Imagine turning a plain metal object into a corrosion-resistant, electrically conductive, and visually stunning piece. That’s the magic of electroplating. This transformative process isn’t just about gold plating your jewelry or nickel plating for wear resistance; it’s a fundamental technique that gives metals a superpower against atmospheric corrosion and wear.

Table of Contents

Electroplating has roots that intertwine with the history of chemistry itself. From the first modern electroplating plant to today’s advanced electrical components, the evolution of plating metals has been nothing short of revolutionary.

It’s a tale of transforming chemical composition into bright metal finishes that protect and enhance everything from silver-plated jewelry to integrated circuits.

The Basics of Electroplating

Electroplating is a meticulous plating process that adorns objects with a metal coating using an electric current. This transformative procedure not only elevates the visual appeal of items but also fortifies them with enhanced features such as superior corrosion resistance, augmented hardness, and improved wear resistance.

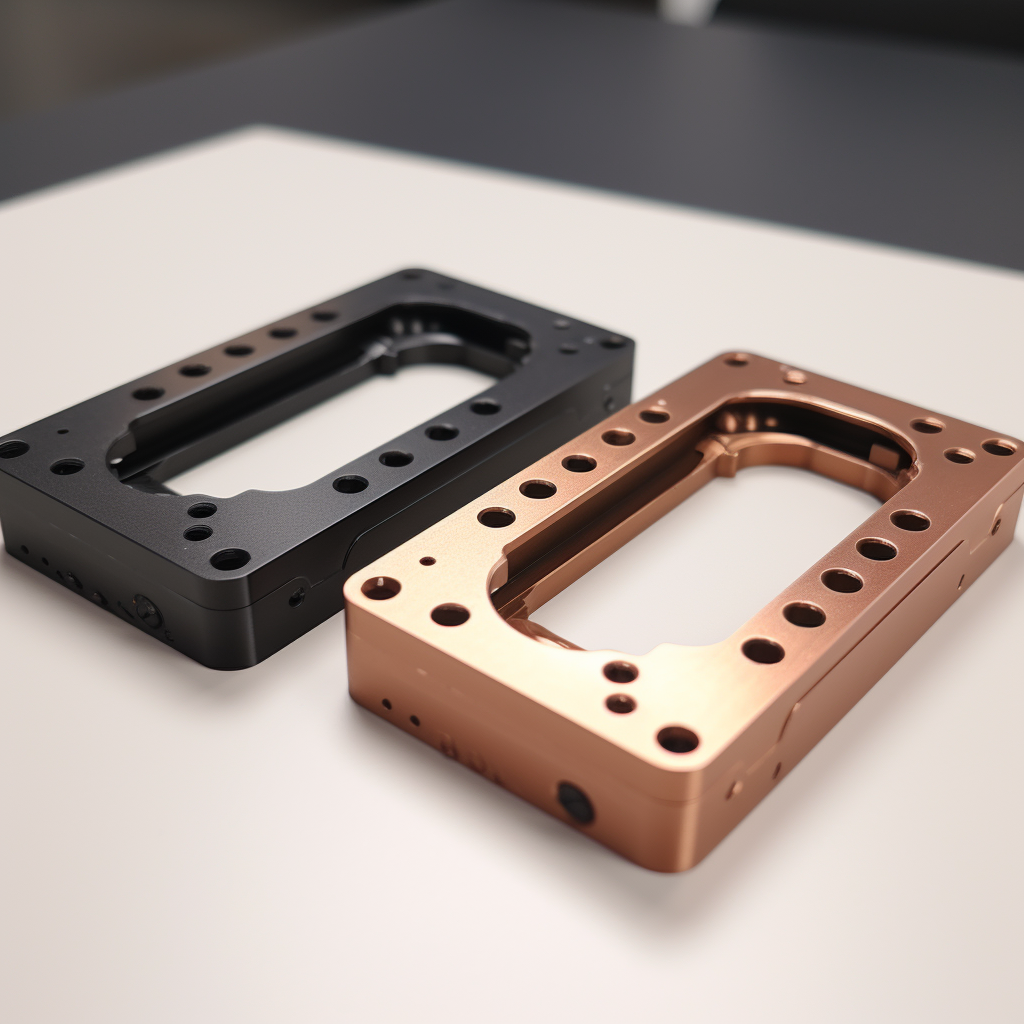

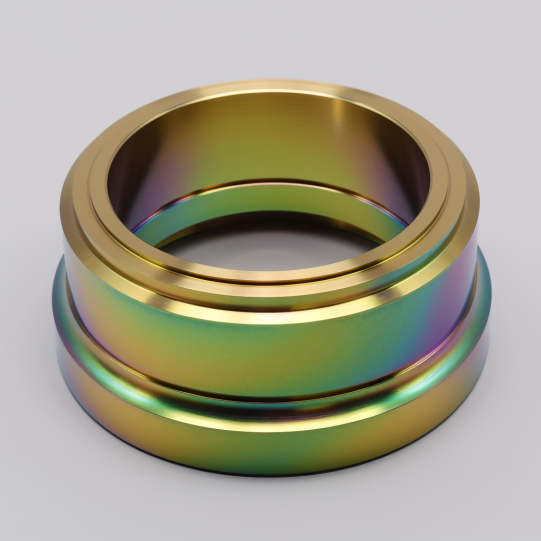

Vibrant Hues of Electroplating

The allure of electroplating lies in its ability to infuse objects with a variety of colors, each representing a different metal used in the process:

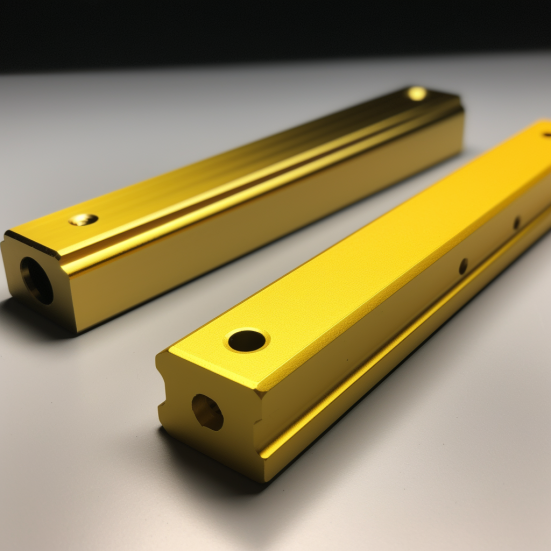

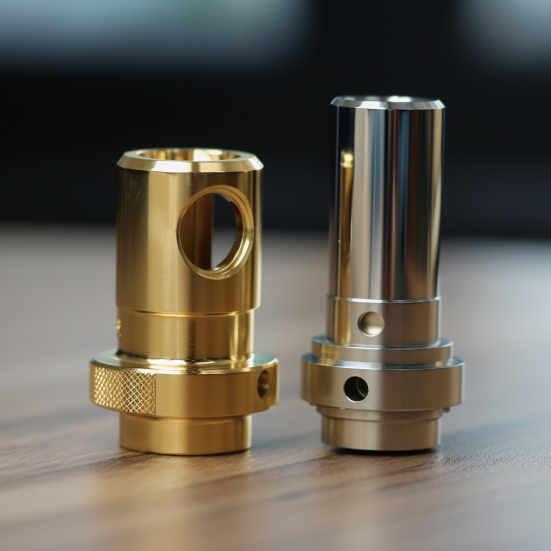

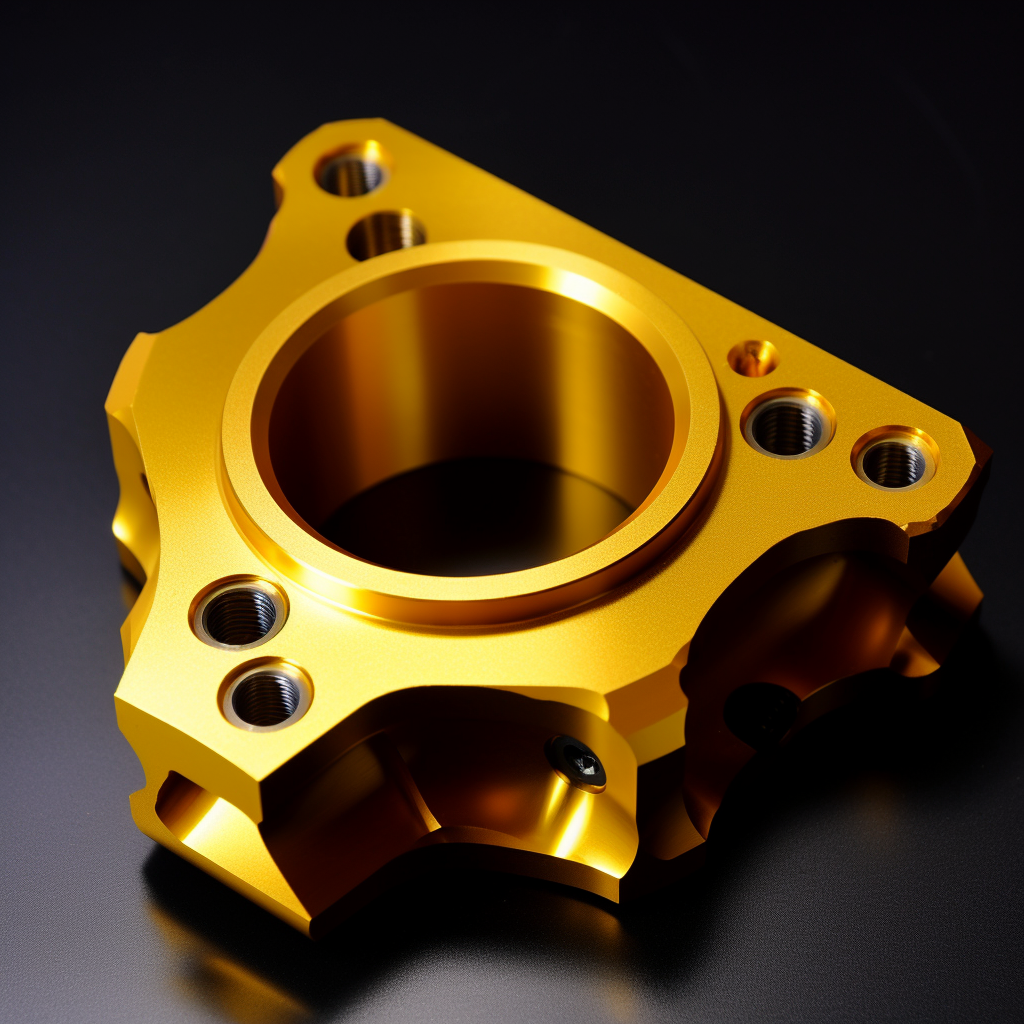

– Gold Plating: Bestows a luxurious, shiny yellow sheen.

– Silver Plating: Imparts a radiant, pure white glow.

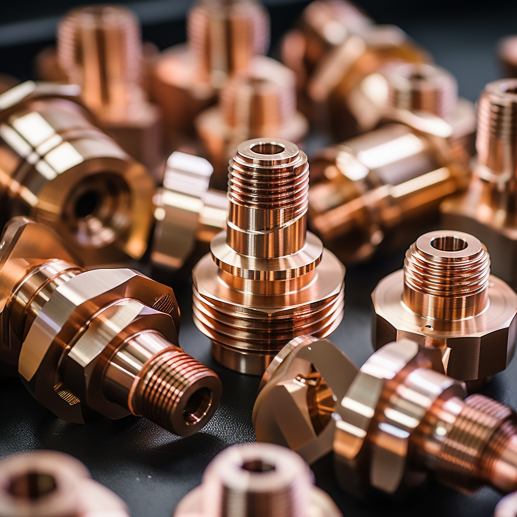

– Copper Plating: Offers a warm, reddish-orange tint.

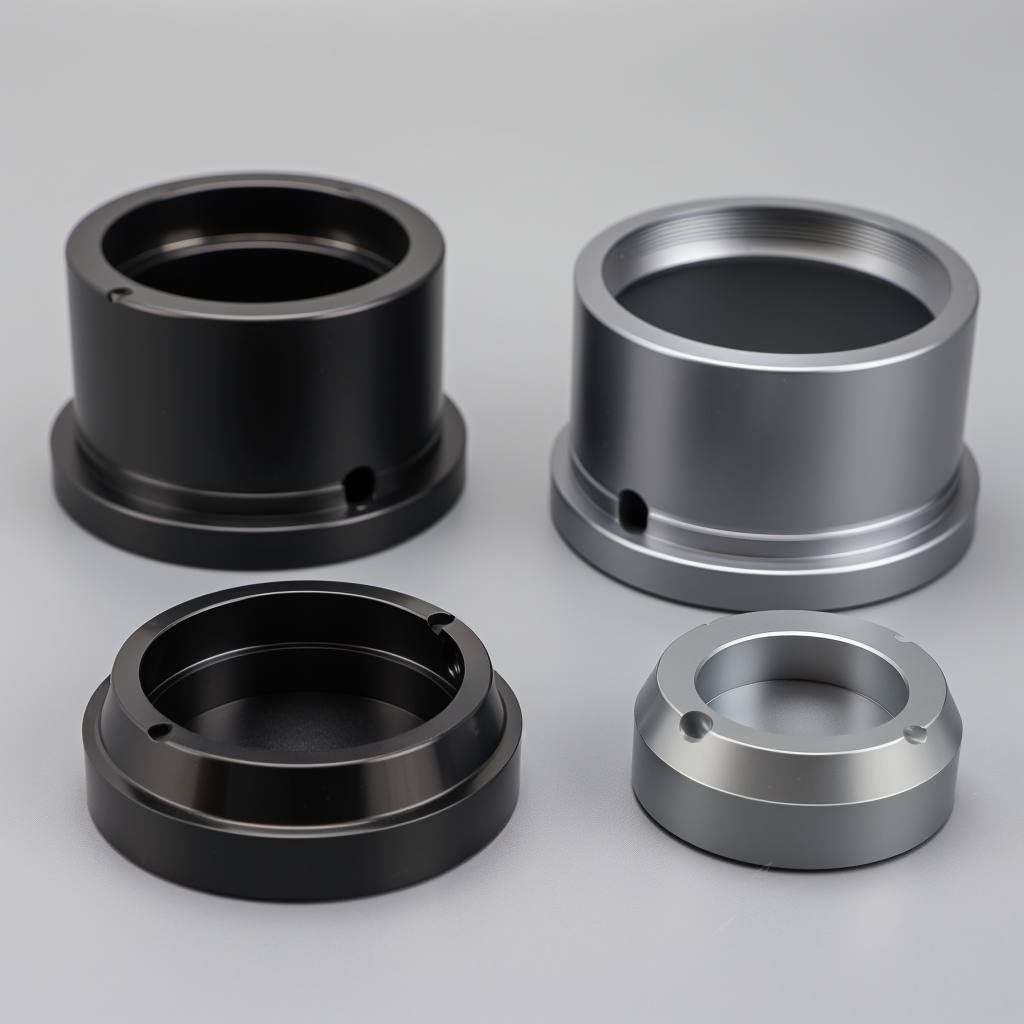

– Nickel Plating: Provides a lustrous, silvery appearance with a subtle yellow cast.

– Chrome Plating: Delivers a mirror-like, blue-tinged brilliance.

Precision in Thickness

The thickness of the electroplated layer is a game of precision tailored to the item’s intended use. Decorative coatings might be as delicate as 0.1 to 0.5 microns, while functional layers for corrosion protection or wear resistance can be more robust, ranging from 5 to 100 microns or more. The uniform coating achieved through this process is a testament to the meticulous control of the plating parameters.

In the heart of the electroplating bath, the copper sulfate solution plays a pivotal role, especially in copper plating. It serves as the electrolyte that facilitates the transfer of copper ions from the copper anode to the substrate, ensuring a consistent and uniform coating. The metal salt within the solution is crucial, as it determines the quality and characteristics of the final plated layer.

How Does Electroplating Work?

Here’s how the electroplating circuit brings a metal’s makeover to life:

1. Prep and Polish: The metal object gets a thorough clean-up, prepping it for electroplating work.

2. The Electrolytic Cell: Into the plating solution it goes, where our metal becomes the cathode, ready for its transformation.

3. Power Up The power supply kicks in, and positively charged metal ions journey toward the negatively charged electrode.

4. Layering Magic: These ions deposit a thin coating, layer by layer, whether for continuous or barrel plating.

5. Rack ’em Up: For larger items, rack plating ensures surface uniformity and precise plate thickness.

6. Finishing Touches: After the plating occurs, the item emerges with a new outer coating, boasting improved properties and a shiny new look.

Through this process, electroplating is widely used for electroplating plastics, creating uniform coatings for manufacturing processes, and even producing precious metal finishes on different metals. It’s a world where copper anodes and dissolved metal cations meet to create everything from the thin coatings on your smartphone to the bright finish on your car’s trim.

Metals and Materials in Electroplating

The Electroplated Ensemble: Gold, Nickel, and Copper

In electroplating, metals like gold, nickel, and copper take center stage.

Gold plating, with its exceptional corrosion resistance and electrical conductivity, isn’t just about luxury—it’s about precision and performance.

Nickel plating follows suit, offering a robust shield of wear resistance and a lustrous finish that’s as practical as pleasing to the eye.

Copper plating, facilitated by a copper sulfate plating solution, is the unsung hero, providing a thin layer of metal that enhances electrical conductivity without breaking the bank.

Bestowing Superpowers with Metal Atoms

The electroplating process is a marvel of metal deposition. It’s a chemical reaction where positively charged ions, like those of gold, nickel, or copper, journey from the anode to the negative electrode, the substrate material, in an electrolyte solution.

A plated layer results from this journey, powered by an electric current. It’s a transformation, a metamorphosis where dissolved metal ions become a solid, corrosion-resistant coating metal through electroplating methods like barrel plating, rack plating, or continuous line plating.

From Rack to Mass: The Versatility of Electroplating

Whether it’s the uniformity of rack plating or the efficiency of mass plating, the electroplating process adapts to the needs of the manufacturing process. The result?

A thin layer of metal that’s electroplated onto plastics, metals, and other materials, enhancing everything from the wear resistance of hand tools to the glossy gold coating on high-end audio connectors.

The plating metal, whether for silver plating or copper electroplating, is chosen for the desired metal properties it imparts—be it for electroplating applications in aerospace or the continuous plating of automotive parts.

The Charged Dance of Electroplating Solutions

In the electrolytic ballet of electroplating, every component plays a pivotal role. The power supply hums as it orchestrates the flow of electric current, prompting metal salts to dissolve and release metal ions.

These positively charged metal ions are then drawn to the substrate, bonding to create a corrosion-resistant and aesthetically pleasing finish. The types of electroplating are as varied as their applications, with each plating method tailored to the specific requirements of the substrate material and the end-use of the electroplated product.

Applications of Electroplating

Electroplating: The Industry's Secret Weapon

Electroplating isn’t just a process; it’s a game-changer. Take nickel plating, for instance. It’s not merely a layer; it’s a shield that grants endurance to the automotive parts that power your commute. In electronics, copper plating does more than cover surfaces; the conductor keeps your devices alive and kicking, ensuring seamless connectivity and performance.

Tailored Solutions: Electroplating's Role Across Industries

Electroplating adapts like a chameleon to industry needs. In aerospace, the precision of barrel plating ensures that every component can withstand the rigors of the skies. Rack plating, on the other hand, offers a bespoke touch to larger parts, providing corrosion protection and wear resistance that’s second to none.

Advantages and Considerations

Beyond Aesthetics

Electroplating isn’t just about aesthetics; it’s about adding a layer of invincibility. It’s a chemical reaction that transforms vulnerable surfaces into bastions of durability, offering corrosion resistance that extends the life of metal parts. And when it comes to functionality, the positive electrode in the electroplating circuit doesn’t just attract; it engineers a surface that’s ready for action.

Navigating the Trade-offs

For all its perks, electroplating comes with its own set of trade-offs. Precision is paramount; a misstep in the electroplating solution can lead to a more-than-stellar finish. And while we’re mastering the reduction of dissolved metal cations, we’re also juggling the environmental implications. Electroplating is a craft that demands a balance between achieving that perfect metal electroplating finish and maintaining ecological harmony.

Environmental and Safety Aspects

Electroplating and Mother Nature: Striving for Harmony

Electroplating, while a marvel of modern engineering, doesn’t come without its environmental footprint. The process, if not managed with care, can introduce metals and chemicals into our ecosystems. But here’s the good news: the industry is on it, innovating cleaner, greener methods to reduce waste and recycle water. It’s not just about making parts last longer; it’s about ensuring our planet does, too.

Safety First: The Electroplater's Creed

In electroplating, safety isn’t an afterthought—it’s the main event. Professional setups are akin to well-oiled machines, with protocols that could rival any high-security operation. From proper ventilation to avoiding caustic fumes to rigorous training in handling chemicals, electroplating professionals are the unsung heroes who make sure every piece comes out not just coated but also safe.

Cost Factors

When it comes to electroplating, the allure isn’t just in the shiny finish; it’s also in the savvy investment. But before you dive into the electroplating pool, let’s talk brass tacks—specifically, what will affect the weight of your wallet.

- Material Costs: Think of metals like a high-end buffet. Gold and silver? They’re your lobster and caviar. Nickel and copper are more like your bread and butter—essential but won’t have you breaking the bank. Remember, the market’s mood swings will play a part in pricing these metals, so keep an eye on those trends.

- Surface Preparation: Just like you wouldn’t paint over a dirty wall, you can’t plate on a grimy surface. Getting that substrate squeaky clean and ready for its metal coat can be like prepping for a black-tie event—it needs to be just right, and meticulous attention to detail can add to your tab.

- Plating Method: Are we talking about a quick dip or a full spa treatment? Barrel plating can handle many parts simultaneously, making it the cost-effective choice for the little guys. Rack plating, on the other hand, is like giving each part its butler, which can bump up the price.

- Complexity of the Part: If your part has more nooks and crannies than an English muffin, it will need extra TLC during plating. And just like those artisanal breads, intricate designs come with a gourmet price tag.

- Thickness of the Plating: Here’s where you decide between a light jacket and full armor. Thicker plating not only lasts longer but also costs more. It’s a classic case of pay now or pay later.

- Volume and Batch Size: Bulk buying isn’t just for warehouse stores; it applies to electroplating, too. The more you plate in one go, the less you pay for each celebrity-worthy finish.

- Quality and Specification Requirements: High standards mean high costs. If your parts need to strut down the quality runway, expect to pay for those extra inspections and touch-ups.

- Environmental and Safety Regulations: Going green isn’t just good for the planet; it’s the law. But all those filters and treatments to keep Mother Nature smiling? They’re not free.

- Energy Consumption: Electroplating can be an energy hog, especially for heavy-duty jobs. And as we all know, utilities are a bit like a hungry teenager—they can eat into your budget fast.

- Labor Costs: Good help is hard to find, and it’s not cheap either. Skilled technicians are the artists of the electroplating world, and their expertise comes at a premium.

- Post-Plating Processes: Sometimes, a part needs some extra pampering after plating. Whether it’s a stress-relieving bake or a protective topcoat, these spa treatments for your parts will appear on the final bill.

- R&D and Customization: Need something out of the ordinary? Custom work and innovation are like ordering off-menu—it will cost extra, but it might just be worth it for that one-of-a-kind finish.

So, when weighing the pros and cons of electroplating, remember that quality doesn’t come cheap—but it’s an investment that can pay off in durability, functionality, and sheer good looks.

Innovations and the Future of Electroplating

Electroplating is a field where tradition meets innovation. Picture this: a world where copper plating isn’t just about the shiny exterior but also the smart, functional surfaces it creates. The electroplating process of tomorrow is being redefined today, with researchers finding ways to reduce dissolved metal cations more efficiently and developing plating solutions that are kinder to our planet.

Imagine electroplating methods that allow us to electroplate plastics with the finesse of a master jeweler, creating components that could revolutionize industries. The future is about more than just copper anodes and line plating; it’s about harnessing positive ions in plating solutions for mass plating operations that are as environmentally responsible as they are technologically advanced.

Choosing the Right Electroplating Service

Beyond Basic Copper Plating

When it’s time to choose an electroplating service, think beyond the basic copper plating. You want a partner who understands the nuances of the electroplating process and offers a range of plating solutions to meet your specific needs. Whether for corrosion resistance, aesthetic appeal, or enhancing electrical conductivity, the right service should offer a tailored approach to your electroplating applications.

Tailored Plating Methods for Optimal Results

Ask about their plating methods. Do they offer electroless plating for a more uniform coat? Can they handle the intricacies of plating metal with complex geometries? Inquire about their use of metal salts in the plating solution and how they manage to reduce dissolved metal cations effectively.

Transparency and Quality Assurance

A reliable service provider will be transparent about their process, from mass plating with copper anodes to the final inspection of the electroplated piece. They should be able to articulate how their plating solutions enhance the properties of other metals and the longevity of the plating itself.

Conclusion

We’ve delved into electroplating’s complexities, from the resilience of copper plating to the precision of electroless plating. This process is crucial across various sectors, impacting product functionality and aesthetics.

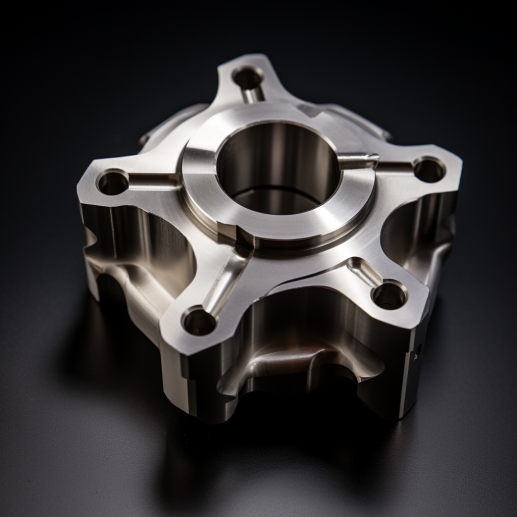

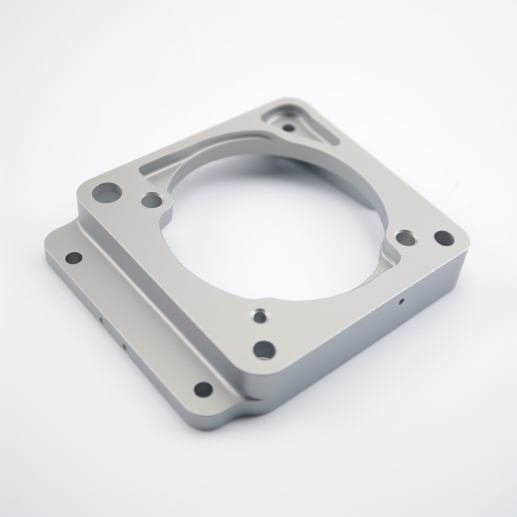

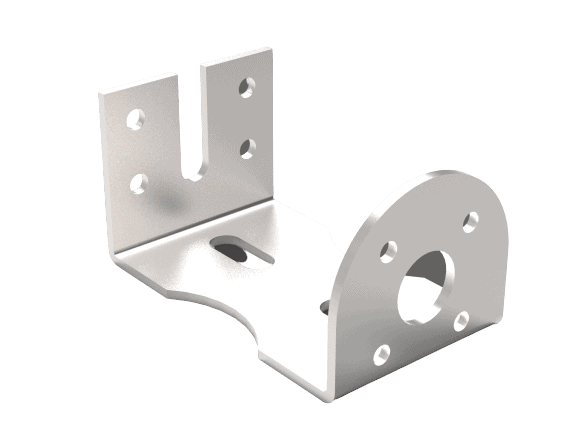

Partnering with okdor

For custom part manufacturing that includes expert surface finishing, consider Okdor as your go-to collaborator. Our proficiency in CNC machining, sheet metal fabrication, and progressive die stamping, coupled with our commitment to quality, positions us to meet your project’s unique demands. Contact us at sales@okdor.com to discuss how we can contribute to your success.

Frequently Asked Questions

it can last for years

The longevity of an electroplated coating depends on several factors, including the thickness of the plating, the type of metal used, the environment the item is in, and how the plated item is used. For example, a thick nickel plating might last decades under normal conditions, while a thin layer of silver might tarnish more quickly.

Electroplated metals can rust if the plating is damaged, exposing the underlying metal, or if the plating metal itself is prone to oxidation. For instance, iron plated with a thin chrome layer will rust if the chrome layer is breached, while gold plating typically does not rust because gold is highly resistant to oxidation.

Electroplating costs can vary significantly depending on the material used. Gold plating, for instance, is on the pricier end due to the high cost of the metal itself. In contrast, plating with metals like zinc or nickel is generally more affordable. The overall cost also factors in the complexity of the part being plated, the thickness of the metal layer required, and the volume of parts processed.

The “best” type of electroplating depends on the application. For wear resistance, hard metals like chromium are sought, while for electrical conductivity, gold or silver might be better. For corrosion resistance, nickel and zinc are common choices.

Common metals used for electroplating include brass, cadmium, chromium, copper, gold, iron, nickel, silver, titanium, and zinc. The substrate must be conductive, but with modern techniques, even non-conductive materials like plastic can undergo plating after being made conductive with a special coating.

1. Increasing the durability and lifespan of parts, such as in aerospace components.

2. Enhancing the aesthetic appeal of items, like jewelry and art pieces.

3. Improving the electrical conductivity of components, such as antennas and electrical connectors.

4. Adding corrosion resistance to various parts, which is essential in automotive and marine applications.

5. cost-effectively creating prototypes and custom parts, often combined with 3D printing.

Preparation typically involves cleaning the substrate to remove any oils, dirt, or oxides, including polishing, sandblasting, or chemical cleaning. The substrate needs to be activated with a special solution to ensure good plating adhesion.

For more detailed and specific information, consult with a professional electroplating service provider or look into technical resources on the subject.