Getting shocked by end mill machining quotes? You’re not alone. After years of machining custom parts for product developers across aerospace, audio, and medical sectors, we’ve seen the same costly design mistakes repeated – turning simple parts into budget nightmares.

Most expensive end mill quotes stem from seven design issues: sharp internal corners requiring special tooling, thin walls causing deflection, deep features needing long tools, poor material selection, over-tight tolerances, multiple setup requirements, and unnecessary geometric complexity. Fixing these can cut costs 30-50%.

Learn exactly what drives up end mill costs and get practical design fixes that can slash your machining budget without compromising part function or quality.

Table of Contents

Can End Mills Actually Cut the Corners I Drew?

Your sharp corners are killing your budget because end mills are round tools that can’t cut sharp angles. That innocent corner in your CAD forces shops to quote expensive wire EDM ($200/hour) instead of standard milling ($75/hour). Adding 0.5mm radius to internal corners typically cuts quotes by 60-70% with zero functional impact.

We machine thousands of parts monthly and see this cost trap constantly. A 3mm end mill physically creates 1.5mm radius – when prints show sharp corners, shops assume you need wire EDM precision. In 6061 aluminum, we hold ±0.02mm on 0.5mm radii using standard tooling, verified with CMM inspection. For 304 stainless steel, 0.3mm is the practical minimum before excessive tool wear.

A 0.5mm radius is thinner than a credit card edge – functionally invisible to the naked eye but dramatically easier to manufacture. Your parts will look identical and perform the same, but cost 60-70% less to produce. Sharp corners actually weaken parts by creating stress concentrators where cracks can start.

ISO 2768 general tolerances don’t specify corner radii, so unmarked drawings default to expensive sharp corner assumptions.

Material Min Radius Cost vs Sharp Finish Achievable

6061 Aluminum 0.5 mm 65% savings Ra 1.6 μm

304 Stainless 0.3 mm 70% savings Ra 0.8 μm

POM Plastic 0.2 mm 60% savings Ra 3.2 μm

Design Takeaway: Open your CAD file and add 0.5mm fillets to all internal corners (Insert > Features > Fillet in SolidWorks). This 2-minute change prevents EDM charges and keeps you in standard CNC pricing, saving hundreds per part.

What Happens If My Walls Are Too Thin for End Mills?

Your thin walls are about to turn into expensive potato chips. When walls are too thin, they flex away from the cutting tool like a diving board, creating parts that are warped, out-of-spec, or completely destroyed. Walls under 1.5mm thick cause deflection problems that can ruin entire batches and cost you hundreds in scrapped parts.

Here’s the brutal reality we see daily: a designer sends us a beautiful 0.8mm wall design, we machine the first part, and it comes out looking like a bent taco shell. In 6061 aluminum, walls under 1.2mm deflect 0.1-0.3mm during cutting, verified through CMM measurement. Your ±0.05mm tolerance just became ±0.3mm. Total scrap.

But here’s what really hurts – you don’t find out until after we’ve machined 20 parts at $50-200 each. For stainless steel, deflection starts at 1.8mm thickness due to higher cutting forces. Surface finish drops to Ra 6.3 μm or worse when walls flex during cutting.

Material Min Radius Cost vs Sharp Finish Achievable

6061 Aluminum 0.5 mm 65% savings Ra 1.6 μm

304 Stainless 0.3 mm 70% savings Ra 0.8 μm

POM Plastic 0.2 mm 60% savings Ra 3.2 μm

Can’t make walls thicker? Add ribs every 25mm (minimum 0.5mm height) or create lattice backing. ISO 2768-m allows reasonable tolerances on supported thin sections.

Design Takeaway: Measure your thinnest walls right now. Under the safe thickness above? Either thicken them, add structural ribs, or prepare for expensive custom fixturing and potential scrap costs. Don’t learn this lesson the expensive way.

Will Deep Features Break My End Mills?

That deep narrow slot you drew just became an end mill graveyard. Deep pockets trap metal chips that can’t escape, causing tools to jam, snap, and potentially ruin your expensive work-in-progress part. If your feature depth exceeds 3 times the width, expect tool breakage and machining quotes 200-300% higher.

We see this disaster constantly: a designer needs a 5mm wide slot that’s 20mm deep (4:1 ratio). The 3mm end mill gets halfway down, chips pack like concrete around the tool, carbide snaps with a loud crack, and we’re extracting broken tool from your $150 aluminum block. Tool life drops 80% when depth-to-width ratios exceed 3:1.

Chip evacuation becomes impossible in narrow spaces over 15mm deep. Flood coolant can’t reach the bottom, chips overheat to 300°C+, and weld to the cutting edge. Surface finish degrades to Ra 6.3 μm from chip rewelding.

Depth:Width Ratio Tool Life Cost Impact Success Rate

2:1 100% Standard 95%

3:1 60% +50% 85%

4:1 20% +200% 40%

5:1+ <10% +300% <20%

Need that deep feature? Break it into steps – two 10mm levels with 2mm ledges machine 50% faster than one 20mm plunge. ASME Y14.5 allows stepped features without compromising most functions.

Design Takeaway: Calculate your depth-to-width ratios right now using the table above. Over 3:1? Redesign with steps, accept the higher costs, or prepare for multiple broken tools and extended lead times.

Which Aluminum Grade Won't Kill My End Mill Budget?

Your material choice is quietly destroying your machining budget. That “premium” 7075 aluminum you specified because it sounds stronger? It’s about to cost you 40-60% more in machining time and tool wear compared to 6061. Unless you actually need aircraft-grade strength, 6061-T6 will save you serious money while machining beautifully.

Here’s what happens when you pick the wrong aluminum: 7075 is hard and abrasive. It chews through end mills 3x faster than 6061, meaning more tool changes, longer cycle times, and higher labor costs. We machine a simple bracket in 6061 for $45 – the same part in 7075 costs $75 because tools dull quickly and cutting speeds drop 40%. 6061 achieves Ra 1.6 μm surface finish easily, while 7075 requires slower cutting for Ra 3.2 μm.

Is 6061 strong enough for your part? We’ve machined thousands of 6061 parts over 15 years – camera mounts that handle $50K equipment, audio chassis supporting heavy amplifiers, and medical device housings that pass drop tests. 6061-T6 yields at 276 MPa versus 7075’s 503 MPa – but unless you’re designing aircraft landing gear or race car suspension, that extra strength just costs money.

When your boss questions the material choice, tell them this: “6061 has 276 MPa yield strength per ASTM B221 – plenty for our application. Using 7075 would cost 50% more in machining with no functional benefit.” We’ve helped dozens of product teams justify this switch using DFMA principles.

Quick material decision tool:

- General brackets, enclosures = 6061-T6

- High-stress structural parts = 7075-T6

- Corrosion-critical applications = 5052-H32

Design Takeaway: Unless your part sees extreme loads (think structural beams or high-impact components), specify 6061-T6. Your machining quotes will drop significantly, parts will hold ±0.02mm tolerances reliably, and performance will be identical for typical applications.

What Tolerances Can End Mills Really Hold?

Stop over-tolerancing your parts and watching quotes explode. That ±0.01mm tolerance you casually threw on every dimension? It just tripled your machining cost because it requires special setups, climate control, and extensive inspection. For most features, ±0.05mm works perfectly and keeps you in standard pricing.

Here’s the tolerance reality check: achieving ±0.01mm means slower feeds, multiple finishing passes, temperature-controlled machining, and CMM inspection of every part. What should be a $50 part becomes $150+ because you over-specified tolerances that don’t actually matter for function. Standard end mill work reliably holds ±0.05mm with Ra 1.6 μm finish, verified through coordinate measuring machine inspection.

How to identify what you can safely loosen: Look at your drawing right now. Clearance holes for screws? Those can be ±0.2mm easily per ISO 2768-m. Overall part dimensions that don’t mate with anything? ±0.1mm is fine. Decorative features or non-functional surfaces? Even looser. We only hold tight tolerances on bearing fits, threaded holes per ISO 965, and critical mating surfaces.

When customers expect tight tolerances everywhere, we explain this: “Tight tolerances where they don’t matter just waste money. We’ll hold ±0.02mm on your critical bearing seat using CMM verification, but that mounting hole can be ±0.1mm with zero impact on function.” Professional customers appreciate this DFMA-based guidance.

Tolerance decision framework:

- ±0.2mm = Clearance holes, non-critical features

- ±0.05mm = General mating surfaces, standard work

- ±0.02mm = Bearing fits, precision assemblies

- ±0.01mm = Critical functional surfaces only

From 15 years of machining experience following ISO 2768 standards, 90% of part features work perfectly with ±0.05mm or looser.

Design Takeaway: Apply ISO 2768-m as your default (±0.1mm for most dimensions), then tighten only critical fits to ±0.02mm. This DFMA approach will drop your quotes 30-50% while maintaining full functionality and CMM-verified quality.

How Do I Design Parts That Don't Need Multiple Setups?

Multiple setups double your machining costs because each flip requires stopping production, custom fixturing, and re-zeroing all coordinates. Setup changes add $150-300 per operation while risking ±0.1mm positioning errors that can ruin tight tolerances. Design all features accessible from one face to stay in single-setup pricing.

We machine single-setup parts at $75/hour standard rates, but multi-setup work jumps to $200+ per part due to fixturing complexity. CMM verification shows positioning repeatability degrades from ±0.02mm to ±0.1mm between setups, verified across thousands of parts following ISO 2768-m standards.

Quick setup audit: Place your CAD model in a vise position – can every hole, pocket, and feature be machined from above? Multi-setup becomes unavoidable when designers place holes on opposite faces or create undercuts requiring bottom tool access.

Most parts work perfectly with single-face design. We’ve converted complex 3-setup assemblies into single-operation parts by relocating features and using through-holes instead of blind holes from multiple directions.

Design Takeaway: Run the “vise test” before requesting quotes – verify all machined features have clear tool access from one orientation to avoid expensive multi-setup penalties.

Why Are My End Mill Quotes So High?

requiring EDM, thin walls needing special fixturing, wrong materials, and over-tight tolerances. Each factor compounds the others, turning $80 parts into $400+ disasters. Systematic design audit identifies specific cost drivers for targeted fixes.

We analyze shocking quotes daily and consistently find 4-6 cost penalties working together. Sharp internal corners force $200/hour EDM work instead of $75/hour milling. Walls under 1.5mm require specialized fixturing and slower feeds to prevent deflection beyond ±0.05mm, verified through CMM inspection.

Your $400 quote typically breaks down as: wrong material (+40%), sharp corners (+200%), thin walls (+100%), tight tolerances (+200%), and multiple setups (+100%). These aren’t additive – they compound exponentially.

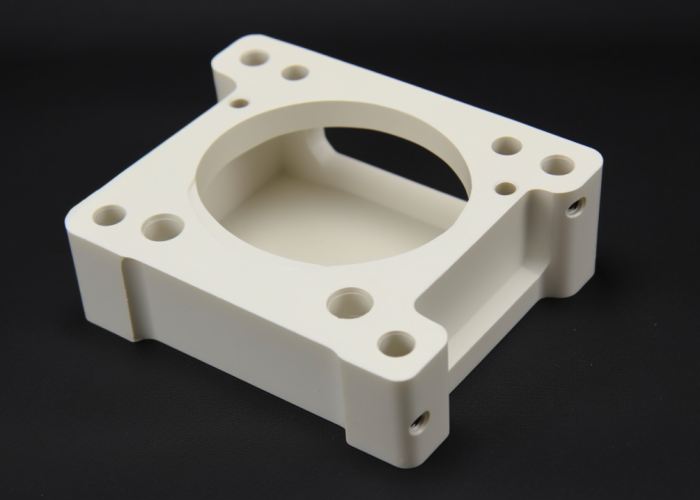

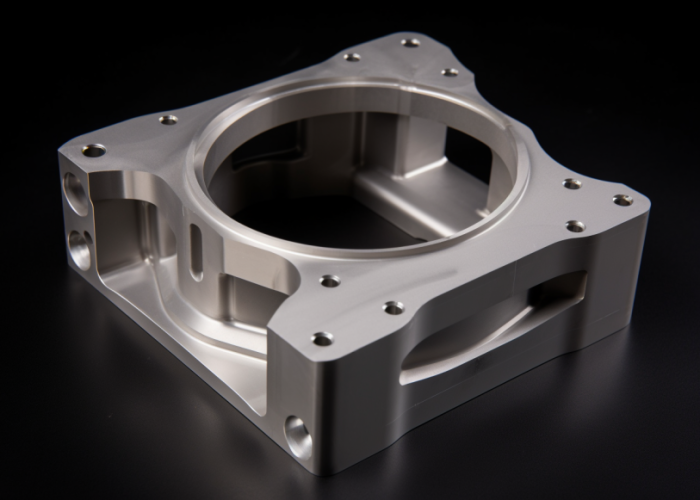

Recent cost audit: 7075 housing with all penalties = $485 quote. Post-optimization: 6061 material, 0.5mm radii, proper wall thickness, ISO 2768-m tolerances = $125 quote, maintaining Ra 1.6 μm finish quality.

Design Takeaway: Check your design against the six cost factors systematically. Multiple penalties create exponential cost growth – fix material choice and corner radii first for maximum impact with minimal design changes.

Conclusion

End mill machining costs spiral when designs ignore basic CNC constraints. Apply 0.5mm corner radii, use 6061 aluminum, maintain 1.5mm+ wall thickness, and design for single setups to cut quotes 50-70%. Contact us to explore manufacturing solutions tailored to your product requirements.

Frequently Asked Questions

Yes, for non-critical features. ±0.01mm tolerances triple machining costs through precision setup requirements and CMM inspection. Most clearance holes and non-mating surfaces work perfectly at ±0.1mm per ISO 2768-m standards. Reserve tight tolerances only for bearing fits and critical assemblies – this alone cuts quotes 30-50%.

No – many expensive quotes result from design issues, not inherent complexity. Simple 6061 parts with reasonable tolerances should cost $50-150 each. Quotes over $300 typically indicate multiple cost penalties: sharp corners, thin walls, wrong materials, tight tolerances, or multi-setup requirements. Most can be fixed with minor design adjustments.

Sharp internal corners requiring EDM instead of standard milling. Each sharp corner adds $50-200 per part because shops must switch from $75/hour CNC milling to $200/hour wire cutting. Adding 0.5mm radii to internal corners keeps you in standard pricing and can reduce quotes by 60-70% instantly.

Design stepped features instead of deep single cuts. A 20mm deep pocket should become two 10mm steps with small ledges between them. This prevents tool deflection and breakage while improving chip evacuation. Deep features over 3:1 depth-to-width ratio cause 80% tool life reduction and potential part scrapping.

Perform the “vise test” – imagine your part clamped in one position. If you can’t reach every hole, pocket, and feature from above, you need multiple setups that double base costs. Through-holes instead of blind holes from opposite faces, and relocating back-side features to the primary face, keeps you in single-setup pricing.

7075 aluminum costs 40-60% more to machine than 6061 due to reduced tool life and slower cutting speeds. A simple bracket costs $45 in 6061 but $75 in 7075 because harder materials chew through end mills 3x faster. Unless you need aerospace-grade strength, 6061 delivers identical performance at much lower cost.