Got a ‘not machinable’ rejection after specifying an exotic material? It’s a common sourcing roadblock — and usually not your fault. Titanium, Inconel, Ultem, PEEK — these high-performance materials often trigger supplier rejections or inflated quotes. But in most cases, it’s not about your drawing. It’s about their limits.

Most rejections happen because shops fear tool wear, scrap risk, or setup delays — not because the part can’t be made. General-purpose suppliers avoid exotic jobs by marking up quotes or saying no outright. The fix is working with shops that specialize in exotic materials and quote based on capability, not risk.

Learn why exotic material parts get rejected or overpriced—and how to adjust designs or drawings to unlock valid CNC quotes fast with Okdor’s 24-hour support.

Table of Contents

Why do exotic materials make it harder to find capable manufacturers?

Most supplier rejections of exotic material parts reflect quoting hesitation — not actual machining limits.

When your design calls out titanium, Inconel, Ultem, or glass-filled PEEK, many shops quietly rule themselves out. It’s not that the part can’t be made — it’s that most general-purpose CNC suppliers aren’t set up to succeed with unfamiliar materials under pressure.

Behind the scenes, shops worry about:

• Tooling and programming gaps — unfamiliar materials mean slow setup and high risk

• Scrap costs and broken tools — especially on expensive or hard-to-source stock

• Delivery timeline blowouts — exotic jobs can derail their standard workflow

We’ve seen this exact pattern: one customer submitted a titanium bracket with thin walls and radiused slots — and got three rejections within 48 hours. One shop cited “material difficulty,” another never replied, and the third padded the quote by 3x to scare the job off. The design didn’t change — the supplier did. Once it reached a shop experienced in titanium, the part was approved and quoted in 36 hours.

Shops that work with exotic materials regularly can maintain ±0.02 mm tolerances on glass-filled plastics and machine Inconel features without deformation — but only when they’ve invested in stable fixturing, high-rigidity spindles, coolant-through tools, and heat-aware toolpaths. These are not standard capabilities.

And quoting speed tells you a lot: exotic-capable shops typically respond within 24–48 hours because they’ve built proven processes. General shops hesitate, delay, or overprice due to internal uncertainty.

Takeaway:

If you’re struggling to get a real quote on your exotic material part, the problem is likely supplier readiness — not manufacturability. Shift your search toward shops with demonstrated experience in your material. If needed, we can assess exotic material feasibility and provide alternate quoting paths within 24 hours.

What design features cause exotic material rejections?

Exotic material parts often get rejected not because of the material — but because the geometry demands more than the supplier is ready for.

High heat, tool deflection, and wear sensitivity mean that even basic design features can cause trouble in exotic materials. What passes for “machinable” in 6061 often breaks tools or fails inspection in Inconel, Ultem, or titanium.

The most rejection-prone features include:

• Thin or unsupported walls — tend to vibrate, warp, or melt during roughing

• Tight inside radii — require small tools with higher breakage risk

• Deep cavities with poor tool access — increase cycle time and deflection

• Tight tolerances on flexible plastics — cause dimensional instability post-machining

We’ve seen parts with 0.3 mm wall thickness, R0.5 corners, and unsupported ribs get instant rejections — not because the part was unmachinable, but because most shops weren’t confident holding tolerances on heat-sensitive stock. A shop that only runs aluminum may quote it anyway — and miss every spec.

Shops that succeed with exotic materials look for design red flags early. They know what’s risky at 300°C tool heat and where unsupported ribs buckle. That translates into realistic quotes and faster approvals — but only if your geometry respects the material limits.

Material Min Wall Thickness Min Internal Radius

Titanium 0.5 mm 0.8 mm

PEEK (unfilled) 0.7 mm 1.0 mm

Inconel 1.0 mm 1.2 mm

Ultem 0.8 mm 1.0 mm

Use these as quoting-safe thresholds. Going below them? Expect to justify it with support ribs, relief radii, or inspection flexibility.

Takeaway:

If your exotic material design keeps getting rejected, review the geometry under the lens of thermal distortion, rigidity, and tool access. Use relief radii, add support walls, and avoid aggressive tolerances on flexible plastics. Upload your drawing — we’ll flag rejection risks and suggest geometry fixes that still meet function.

Why do exotic material parts get overpriced or no-quoted?

When shops aren’t confident in your exotic material job, they do one of two things: pad the quote by 2–4x, or reject it outright.

This isn’t price gouging — it’s quoting psychology. Exotic jobs carry more unknowns: tool wear, material stress, long setup time, and scrap risk. Without prior experience, most shops can’t predict cost — so they inflate it or ghost you.

You might see:

- A $400 6061 part quoted at $1,600+ for Inconel

- No response after “reviewing with the team”

- TBD lead times or vague “let me get back to you” replies

- Wild quote spread from $1,200 to $3,500 — all for the same drawing

We’ve reviewed quotes where the only change was a material note — and the price doubled. One customer submitted a glass-filled nylon baseplate that was previously $900 in ABS. The supplier returned a $2,400 quote due to “flatness risk.” We machined it for $1,050 using staged roughing and warp-prepped fixtures.

Shops that know how to handle exotic materials quote based on setup readiness, toolpath control, and risk-managed inspection — not fear. They also move faster. Capable exotic shops typically quote in 24–48 hours, while generalist shops hesitate, delay, or inflate.

🔍 Quoting Confidence Indicators

Behavior Interpretation

Quote triples without drawing changes Risk padding

Lead time TBD No internal workflow for material

Needs review, will get back Stalling; likely no-quote soon

>5x variation across quotes Market mismatch; quoting uncertainty

Takeaway:

If your exotic material quote tripled, it’s likely due to supplier risk buffering — not just material cost. Work with shops that have already run your material and know what controls are needed. Send us your quote or drawing — we’ll review and offer a quoting alternative within 24 hours.

What design changes prevent exotic material rejections?

Many exotic material rejections can be prevented with small design changes — ones that reduce tool stress, thermal distortion, or setup risk.

It’s not about compromising function. It’s about understanding how the material behaves — and what suppliers need to see in order to say yes.

Here are DFM changes that make exotic material parts more quoteable:

• Increase internal radii — R1.0+ allows larger, more rigid tools with better heat control

• Thicken walls to ≥0.5–1.0 mm — avoids chatter and deflection on brittle or soft stock

• Add structural ribs — especially on wide flat faces or unsupported corners

• Break up long cuts — segment deep cavities to avoid tool deflection

• Adjust tolerances by material — PEEK can’t hold ±0.02 mm like aluminum

• Add radius relief behind vertical walls — for better chip clearance

One customer submitted a titanium housing with 0.3 mm walls and sharp corners. It was rejected by two suppliers. After increasing wall thickness to 0.8 mm and adding relief radii, the part was accepted within 48 hours — same function, but now quoteable.

Where possible, follow ISO 2768-m for general tolerances — unless critical features require tighter fits. It helps suppliers quote confidently without assuming excessive risk.

These changes reduce rejection risk — but they also increase your chances of first-pass success. And in exotic materials, a failed run is rarely cheap.

Takeaway:

If your design gets flagged in exotic materials, don’t default to changing the material — start by adjusting the geometry. Small DFM tweaks often unlock quoting approval without compromising performance. Upload your current model — we’ll provide rejection-risk feedback within 24 hours.

Struggling to get your exotic material parts quoted?

At Okdor, we machine titanium, Inconel, POM, hardened steels, and specialty plastics every day.

Send us your drawing and we’ll flag design risks early — before you waste time sourcing

What drawings help suppliers approve exotic material quotes?

Your drawing format often makes or breaks the quote — especially with exotic materials where ambiguity equals risk.

A supplier deciding whether to quote titanium, Inconel, or high-performance plastics needs total clarity: tolerances, finishes, inspection expectations, and feature intent. If anything’s vague, they’ll pad the quote — or walk away.

Here’s what exotic-capable suppliers want to see:

✅ Paired 2D + 3D models

- STEP or IGES + fully dimensioned PDF

- 3D for toolpath planning, 2D for tolerances and inspection

✅ Defined surface finishes

- Indicate finish types only where needed (Ra 1.6? Alodine?)

- Avoid defaulting entire part to tight finishes unless functional

✅ Call out material specs precisely

- Avoid generic “Ultem” — use UL grades (e.g., PEI 1000), alloy numbers, or ASTM references

- If substitute grades are acceptable, say so

✅ Inspection method clarity

- Don’t just say “critical” — note CMM required? Visual check?

- This lets suppliers quote more accurately — and faster

✅ Tolerance stackup transparency

- Let suppliers know which features drive alignment, not just individual tight fits

We’ve reviewed many rejected quotes where the only issue was drawing ambiguity. In one case, a glass-filled nylon part was marked “critical Ra 0.8 µm” on all faces — the shop saw it as a finishing nightmare. Once clarified that only one bore mattered, cost dropped by 40%.

Well-prepared drawings don’t just reduce confusion — they cut quote timelines too. Suppliers receiving paired 2D/3D files with realistic finish and inspection specs often quote 2–3 days faster and with fewer back-and-forth delays.

Takeaway:

If your exotic part quote got rejected or delayed, your drawing may be the blocker. Suppliers need clarity to quote with confidence. Pair clean 3D models with fully detailed 2D prints, flag realistic finish requirements, and specify inspection expectations. If you’re unsure, we’ll review and optimize your file package within 24 hours.

When to consult manufacturers about exotic material feasibility?

The earlier you involve a manufacturer in an exotic material design, the fewer rejections and costly reworks you’ll face.

Too often, engineers finalize specs, send out RFQs, and only then learn that suppliers can’t meet the requirements. By that point, time is lost and redesign pressure is high.

The best time to consult is:

• During material selection — before finalizing between titanium, Inconel, Ultem, etc.

• When tolerances push past ISO 2768-m — many materials can’t hold ±0.01 mm without risk

• If your CAD has thin walls or deep cavities — suppliers can quickly flag issues

• When surface finish is functional — Ra 0.8 vs. Ra 3.2 µm changes machining strategy

We’ve seen projects delayed by weeks because engineers waited until quote stage to ask for feasibility feedback. In contrast, when drawings arrive with early notes (“Material TBD between Ultem and PEEK, tolerance feedback welcome”), capable suppliers can respond in 24 hours and prevent dead-end quoting.

Takeaway:

Don’t wait for rejection emails to learn your design isn’t quoteable. Involve a qualified manufacturer as soon as exotic materials enter the discussion. Even a quick feasibility check can save weeks of redesign later.

How to find shops that specialize in exotic material machining?

Not all CNC shops are set up for exotic materials — and most won’t admit it until after delays or rejections.

The challenge is spotting true capability before you waste time on quotes.

Here’s what to look for in an exotic-capable shop:

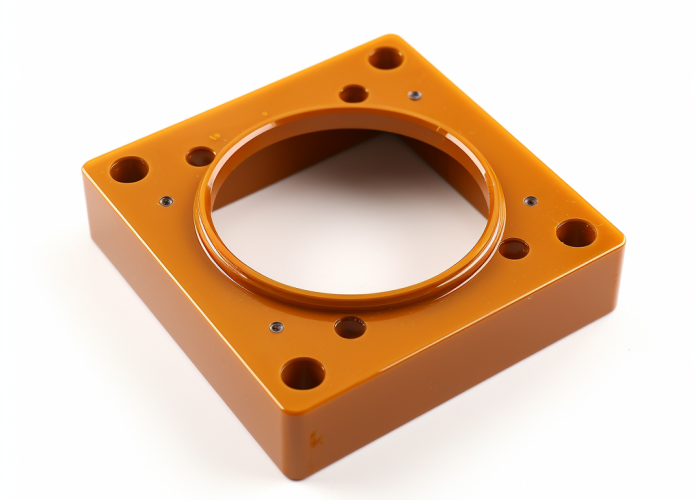

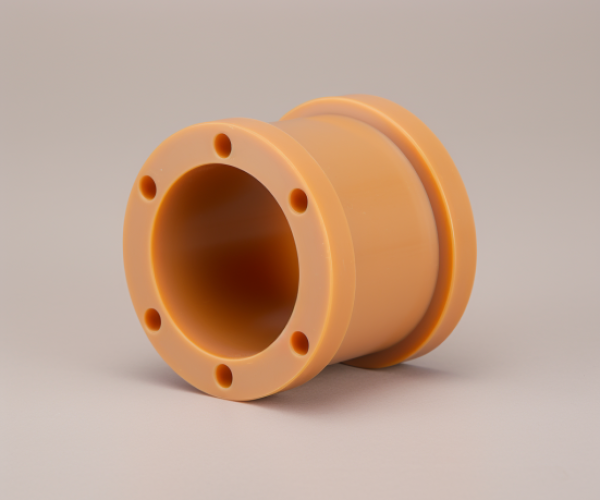

• Portfolio proof — case studies or images of titanium, Inconel, or high-performance plastics

• Inspection depth — CMM, profilometers, and gear analyzers (not just calipers and micrometers)

• Tooling and spindle setup — coolant-through tools, high-rigidity spindles, multi-axis fixturing

• Certifications — ISO 13485, AS9100, or aerospace/medical documentation experience

• Quote behavior — 24-48 hr response with clear material sourcing notes (not silence or TBD)

• Engineering support — willingness to review drawings and suggest alternatives

Shops that specialize don’t just quote — they consult. They’ll highlight risks, suggest design adjustments, and provide alternate paths. General shops simply reject or stall.

Takeaway:

Evaluate suppliers by their readiness signals: fast, confident quoting, visible exotic material portfolio, and inspection systems beyond basics. If you’re only hearing silence or padded quotes, it’s time to move to a shop with demonstrated exotic experience.

What should you expect from an exotic material machining partner?

A true exotic material partner does more than cut parts — they share risk, provide feedback, and keep projects moving under pressure.

This goes beyond capability. It’s about how they work with you when material, geometry, and deadlines intersect.

Here’s what to expect from the right partner:

• Clear communication — daily or every-other-day progress updates

• DFM support — specific advice on wall thickness, radii, and tolerance trade-offs

• Risk sharing — transparency on scrap rates and how issues will be handled

• Quality systems — dimensional inspection reports, ISO-backed traceability

• Emergency readiness — willingness to fast-track when deadlines slip

• Honest capability limits — they’ll tell you when a feature needs redesign or referral

We’ve seen projects rescued when a new shop provided candid feedback: “This bore at ±0.005 mm in Inconel will fail inspection. Adjust to ±0.02 mm, and we’ll deliver in two weeks.” That transparency saves more time and money than chasing shops who say yes and fail later.

Takeaway:

An exotic material machining partner isn’t just a vendor — they’re an engineering extension of your team. Expect communication, risk sharing, and DFM guidance at every stage. If your current supplier isn’t offering that, you’re not working with a true partner.

Conclusion

Struggling to get your exotic material parts quoted or approved? Most suppliers reject due to risk, not capability. At Okdor, we specialize in machining the parts others avoid — with fast DFM feedback, quoting clarity, and proven results. Upload your rejected drawing today for a 24-hour feasibility review and quote.

Frequently Asked Questions

Yes. We support mid-project supplier changes all the time. If you’ve got rejected parts, prototype urgency, or stalled progress, we can start with a fast-turn sample batch (often 5–7 working days) while reviewing your design for any hidden manufacturability risks that could cause further delays.

We see this often. Exotic materials scare general suppliers, and they price to avoid risk. Send us your quote and drawing — we’ll give a second opinion within 1 business day and explain if the cost is justified or padded, and what DFM tweaks could bring it back under control.

We don’t just quote tolerances — we explain how they’ll be achieved. We use CMM inspection, high-rigidity setups, and heat-aware toolpaths for exotic materials. If you send us your spec, we’ll confirm whether we can meet it reliably — and back it with inspection reports on delivery.

Same day in most cases — we treat exotic material feasibility as priority. Just send the drawing, 3D file, and your material/tolerance targets. Within 24 hours, we’ll flag risks, propose DFM fixes if needed, and confirm whether it’s something we can quote, prototype, or refer to a partner.

We don’t “try” — we’ve delivered. We’ve machined glass-filled plastics with ±0.02 mm, thin-walled titanium housings, and Inconel brackets under urgent timelines. We quote based on proven setups, not guesses. And if your part’s a poor fit? We’ll say so — and even help you pivot to a better solution.

You’re not alone — many shops go silent once they realize the job’s too risky. We can assess your drawing and material spec (e.g., titanium, Inconel, Ultem) within 24 hours and let you know if it’s quoteable, what needs adjusting, or how fast we can move to samples.