Choosing black oxide for machined steel parts requires balancing appearance, dimensional precision, and actual protection needs. From our experience finishing components across industrial and precision applications, the decision often comes down to specific performance requirements versus cost.

Consider black oxide when you need minimal thickness buildup (0.0001-0.0003″), dark appearance, and can accept limited corrosion protection. Avoid it for outdoor exposure, high-wear applications, or when serious environmental protection is required. Black oxide works best for interior components where aesthetics and tight tolerances matter more than durability.

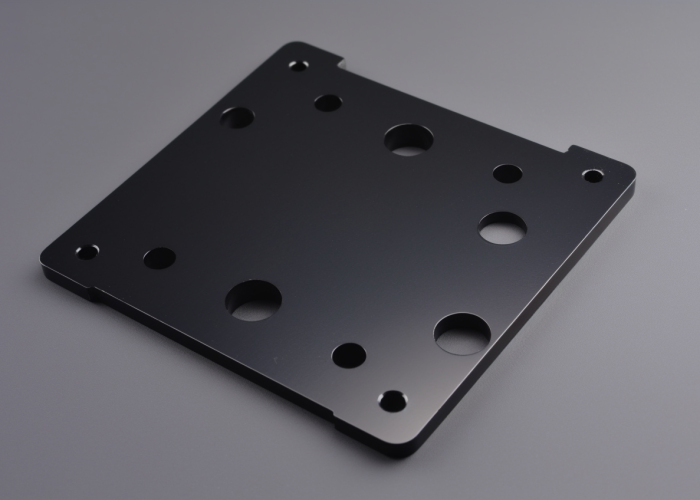

Learn when black oxide suits your application, its effects on tolerances, steel compatibility, and when alternatives like zinc plating add better value.

Table of Contents

Does black oxide protect my part in its actual environment?

Black oxide provides minimal environmental protection and relies entirely on post-treatment oil to prevent rust. Without oil, parts can show corrosion within 24-48 hours in typical indoor humidity above 50%. Salt spray testing confirms this – black oxide typically fails within 24 hours while zinc plating withstands 200-1000+ hours depending on thickness.

From our experience finishing components across different industries, the critical factor isn’t just “indoor vs outdoor” – it’s whether your parts will lose their protective oil layer. We’ve seen black oxide failures in seemingly controlled environments when parts get handled during assembly, wiped during cleaning, or stored in warehouses with temperature swings that create condensation. The practical reality is that black oxide has “almost no corrosion resistance” and can “rust horribly within 45 minutes when the oil was stripped.”

The dividing line we use with customers is simple: if workers will handle the parts regularly, if humidity can exceed 50%, or if the part might get wet even occasionally, zinc plating becomes necessary. Zinc creates a physical barrier and provides sacrificial protection – meaning it continues protecting the steel even when scratched, unlike black oxide which offers no protection once damaged. For medical device housings, we routinely recommend zinc because cleaning protocols strip oils. For audio equipment in climate-controlled studios, black oxide works fine.

Design Takeaway: Evaluate black oxide based on oil retention, not just location. If your part will be handled, cleaned, or exposed to humidity above 50%, specify zinc plating to avoid field failures and warranty issues.

Can black oxide cause tolerance or fit issues in assembly?

Black oxide adds only 0.5-2.5 microns (0.00002″-0.0001″) to part dimensions, making it safe for tolerances looser than ±0.0005″. For tighter tolerances, test fit assemblies before production. This is a conversion coating rather than a deposited layer, so there’s “no dimensional change to the part and no potential for build up” in most applications.

The coating maintains dimensional stability where other finishes would cause interference issues. Parts “retain their precise dimensions and tolerances, ensuring they fit and function as intended without needing post-coating adjustments.” Critical applications include bearing races where 0.001″ buildup would bind, mating shafts with press fits, and threaded holes that must meet class specifications.

Compare this to alternatives: zinc plating adds 0.0002″-0.0008″, powder coating adds 0.002″-0.008″, and anodizing adds 0.0005″-0.002″. Unlike these finishes, “black oxide does not change the fasteners’ dimensions,” preserving original machined geometry.

The risk comes from poor surface preparation causing uneven coating thickness. Inadequate cleaning can cause “color variation” though this doesn’t typically affect critical dimensions.

Design Takeaway: Use black oxide when tolerances are ±0.0005″ or tighter, when post-coating machining isn’t feasible, or when maintaining exact fits is more critical than maximum corrosion protection. Always specify surface cleanliness requirements to ensure uniform results.

Is black oxide durable enough for wear and friction?

Black oxide provides temporary wear protection suitable for hand-operated controls used <5 times daily or manual adjustments made monthly. For automatic mechanisms, motorized systems, or daily-cycle operations, the coating wears through within 3-6 months.

The coating works reliably for infrequent operations like calibration screws, manual valve stems, optical adjustment rings, and protective covers that move occasionally. Black oxide creates “anti-galling properties” and “low friction coefficient, especially if treated with wax/oil,” while surfaces become “work-hardened” during break-in. Set-and-forget mechanisms benefit from the improved break-in characteristics without needing long-term durability.

Expect rapid failure in frequent-use applications. Automatic door actuators, motorized valve stems, daily-operated switches, or any mechanism cycling more than 50 times per week will show base metal within months. The coating has “limited wear and impact resistance” and exhibits “high wear in low λ conditions” where adequate lubrication isn’t maintained. Snap-fit connectors that engage/disengage regularly lose coating at contact points, making the finish purely cosmetic.

Quick evaluation: If operators touch it daily, if it’s motor-driven, or if it’s part of an automated sequence, black oxide won’t provide meaningful wear protection. For comparison, nitriding handles 1,000+ daily cycles, while black oxide begins failing after 50-100 cycles without lubrication.

Design Takeaway: Specify black oxide for manual controls operated weekly or less, one-time adjustments, or protective mechanisms. For any daily-use, automated, or high-frequency application, choose engineered wear coatings designed for your specific cycle count and load conditions.

Black oxide or better alternatives?

We match surface finish to performance need • Get coating advice before you order

Does black oxide provide enough corrosion resistance, or is plating better?

For serious corrosion protection, zinc plating significantly outperforms black oxide. Black oxide provides only 24 hours of salt spray resistance (ASTM B117), while zinc plating delivers up to 500 hours depending on thickness and chromate treatment. Zinc plating “can provide protection against rust and other forms of corrosion for up to 500 hours in a salt spray test, while black oxide may only provide protection for up to 24 hours.”

Black oxide works adequately for climate-controlled environments like server rooms, electronics enclosures, or precision instruments stored indoors. It fails quickly in automotive underhood applications where temperature cycling creates condensation, industrial facilities with chemical vapors, or anywhere parts get wet regularly. Without oil treatment, “a part that has ONLY been blackened by the process isn’t much more resistant to rusting than a bare steel part.”

Zinc plating becomes necessary for warehouse storage where humidity varies, outdoor equipment, automotive components, or any salt exposure. For marine environments within 5 miles of coastline, neither finish provides adequate protection – specify stainless steel instead. Zinc creates “a metallic barrier that keeps moisture from reaching the surface” and corrodes sacrificially to protect underlying steel.

The cost trade-off: black oxide costs 30-50% less but may require replacement within 1-2 years in challenging environments, while zinc plating provides 5-10 year protection.

Design Takeaway: Use black oxide for controlled indoor environments or short-term protection. Specify zinc plating for humidity above 60%, weather exposure, or where failure creates safety risks.

Does my steel grade work well with black oxide?

Common carbon steels (1018, 1045, A36, 4140) produce excellent black oxide coatings with uniform appearance and good adhesion. Avoid free-machining grades like 12L14 which create uneven finishes, and evaluate stainless steel carefully due to adhesion challenges. The process works well on “carbon steel and some non-ferrous metals such as zinc and copper” and is “frequently utilized on carbon steel and stainless steel components.”

Most structural and machinery steels work reliably: A36 structural steel, 1018 mild steel, 1045 medium carbon, and 4140 alloy steel all produce consistent results. Tool steels above 40 HRC typically yield better coating quality due to surface hardness. Cast iron also blackens well for machinery housings.

Problematic grades include 12L14, 1215, and other free-machining steels where sulfur content causes mottled appearance. Stainless steel grades (304, 316, 17-4 PH) require “50% sulfuric or hydrochloric acid solution” activation pretreatment and may still show uneven coating or adhesion problems.

Quick evaluation: If your steel is magnetic and machines easily without gumming, black oxide will likely work well. If it’s stainless or contains >0.3% sulfur/lead, expect coating challenges.

Design Takeaway: Stick with standard carbon and alloy steels for reliable black oxide results. For stainless applications requiring black finish, consider black anodized aluminum alternatives or accept additional processing costs and quality variations with stainless steel black oxide.

Will surface prep or machining marks affect the black oxide finish?

Surface preparation is critical for black oxide quality – poor cleaning causes uneven coating, mottled appearance, and adhesion problems. Machining marks show through the thin coating, so specify surface finish requirements before machining if appearance matters. The coating takes on the same surface texture as the substrate underneath.

Black oxide requires extensive cleaning to remove all oils, dirt, and oxidation before processing. Parts must be “thoroughly cleaned and prepared before the black oxide process” using “degreasing, sandblasting, or chemical cleaning” to prevent “uneven coating” that occurs “when the parts are not properly cleaned.” Common defects include blotchy appearance from inadequate surface preparation and discoloration from contaminated rinse water.

Specify surface requirements clearly: Ra 32 µin (0.8 µm) or better produces uniform appearance. Call out “degrease per MIL-DTL-13924” on drawings for proper cleaning. Glass bead blast to 125-180 µin if smooth finish is required. Avoid EDM or laser-cut surfaces without post-processing as they may not coat evenly.

The finish “can be glossy or matte, usually depending on the finish of the part before the process” and “black oxide is not always uniform in appearance.” Surface hardness above 40 HRC typically produces better, more uniform coating quality.

Design Takeaway: Budget for surface conditioning (polishing, glass beading) to achieve uniform coating quality. Don’t expect black oxide to hide machining marks or improve surface texture. Always specify cleaning requirements and acceptable surface finish ranges on drawings to ensure consistent results.

Is black oxide the most cost-effective finish for my project?

Black oxide costs significantly less than alternatives but total cost-of-ownership depends on service life requirements. For quantities above 100 parts in controlled environments, black oxide offers the best economics. Real pricing examples show black oxide at “$0.45 to $1.20 each” while zinc costs roughly 50% more.

The economics favor black oxide for rackable parts in large quantities. Small parts suitable for “racking setups will be far cheaper than larger parts which have to be handled individually” – with costs jumping to “$4.50 each in quantities of 100 pcs” for large individual parts. Black oxide “tends to be more affordable due to its relatively simple application process” compared to zinc plating which “can be relatively expensive, depending on the application and the size of the part.”

However, calculate total cost-of-ownership. Black oxide provides 1-2 year protection in challenging environments while zinc delivers 5-10 years. Factor replacement labor, downtime, and warranty exposure. For outdoor applications or long service intervals, zinc’s higher upfront cost pays for itself through avoided replacement cycles.

Break-even analysis: Production volumes above 100 parts favor black oxide for tooling amortization. Service life above 3 years usually justifies zinc plating investment. Indoor electronics applications allow black oxide cost savings.

Design Takeaway: Choose black oxide when upfront cost matters more than longevity, parts operate indoors with regular maintenance, or tight tolerances prohibit thicker coatings. For outdoor exposure or long service intervals, invest in zinc plating to avoid total lifecycle costs.

Conclusion

Black oxide provides cost-effective finishing for precision parts in controlled environments, but zinc plating offers superior protection for demanding applications. The right choice depends on balancing dimensional requirements, environmental exposure, and total lifecycle costs against upfront investment.

Contact us to explore manufacturing solutions tailored to your black oxide coating requirements.

Frequently Asked Questions

Properly oiled black oxide parts have indefinite shelf life in dry storage. Without oil treatment, expect surface rust within weeks in normal humidity. For long-term storage, apply rust preventive oil and store in moisture-controlled environment below 50% relative humidity.

Call out “Black Oxide per MIL-DTL-13924 Class 1” for carbon steel or “Class 4” for stainless steel. Add surface prep requirements like “Degrease per specification” and post-treatment if needed: “Oil seal after coating.” Include acceptable appearance standards to avoid disputes over finish uniformity.

Yes, black oxide works well on heat-treated parts and actually produces better coating quality on harder surfaces above 40 HRC. The process operates at 280°F, which won’t affect the temper of most heat-treated steels. Apply black oxide after all machining and heat treating operations are complete.

The coating must be removed from weld zones since it will burn off and contaminate the weld. Mask weld areas before coating or mechanically remove coating afterward. The thin oxide layer machines off easily for post-coating operations, but factor this into your process planning.

Black oxide maintains electrical conductivity since it’s only 1-2 microns thick and doesn’t insulate the base metal. Magnetic properties remain unchanged – the magnetite coating is actually magnetic itself. This makes it suitable for electrical connections and magnetic assemblies where other coatings would interfere.

Black oxide provides better appearance and dimensional stability, while phosphate offers superior paint adhesion and slightly better corrosion resistance. Both provide anti-galling properties for threading. Choose black oxide for precision fit requirements, phosphate when parts will be painted or need maximum corrosion protection.