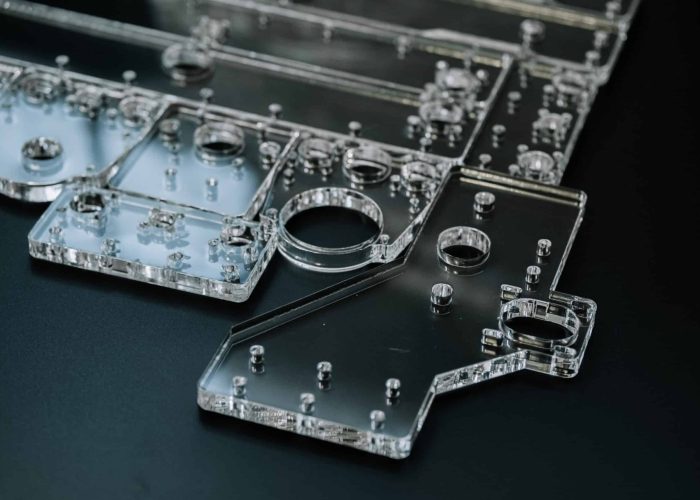

Designing precision parts with acrylic isn’t just about transparency — it’s about understanding thermal limits and stress behavior. With decades of CNC experience across medical and aerospace sectors, material selection makes the difference between success and costly failures.

Yes, acrylic is relatively easy to machine when you use sharp carbide tools, moderate speeds, and proper cooling. Most features hold ±0.05 mm tolerances with excellent surface finishes, but heat sensitivity requires careful parameter control.

Discover feed rates that prevent melting, geometries that risk cracking, and how to get optical-quality finishes—backed by real machining experience.

Table of Contents

Should I use acrylic or switch to polycarbonate for machining?

For most CNC applications, start with acrylic unless your part will see impacts above normal handling or continuous temperatures above 80°C. Acrylic machines more easily with superior optical clarity (92% vs 88% light transmission), costs 35-50% less than polycarbonate, and delivers better surface finishes straight off the machine.

Here’s how to validate your material choice: Drop your prototype from 3 feet onto concrete — if acrylic cracks, you need polycarbonate’s impact strength. For temperature, if your application sees sustained heat above 80°C, acrylic will soften while polycarbonate remains stable up to 100°C. From our experience machining medical housings and audio components, acrylic consistently delivers glass-like transparency without post-processing.

Material costs run $1.50-2.00/kg for acrylic versus $2.50-3.50/kg for polycarbonate. Polycarbonate’s toughness also increases cycle times by 20-30% and requires more frequent tool changes due to its abrasive nature.

For precision enclosures, display panels, and clear protective covers where clarity matters most, acrylic remains our top recommendation. Switch to polycarbonate for safety shields or any application where impact failure could cause injury.

Design Takeaway: Use this decision tree: Room temperature + normal handling = acrylic for cost and clarity. High temperature (>80°C) or impact risk = polycarbonate for durability. When in doubt, prototype with acrylic first.

How thick do acrylic walls need to be to avoid breaking?

Keep acrylic walls at minimum 1.5mm thick for reliable CNC machining without cracking or deformation. While 0.8mm is theoretically possible under perfect conditions, 1.5mm provides the structural integrity needed to prevent warping during cutting and handling stress after machining. Walls thinner than 1.0mm tend to vibrate during machining, leading to poor surface finish and dimensional inaccuracy beyond standard ±0.13mm tolerances.

Here’s how to validate your wall thickness: Flex test your prototype — gently bend a 50mm section of your thinnest wall by 3-5mm. If you see stress whitening or micro-cracks, increase thickness by 50%. Standard PMMA shows brittle failure with low deformation (0.002-0.003%) before cracking. For corners and junctions, add fillets with radius equal to half the wall thickness — this reduces stress concentration by 40-60%.

Height-to-thickness ratio matters significantly — keep walls under 10:1 ratio to prevent chatter during machining. A 15mm tall wall needs minimum 1.5mm thickness, while 30mm heights require 3mm for stability. For mixed wall sections, transition gradually over 3-5x the thickness change to avoid stress concentrations.

Design Takeaway: Start with 1.5mm minimum, increase to 2mm for walls over 20mm tall. Add 0.5mm radius fillets at all internal corners. Connect thin features to thicker sections with ribs. Always prototype thin-wall designs first — your flex test will reveal structural weaknesses before costly production failures.

What tolerances can I realistically hold with machined acrylic?

Standard CNC machining holds ±0.13mm (±0.005″) on most acrylic features, with ±0.05mm achievable on critical dimensions using proper temperature control and sharp tooling. Most shops achieve ±0.25mm as standard tolerance, while precision work can reach ±0.02mm on shorter features machined in single setups. Key factors include maintaining 22°C room temperature, using carbide tools, and limiting depth of cut to 0.5-1.0mm per pass.

Which dimensions actually need tight tolerances? Ask yourself: Does this feature mate with another part? Tolerance stack-up occurs when parts are at their size extremes — a 10mm hole at minimum (9.95mm) won’t fit a 10mm shaft at maximum (10.05mm). Reserve ±0.05mm for press fits, threaded holes, and optical surfaces. Use ±0.13mm for non-critical features like overall part dimensions.

Thermal expansion is acrylic’s biggest tolerance enemy — a 10°C temperature swing stretches a 200mm part by 0.12mm, breaking tight tolerance windows. Large parts (>300mm) typically require ±0.20mm tolerance due to thermal effects and machine deflection.

Design Takeaway: Specify ±0.13mm as your default tolerance. Call out ±0.05mm only for functional surfaces like bearings, seals, or assemblies. Cost impact: Each tight tolerance doubles that feature’s machining time. Mark up your drawing showing which dimensions control function — tolerance the function, not every edge.

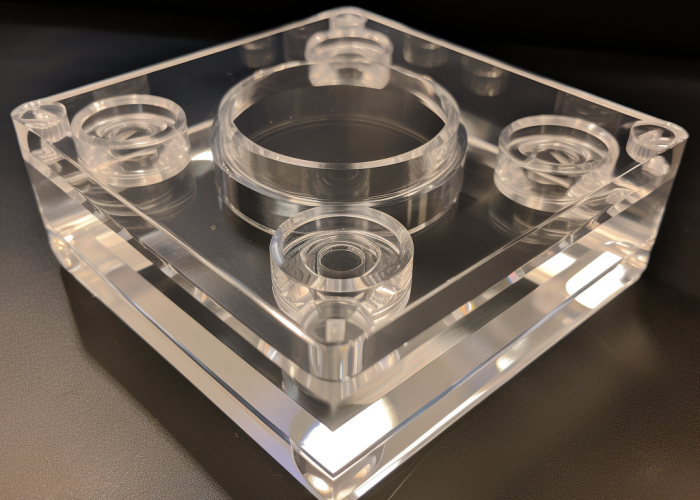

What geometries should I avoid when designing acrylic parts?

Avoid sharp internal corners, deep narrow pockets, and unsupported thin features that create stress concentrations and machining difficulties. Sharp internal corners cannot be fully machined due to round cutting tools and limit cavity depth to 4x their width with minimum 0.5mm radius on all corners. Machining reality check: Can a 3mm end mill reach every corner? If not, add radii or split the part.

Cost-driving geometries: Deep pockets beyond 4:1 ratio require long tools, doubling setup time. Tall thin ribs vibrate during cutting. Text engraving adds tool changes. Assembly economics: Splitting complex parts often costs less than exotic tooling for single-piece construction.

Keep engraved text minimum 0.8mm deep with 5mm font height. For unavoidable complex geometries, budget 2-3x standard machining cost. Use solvent bonding (invisible joints) or mechanical fasteners when complexity becomes cost-prohibitive.

Design Takeaway: Apply the “3mm end mill test” — if standard tooling can’t reach it, redesign or accept cost increases. Consider part splitting when complexity exceeds assembly costs. Mark only functional dimensions for tight tolerances.

What are the biggest design mistakes that make acrylic parts fail?

The top failure mode is stress cracking from environmental stress and temperature cycling, often appearing days or weeks after production. Unlike polycarbonate which flexes, acrylic cracks rather than deforms when stressed beyond its elastic limit. Temperature cycling and chemical exposure accelerate failures.

Validation protocol: Apply 150% of expected service load for 24 hours at operating temperature. Any crazing indicates future failure zones. Material upgrade decision: Switch to polycarbonate when impact resistance exceeds 17x glass strength or operating temperature exceeds 80°C continuously.

Critical mistakes: using acetone-based cleaners (causes environmental stress cracking), insufficient stress-relief annealing, and over-clamping during production. Many parts pass inspection but fail later due to residual stress.

Design Takeaway: Upgrade criteria: If your application involves repeated impacts, vibration above 10Hz, or thermal cycling >30°C, specify polycarbonate despite 35% higher cost. Add 100% safety margins for dynamic applications and specify stress-relief annealing on drawings.

Can I add threads or press-fit features to machined acrylic?

Yes, but use thread cutting tools instead of traditional taps, and limit thread depth to 1.5x diameter to prevent stress cracking. The key difference is using sharp double-tooth cutters with ~0.1mm machining allowance rather than forcing a tap through brittle material. Single-lip threading tools work best for internal threads since they cut rather than displace material like traditional taps.

Thread cutting capabilities include boring, facing, and grooving, with standard sizes from UNC/UNF #2 to 1/2″ and metric M2-M12. However, acrylic’s brittleness means threaded connections are inherently weaker than the base material. For any significant loads or dynamic applications, consider alternatives like heat-set metal inserts which provide reliable metal-to-metal threading without machining stress.

When specifying threaded acrylic parts, your drawing should call out “Thread with single-point tool, stress relieve after machining” to prevent machinists from defaulting to standard taps. Press-fits need even more caution — limit interference to 0.025-0.05mm maximum, or the material simply cracks during assembly.

Design Takeaway: For light-duty static connections, direct threading works fine. For any dynamic loading, vibration, or frequent assembly/disassembly, invest in heat-set inserts or redesign with clearance holes and mechanical fasteners. Always prototype threaded connections under expected loads before committing to production.

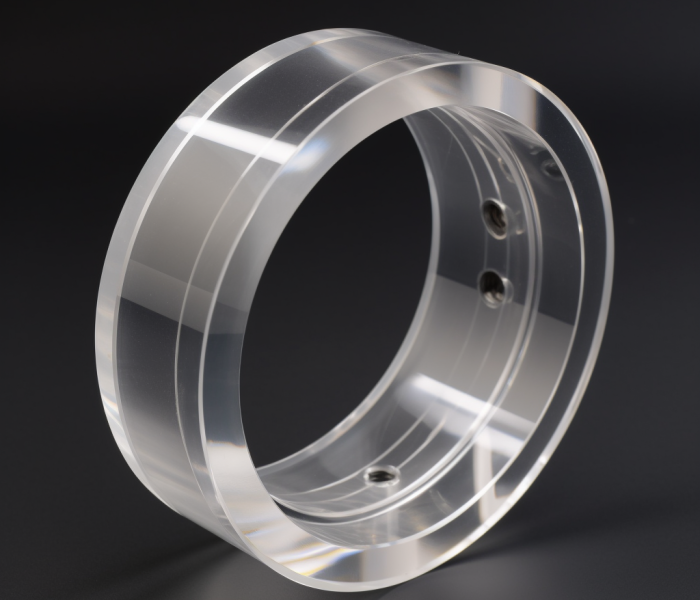

What surface finish can I expect from machined acrylic?

Standard CNC machining produces Ra 0.8-3.2 μm translucent finish with visible tool marks — excellent for non-optical applications but requires post-processing for optical clarity. Think of it this way: fresh off the machine, acrylic looks functional but not beautiful. You can see through it, but tool marks create a frosted appearance that’s fine for internal components but not display-quality work.

The industry uses three practical grades that directly relate to what you can actually see through the material. Grade 1 as-machined works for hidden surfaces where appearance doesn’t matter. Grade 2 vapor polishing lets you detect air bubbles in fluid systems and see general shapes — perfect for functional transparency. Grade 3 optical quality achieves window-glass clarity where you can read text or make precise measurements through the material.

Cost reality hits hard here: finishing can double your part cost, so specify wisely. Flame polishing handles simple edges quickly and cheaply, while vapor polishing reaches internal features that manual methods can’t touch. The smart approach is marking your drawings clearly — call out “Grade 3 optical polish” only where you truly need it, and “Grade 1 as-machined” everywhere else.

Design Takeaway: Request finish samples during prototyping to validate what “optical quality” actually means for your application. Many projects over-specify clarity, then get shocked by finishing costs that could’ve been avoided with better planning.

Conclusion

Acrylic tolerances tighter than ±0.13mm are often unnecessary for most components and increase cost significantly. Focus tolerances on functional surfaces, use 1.5mm minimum wall thickness, and specify stress-relief annealing for reliable parts. Smart geometry choices prevent most failures.

Contact us to explore CNC acrylic manufacturing solutions tailored to your product requirements.

Frequently Asked Questions

Calculate 0.07mm expansion per 100mm length per 10°C temperature change. If your tolerance stack-up has less than 0.1mm total clearance and parts see >20°C temperature swing, either loosen tolerances or add thermal compensation features.

Reference an approved sample part and specify “visual comparison under fluorescent lighting at 24 inches.” Include acceptance criteria: “no visible tool marks or scratches detectable without magnification.” Avoid subjective terms like “crystal clear.”

If your single-piece machining quote exceeds 3x the cost of simple geometry, consider assembly alternatives. Factor in solvent bonding time (~30 seconds) vs complex CNC setup costs. Generally, assemblies become cost-effective when part complexity requires 4+ axis machining.

CNC machining becomes cost-effective around 10-25 parts depending on complexity. Simple geometries favor CNC at lower quantities, while complex internal features may justify 3D printing up to 50+ pieces. Request quotes for both at your target quantity.

Specify “clean with warm soapy water only – NO alcohol, acetone, or ammonia-based cleaners.” Include this warning on product documentation. Environmental stress cracking from improper cleaning causes delayed field failures months after delivery.

For cyclic loads above 25N or any shock loading, use heat-set metal inserts. Direct acrylic threading works only for static mounting under 100N. When in doubt, prototype with expected loads for 1000 cycles before committing to production threading.