Engineers frequently ask us about countersink specifications during design reviews—particularly when balancing aesthetic requirements with manufacturing feasibility. At Okdor, we’ve machined countersunk holes across aerospace, medical, and audio components, giving us insight into what works efficiently versus what creates unnecessary production complexity.

Countersinking creates a conical recess allowing screw heads to sit flush with the part surface. CNC countersinking typically holds ±0.1mm diameter tolerance at 82° or 90° angles, with ±0.05mm depth control when specified. Most applications use 82° to match standard screw geometry.

Specify countersinks correctly to boost manufacturability, avoid costly drawing errors, and select the right angles with real CNC machining insights.

Table of Contents

What Is Better: Countersink vs Counterbore vs Spotface?

Countersinks create flush screw mounting, counterbores provide socket head clearance, and spotfaces ensure flat bolt bearing surfaces. Choose based on fastener type and assembly requirements.

Key differences:

- Countersink: Angled recess for flush-mounted screws (82°-90° typical)

- Counterbore: Flat-bottom recess for socket head cap screws with tool clearance

- Spotface: Shallow flat surface for consistent bolt head bearing contact

We’ve observed that countersinks typically require 0.5-1.0x screw head height for proper flush seating, while counterbores need 1.2-1.5x socket head height based on our assembly testing with clients. Spotfaces require only 0.3mm minimum depth to ensure full bearing contact—verified through CMM inspection on structural components we’ve produced for aerospace applications.

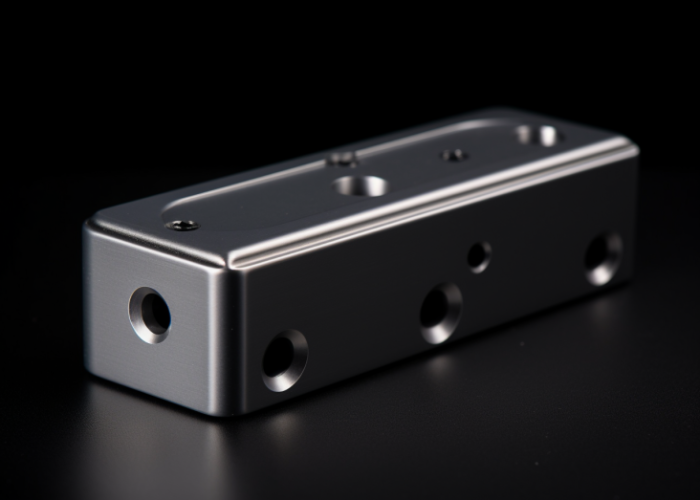

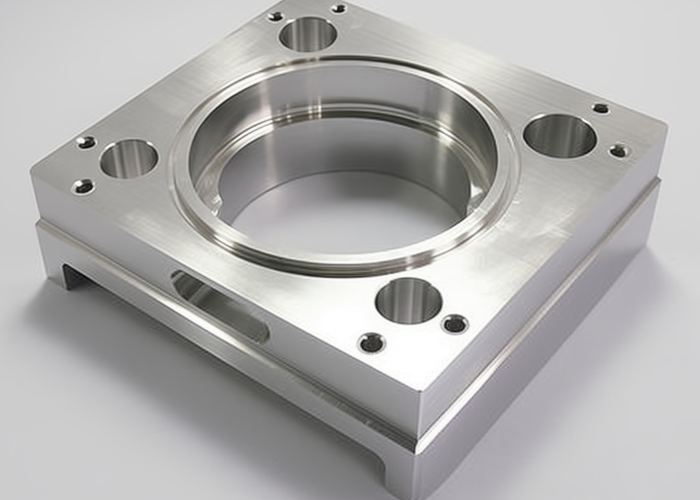

Flush mounting applications favor countersinks for clean exterior surfaces, particularly in precision audio faceplates where we’ve achieved Ra 1.6μm surface finishes. Assembly access drives counterbore selection when socket head tools need clearance space—common in medical housing assemblies we manufacture. Load distribution requirements favor spotfaces when bolt bearing stress must be controlled, as specified in AS9100-compliant structural parts we’ve machined.

ASME Y14.5 defines standard symbology for each feature type, ensuring clear communication between design and manufacturing teams.

Design Takeaway: Choose countersinks for appearance-critical flush mounting, counterbores for socket screws requiring tool access, and spotfaces for controlled bearing stress distribution based on your specific assembly requirements.

What Countersink Angle Should You Use for CNC Parts?

82° matches most commercial screws and wood screws, 90° provides optimal strength in thin materials, and 100° is specified for aerospace fasteners. Angle selection must match your screw head geometry for proper seating and load transfer.

Standard angle applications:

- 82°: Universal compatibility with Phillips, slotted, and Torx screws

- 90°: Reduces stress concentration in materials <2mm thick

- 100°: Required for NAS and MS military specification fasteners

Material behavior around countersink edges drives angle selection in precision applications. We’ve machined 82° countersinks in 6061-T6 aluminum panels where standard commercial screws provide adequate bearing contact, while 90° angles in thin-wall structures prevent crack initiation at countersink-to-material transitions. 100° countersinks appear exclusively in aerospace parts where NAS1097 or MS24693 fasteners require specific angular compatibility for proper torque transfer.

Structural analysis shows that 90° countersinks distribute bearing stress more effectively in materials under 2mm thickness, reducing peak stress concentrations by approximately 15% compared to 82° angles in finite element modeling. Consumer electronics applications default to 82° for off-the-shelf screw compatibility, while defense applications mandate 100° angles per military fastener specifications documented in our quality management system.

Our precision machining centers maintain ±0.5° angular tolerance using carbide countersink tools calibrated to NIST-traceable angle standards.

Design Takeaway: Default to 82° for general applications, use 90° in thin materials where structural integrity matters, specify 100° only when mandated by military or aerospace fastener requirements.

How Do You Dimension Countersinks on Technical Drawings?

Use countersink symbol (⌐) with diameter × angle notation: “⌐8.0 × 82°” specifies an 8mm diameter countersink at 82° included angle. Add depth callouts only when flush seating affects function or appearance.

Standard dimensioning format:

- Symbol placement: Adjacent to hole callout on drawing views

- Dimension sequence: Diameter first, then angle (⌐6.3 × 90°)

- Depth specification: “FLUSH” or “0.2mm BELOW SURFACE” when critical

Clear dimensioning prevents costly manufacturing errors during first article inspection. Our production floor processes standard “⌐6.3 × 82°” callouts without additional clarification, while ambiguous or non-standard dimensioning requires engineering review that can delay project starts. Complete depth specifications like “FLUSH ±0.1mm” eliminate guesswork during setup, ensuring consistent screw head positioning across batch production runs.

Technical drawing clarity directly impacts manufacturing cost and quality. Parts with simple diameter and angle callouts allow immediate CAM programming, while over-dimensioned drawings with unnecessary geometric tolerancing increase inspection requirements without functional benefit. Documentation should specify only critical-to-function dimensions—appearance-critical surfaces justify depth control, while structural applications typically require only diameter and angle specifications.

ASME Y14.5 and ISO 128 define standard countersink symbology recognized across global manufacturing supply chains, ensuring consistent interpretation regardless of production location.

Design Takeaway: Dimension only functionally critical parameters—diameter and angle for most applications, depth control only when screw positioning affects assembly or appearance. Standard symbology eliminates interpretation errors.

Which Materials Machine Best for Countersink Holes?

6061-T6 aluminum produces excellent surface finish with minimal burring, 304 stainless requires controlled speeds to prevent work hardening, and engineering plastics like POM countersink cleanly with proper backing support. Material selection affects machining quality and post-processing compatibility.

Material machinability ranking:

- 6061-T6 Aluminum: Clean cutting, Ra 1.6μm surface finish achievable

- POM/Delrin Plastic: Excellent edge quality, minimal heat generation

- 304 Stainless Steel: Requires sharp tooling, prone to work hardening

Aluminum alloys consistently deliver the best countersinking results. 6061-T6 machines with clean cutting action, allowing us to maintain consistent surface finishes across production runs. Engineering plastics like POM and Delrin countersink exceptionally well with sharp carbide tools, producing crisp edges without melting when properly supported.

Stainless steel presents unique challenges—304 grade work hardens rapidly during countersinking, requiring flood coolant and frequent tool changes. Despite machining difficulties, stainless becomes necessary in corrosive environments where aluminum cannot perform.

Material choice determines post-processing options. Aluminum offers excellent anodizing characteristics after countersinking, ideal for consumer electronics where appearance matters. Engineering plastics provide electrical insulation for specialized applications where metal contamination must be avoided.

Medical device applications specify 316L stainless steel per ISO 10993 biocompatibility standards, while food contact surfaces require 304/316 grades per FDA material regulations.

Design Takeaway: Select 6061 aluminum for optimal machinability and finishing compatibility. Choose stainless steel only when corrosion resistance is functionally required, and engineering plastics for electrical insulation needs.

What Tolerances Can CNC Countersinking Hold?

Standard CNC countersinking holds ±0.1mm on diameter and ±0.05mm on depth. Precision setups achieve ±0.025mm diameter and ±0.01mm depth control with specialized tooling and rigid workholding.

Achievable tolerance ranges:

- Diameter: ±0.05mm standard, ±0.025mm precision capability

- Depth: ±0.02mm typical, ±0.01mm with depth stops

- Angular accuracy: ±1° standard, ±0.5° precision tooling

Production data from our machining centers shows diameter repeatability of ±0.03mm using quality carbide countersink tools in aluminum materials. Depth consistency reaches ±0.015mm with programmable depth stops and temperature-controlled environments.

Precision applications requiring ±0.01mm depth control utilize specialized fixtures and single-point cutting tools rather than standard countersink bits. This approach extends cycle time but ensures dimensional consistency verified through coordinate measuring machine inspection.

Tolerance selection impacts both quality and manufacturability. Precision assemblies justify tighter controls for consistent screw seating, while general applications achieve functional requirements within standard CNC capabilities.

ISO 2768-m general tolerance framework applies when specific countersink tolerances aren’t dimensioned on drawings.

Design Takeaway: Specify precision tolerances only when screw seating consistency affects critical function or appearance. Standard CNC tolerances meet most design requirements while maintaining manufacturing efficiency.

How Do You Reduce CNC Countersink Machining Costs?

Combine countersinking with through-hole drilling in single setups, use standard 82° or 90° angles, and specify looser tolerances to minimize cycle time and tooling costs. Avoid custom angles and unnecessary precision specifications that don’t affect function.

Cost reduction strategies:

- Single-setup operations: 35% cycle time reduction vs. separate operations

- Standard angle tooling: 50-70% cost savings over custom angle tools

- Relaxed tolerances: 40% faster feed rates compared to precision requirements

Setup consolidation provides the largest cost impact in our production environment. Combining pilot hole drilling with countersinking in one operation eliminates part handling, reduces setup time, and maintains better positional accuracy between features. Standard 82° and 90° countersink tools cost significantly less than custom angles and remain readily available from multiple suppliers, preventing delivery delays.

Tolerance specifications directly affect machining parameters and inspection requirements. Relaxed diameter tolerances (±0.1mm vs ±0.025mm) allow faster feed rates and longer tool life, while standard depth specifications eliminate secondary setup operations for precise depth control.

Design modifications can eliminate countersinking entirely. Recessed mounting surfaces created during primary machining operations often provide adequate screw clearance without additional countersink features, particularly in thick-wall enclosures where aesthetics aren’t critical.

Standard tooling ensures competitive pricing and availability from multiple suppliers, supporting both prototype and production scheduling requirements.

Design Takeaway: Design for standard tooling and consolidated operations. Reserve custom angles or precision tolerances for functionally essential applications—standard specifications often meet design intent at significantly lower manufacturing cost.

Conclusion

Countersink specifications significantly impact both part function and manufacturing cost. Choose angles and tolerances based on actual requirements rather than default tight specifications. Standard 82° angles with ±0.1mm tolerances meet most design needs efficiently. Contact us to explore countersink manufacturing solutions tailored to your product requirements.

Frequently Asked Questions

Use standard symbology (⌐8.0 × 82°), specify only diameter and angle unless depth is critical, and avoid over-tolerancing non-functional features. Clear callouts prevent manufacturing delays and cost increases.

Use countersinks for flush-mounted screws in appearance-critical applications and thin materials. Choose counterbores when you need socket head cap screws with tool access clearance or precise pilot hole control.

Yes, using proper workholding and backing support. 90° angles work better than 82° in materials under 2mm thick to reduce stress concentration and prevent cracking around countersink edges.

Aerospace typically requires 100° angles for NAS/MS fasteners with tighter tolerances. Medical devices need 316L stainless material per ISO 10993, with documentation per ISO 13485 quality standards.

Combine countersink operations with through-hole drilling in single setups, use standard 82° angles, and specify ±0.1mm tolerances unless tighter control affects function. This reduces costs by 30-50%.

Custom angles other than 82° or 90°, tolerances tighter than ±0.05mm without functional justification, and depth callouts when flush seating isn’t critical. These can increase costs by 40-70% over standard specifications.