding these impacts helps make environmentally responsible choices while maintaining quality.

Process Considerations

Different finishing processes create varying environmental footprints. Each method has unique resource requirements and environmental implications:

Process Impact Analysis:

Process Element Anodizing Powder Coating Environmental Impact

Energy Usage Moderate High (curing) Carbon footprint

Water Usage Significant Minimal Resource consumption

Chemical Use Controlled Limited Waste management

VOC Emissions None Very low Air quality

Material Recycling

Recyclability affects both environmental impact and end-of-life costs. The ability to recycle treated materials varies significantly between processes:

Anodized Materials: Anodized aluminum remains 100% recyclable, with the anodized layer becoming part of the recycling stream. This maintains the material’s value in the circular economy while reducing waste.

Powder Coated Materials: Powder coated parts typically require coating removal before recycling, adding processing steps but still allowing material recovery. Modern powder coating processes have evolved to minimize environmental impact:

Recovery Methods:

Material State Recovery Process Recycling Efficiency Cost Impact

Clean Aluminum Direct recycling 95-100% Lowest

Anodized Standard process 90-95% Low

Powder Coated Stripping required 85-90% Moderate

Environmental Regulations

Environmental compliance requirements vary by region and industry. Current regulations affect both process selection and operational costs:

Regional Standards: Different geographical areas maintain varying environmental requirements. Understanding these standards ensures compliance while optimizing processes:

Compliance Requirements:

Region Water Standards Air Quality Waste Management

North America Strict Moderate Comprehensive

European Union Very Strict Very Strict Strict

Asia Pacific Varying Developing Emerging

Pro Tip: Consider future environmental regulations when selecting finishing processes. Stricter requirements may affect long-term operational costs and compliance needs.

6. What's Your Budget?

Cost considerations in surface finishing encompass more than just the initial application price. Like investing in a home, the true cost includes both immediate expenses and long-term financial implications. Understanding the complete cost picture helps make financially sound decisions that align with quality requirements.

Initial Costs

Initial investment in surface finishing varies significantly between processes. These upfront costs often influence immediate decision-making but shouldn’t be the only consideration:

Cost Breakdown Comparison:

Cost Element Anodizing Powder Coating Cost Factors

Setup Costs $500-1000 $300-600 Equipment prep

Processing $0.50-2/sq ft $0.30-1.50/sq ft Surface area

Minimum Lot $150-300 $100-200 Batch size

Custom Colors +30-50% +10-20% Color matching

Long-term Value

Long-term value assessment looks beyond initial costs to understand total ownership expenses. This analysis often reveals that higher initial costs may result in better financial outcomes:

Value Considerations:

Time Frame Anodizing Value Powder Coating Value Impact Factors

5 Years Higher initial, lower maintenance Lower initial, moderate maintenance Regular upkeep

10 Years Cost-effective May need refinishing Durability

15+ Years Most economical Multiple refinish cycles Life cycle cost

Process Expenses

Understanding process-related costs helps anticipate and plan for various expenses throughout the finishing lifecycle:

Equipment Requirements:

The specialized nature of each process affects both initial investment and ongoing operational costs:

Operational Costs:

Component Annual Cost Impact Maintenance Needs Efficiency Factors

Energy $5000-15000 Quarterly checks Process optimization

Labor $30000-50000 Ongoing training Skill level

Materials $10000-30000 Regular resupply Waste reduction

Quality Control $8000-20000 Monthly calibration Testing requirements

Pro Tip: Create a comprehensive cost analysis that includes both immediate expenses and projected maintenance costs over your product’s expected lifetime.

7. How Much Maintenance Is Needed?

Maintenance requirements in surface finishing impact both long-term costs and product reliability. Like maintaining a vehicle, proper care of finished surfaces ensures optimal performance and appearance throughout the product’s life. Understanding maintenance needs helps plan resources and predict ongoing costs

Maintenance Requirements

Different finishes demand varying levels of care and attention throughout their service life:

Maintenance Comparison:

Maintenance Type Anodizing Needs Powder Coating Needs Frequency

Routine Cleaning Mild soap/water Gentle cleaners Monthly

Inspection Visual check Detailed examination Quarterly

Touch-up Rarely needed May require spot fixes As needed

Refinishing Not possible Every 5-10 years Scheduled

Inspection Needs

Regular inspection helps prevent major issues and extends coating life:

Environmental Impact on Inspection:

Environment Inspection Focus Frequency Critical Checks

Indoor Wear patterns Semi-annual Contact areas

Outdoor Weather damage Quarterly Exposure points

Industrial Chemical attack Monthly High-risk zones

Marine Corrosion signs Monthly Salt exposure

Long-term Care

Proper maintenance strategies ensure maximum coating performance:

Care Requirements by Application:

Application Care Level Special Needs Annual Cost

Architectural Minimal Aesthetic maintenance $0.10-0.30/sq ft

Industrial Moderate Wear monitoring $0.20-0.50/sq ft

Marine Intensive Corrosion prevention $0.30-0.75/sq ft

Pro Tip: Develop a maintenance schedule based on your specific environment and application. Regular care prevents costly repairs and extends coating life.

Conclusion

Making the right choice between anodizing and other coatings requires careful consideration of these seven key questions. Like choosing the right tool for a specific job, each finishing option has its optimal applications.

Remember to consider:

- Performance requirements for your specific use

- Aesthetic needs and limitations

- Weight and dimensional impacts

- Expected service life

- Environmental factors

- Budget constraints

- Maintenance commitments

Need help selecting the right finish for your parts? Contact okdor’s finishing experts for guidance.

Frequently Asked Questions

Anodizing is preferred for threaded components due to minimal dimensional change (0.0002″ per side). Powder coating’s thicker layer (0.002-0.004″) can interfere with thread function.

Powder coating allows for field touch-ups and repairs, while anodized surfaces cannot be repaired once damaged. Consider this for equipment requiring field maintenance.

Temperature cycling impacts anodized surfaces minimally but can cause powder coating to crack or peel. Anodized surfaces remain stable up to 1000°F, while powder coatings typically limit at 400°F.

Anodized surfaces withstand welding heat better than powder coating. Maintain 1-2 inches clearance for anodized surfaces, while powder coating requires 3-4 inches to prevent damage.

Type III anodizing provides superior resistance to industrial cleaners. Powder coating may degrade with repeated exposure to strong cleaning agents.

Anodizing allows tighter tolerances for press-fits and assemblies. Powder coating’s thicker layer requires more clearance and may affect assembly techniques.