We wrote this post because engineering teams consistently struggle with balancing tight budgets and aggressive timelines while maintaining product quality. With experience machining precision components across aerospace, medical, and audio sectors, we’ve identified specific design decisions that create unnecessary manufacturing complexity and cost.

Strategic design optimization can reduce CNC manufacturing costs by 20-40% and lead times by 2-8 weeks through five key approaches: evaluating performance trade-offs early, choosing part architecture strategy, optimizing material selection for availability, simplifying geometry for single-setup machining, standardizing features to leverage common tooling, and planning manufacturing sequences during design phase.

Discover how design choices affect cost, how to manage risks from changes, and ways to communicate manufacturing trade-offs with your team.

Table of Contents

How to Balance Product Performance With CNC Manufacturing Cost?

The biggest cost savings come from distinguishing truly critical features from assumed requirements. Most engineers over-specify by 30-40% because they lack a systematic approach to evaluate what actually impacts product function versus perceived safety margins.

We consistently see this in medical device housing projects where teams specify ±0.005 mm tolerances on non-critical surfaces that perform identically at ±0.05 mm—reducing machining costs by 60% with zero functional impact. The pattern repeats across industries: audio equipment faceplates with complex geometries that add cycle time without improving acoustics, or aerospace brackets with unnecessary tight tolerances on cable routing features.

The solution is simple feature scoring during design reviews. Rate each element 1-5 based on functional criticality. Structural mounting points score 5 and justify premium costs. Cable routing features typically score 2-3 and can use standard hole patterns and larger radii without compromising performance.

When presenting these trade-offs to stakeholders, lead with performance data rather than cost savings. Show tolerance studies or stress analysis proving simplified designs meet requirements. This positions optimization as better engineering, not cost-cutting.

Design Takeaway: Reserve tight specifications only for features that directly impact safety, function, or compliance. Use systematic evaluation to identify optimization opportunities without compromising product performance.

When to Design One Complex Part vs Multiple Simple Components?

Breaking complex parts into 2-3 simpler components typically reduces manufacturing costs by 25-35% and cuts lead times from 4-6 weeks to 2-3 weeks per component. The break-even point occurs when assembly cost stays below 15% of total part cost.

Key decision factors include:

- Setup complexity: Parts requiring more than two setups benefit from component strategy

- Tooling accessibility: Deep pockets or internal features needing specialized long-reach tools

- Assembly requirements: Joint design capabilities and sealing needs

- Volume considerations: Higher volumes favor single parts, prototypes favor components

Audio equipment chassis demonstrate this clearly. Complex single-piece aluminum housings requiring multiple setups and specialized tooling cost $180-220 per part with 5-week lead times. Breaking into base plate, side panels, and faceplate reduces individual costs to $40-60 each with 2-week parallel manufacturing.

Medical device housings often justify single-part complexity when sealing requirements make joints problematic or when regulatory documentation favors fewer assembly steps. The trade-off depends on functional requirements versus manufacturing efficiency.

Design Takeaway: Calculate total cost including assembly labor—if joint costs stay below 15% of machining savings, component strategy typically wins. Use mechanical fasteners for non-critical assemblies, precision dowel pins for alignment-critical applications.

Which Materials Reduce CNC Manufacturing Costs Most?

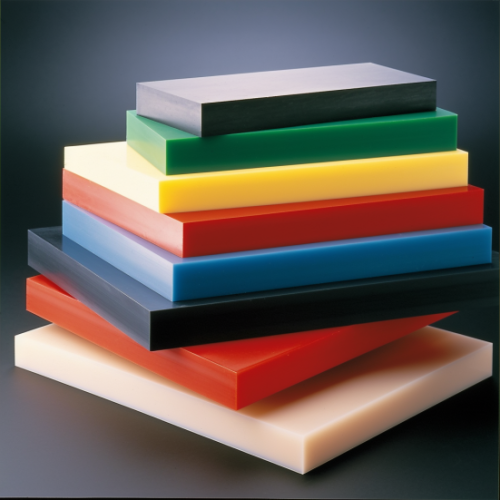

6061-T6 aluminum offers the best cost-performance balance for most CNC applications at $3-5 per pound with 2-week standard lead times. Switching from specialty alloys to 6061 typically reduces material costs by 40-60% while maintaining adequate strength for non-critical structural applications.

Material selection priorities for cost optimization:

- Machinability rating: 6061 aluminum (excellent) vs 304 stainless (good) vs titanium (poor)

- Availability: Common alloys stock locally, specialty materials require 4-8 week lead times

- Tool wear impact: Harder materials increase tooling costs significantly

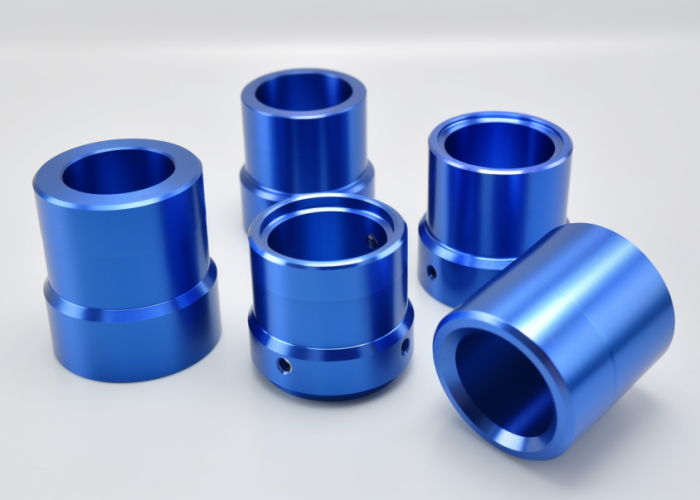

- Post-processing compatibility: Anodizing, plating, coating requirements

The machinability difference translates directly to production costs. 6061 aluminum cuts cleanly with standard HSS tooling and allows aggressive feed rates. Stainless steel demands carbide tooling and generates more heat, requiring coolant systems and slower production speeds. Titanium takes this further—excellent strength-to-weight but machines like hardened steel, making it cost-prohibitive except for aerospace applications.

For corrosion resistance, many engineers default to stainless steel without considering alternatives. 6061 with Type II anodizing provides superior wear resistance and aesthetic options while maintaining easy machinability. Medical device applications requiring ISO 13485 compliance and sterilization cycles do justify stainless steel, but consumer electronics rarely need that level of corrosion protection.

Supply chain stability varies dramatically. We maintain relationships with multiple 6061 and 304 stainless suppliers, ensuring consistent availability. Specialty alloys like Inconel face single-source suppliers and minimum order quantities that can delay projects by months.

Design Takeaway: Start material selection with 6061-T6 aluminum and justify upgrades only when specific properties (biocompatibility, high temperature, extreme strength) are functionally required. Document these requirements clearly to avoid unnecessary material premiums.

What Geometry Changes Reduce CNC Manufacturing Costs?

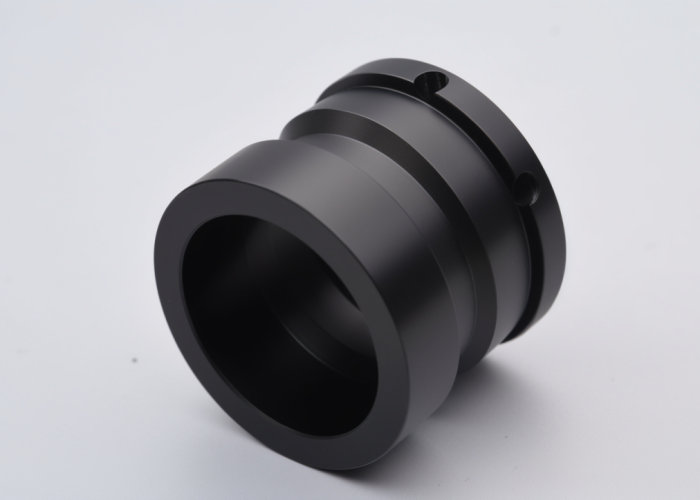

Designing for single-setup manufacturing eliminates part repositioning and reduces labor costs by 30-40%. The most effective changes involve matching internal features to standard tooling and maintaining consistent wall thicknesses that prevent machining deflection.

Geometry optimization priorities:

- Internal corner radii: Match standard end mill sizes to avoid custom tooling

- Wall thickness consistency: Prevent thin sections that require special workholding

- Feature accessibility: Orient primary features for single-sided machining

- Pocket proportions: Control depth-to-width ratios for standard tooling reach

Internal corners present the clearest cost impact. Sharp corners force tiny end mills that vibrate, break frequently, and machine slowly. When we redesign 0.5mm internal radii to 3mm—matching our standard tooling—parts machine 25% faster with better surface finish and fewer tool changes. The 3mm radius also improves stress distribution compared to sharp corners.

Inconsistent wall thickness creates expensive workholding challenges. Thin sections flex under cutting forces, causing dimensional errors and poor surface finish. Audio equipment faceplates often specify 1mm walls for weight reduction, but 2.5mm walls machine more reliably while adding minimal weight penalty.

Deep, narrow pockets force expensive long-reach tooling and create chip evacuation problems. Features deeper than three times their width require specialized tools that cost 3-4x standard end mills and machine at reduced speeds. Stepped pocket designs or through-hole strategies often achieve the same functional goals with standard tooling.

Design Takeaway: Size internal features for standard tooling (1.5mm, 3mm, 6mm radii), maintain structural wall thickness minimums, and orient critical features for single-setup accessibility. These constraints rarely impact product function but significantly reduce manufacturing complexity.

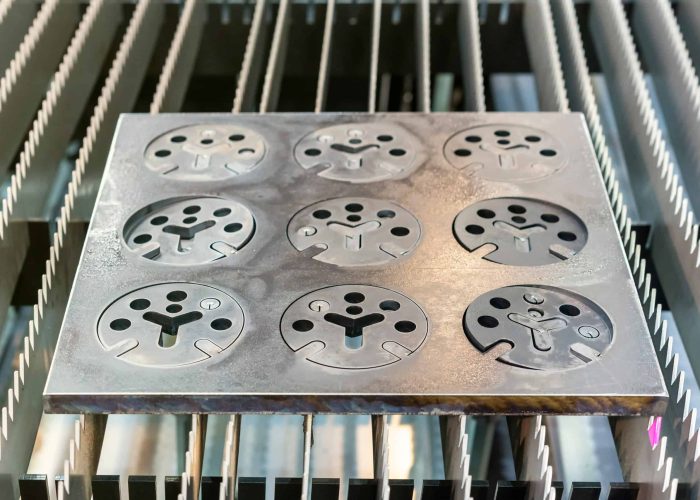

How Much Do Standardized Features Save in CNC Manufacturing?

Using standard hole sizes, thread specifications, and fastener patterns reduces tooling costs by 25-40% and eliminates custom tool delays that add 1-3 weeks to project timelines. Standard features enable predictable machining with established feeds, speeds, and quality parameters.

Cost impact of standardization:

- Tooling availability: Standard sizes use stock tooling vs. custom orders

- Setup efficiency: Established parameters reduce programming time

- Quality consistency: Proven processes minimize scrap rates

- Cross-project benefits: Common tools serve multiple designs

ISO metric threading demonstrates this clearly. M6 x 1.0 standard pitch threads use readily available taps costing $15-25, while M6 x 0.8 fine pitch requires special ordering with 2-week lead times and $75+ tool costs. Audio equipment often specifies fine threads for “premium feel” without functional justification—standard pitch provides identical holding strength per ISO 898 tensile requirements.

Similarly, standard drill sizes (3mm, 6mm, 8mm, 10mm) correspond to common fasteners and stock tooling. Custom 7.2mm holes force special drill orders and complicate future service. We routinely see 30% setup time reductions when designs stick to standard dimensional series.

Design Takeaway: Default to standard hole sizes, thread specifications, and fastener patterns unless custom features provide documented functional benefits. Maintain standard feature libraries to guide design teams toward cost-effective choices.

How to Plan CNC Manufacturing Processes During Design?

Planning manufacturing sequences during design prevents costly redesigns and reduces lead times by 2-4 weeks. Design primary features for single-sided machining while scheduling secondary operations like anodizing (+3-5 days) or plating (+1-2 weeks) during project timeline planning.

Process planning priorities:

- Feature accessibility: Orient critical dimensions for single setup

- Operation sequencing: Plan machining, heat treatment, finishing order

- Surface finish alignment: Match specifications to process capabilities

- Secondary timing: Schedule coating operations early in timeline

Process sequence directly affects quality and cost. Machining anodized surfaces removes coating and requires refinishing. Drilling after anodizing risks coating contamination in threaded holes. Planning these sequences during design reviews prevents expensive process reversals during production.

Surface finish specifications should match manufacturing capabilities. Ra 1.6 μm finishes come directly from machining operations per ISO 4287 surface texture standards, while Ra 0.8 μm requires additional grinding that doubles surface preparation time and cost.

Heat treatment timing affects tolerance achievement. Parts requiring stress relief must be machined semi-finished, then final-machined after treatment to achieve final dimensions—requiring careful fixture and datum planning.

Design Takeaway: Map manufacturing sequences during design reviews and schedule secondary operations early in project timelines. Design features to support intended manufacturing sequence rather than forcing complex workarounds during production.

Conclusion

Strategic design optimization can reduce CNC manufacturing costs by 20-40% and lead times by 2-8 weeks through systematic evaluation of performance requirements versus manufacturing constraints. The key is early collaboration between design and manufacturing teams to balance product functionality with production efficiency. Contact us to explore manufacturing solutions tailored to your product requirements.

Frequently Asked Questions

Type II anodizing adds 0.025-0.050mm coating thickness total. Critical dimensions must account for this buildup, and tight-tolerance features may need post-anodizing machining. Plan anodizing early in the design phase to avoid dimensional conflicts during production.

Titanium typically costs 3-4x more than 6061 aluminum due to slower cutting speeds, specialized carbide tooling, and increased tool wear. Material cost is $15-25/lb vs $3-5/lb for aluminum, plus 50-70% longer cycle times for equivalent parts.

Single-setup machining depends on feature accessibility and geometric complexity. Parts with features on multiple faces requiring tight tolerances between them typically need repositioning. Share your CAD file for setup evaluation and cost comparison between single vs multi-setup approaches.

Standard tolerance is ±0.05mm for most aluminum features. Tighter tolerances like ±0.01mm require additional setup time, temperature control, and inspection—typically adding 25-40% to machining cost depending on feature complexity and material type.

Standard metric threads (M3, M4, M5, M6 x 1.0 pitch) use stock tooling and don’t affect lead time. Custom or fine-pitch threads require tool ordering, adding 1-3 weeks to project timeline plus 25-40% higher tooling costs per part.

3mm minimum wall thickness in aluminum prevents deflection during machining and allows standard cutting speeds. Thinner walls require specialized workholding, slower feeds, and careful programming—increasing both cycle time and setup complexity significantly.