Table of Contents

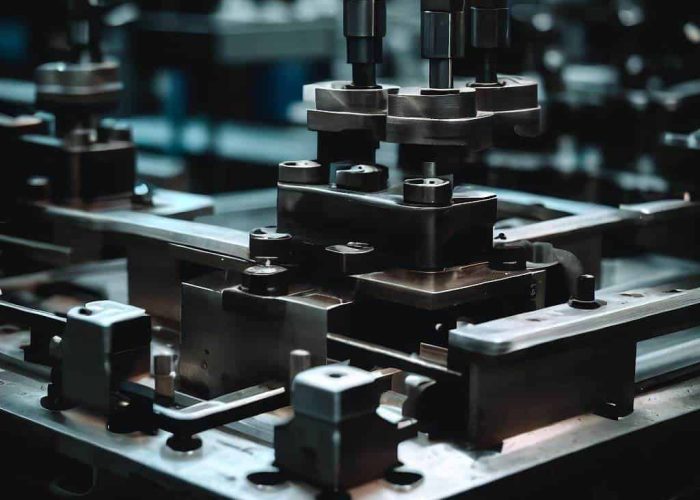

Defining Jigs and Fixtures

Jigs: A Brief Overview

Jigs are specialized manufacturing tools designed to guide cutting tools, drill bits, and other machining tools during production processes. They are a template or reference point for accurate and consistent machining operations.

One typical example of a jig is a drill jig, which aids in maintaining the correct position and alignment of the drill bit for precise hole drilling. Jigs play a vital role in manufacturing industries, such as automobile assembly lines and CNC machining centers, where dimensional accuracy and repeatability are essential.

Fixtures: Understanding Their Purpose

On the other hand, fixtures are work-holding devices that securely hold and locate workpieces during machining operations. Their primary function is to provide a secure mounting point and a predefined location for the workpiece, ensuring its stability and proper orientation throughout manufacturing.

Fixtures come in various types, including milling, grinding, and drilling fixtures, each designed for specific machining operations. They are often constructed from cast iron and metal threaded inserts to ensure durability and rigidity.

In CNC machining and other manufacturing processes, fixtures are crucial in maintaining the workpiece steady and preventing distortion due to machining forces.

They also reduce labor costs and production time by enabling efficient and accurate workpiece positioning during secondary operations, such as turning, tapping holes, and grinding. Fixtures are indispensable to modern manufacturing, promoting smooth operation and consistent quality across various processes.

Differences Between Jigs and Fixtures

While jigs and fixtures may appear similar and often coexist in manufacturing processes, they serve distinct purposes and have several differences.

- Function: The primary difference between jigs and fixtures is their function. Jigs help to guide cutting or machining tools, ensuring accurate and consistent operations. For example, a drill jig helps maintain the correct position and alignment of the drill bit for precise hole drilling. On the other hand, fixtures are work-holding devices that provide a secure mounting point and a predefined location for the workpiece, ensuring its stability and proper orientation during machining.

- Design complexity: Jigs tend to have a more complex design than fixtures, as they need to accommodate tool guidance features like drill bushings while also providing locating components for the workpiece. Fixtures, conversely, focus primarily on workpiece positioning and holding, with fewer moving parts and a more straightforward overall design.

- Application: Jigs play a crucial role in processes where the cutting tool must follow a specific path or pattern, such as drilling, tapping, and grinding operations. On the other hand, CNC machines have more uses and can be applied to a wider variety of manufacturing techniques, such as milling, turning, and even welding.

- Tooling interaction: Another significant difference between jigs and fixtures is their interaction with the cutting or machining tools. Jigs typically have direct contact with the tool, guiding it throughout the operation. In contrast, fixtures maintain their focus on the workpiece, providing a stable and secure platform for the machining process without interacting with the tool itself.

- Adaptability: Jigs are often designed for specific tasks or tooling, making them less adaptable than fixtures. Fixtures, however, can often be adjusted or reconfigured to accommodate different workpieces or machining processes, offering greater flexibility in manufacturing operations.

By understanding these differences, manufacturing professionals can make informed decisions when selecting the appropriate jig or fixture for a given process, ultimately improving efficiency, accuracy, and production quality.

Designing Jigs and Fixtures

General Design Rules

Following specific general rules when designing jigs and fixtures is crucial for achieving optimal performance and efficiency in manufacturing processes.

- Simplicity: To minimize errors, make maintenance more accessible, and lower manufacturing costs, please complete the design as simply as possible by reducing the number of moving parts and complexity.

- Rigidity: Design the jig or fixture to be rigid and robust, resisting any deformation or movement during the machining operation. This ensures accurate and consistent results.

- Accurate locating components: Incorporate specific locating elements, such as pins, slots, or surfaces, to ensure proper workpiece positioning and alignment during machining.

- Secure clamping: Provide reliable and secure mechanisms to keep the workpiece steady during manufacturing, preventing movement or distortion.

- Accessibility: Ensure the design allows easy access for the cutting or machining tool and easy loading and unloading of the workpiece.

- Material selection: To ensure your project lasts long and resists wear and tear, opt for materials like cast iron or steel that provide durability, robustness, and protection. Additionally, use threaded metal inserts to enhance the strength and stability of your project.

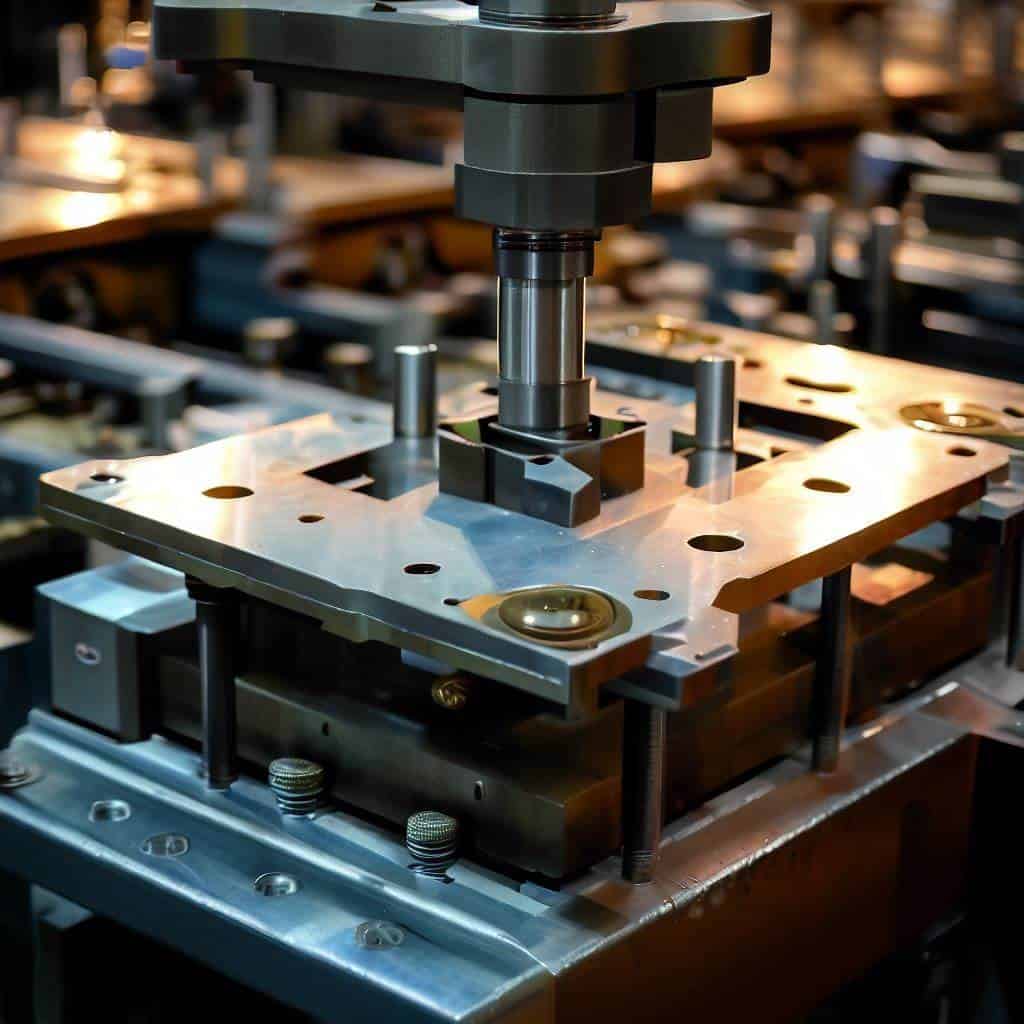

Fixture Design Basics and Calculations

When designing fixtures, it is essential to consider the following design elements and perform the necessary calculations to ensure optimal performance:

- Workpiece support: Determine the number and location of support points to minimize workpiece distortion and provide stability during machining.

- Locating principles: Apply the 3-2-1 principle or other appropriate locating methods to position the workpiece within the fixture accurately.

- Clamping forces: Calculate the required clamping forces to securely hold the workpiece without causing distortion or damage. Ensure that the clamping power is distributed evenly across the workpiece.

- Clearances: Consider the necessary clearances for cutting tools, chips, and coolant to prevent interference during machining.

- Modularity and adaptability: Design the fixture to be adjustable or modular, allowing quick and easy reconfiguration to accommodate different workpieces or machining processes.

By following these design guidelines and performing the necessary calculations, manufacturing professionals can create practical and efficient jigs and fixtures that improve manufacturing quality and reduce production costs.

Functions and Applications

Jigs in Machining and Production

Jigs play a significant role in machining and production by guiding cutting and machining tools to ensure accurate, consistent, and efficient operations. Some of the most common applications of jigs include:

- Drilling operations: Drill jigs help maintain the correct position and alignment of the drill bit for precise hole drilling, ensuring consistent hole locations and diameters.

- Tapping operations: Jigs guide tapping tools for threading holes, ensuring the correct alignment and depth of the threads.

- Grinding operations: Jigs can guide grinding tools, providing a predefined path or pattern for precise material removal.

Manufacturers can achieve greater dimensional accuracy, improved production quality, and reduced labor costs by using jigs in these machining processes.

Fixtures in Various Manufacturing Processes

Fixtures are crucial in manufacturing by providing a stable, secure workpiece positioning and holding platform. Some of the most common applications of fixtures include:

- Milling operations: Milling fixtures are designed to hold workpieces securely during milling processes, ensuring proper orientation and stability.

- Turning operations: Turning fixtures hold workpieces during turning processes, such as on a lathe, maintaining the workpiece’s stability and orientation.

- Grinding operations: Grinding fixtures provide accurate positioning and support for workpieces during grinding processes, ensuring consistent material removal and surface finish quality.

By utilizing fixtures in these manufacturing processes, manufacturers can maintain consistent workpiece positioning, minimize distortion, and improve product quality.

Jigs and Fixtures in Welding

In welding operations, jigs and fixtures are essential in ensuring accurate, consistent, and efficient assembly and joining of workpieces. They provide precise positioning and alignment of the components to be welded, promoting the proper joint formation and reducing the potential for defects.

Additionally, they help maintain the workpieces’ stability during welding, minimizing distortion and ensuring consistent weld quality.

Manufacturers can achieve improved weld quality, reduced labor costs, and increased production efficiency by incorporating jigs and fixtures into welding operations.

Applications of Jigs and Fixtures

Jig Tools and Applications

Various jigs are employed in the manufacturing industry, each designed for specific applications and machining operations. Some common examples of jig tools include:

- Drilling jig: These jigs guide the drill bit during drilling operations, ensuring accurate hole location, alignment, and diameter. Drill bushings often provide a predefined path for the drill bit.

- Template jigs: These jigs serve as a pattern or template for the cutting tool to follow during machining operations, such as in contour milling or grinding.

- Table jigs: Table jigs are used to position and align workpieces on machine tables, such as during milling or drilling operations. They typically feature T-slot plates, mounting holes, or other locating elements to ensure accurate workpiece positioning.

These and other jig tools increase production efficiency, accuracy, and consistent quality in various machining operations.

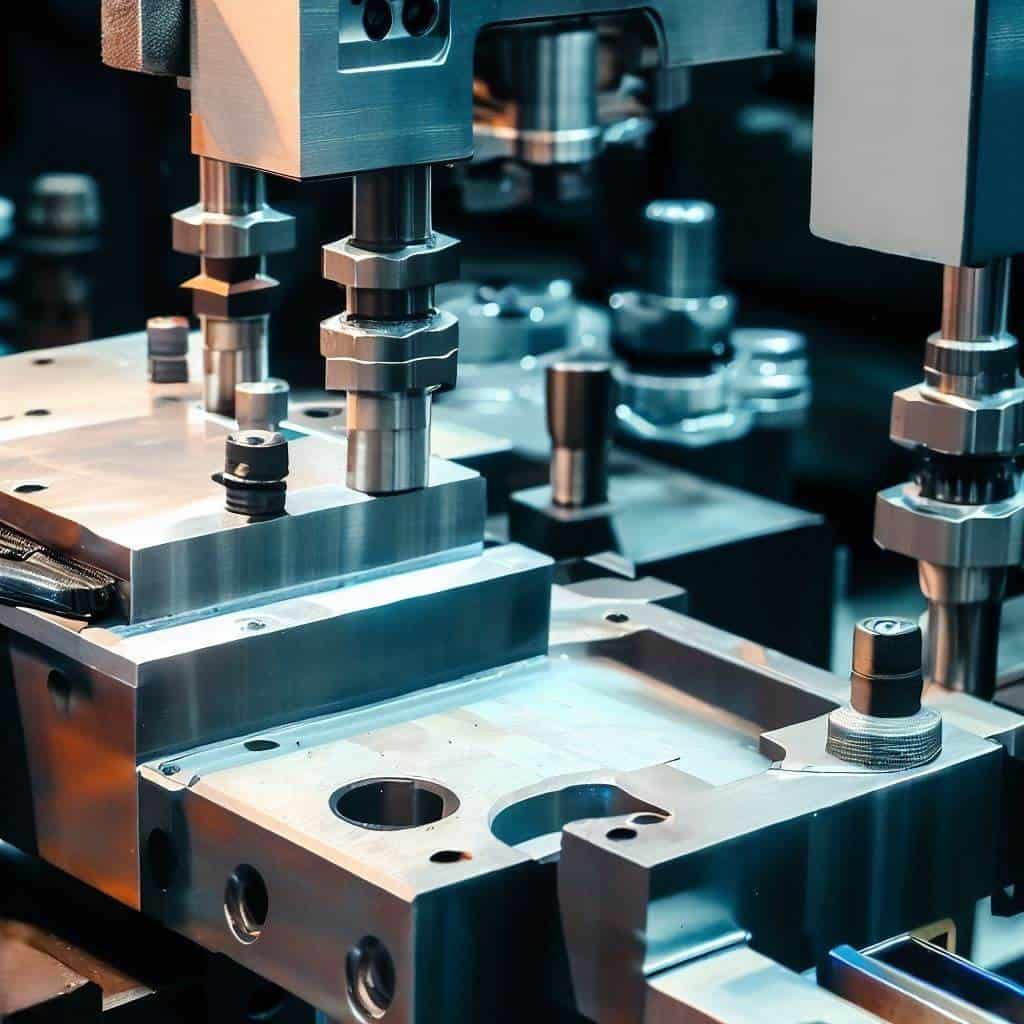

Fixtures Applications: Drilling, Milling, and More

Fixtures come in various designs tailored to specific machining operations and manufacturing processes. Some common types of fixtures include:

- Drilling fixtures: These fixtures are designed to hold securely and position workpieces during drilling operations, ensuring proper alignment and stability. Drilling fixtures often incorporate drill bushings to guide the drill bit and maintain hole accuracy.

- Milling fixtures: Milling fixtures securely hold workpieces during milling processes, providing a stable and accurate platform for material removal. They may include T-slot plates, clamps, and locating pins to ensure precise workpiece positioning.

- Grinding fixtures: Grinding fixtures provide accurate positioning and support for workpieces during grinding processes, ensuring consistent material removal and surface finish quality. They may incorporate V-blocks, clamps, and magnetic chucks to secure the workpiece.

- Boring fixtures: Boring fixtures hold and position workpieces during boring operations, ensuring proper alignment and stability. They may include V-blocks, clamps, and adjustable supports to accommodate various workpiece shapes and sizes.

These and other fixtures are critical in maintaining workpiece stability, minimizing distortion, and improving overall product quality in various manufacturing operations.

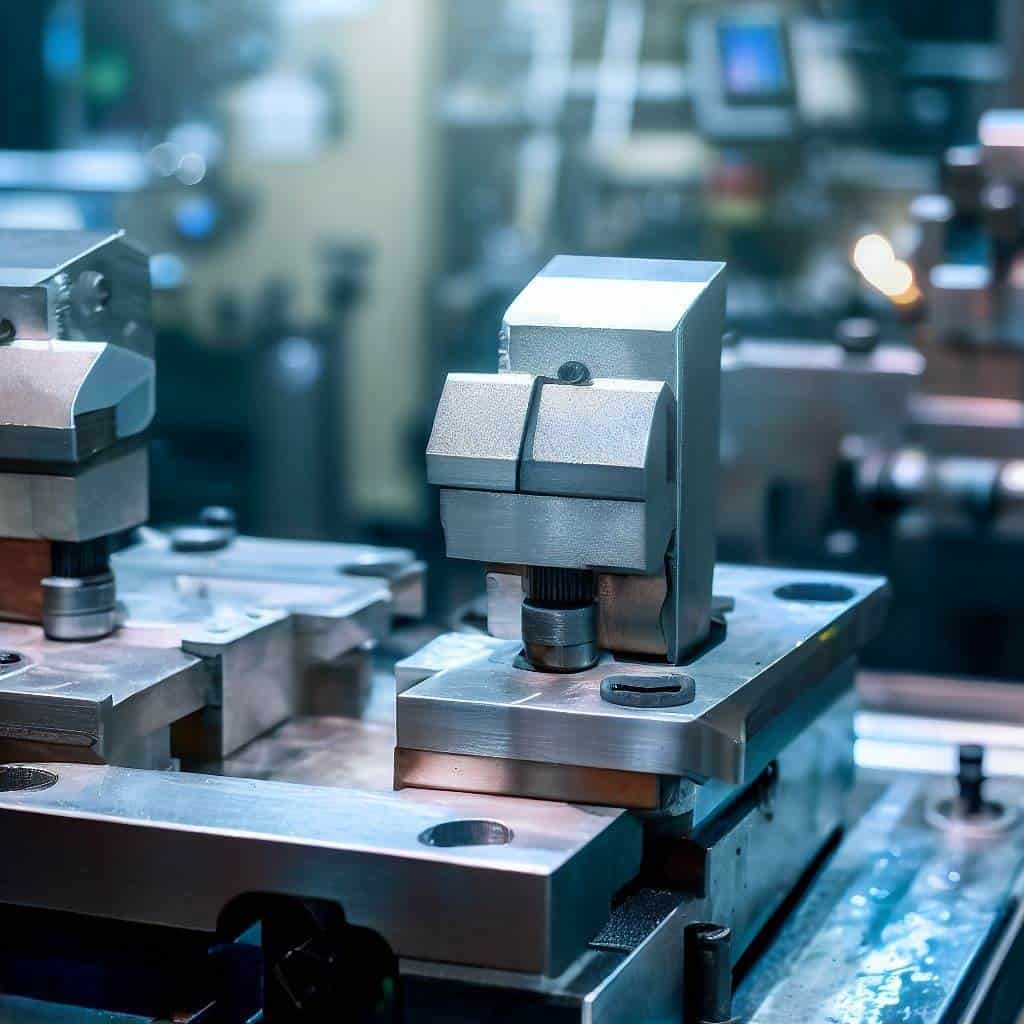

Benefits of Using Jigs and Fixtures in Manufacturing

Incorporating jigs and fixtures into manufacturing processes offer numerous advantages that increase productivity, efficiency, and product quality. Some of the key benefits include:

- Enhanced precision and accuracy: Jigs and fixtures ensure precise workpiece positioning and tool guidance, improving dimensional accuracy and consistent quality in machining operations.

- Increased production speed: By streamlining workpiece setup and tool alignment, jigs and fixtures reduce the time spent on manual adjustments, resulting in faster production rates.

- Improved repeatability: Jigs and fixtures enable manufacturers to achieve consistent results across multiple production runs, ensuring uniform product quality and reducing the potential for defects.

- Reduced labor costs: With jigs and fixtures in place, operators can perform machining tasks more efficiently and with less manual intervention, reducing labor costs and improving productivity.

- Minimized workpiece distortion: Secure clamping and support provided by fixtures help prevent workpiece distortion during machining, ensuring consistent quality and reducing the need for rework.

- Simplified production processes: Jigs and fixtures simplify complex machining operations, making them more accessible and manageable for operators.

- Enhanced flexibility: Modular and adjustable fixtures can accommodate different workpieces and machining processes, enabling manufacturers to quickly adapt their production lines to changing demands.

- Lower scrap rates: By improving accuracy and repeatability, jigs and fixtures reduce the likelihood of errors and defects, decreasing scrap rates and reducing production costs.

By leveraging the benefits of jigs and fixtures in manufacturing operations, companies can significantly improve productivity, efficiency, and product quality, ultimately leading to a competitive advantage in the marketplace.

Conclusion

In conclusion, jigs and fixtures are vital in manufacturing, ensuring precise workpiece positioning, tool guidance, and overall process efficiency. By understanding the differences between jigs and fixtures, their design principles, and applications across various manufacturing processes, professionals can make informed decisions when selecting the appropriate work-holding and tool-guiding solutions for their operations.

The benefits of using jigs and fixtures, such as enhanced precision, increased production speed, and improved repeatability, ultimately contribute to increased productivity, efficiency, and product quality. By incorporating jigs and fixtures into their manufacturing processes, companies can achieve a competitive edge in the ever-evolving manufacturing landscape.

Frequently Asked Questions

Fixtures and jigs are essential manufacturing tools used in machining. Fixtures are work-holding devices that secure and support the workpiece during machining operations, while jigs are custom-made tools that guide the cutting tool or hold the workpiece in a fixed position. Both types of tools help ensure precision, accuracy, and consistency during the manufacturing process.

Drill bushings are essential for drilling operations of jigs and fixtures. They guide the drill bit and ensure proper alignment during the drilling process. Drill bushings improve accuracy, precision, and consistency during drilling operations by maintaining a fixed position and providing a stable platform for the drill bit.

Jig controls are essential in maintaining the proper position, orientation, and alignment of the cutting tool or workpiece during machining operations. They help ensure that the machine table and raw material are aligned correctly, improving accuracy and precision. Jig controls can also minimize workpiece distortion and reduce production costs by streamlining the manufacturing process.

CNC fixture is designed for computer numerical control (CNC) machines. These fixtures help secure the workpiece in a stable position, enabling the machine tool to perform precise and accurate machining operations. CNC fixtures play a crucial role in achieving consistent quality and improving the overall efficiency of the manufacturing process.

Fixture design calculations involve determining the optimal shape, size, and configuration for a fixture to function appropriately within a specific manufacturing operation. Key considerations include selecting appropriate materials, ensuring secure mounting points, and considering locating components to maintain proper alignment. These factors are essential for designing fixtures that can withstand the forces exerted during manufacturing and provide a stable platform for machining operations.

In automobile assembly lines, jigs and fixtures hold and position various components and parts during manufacturing. They help ensure the pieces are aligned correctly, maintain a fixed position during assembly, and improve overall manufacturing quality. Using jigs and fixtures in automobile assembly lines also helps reduce labor costs and increase efficiency by automating repetitive tasks.

Examples of machining fixtures include plate fixtures, fixture plates, and drilling jigs. Manufacturing jigs can have tooling plates, metrology tools, and plate jigs. These tools hold workpieces securely and guide cutting tools during various machining operations.

The fixture body design plays a crucial role in ensuring the stability and reliability of the fixture during the manufacturing process. A well-designed fixture body provides a secure attachment for the workpiece and minimizes unwanted movement or vibrations during machining operations. This helps achieve higher precision, accuracy, and efficiency in manufacturing.