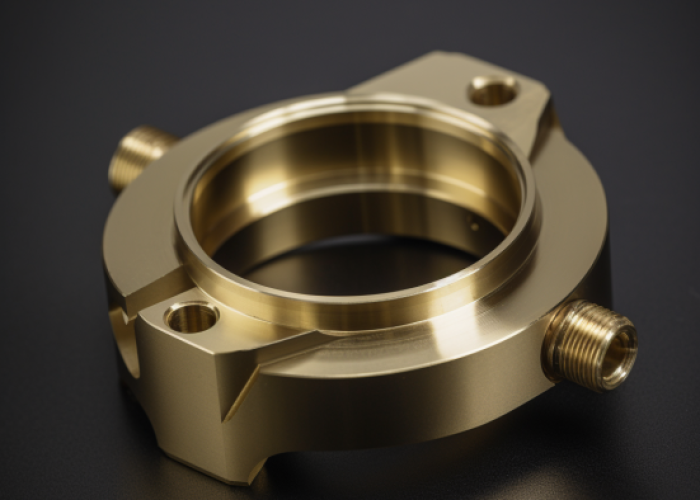

Choosing the right material for CNC parts isn’t just about strength or cost – it’s about balancing performance with manufacturability. With decades of experience machining brass components for audio, medical, and aerospace applications, we’ve helped engineers navigate the brass-versus-aluminum decision countless times.

Yes, brass is exceptionally easy to machine – typically 20-30% faster than aluminum with superior surface finishes. Brass cuts cleanly at high speeds with minimal tool wear, often making it cost-competitive despite higher material costs. Most CNC operations can hold ±0.01 mm tolerances on brass using standard tooling and ISO 2768-m practices.

Find out when brass is more cost-effective than aluminum, which uses justify the premium, and how to avoid spec mistakes that raise costs.

Table of Contents

Should I consider brass over aluminum for my part?

Choose brass when you need premium appearance for visible parts or when working with existing brass components. Choose aluminum for everything else – it’s stronger, lighter, cheaper, and actually conducts electricity better than brass. Brass costs $2-3 more per pound, so only use it when aluminum won’t work.

Simple Decision:

- Looks matter: Brass for that premium gold-like finish

- Strength matters: Aluminum (much stronger and 3x lighter)

- Electrical parts: Aluminum (better conductivity despite myths)

- Marine/outdoor: Aluminum with protective coating

- Budget matters: Aluminum

Aluminum is significantly stronger (240 MPa vs 95 MPa) and conducts electricity better (61% vs 28% IACS)han brass. The main reason to choose brass is appearance – it looks like gold and gives products a premium feel.

Choose brass for: High-end audio equipment faceplates, decorative trim, luxury product housings. Choose aluminum for: Almost everything else – brackets, enclosures, heat sinks, structural parts.

Design Takeaway: Unless you specifically need brass’s gold-like appearance for marketing reasons, aluminum performs better in nearly every way while costing less.

How much more will brass cost than aluminum or steel?

For a typical 0.5 lb part, brass adds $1-1.50 in material cost over aluminum. Brass costs $2-3 more per pound than aluminum , but both materials machine similarly in terms of speed and efficiency. The total cost impact depends more on part complexity and volume than machining time differences.

Real Budget Impact:

- 1-10 parts: Cost difference usually under $20 total – choose based on performance

- 100 parts: Brass adds $100-150 – consider if features justify premium

- 1000+ parts: Material premium becomes significant – use aluminum unless brass essential

- Parts under $5 total cost: Material choice rarely affects project budget

- Parts over $20 total cost: Brass premium typically <15% of total cost

Brass is also “much harder to find compared to aluminum,” which can drive up prices due to limited availability. For simple parts with minimal machining, aluminum’s cost advantage dominates. For complex geometries, brass “cuts much more easily with faster speeds and feeds without negatively impacting tool wear” can help offset some material premium.

When brass costs more: Large parts (>2 lbs), simple geometries, high-volume production. When costs are similar: Complex machined parts, short runs, when material cost is small portion of total part cost.

Design Takeaway: Calculate total part cost including machining. For budgets under $500 total, choose based on performance needs. For high-volume production, aluminum’s material savings usually win unless brass features are essential.

What applications is brass actually good for?

Choose brass when aluminum looks too industrial for consumer products, when you need better threading performance in assemblies, or when moderate electrical conductivity with premium appearance matters. Brass solves specific problems that aluminum and plastic can’t handle well.

Choose Brass When You Need:

- Premium appearance: Consumer electronics where aluminum looks cheap or industrial

- Better threading: Direct threading into aluminum “is rarely a good idea” while brass handles threading better

- Electrical + aesthetic: Audio binding posts, high-end switch housings, luxury connectors

- Moderate marine exposure: Short-term marine applications where appearance matters

- Precision + durability: Instrument housings, gauge components, measurement equipment

Specific Problem-Solving:

- Threading reliability: Aluminum threading requires “inserts are a better option” while brass can be directly threaded

- Appearance problems: When anodized aluminum still looks “industrial” for luxury products

- Electrical needs: 28% IACS conductivity adequate for most terminals and low-current applications

- Machining advantages: Brass “wants to get out of the way” while aluminum “often sticks to the tool”

Never Choose Brass When:

- High loads: Aluminum’s 240 MPa yield strength beats brass’s 95 MPa for structural parts

- Weight matters: Aerospace, automotive, portable devices benefit from aluminum’s 3x lighter weight

- High current: Power applications need aluminum’s superior 61% IACS conductivity

- Extended marine exposure: Both materials show corrosion over time in ocean environments

Design Takeaway: Use brass to solve specific problems – appearance, threading reliability, or moderate electrical needs. Choose aluminum when strength, weight, or electrical performance are priorities over aesthetics.

| Brass Grade | Brass Name | Composition | Typical Applications |

| C26000 | Cartridge Brass | 70% Copper, 30% Zinc | Ammunition casings, decorative hardware, musical instruments |

| C36000 | Free-Cutting Brass | 61.5% Copper, 35.5% Zinc, 3% Lead | High-speed machining, gears, valves |

| C46400 | Naval Brass | 60% Copper, 39.2% Zinc, 0.8% Tin | Marine hardware, propeller shafts, saltwater applications |

| C22000 | Commercial Bronze | 90% Copper, 10% Zinc | Architectural applications, screws, rivets |

| C23000 | Red Brass | 85% Copper, 15% Zinc | Plumbing fittings, heating equipment, fire extinguishers |

| C28000 | Muntz Metal | 60% Copper, 40% Zinc | Architectural work, fasteners, marine construction |

| C38500 | Architectural Bronze | 57% Copper, 40% Zinc, 3% Lead | Door and window frames, ornamental designs |

| C68700 | Aluminum Brass | 76% Copper, 22% Zinc, 2% Aluminum | Heat exchangers, condenser tubes |

| C71500 | 70-30 Copper-Nickel | 70% Copper, 30% Nickel | Desalination units, marine applications, high-performance tubing |

| C92200 | Navy M Bronze | 88% Copper, 6% Tin, 4.5% Zinc, 1.5% Lead | High-strength bearings, gears, marine applications |

Will brass corrode or tarnish in my environment?

For internal components, aluminum works fine 95% of the time – only choose brass when saltwater contact, chemical exposure, or galvanic corrosion creates actual functional problems. After 155 days in ocean exposure, brass showed “tarnishing but maintains structural strength” but most internal parts never see these conditions.

Most internal components live in benign environments where corrosion differences don’t matter functionally. Your internal bracket in an outdoor equipment enclosure? Aluminum works fine. Internal housing for office equipment? Definitely aluminum. The brass premium only makes sense when you have real environmental threats – not imaginary “what if” scenarios.

The exceptions are specific: internal components in marine electronics that might see saltwater intrusion, chemical processing equipment where fluids contact internal parts, or mixed-metal assemblies where galvanic corrosion between aluminum and steel fasteners becomes problematic. Dezincification in brass “retains its shape but little of its strength” but this only matters in actual corrosive environments, not typical enclosed applications.

Design Takeaway: Start with aluminum for all internal parts. Only specify brass when you can point to specific environmental conditions (saltwater, chemicals, galvanic issues) that will actually contact the part and cause functional problems.

Can I get the surface finish and appearance I need?

Both materials achieve any surface finish you need for internal parts – choose brass only when threaded components require repeated assembly/disassembly by service technicians. Both materials “can achieve smooth finish” for any functional requirement.

Surface finish is rarely the limiting factor for internal components. Ra requirements for sealing, press fits, or sliding surfaces are easily met by both materials. The real question is whether people will be threading and unthreading your part multiple times in the field.

Direct threading into aluminum “is rarely a good idea” when service techs need to remove internal access panels, housings, or covers repeatedly. Aluminum threads strip after 10-20 cycles; brass handles hundreds. But for permanent internal assemblies – brackets welded in place, press-fit components, or one-time factory assembly – aluminum’s strength advantage outweighs threading concerns.

Design Takeaway: Use aluminum for permanent internal assemblies. Specify brass only for internal threaded parts that field service will repeatedly remove – access covers, service panels, or maintenance points that technicians must regularly unthread.

What are the downsides of choosing brass?

Brass costs 2-3x more than aluminum, is significantly weaker for structural applications, and creates supply chain complications that affect project timelines and budgets. Aluminum’s 240 MPa yield strength significantly outperforms brass at 95 MPa, forcing design compromises most projects don’t need.

The material cost difference might seem manageable for prototypes, but volume production reveals the true impact. A 1000-piece run of 0.5 lb parts adds $1000-1500 in raw material costs over aluminum – money that rarely improves product performance for internal components. This cost premium forces difficult conversations with procurement teams who will question brass specifications unless you can demonstrate clear functional benefits.

Beyond material cost, brass creates additional project burdens through its physical properties. The metal is approximately 3x heavier than aluminum, adding shipping costs and requiring stronger mounting points throughout your design. Brass is “much harder to find compared to aluminum” creating longer lead times and fewer supplier options. When project timelines tighten, aluminum’s universal availability keeps production moving while brass sourcing becomes a bottleneck.

Assembly complications add further challenges. Aluminum and brass “should never be in direct contact with one another in the marine environment” requiring isolation methods that complicate manufacturing processes.

Design Takeaway: These accumulated downsides – cost, weight, supply constraints, and assembly complications – typically outweigh brass’s benefits unless aluminum creates specific functional problems most projects cannot solve through design modifications.

How does brass compare to other metals for machining?

Both brass and aluminum machine efficiently enough that manufacturing considerations rarely justify choosing one over the other – focus on part performance and supply chain reality instead. “Aluminum is generally easier to machine than brass. Aluminum is softer, more ductile, and less prone to tool wear, allowing for faster cutting speeds”.

While machinists often debate subtle differences between these materials, the practical reality is that both cut cleanly and efficiently. Brass machines “40 to 50% more efficient” than stainless steel, but this advantage becomes irrelevant when comparing to aluminum, which also machines far better than steel. Both materials allow similar cutting speeds, achieve comparable surface finishes, and require similar tooling approaches.

The real manufacturing decisions stem from supply chain logistics rather than machining characteristics. Aluminum’s universal availability means any machine shop can source material quickly, and virtually every machinist has extensive experience optimizing cutting parameters for aluminum projects. This familiarity translates to predictable cycle times and reliable delivery schedules.

In contrast, brass sourcing introduces variables that affect project timelines more than any machining efficiency gains. Brass availability issues create procurement delays that dwarf any time savings from marginally easier cutting.

Design Takeaway: Choose materials based on part performance requirements and supply reliability rather than machining characteristics. Both materials machine predictably enough that manufacturing ease won’t determine project success – material availability and cost control will.

conclusion

Brass offers excellent machinability and specific performance advantages in threading and corrosion resistance, but aluminum provides superior strength-to-weight ratios and cost efficiency for most applications. Choose brass when aluminum’s limitations become design constraints, otherwise aluminum delivers better value. Contact us to explore manufacturing solutions tailored to your brass or aluminum machining requirements.

Frequently Asked Questions

Direct threading into aluminum “is rarely a good idea” for repeated assembly/disassembly. Brass handles threading cycles much better. For permanent assemblies, aluminum’s superior strength outweighs threading concerns. Use threaded inserts in aluminum for best of both worlds.

Brass is “much harder to find compared to aluminum” resulting in longer procurement times. Aluminum is universally available with shorter lead times. For tight project schedules, aluminum’s supply chain advantages often outweigh brass’s material benefits.

Aluminum actually has better electrical conductivity (61% IACS) than brass (28% IACS). This is a common misconception. Choose aluminum for electrical applications requiring high conductivity, brass only when moderate conductivity combined with threading durability or corrosion resistance is needed.

Both materials can hold ±0.01 mm tolerances with proper setups. Brass’s softer nature makes it slightly easier to achieve fine surface finishes, but aluminum’s dimensional stability often performs better in temperature variations. Choose based on your specific tolerance requirements and operating environment.

Aluminum and brass “should never be in direct contact with one another in the marine environment” due to galvanic corrosion. For indoor applications, direct contact is generally acceptable, but use isolation washers or coatings in humid or outdoor environments to prevent electrochemical reactions.

Brass typically costs $2-3 more per pound than aluminum. For a 0.5 lb part, expect $1-1.50 additional material cost. In 1000-piece production runs, this adds $1000-1500 to material costs. Factor in machining efficiency – both materials machine similarly, so material cost drives the difference.