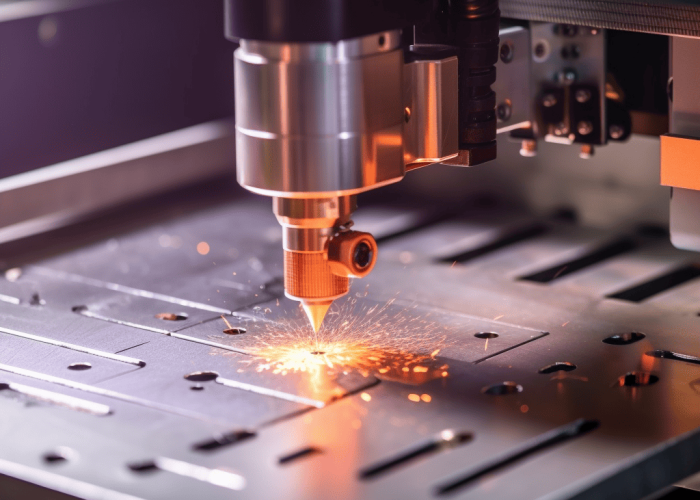

Choosing between conventional EDM and Wire Cut EDM requires matching the right process to your part’s geometry, material, and precision requirements. With extensive experience in aerospace, medical, and industrial precision components, wrong EDM process selection often leads to missed tolerances, extended lead times, or cost escalation.

Use conventional EDM when you need blind cavities, 3D complex shapes, or textured surfaces that require custom electrode access. Choose Wire EDM when cutting through-thickness profiles, achieving tolerances tighter than ±0.0002″, or creating sharp internal corners in hardened materials. Wire EDM is preferred for high-precision 2D cuts, while conventional EDM handles complex 3D geometries.

Learn how geometry, materials, and tolerances guide EDM selection—and when conventional machining offers a better solution.

Table of Contents

Which EDM process works better for complex geometries?

Conventional EDM excels at creating complex 3D cavities, blind pockets, and intricate internal features using custom-shaped electrodes. Wire EDM is limited to 2D profiles that cut completely through the part thickness but can achieve precise contours and sharp corners down to 0.002″ radius that electrodes cannot reach. The geometry of your part determines which process is feasible.

We routinely machine complex mold cavities using conventional EDM, creating intricate 3D shapes with undercuts up to 12″ deep according to ISO 13485 standards. Wire EDM produces precise 2D profiles, handling slots as narrow as 0.004″ with tolerances down to ±0.0001″. However, wire EDM struggles with slots deeper than 50 times their width due to wire deflection.

Quick decision criteria: If your part has blind holes, internal cavities, or undercuts, choose conventional EDM. If you need through-cutting with feature widths under 0.006″ or sharp internal corners under 0.005″ radius, select Wire EDM. Parts requiring internal threads always need conventional EDM.

In injection mold manufacturing, conventional EDM creates complex cooling channels and cavity details in hardened H13 tool steel. Wire EDM works best for through-slots and precise cutouts where sharp corners are critical. Wire EDM requires entry/exit points but enables features conventional electrodes cannot create due to access limitations.

Design Takeaway: Use conventional EDM for blind cavities, undercuts, and 3D complex shapes. Select Wire EDM for through-cutting applications needing sharp corners, narrow slots, or precise 2D profiles.

Can EDM and Wire EDM cut hardened steel and exotic alloys?

Yes, both EDM processes cut hardened steel up to 72 HRC, titanium, Inconel, and carbide without tool wear since they use electrical discharge rather than mechanical cutting. Any electrically conductive material works regardless of hardness, but exotic alloys like titanium cost 2-3x more due to slower cutting speeds.

We routinely machine hardened 4140 steel (50-55 HRC), D2 tool steel, Ti-6Al-4V, and Inconel 718 using both processes according to AS9100 standards. However, your material choice significantly impacts both timeline and budget. Titanium cuts beautifully with EDM but runs 30% slower than steel, typically doubling machining costs due to extended cycle times. Inconel 718 presents even greater challenges—expect 50% longer lead times and roughly triple the standard EDM rates.

Material behavior varies considerably across common grades. Aluminum 6061 EDMs well but may require secondary finishing to achieve smooth surfaces, while stainless steel grades like 304 and 316 machine cleanly at standard rates. The precipitation-hardened 17-4 PH stainless requires stress relief considerations that can affect dimensional stability. Copper creates electrode contamination issues in conventional EDM but works excellently with Wire EDM’s continuous wire feed.

Both processes handle work-hardening materials like 17-4 PH that become problematic in conventional machining, maintaining consistent cutting rates regardless of hardness while conventional EDM may require premium electrode materials for exotic alloys, adding 15-25% to tooling costs.

Design Takeaway: Choose EDM when material hardness exceeds 45 HRC or contains work-hardening alloys. Budget 2-3x standard rates for titanium and Inconel, but expect consistent quality regardless of material hardness.

Does Wire EDM hold tighter tolerances than conventional EDM?

Yes, Wire EDM holds tighter tolerances of ±0.0001″ to ±0.0002″ compared to conventional EDM’s ±0.0005″ to ±0.001″ capability. Wire EDM‘s superior precision comes from consistent wire diameter and computer-controlled path accuracy, but costs 40-60% more than conventional EDM.

We consistently hold ±0.0001″ on Wire EDM parts using climate-controlled machining and CMM verification. Conventional EDM achieves ±0.0005″ on cavity dimensions with proper electrode manufacturing. The reality is that most engineers over-specify tolerances. We’ve found that ±0.0003″ handles most precision assembly requirements without the premium pricing that comes with ultra-tight specifications, while ±0.0005″ works perfectly for conventional EDM cavities unless functional requirements truly demand tighter control.

Feature geometry affects achievable tolerances significantly. Holes typically hold tighter tolerances than complex slots, while thin wall thickness control depends heavily on material stress relief during the EDM process. Going from ±0.001″ to ±0.0002″ roughly doubles both machining time and inspection requirements, which drives the cost premium beyond just machine time.

Wire EDM maintains consistent accuracy across entire cut paths thanks to computer control and continuous wire replacement. Conventional EDM tolerances depend more heavily on electrode wear patterns and spark gap control throughout the cutting cycle. For critical applications requiring documented repeatability—like medical device components or aerospace parts—Wire EDM’s consistent performance often justifies both the process selection and premium cost.

Design Takeaway: Specify the loosest tolerance that meets function—±0.0003″ handles most precision work effectively, while ±0.0001″ should be reserved for critical bearing fits or sealing surfaces where function truly demands it.

Which EDM process is faster for production parts?

Wire EDM is typically faster for simple 2D profiles and thin sections, while conventional EDM becomes more efficient for complex 3D cavities and multiple identical features. Setup time varies significantly—Wire EDM starts cutting immediately, but conventional EDM requires electrode manufacturing that can add 1-3 days to your project timeline.

Speed depends heavily on your part complexity and volume requirements. For single prototypes with straightforward profiles, Wire EDM often delivers parts within 24-48 hours since there’s no tooling to manufacture. However, if you need multiple identical cavities or complex 3D shapes, conventional EDM becomes more efficient once the initial electrode investment is made. The electrode can produce dozens of identical features without the wire’s need to recut each part individually.

Material thickness significantly affects the speed equation. Wire EDM handles thick sections but slows down considerably—a recent order included 2.5-inch-thick steel parts that required 60 hours of rough cutting over a weekend. Conventional EDM maintains relatively consistent cycle times regardless of material thickness, though small features typically take 2-6 hours minimum for decent finish.

Consider your production volume carefully. Wire EDM excels for one-off prototypes and low-volume runs where setup flexibility matters most. Conventional EDM justifies electrode manufacturing time when producing multiple parts using multi-up electrodes that can machine several components simultaneously, significantly boosting productivity for production runs.

Design Takeaway: Choose Wire EDM for quick prototypes and simple profiles where immediate turnaround matters. Select conventional EDM when you need multiple identical features or complex 3D shapes, accepting longer initial setup for better production efficiency.

Is Wire EDM or conventional EDM more cost-effective?

Wire EDM costs less upfront since it requires no custom electrodes, but conventional EDM becomes more economical for multiple parts or complex 3D features. Wire EDM typically runs $60-200 per hour, while conventional EDM ranges $60-150 per hour plus electrode manufacturing costs of $500-2000 depending on complexity.

The cost equation shifts based on your specific requirements. For single prototypes or simple profiles, Wire EDM wins with no tooling investment—shops report around $4-5 per square inch for single rough cuts. However, conventional EDM becomes cost-effective when producing multiple identical parts since the electrode cost spreads across higher volumes, and you avoid re-cutting each part individually.

Wire consumption represents the single highest expense in Wire EDM operations, with even basic brass wire costing $5-6 per pound. Modern machines consume 0.5-1.2 pounds per hour, meaning annual wire costs can range from $5,000-12,000 for a busy machine. Conventional EDM uses expensive graphite electrodes but typically has lower consumable costs during operation.

Think about break-even volume realistically. Wire EDM suits urgent prototypes where time matters more than absolute cost efficiency. Conventional EDM makes sense for production runs of 3-5 parts or more, especially for complex mold cavities or designs requiring future reproduction since electrodes can be stored and reused.

Design Takeaway: Choose Wire EDM for single parts, prototypes, or urgent projects where tooling costs don’t justify the volume. Select conventional EDM when producing multiple parts, complex 3D features, or designs requiring future reproduction.

What design changes are needed for different EDM processes?

Wire EDM requires planning entry/exit points on non-critical surfaces and adding 0.006-0.012″ to CAD dimensions for kerf compensation. Conventional EDM needs straight electrode access paths, 0.5-1.0 degree draft angles, and minimum 0.005″ corner radii for practical electrode manufacturing.

Design planning becomes critical when choosing between EDM processes. Wire EDM creates small witness marks (0.010-0.030″ diameter) where cutting starts and finishes. Plan these entry/exit points on non-critical surfaces like the back side of faceplates or areas for secondary machining. For thin walls under 0.030″, add temporary support bridges to prevent deflection during cutting.

Conventional EDM requires straight-line electrode access without hitting part geometry. Features closer than 0.050″ to part edges may need redesign or multiple setups. Draft angles of 0.5-1.0 degrees help electrode withdrawal and improve surface finish for deep cavities over 1″ depth.

Kerf width affects final dimensions significantly. Wire EDM removes 0.006-0.012″ total material width (wire diameter plus spark gap). Account for this in CAD dimensions, especially for tight-fitting assemblies. Conventional EDM dimensions match electrode geometry exactly, but electrode wear affects sizes on production runs.

Part stability during cutting maintains tolerances. Wire EDM cuts release internal stresses causing movement—design with temporary holding tabs or planned cutting sequences. For delicate features like thin ribs, consider conventional EDM to avoid through-cutting stress release.

Design Takeaway: Plan Wire EDM entry/exit points on non-critical surfaces and add 0.006-0.012″ to CAD dimensions for kerf compensation. Design conventional EDM with straight electrode access, 0.5-1.0 degree draft angles, and minimum 0.005″ corner radii.

Which process gives me the surface finish I need?

Choose Wire EDM for Ra 32-125 µin smooth finishes on sealing surfaces and cosmetic parts. Select conventional EDM for Ra 125-250 µin when you need specific surface textures, paint adhesion preparation, or controllable mold cavity finishes that Wire EDM cannot provide.

Surface finish requirements often drive process selection based on end-use applications. For O-ring sealing surfaces, specify Wire EDM to achieve Ra 32 µin or better for reliable sealing. Cosmetic aluminum parts requiring anodizing work best with Ra 63 µin maximum to avoid visible machining marks. Paint adhesion applications need Ra 125-250 µin texture, making conventional EDM ideal without additional surface prep.

Conventional EDM offers controllable surface textures through electrode selection. Graphite electrodes create specific mold cavity textures—from fine 32 µin for optical clarity to aggressive 250+ µin for grip surfaces. Copper electrodes produce mirror-like finishes under Ra 32 µin for precision sealing, while specialty electrodes create unique decorative or functional patterns.

Cost impacts vary significantly with surface requirements. Achieving Ra 32 µin with Wire EDM adds 30-50% to cycle time compared to standard Ra 125 µin finishes. Conventional EDM surface costs depend on electrode preparation—mirror finishes require premium copper electrodes, adding $200-500 to electrode costs.

Application-specific requirements determine process selection. Gasket grooves need Ra 32 µin smoothness—Wire EDM delivers consistently. Injection mold cavities requiring specific textures need conventional EDM’s controllable characteristics. Audio faceplates benefit from Wire EDM’s smooth finish that eliminates manual polishing.

Design Takeaway: Specify Wire EDM for sealing surfaces (Ra 32 µin), cosmetic parts requiring smooth finishes, or eliminating secondary polishing. Choose conventional EDM for functional textures, paint prep (Ra 125-250 µin), or mold cavity texturing.

Conclusion

EDM process selection depends on your part geometry, material requirements, and surface finish specifications. Wire EDM excels for tight tolerances and smooth finishes on 2D profiles, while conventional EDM handles complex 3D cavities and textured surfaces. Contact us to explore manufacturing solutions tailored to your precision part requirements.

Frequently Asked Questions

Most EDM shops accept single prototype quantities with no minimum order requirements. Setup fees range from $100-500 depending on complexity. Production runs of 10+ parts often reduce per-piece costs significantly, especially for conventional EDM with reusable electrodes.

STEP (.stp) and IGES (.igs) files work best for EDM programming since they preserve 3D geometry accurately. Include material specifications, tolerances, and surface finish requirements in your drawings. Most EDM shops can work from PDF prints for simple 2D Wire EDM profiles.

Wire EDM typically delivers simple profiles in 24-48 hours with no tooling delay. Conventional EDM requires 1-3 days for electrode manufacturing plus machining time, but becomes faster for multiple identical parts since electrodes can produce dozens of components.

EDM typically costs 2-5x more than conventional machining but becomes cost-effective when machining hardened materials above 45 HRC or achieving tolerances tighter than ±0.001″. Consider EDM when conventional tools would wear quickly or when complex geometries are impossible to machine.

Specify ±0.001″ for most EDM applications to balance cost and performance. Reserve ±0.0002″ tolerances only for critical fits or sealing surfaces. Looser tolerances reduce both machining time and inspection costs significantly while meeting most functional requirements.

Many EDM shops offer deburring and basic finishing, but anodizing typically requires specialized vendors. Wire EDM produces minimal burrs compared to conventional machining. Ask your EDM shop about partnerships with local finishing services for one-stop project management.