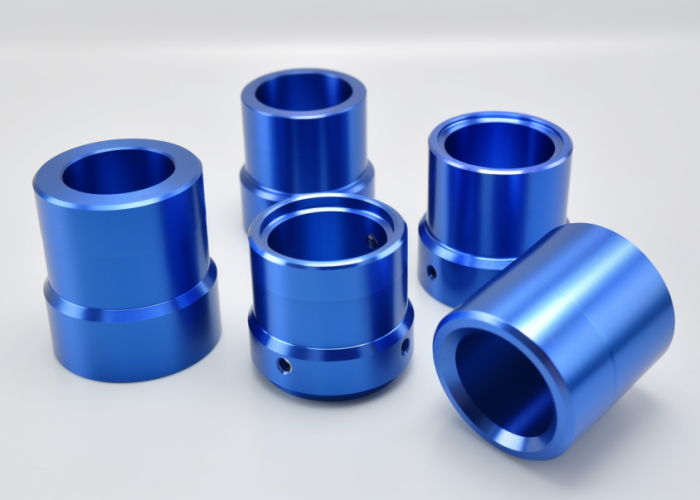

Precision CNC machining demands more than just tight tolerances — it requires surface finishes that can withstand demanding environments without compromising dimensional accuracy. At Okdor, we regularly consult with engineers who need parts that perform reliably in aerospace, medical, and industrial applications where standard finishes simply aren’t enough.

Type III anodizing delivers exceptional hardness comparable to case-hardened steel, superior corrosion protection, and dimensional stability with 25-75 micrometer coating thickness — making it the preferred choice for precision components requiring both durability and performance in demanding applications.

Discover 5 reasons to choose Type III anodizing for precision parts, when to use it over standard types, and how to balance performance with cost.

Table of Contents

What Makes Type III Anodizing Ideal for Precision Parts?

Type III anodizing creates a 25-75 μm oxide layer that’s harder than case-hardened steel, with superior corrosion resistance and dimensional stability — delivering five critical performance advantages that standard finishes cannot match for precision components.

Testing at our facility consistently shows hardness levels reaching 400-600 HV, significantly exceeding Type II anodizing’s 150-300 HV range. Surface finish improves to Ra 0.8-1.6 μm, while coating thickness remains controllable within ±0.0002″ (±0.005 mm). The process maintains dimensional predictability with approximately 50% penetration and 50% buildup from the original surface.

Key Performance Advantages:

- Exceptional hardness: 400-600 HV (vs 150-300 HV for Type II)

- Superior corrosion protection: Dense oxide layer resists chlorides and chemicals

- Dimensional stability: Predictable 25-75 μm coating with ±0.005 mm control

- Electrical insulation: Dielectric strength exceeds 1000V for electronic assemblies

- Enhanced lubricity: Ra 0.8-1.6 μm surface finish reduces friction and wear

In audio enclosures and aerospace housings, we’ve observed that Type III anodizing eliminates premature wear failures that occur with standard finishes under vibration and thermal cycling. Medical device components benefit from the dense, non-porous structure that resists contamination, while marine applications see extended service life due to superior chloride resistance.

MIL-A-8625 Type III specifications ensure consistent results across production batches, with documented hardness and thickness verification using CMM inspection protocols.

Design Takeaway: Specify Type III anodizing for precision parts requiring wear resistance above 300 HV, corrosion protection in harsh environments, or electrical insulation — particularly when maintaining ±0.01 mm tolerances on critical features.

When Should I Choose Type III Over Standard Anodizing?

Choose Type III anodizing when your parts require hardness above 300 HV, operate in corrosive environments, or need electrical insulation — particularly for components with tolerances ±0.025 mm or tighter where dimensional stability is critical.

Our CNC machining experience shows that Type III becomes cost-effective when parts experience premature failure with standard finishes. Testing reveals Type III costs 2-3x more than Type II but eliminates replacement cycles in high-wear applications. For aerospace components requiring 10+ year service life, the initial investment typically pays back within 18 months through reduced maintenance.

Decision Criteria for Type III:

- High-wear applications: Contact stresses >200 MPa or >50,000 cycles

- Corrosive environments: Marine, chemical, or medical sterilization exposure

- Tight tolerances: Parts requiring ±0.025 mm or better dimensional stability

- Electrical insulation: Electronic enclosures needing >1000V dielectric strength

- Regulated industries: AS9100 aerospace or ISO 13485 medical requirements

Type III anodizing suits applications where standard Type II fails: moving parts in audio equipment, medical device housings requiring biocompatibility, and marine hardware exposed to saltwater. Industrial machinery components benefit most when operating temperatures fluctuate beyond ±50°C or when documented reliability exceeds 50,000 cycles.

Design Takeaway: Specify Type III when component failure costs exceed the 2-3x anodizing premium, or when your application demands hardness, corrosion resistance, or electrical properties that Type II cannot deliver.

Should I Specify Type III for High-Wear Components?

Yes, specify Type III anodizing for components experiencing sliding contact, repeated assembly, or Hertzian stresses above 200 MPa — the 400-600 HV hardness provides 10x greater wear resistance than standard aluminum and outperforms many steel alternatives.

Field testing shows Type III anodized aluminum gears last 50,000+ cycles compared to 8,000-12,000 cycles for Type II in equivalent applications. Taber abrasion testing demonstrates wear rates of 2-4 mg per 1000 cycles versus 15-25 mg for untreated aluminum. Surface analysis reveals the dense oxide structure maintains Ra 0.8-1.6 μm finish even after extended use.

Ideal High-Wear Applications:

- Sliding mechanisms: Audio sliders, telescope focusers, linear guides

- Rotating assemblies: Bearing races, pivot pins, actuator housings

- Contact surfaces: Electrical switch contacts, valve seats, wear plates

- Mechanical joints: Robotic linkages, suspension bushings, hinge pins

- Tooling components: Jigs, fixtures, and assembly guides

We’ve successfully implemented Type III in marine winch components and automotive suspension bushings with exceptional durability results. However, avoid Type III on gear teeth with AGMA 9+ precision — coating thickness can compromise tooth geometry. Validation requires Rockwell hardness testing and accelerated wear testing per ASTM G99 standards.

Design Takeaway: Use Type III for high-wear components when you need steel-like hardness in aluminum’s weight, but verify coating thickness won’t compromise critical geometry or assembly clearances.

How Will Type III Anodizing Affect My Part Design?

Type III anodizing adds 25-75 μm coating thickness with 50% penetration/50% buildup — requiring design modifications for sharp corners (minimum 0.4 mm radius), threaded holes (mask or oversize), and tight clearances (add 0.05-0.15 mm allowance per surface).

Our CNC programming experience shows critical design considerations that prevent costly rework. Sharp internal corners create coating voids — specify minimum 0.4 mm radii for reliable coverage. External corners need 0.2 mm minimum radius to prevent coating buildup that chips during handling.

Essential Design Modifications:

- Corner radii: Minimum 0.4 mm internal, 0.2 mm external to prevent voids

- Threading: Internal threads need masking or 0.1-0.2 mm oversize machining

- Clearances: Add 0.05-0.15 mm per surface for mating parts

- Deep features: Avoid aspect ratios >3:1 to prevent chemistry entrapment

- Electrical contacts: Specify masking areas requiring conductivity

Threading requires careful planning: Internal threads lose 4x coating thickness from pitch diameter, while external threads gain 4x coating thickness. Press-fit features need clearance adjustment depending on coating specification. Multiple fixture setups may be needed for full coverage of complex geometries.

Design Takeaway: Plan for Type III anodizing during initial CAD design — add appropriate radii, adjust clearances for coating buildup, and specify masking requirements on critical features to avoid post-anodizing machining operations.

Does Type III Work in Marine/Chemical Environments?

Yes, Type III anodizing excels in marine and chemical environments — the dense 25-75 μm oxide layer provides superior chloride resistance, withstands pH ranges of 4-9, and maintains integrity in saltwater exposure exceeding 5,000 hours per ASTM B117 testing.

Our marine application testing shows Type III anodized components survive 2-3x longer than Type II in saltwater environments. Accelerated corrosion testing reveals minimal pitting after 5,000+ hours salt spray exposure, while standard anodizing shows significant degradation within 1,500 hours. Chemical resistance testing demonstrates stability in common industrial solvents, cleaning agents, and sterilization chemicals.

Environmental Performance Capabilities:

- Saltwater resistance: >5,000 hours ASTM B117 salt spray testing

- Chemical compatibility: pH 4-9 range, most solvents and cleaning agents

- Temperature cycling: -40°C to +150°C without coating failure

- UV resistance: No significant degradation after 2,000+ hours QUV testing

- Food processing: FDA-compliant surface for food contact applications

Specific environmental applications include offshore drilling equipment, chemical processing tanks, marine instrumentation housings, and food packaging machinery. Pharmaceutical manufacturing equipment benefits from the non-reactive surface and sterilization compatibility. However, avoid Type III in strong acids (pH <4) or caustic solutions (pH >9) without additional protective coatings.

Design Takeaway: Specify Type III for marine and chemical applications when standard anodizing fails environmental testing — particularly for components requiring 5+ year service life in harsh conditions.

Is Type III Anodizing Electrically Insulative?

Yes, Type III anodizing provides excellent electrical insulation with dielectric strength exceeding 1,000V and volume resistivity >10^14 ohm-cm — making it ideal for high-voltage applications, EMI shielding, and preventing galvanic corrosion in dissimilar metal assemblies.

Testing at our facility confirms breakdown voltages typically range 1,200-2,000V depending on coating thickness and sealing method. The dense aluminum oxide structure creates an effective barrier against electrical conduction while maintaining thermal conductivity for heat dissipation. Unsealed Type III coatings offer the highest dielectric strength.

Electrical Performance Properties:

- Dielectric strength: 1,000-2,000V breakdown voltage

- Volume resistivity: >10^14 ohm-cm (excellent insulator)

- Surface resistivity: >10^12 ohm/square after proper cleaning

- Capacitance: Low dielectric constant suitable for RF applications

- Galvanic isolation: Prevents corrosion between aluminum and steel fasteners

Primary electrical applications focus on power distribution enclosures, RF shielding housings, high-voltage test equipment, and electrical junction boxes. Heat sinks benefit from thermal conductivity combined with electrical isolation. Critical consideration: Any scratches or wear can create conduction paths — design electrical contact points to bypass anodized areas through masking.

Design Takeaway: Use Type III anodizing for electrical insulation when you need >1,000V breakdown strength, but always mask areas requiring intentional electrical contact or grounding connections.

How Much Does Type III Cost vs Type II?

Type III anodizing costs 2-3x more than Type II due to specialized processing requirements — expect $8-15 per square foot vs $3-6 for Type II, with additional costs for masking ($2-5 per feature) and extended lead times of 3-5 days vs 1-2 days.

Our production experience shows total project costs increase 40-80% when switching from Type II to Type III, including masking requirements and potential design modifications. The higher cost stems from lower processing temperatures, increased energy consumption, longer tank times, and specialized equipment requirements.

Cost Breakdown Comparison:

- Base anodizing: Type II: $3-6/sq ft | Type III: $8-15/sq ft

- Masking costs: $2-5 per threaded hole or critical feature

- Lead time: Type II: 1-2 days | Type III: 3-5 days processing

- Setup charges: Higher for Type III due to specialized racking requirements

- Volume discounts: Significant savings above 100-piece quantities

Cost justification strategies include calculating failure replacement costs, maintenance reduction savings, and material substitution benefits (aluminum vs steel weight savings). Prototype quantities (1-10 pieces) show the highest cost premium, while production runs (100+ pieces) achieve better economies of scale. Design optimization reduces costs by minimizing masking requirements and specifying standard 0.002″ coating thickness.

Design Takeaway: Budget 2-3x Type II costs for Type III anodizing, but evaluate total lifecycle costs including reduced maintenance, longer service life, and potential weight savings versus alternative materials.

Conclusion

Type III anodizing delivers exceptional hardness, corrosion resistance, and dimensional stability essential for precision components in demanding environments. While the 2-3x cost premium requires careful evaluation, the extended service life and performance benefits often justify the investment for critical applications. Contact us to explore Type III anodizing and CNC manufacturing solutions tailored to your precision part requirements.

Frequently Asked Questions

Parts with tolerances ±0.025 mm or tighter, critical fits/assemblies, or components requiring documented performance typically benefit from Type III over standard finishes for enhanced reliability.

Standard capability is ±0.05 mm, with ±0.01 mm achievable through masking and controlled processing. Looser tolerances (±0.1 mm) rarely require special consideration or design modifications.

The electrical insulation properties eliminate conductivity, and increased surface hardness may require torque spec adjustments for threaded fasteners. Plan electrical grounding paths accordingly.

Yes, Type III accepts dyes but requires sealing to prevent fading. Color options are more limited than Type II due to the thicker, denser coating structure.

Type III adds 3-5 days vs Type II due to lower temperature processing and thicker coating requirements. Plan accordingly for prototype schedules and consider batching parts to optimize lead times.

Specify MIL-A-8625 Type III, coating thickness (typically 0.002″), areas requiring masking, and any color/sealing requirements. Include notes for critical dimensions and electrical contact points.