Material selection between galvanized steel and stainless steel affects both upfront cost and long-term performance. With extensive experience manufacturing components for industrial, automotive, and outdoor applications, the right choice depends on your specific corrosion requirements, budget constraints, and environmental conditions.

For most outdoor and moderate corrosion applications, galvanized steel offers 85% of stainless steel’s protection at 40-60% of the cost. Choose stainless steel when you need superior corrosion resistance, food-grade compliance, or aesthetic durability. Galvanized steel works well for structural, industrial, and temporary outdoor applications.

Learn to evaluate coating performance vs cost, choose the right material, and specify the right grade—backed by real-world manufacturing data.

Table of Contents

Is galvanized steel right for corrosion protection in my application?

For most outdoor applications, galvanized steel provides decades of reliable protection at about 20% the cost of stainless steel. The zinc coating sacrificially corrodes to protect the base steel underneath, making it ideal for structural components, outdoor equipment, and industrial parts exposed to weather and humidity.

Quick Decision Framework: If your part will be outdoors or in humid environments without chemical exposure, choose galvanized steel. If it needs to handle food contact, acids, or marine environments, choose stainless steel instead.

Galvanized steel typically lasts 50+ years in normal outdoor conditions and costs significantly less than stainless alternatives. We’ve seen galvanized brackets, enclosures, and chassis components perform excellently for 20+ years in automotive, HVAC, and industrial applications. However, harsh chemical environments or salt water exposure can reduce this lifespan substantially.

Where Galvanized Steel Works Well:

- Electronics enclosures in industrial buildings

- Automotive brackets and structural components

- Audio equipment chassis and faceplates

- HVAC ductwork and mounting hardware

- Outdoor structural applications

Where It Doesn’t Work: Galvanized steel degrades quickly in salt water or chlorinated water and isn’t suitable for food contact applications due to potential zinc migration. Continuous acid exposure will also consume the protective coating rapidly.

Cost Reality: Stainless steel costs 4-5 times more than galvanized steel for equivalent parts. For typical enclosures or brackets, this translates to $15-25 for galvanized versus $75-125 for stainless steel, making galvanized an attractive option when the application fits its capabilities.

Design Takeaway: Choose galvanized steel for outdoor, industrial, or humid environments where you need reliable corrosion protection without premium cost. Reserve stainless steel for food contact, marine, chemical, or high-aesthetic applications where galvanized steel’s limitations outweigh its cost advantages.

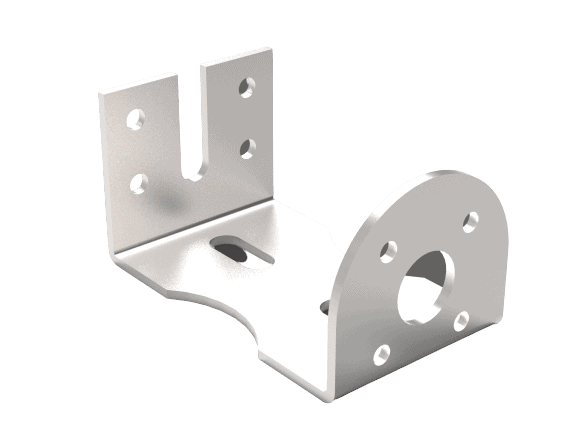

Will the zinc coating affect how my part welds, bends, or forms?

Yes, galvanized coating significantly affects welding, bending, and forming operations. Welding requires ventilation for toxic zinc fumes and may need coating removal. Sheet metal bending can crack the coating at tight radii. CNC machining and stamping generally work well with proper tooling and speeds.

Welders working with galvanized steel need protection against breathing zinc fumes which cause metal fume fever and require OSHA-compliant ventilation. For welding jobs under 5 linear inches, plan coating removal and add $3-8 labor per part. Beyond 5-20 inches of welding, mechanical fasteners ($0.50-2 per connection) often cost less than coating removal. For extensive welding, use bare steel and galvanize the complete assembly afterward.

Sheet metal bending creates coating cracks at bend radii less than 3T material thickness. For decorative applications where cracks show, specify 2T minimum radius and budget touch-up paint. Structural bends can accept tighter radii since coating cracks won’t affect performance in hidden areas.

CNC machining requires 15-20% speed reduction and increased coolant to prevent zinc buildup, but provides corrosion protection during storage, eliminating $2-5 per part in rust preventative costs.

Design Takeaway: Avoid welding galvanized steel when possible – use mechanical connections or weld-then-galvanize sequences. Specify bend radii greater than 3T for structural applications, 2T minimum for decorative parts. Factor reduced machining speeds into production planning.

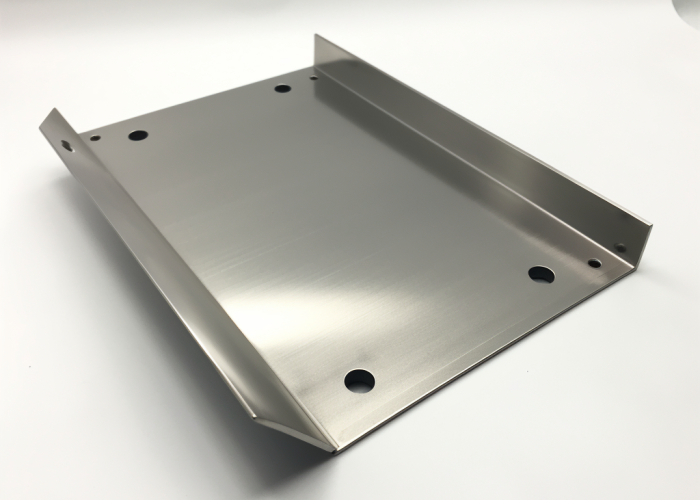

Do I need to account for coating thickness in my part tolerances?

Yes, galvanized coating adds 0.0015-0.003″ total thickness that affects tight-fitting assemblies and threaded connections. G90 coating adds ~0.0015″ per side, while electro-galvanized adds 0.0002-0.0005″ per side. Account for coating thickness in hole sizes, mating parts, and thread specifications.

G90 galvanized coating adds approximately 0.76 mils (0.0008″) per side according to ASTM A653, totaling 0.0015″ on part thickness. We’ve seen bearing installations fail when coating thickness created interference fits, requiring expensive post-galvanizing machining.

Critical adjustments: Increase bearing bore diameters by 0.003″ before galvanizing. For pin connections, reduce pin diameter by 0.002″ or increase holes by 0.003″. Tap threaded holes 0.004″ oversize before galvanizing.

Cost approach depends on complexity: Designs with fewer than 5 critical dimensions work best with post-galvanizing machining ($8-15 per feature). 5-15 critical dimensions favor adjusting CAD dimensions with no cost penalty. More than 15 critical dimensions suggests bare steel with post-assembly galvanizing.

When clearances exceed 0.010″, coating thickness rarely creates problems. Clearances of 0.005-0.010″ should be adjusted during design. Clearances under 0.005″ require post-galvanizing machining or alternative materials.

Design Takeaway: Build coating thickness into tolerance calculations during CAD design phase. Specify post-galvanizing machining only for truly critical fits. Plan coating thickness verification for production quality control.

What galvanized steel grades work best for structural vs decorative parts?

G90 galvanized steel works best for structural CNC machined parts and sheet metal fabrication, providing 50+ year durability. Electro-galvanized steel suits decorative stamped components requiring smooth finishes. G60 offers balanced performance for general metal fabrication applications.

Quick Grade Selection Decision Tree:

- Outdoor exposure >15 years + structural loads → G90 galvanized

- Indoor decorative + smooth finish required → Electro-galvanized

- General industrial + 10-15 year service life → G60 galvanized

- Cost-critical + indoor use only → G60 galvanized

G90 coating provides 0.9 oz/ft² of zinc under ASTM A653 (0.76 mils per side), delivering maximum corrosion protection for structural applications. Based on 15+ years machining galvanized components, G90’s thicker coating requires 15-20% speed reduction to prevent zinc buildup on carbide tools, but delivers exceptional outdoor durability for CNC machined brackets and chassis components.

Manufacturing Performance Data:

- G90 CNC Machining: Requires flood coolant, produces excellent surface finish at 200-250 SFM in aluminum toolpaths

- Electro-galvanized Stamping: 95% die life compared to bare steel, minimal galling in progressive operations

- G60 Sheet Metal Forming: Standard forming forces, coating adds 0.001-0.002″ to bend radius calculations

Real Application Examples: We’ve machined G90 automotive brackets performing excellently after 18 years of road salt exposure, while G60 indoor enclosures show first rust signs after 12-15 years in humid industrial environments. Electro-galvanized faceplates maintain smooth appearance for 8-10 years indoors but fail within 2-3 years if exposed to outdoor conditions.

Cost Analysis for 12″ x 8″ CNC Machined Component:

- G90 galvanized: $28-35 (material + machining + 20% cycle time increase)

- G60 galvanized: $25-30 (standard machining speeds)

- Electro-galvanized: $22-28 (fastest machining, premium material cost)

- 304 Stainless alternative: $45-60 (50% slower machining, no coating limitations)

Risk Assessment: Choosing G60 for 20+ year outdoor applications typically results in coating failure after 8-12 years, requiring replacement or refinishing at 60-80% of original part cost. Over-specifying G90 for indoor decorative applications wastes 15-25% in material and machining costs with no performance benefit.

Design Takeaway: Match coating grade to actual environmental exposure and service life requirements. G90 for outdoor structural CNC and sheet metal work, electro-galvanized for decorative stamped components, G60 for cost-sensitive general fabrication. Factor coating thickness into machining speeds and forming calculations during manufacturing planning.

Will galvanized coating affect electrical conductivity or grounding in my design?

Galvanized coating adds 0.1-1.0 ohms electrical resistance, affecting CNC machined enclosures and stamped electrical components. Plan grounding provisions for sheet metal assemblies requiring EMI shielding or safety grounding.

Electrical Resistance Decision Framework:

- <5 electrical connections → Use star washers or grounding hardware ($1-3 per connection)

- 5-10 connections → Machine grounding pockets during CNC operations ($2-5 per feature)

- >10 connections → Consider 304 stainless steel (60% material premium, eliminates grounding issues)

- EMI shielding required → Mandatory conductive provisions regardless of connection count

Testing with calibrated multimeters shows galvanized coating typically measures 0.3-0.8 ohms contact resistance compared to <0.01 ohms for bare steel. This resistance affects both grounding effectiveness and EMI shielding performance, creating compliance issues for electronics enclosures and safety circuits that require <0.1 ohm protective grounding per electrical codes.

Manufacturing Solutions by Resistance Level:

- Low resistance needed (<0.1 ohm): CNC machine 0.010″ deep grounding pockets, removing coating completely

- Moderate resistance acceptable (0.1-0.5 ohm): Use star washers with 50+ lb torque to bite through coating

- High resistance tolerable (>0.5 ohm): Standard hardware with conductive paste or EMI gaskets

Compliance Testing Requirements: UL and CE electrical safety standards require documented continuity testing showing <0.1 ohm resistance for protective grounding circuits. Plan for production testing costs of $2-5 per unit when electrical continuity is critical for product certification.

Real Failure Examples: We’ve seen CNC machined electronics enclosures fail FCC EMI testing due to poor gasket contact through galvanized coating, requiring $15,000 in redesign and retesting. Automotive stamped brackets showed intermittent grounding failures until star washers were added at all electrical connection points.

Process Integration Strategies: Program grounding pocket removal during initial CNC setup rather than secondary operations (saves 60% of grounding provision costs). Design stamping dies to include electrical contact tabs that pierce coating during forming. Specify conductive hardware on assembly drawings to avoid field grounding issues.

Design Takeaway: Address electrical continuity during design phase, not assembly. Specify grounding provisions on manufacturing drawings, budget for electrical testing, and consider material alternatives when electrical performance equals corrosion protection in importance. Don’t discover grounding problems during final product testing or field deployment.

Can I paint, powder coat, or finish galvanized steel without issues?

Yes, but galvanized steel requires surface preparation for proper paint adhesion. Light sandblasting or chemical etching is needed for G90/G60 coatings, while electro-galvanized accepts paint with minimal prep. Powder coating works excellently on all galvanized grades with proper surface treatment.

Do you even need finishing? Outdoor structural parts like brackets need no additional coating – galvanized alone provides 50+ years protection. Indoor industrial components work fine bare. Paint outdoor visible parts for aesthetics, indoor decorative parts for professional appearance.

G90/G60 galvanized steel requires surface prep due to rough zinc crystalline texture. Light sandblasting ($3-8 per part) or phosphoric acid etching ($2-5 per part) ensures adhesion. Electro-galvanized accepts paint with simple degreasing. Skip prep and expect paint failure within 6-12 months.

Powder coating outperforms liquid paint on galvanized substrates, providing 15-25 year durability versus 5-10 years for powder over bare steel. The 300-400°F curing doesn’t damage zinc coating.

Surface prep adds 2-3 days to finishing schedules. Field touch-up uses zinc-rich spray pens for 15 minutes per scratch. Light colors last longer than dark colors in UV exposure.

Design Takeaway: Question whether additional finishing is necessary beyond galvanized protection. Specify surface prep method on drawings and factor 2-3 days into delivery schedules. Consider powder coating for maximum outdoor durability.

How does galvanized steel compare to stainless in cost and performance?

Galvanized steel costs 75-80% less than stainless steel while providing adequate corrosion protection for most outdoor applications. Stainless steel offers superior corrosion resistance, strength, and aesthetics but at 4-5x higher material cost. Choose galvanized for cost-sensitive structural applications, stainless for marine, food contact, or high-aesthetic requirements.

Stainless steel costs 4-5 times more than galvanized steel. A 12″ x 8″ enclosure costs $25-35 galvanized versus $75-125 stainless. Galvanized provides 50+ years protection with touch-up after 15-20 years, while stainless remains maintenance-free.

Application selection guide: Electronics enclosures use galvanized for budget products, stainless for premium/EMI shielding. Audio equipment benefits from stainless for high-end lines, galvanized for budget models. Industrial brackets typically use galvanized unless chemical exposure requires stainless.

Hybrid strategy: Use galvanized for hidden structural parts, stainless for visible surfaces. Reduces material costs 40-60% versus all-stainless while maintaining premium appearance where customers interact.

Manufacturing differences matter: galvanized machines 15-20% slower but offers shorter lead times and broader supplier availability. Stainless requires specialized tooling but provides better surface finish and tolerances.

Customer perception: Stainless conveys premium quality, justifying higher selling prices. Galvanized works for industrial customers prioritizing function over aesthetics.

Design Takeaway: Evaluate total lifecycle cost including material, manufacturing, and customer expectations. Use galvanized for cost-sensitive applications where 50+ year service life meets requirements. Reserve stainless for premium products, food contact, or marine environments.

Conclusion

Galvanized steel delivers excellent corrosion protection for most industrial applications at significantly lower cost than stainless steel. Choose grades and processes based on your specific environment, aesthetic requirements, and budget constraints. Contact us to explore CNC machining, sheet metal fabrication, and stamping solutions tailored to your galvanized steel product requirements.

Frequently Asked Questions

Account for 0.0015-0.003″ total coating thickness in clearance calculations. For bearing fits or precision assemblies, increase bore diameters by 0.003″ or specify post-galvanizing machining. Thread connections work best when tapped 0.004″ oversize before galvanizing.

Outdoor structural components need no additional finish – galvanized alone provides 50+ year protection. Indoor decorative parts or customer-facing surfaces typically require powder coating for professional appearance. Budget surface prep costs of $2-8 per part for proper paint adhesion.

Galvanized steel requires design considerations for welding (prefer mechanical fasteners), electrical grounding (plan connection points), and tight tolerances (account for coating thickness). These are manageable design constraints that enable significant cost savings for most applications.

For budget products and general industrial use, galvanized steel provides excellent corrosion protection at 75% lower cost. Choose stainless steel when you need premium aesthetics, EMI shielding properties, or marine environment resistance that justifies 4-5x higher material cost.

G90 galvanized steel easily meets 15-year outdoor requirements and typically lasts 50+ years in atmospheric conditions. G60 works for lighter-duty applications but may require touch-up after 10-12 years in harsh environments. Avoid electro-galvanized for outdoor warranty commitments.

Yes, galvanized coating adds 0.1-1.0 ohms contact resistance. For products with electrical safety requirements, specify grounding pocket removal during machining or use star washers that bite through coating. Consider stainless steel if you have 10+ electrical connection points.