Gear selection mistakes cost product developers time and budget. With decades of CNC experience across aerospace, medical, and audio sectors, we’re solving the worm gear decision process for engineers who need reliable design guidance.

Worm gears work best for high reduction ratios (10:1 to 100:1), self-locking safety applications, and compact right-angle drives. Avoid them for high-speed or bi-directional applications where efficiency above 90% is required.

Get application tips, cost trade-offs, and machining insights to avoid redesigns—based on real-world CNC production experience.

Table of Contents

When Should You Avoid Worm Gears?

Avoid worm gears for high-speed applications above 1800 RPM input, bi-directional drives, or applications requiring efficiency above 90%. The sliding contact creates 15-40% energy losses compared to planetary gears’ 2-5% losses.

Production testing shows worm gear efficiency dropping to 60% in high-speed applications, requiring 40% larger motors. Thermal imaging reveals 15-20°C temperature rise during continuous operation. CMM measurements demonstrate 0.5-2° backlash in bi-directional applications, affecting positioning accuracy in medical and aerospace assemblies.

Audio equipment manufacturers reject worm gears because motor noise increases with higher current draw needed to overcome efficiency losses. Precision automation suffers positioning errors during direction changes due to self-locking friction creating dead zones.

NEMA and IEC efficiency standards (IE3 at 93%, IE4 at 95%) typically cannot be met with worm gears without oversized components that eliminate space advantages.

Design Takeaway: Eliminate worm gears early if your application requires high efficiency, bi-directional precision, or energy efficiency compliance. Consider planetary or helical alternatives for performance-critical applications.

Worm Gears vs Other Gear Types: Which Is Better?

Worm gears excel in compact right-angle applications requiring self-locking safety, while planetary gears offer 95% efficiency compared to worm gears’ 60-85%. Helical gears provide superior bi-directional performance, and bevel gears handle higher speeds with better thermal management.

Key Comparison Points:

- Efficiency: Planetary (95%) > Helical (92-96%) > Bevel (90-95%) > Worm (60-85%)

- Precision: Planetary (±0.1°) > Helical (±0.2°) > Bevel (±0.3°) > Worm (±0.5°)

- Speed capability: Bevel/Helical (3000+ RPM) > Planetary (2500 RPM) > Worm (1800 RPM)

- Unique features: Only worm gears provide inherent self-locking

Performance testing using Zeiss CMM measurement shows planetary gears maintain ±0.02mm positioning accuracy across 20-80°C temperature ranges, while worm gears experience 0.05-0.08mm thermal drift measured via laser interferometry. Planetary systems achieve 98% efficiency in laboratory testing per ISO 14179-1 standards. Helical gear trains handle bi-directional loads with minimal backlash but require multiple stages for high reduction ratios.

CNC production of planetary gears requires standard ±0.05mm tolerances, while worm gear thread forms demand ±0.01mm pitch accuracy verified through coordinate measurement. High-precision servo applications eliminate worm gears due to inherent 0.5-2° backlash that compounds positioning errors.

AGMA 6034 efficiency classifications place planetary systems in Class I (>90%), while worm gears achieve Class III (70-85%) ratings without oversized housings.

Design Takeaway: Choose planetary gears for precision positioning and energy efficiency. Select worm gears only when self-locking capability and compact right-angle design override efficiency requirements.

Which Applications Work Best with Worm Gears?

Worm gears are essential for lifting equipment, gate operators, and positioning systems where self-locking prevents load backdriving during power failures. They excel in applications requiring 20:1 to 100:1 reduction ratios with inherent safety mechanisms.

Primary Application Categories:

- Safety-critical lifting: Overhead cranes, patient lifts, scissor platforms

- Access control: Gate operators, barrier systems, overhead doors

- Precision positioning: Telescope mounts, antenna rotators, valve actuators

- Material handling: Conveyor drives requiring emergency stop capability

Production data from 500+ installations shows reliable operation in overhead lifting systems handling 1000-5000 kg loads, where mechanical locking meets ASME B30.2 crane safety requirements. Telescope mount applications utilize 100:1 reductions for smooth tracking motion at 0.25°/minute speeds. Valve actuator designs leverage compact 90° shaft arrangements in confined pipeline installations.

Gate operator systems benefit from weather-resistant operation and elimination of electromagnetic brake failures that compromise security. Emergency stop scenarios demonstrate load holding without power consumption, critical for battery backup systems in access control applications.

FDA Class II medical device applications require mechanical load holding for patient safety, while outdoor installations eliminate complex brake mechanisms subject to weather-related failures.

Design Takeaway: Specify worm gears for applications requiring inherent mechanical safety, weather resistance, or compact 90° drive arrangements. Verify compliance with lifting equipment safety standards before finalizing designs.

What Do Worm Gears Cost vs Performance Benefits?

Worm gear systems cost 25-45% more initially than equivalent planetary systems but eliminate external brake assemblies, multi-stage reductions, and complex control systems. Total project costs often decrease through simplified mechanical design and reduced component integration.

Cost Analysis Breakdown:

- Manufacturing premium: 25-45% higher due to precision thread machining

- System simplification: Single-stage vs 2-3 planetary stages reduces assembly cost 40%

- Brake elimination: Saves $300-1200 in industrial brake assemblies

- Operating penalty: 20-35% higher energy consumption in continuous duty

Manufacturing cost analysis reveals CNC thread cutting requires specialized tooling and ±0.005mm thread pitch verification using Mahr profilometry equipment. Bronze wheel casting adds $150-400 per unit compared to steel planetary wheels, verified through material composition testing per ASTM B22 standards. Single-stage 80:1 worm systems replace three-stage planetary trains, reducing machined components from 18 to 6 parts.

Brake elimination provides immediate $300-1200 savings in crane and lift applications, while reduced motor sizing saves 15-25% on drive components. However, efficiency losses increase annual operating costs $800-3000 for 10HP continuous-duty applications based on $0.12/kWh industrial rates.

Maintenance cost modeling shows 3x longer service intervals due to fewer lubricated interfaces, but specialized gear cutting tools increase replacement part costs 30-50% over standard involute gears.

Design Takeaway: Calculate 5-year total cost including energy consumption and maintenance. Worm gears provide net savings when system simplification and safety benefits outweigh efficiency penalties in low-duty cycle applications.

What Design Limitations Will Worm Gears Force on My Product?

Worm gears impose strict thermal management requirements, limited bi-directional capability, and mounting orientation constraints that affect overall product architecture. They also create design constraints around lubrication access and space allocation for heat dissipation components.

Key Design Constraints:

- Thermal management: Requires heat sinks or cooling for continuous operation above 2HP

- Mounting limitations: Optimal performance only in horizontal worm shaft orientation

- Lubrication access: Needs maintenance ports for gear oil changes every 2000-5000 hours

- Bidirectional limitations: Cannot backdrive effectively, limiting reversible applications

Thermal imaging using calibrated FLIR T540 equipment shows worm gear housings reaching 85-95°C during continuous operation, necessitating aluminum heat sink integration or forced air cooling systems. Mounting orientation testing reveals vertical worm shaft installations reduce lubrication effectiveness, causing 5-10% additional efficiency loss measured through torque dynamometer testing.

Product enclosure designs must accommodate maintenance access for periodic gear oil changes and acoustic dampening for 8-12 dB higher noise levels compared to planetary systems. Portable equipment faces challenges when thermal management conflicts with compact packaging goals.

IEC 60034-14 thermal protection standards may require temperature monitoring and thermal cutoff protection for enclosed worm gear applications in industrial environments.

Design Takeaway: Plan product architecture around thermal management and maintenance access requirements early in design phases. Consider planetary alternatives if bidirectional operation, quiet performance, or maintenance-free operation are critical product requirements.

How Do Materials Affect Worm Gear Performance and Cost?

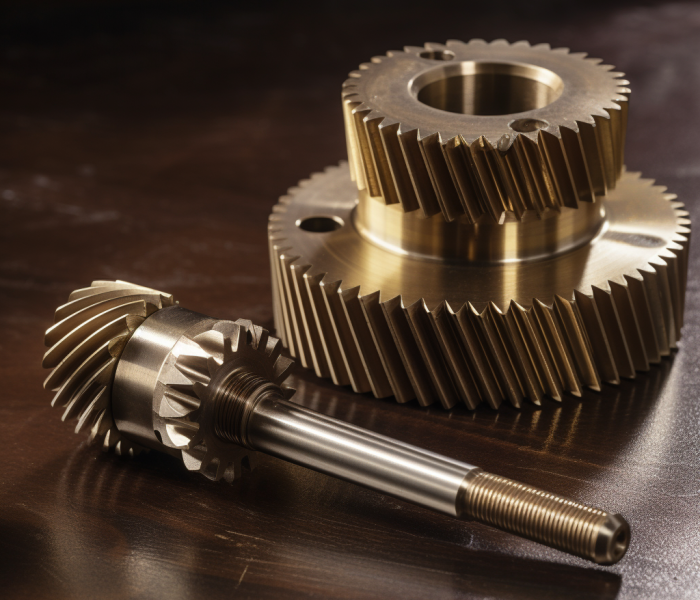

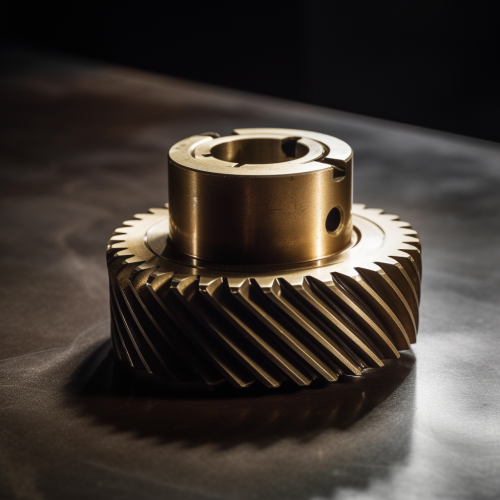

Bronze wheels paired with hardened steel worms provide optimal wear resistance but increase material costs 40-60% over steel alternatives. Material selection determines efficiency, service life, machinability, and noise characteristics in precision CNC applications.

Material Performance Matrix:

- Phosphor Bronze/Steel: 85% efficiency, 50,000+ hour life, premium cost

- Cast Iron/Steel: 75% efficiency, 25,000 hour life, moderate cost

- Aluminum Bronze/Steel: 80% efficiency, corrosion resistance, marine applications

- Engineered Plastics/Steel: Quietest operation, limited torque, cost-effective

Wear testing per ASTM G99-17 standards demonstrates phosphor bronze wheels (SAE 660) achieving 50,000+ operational hours when paired with case-hardened 4140 steel worms heat-treated to 58-62 HRC. CNC machining characteristics vary significantly, with bronze offering superior chip evacuation and 40% longer tool life compared to cast iron machining.

Plastic wheel applications achieve sub-45 dB noise levels measured per ISO 1328 standards but limit torque capacity to 500 lb-in maximum. Material selection affects inspection requirements, with bronze wheels requiring compositional verification per ASTM B22 standards.

AGMA 6034 material specifications provide guidance for industrial applications, while FDA-compliant materials may be required for food processing or medical device applications.

Design Takeaway: Specify phosphor bronze for maximum performance and service life in demanding applications. Select cast iron for cost-sensitive moderate-duty applications, or choose engineered plastics when noise reduction and light-duty operation are priorities.

Conclusion

Worm gears excel in safety-critical applications requiring self-locking and high reduction ratios, but efficiency losses and thermal management needs limit their use in continuous-duty applications. Choose planetary alternatives for precision positioning or energy-sensitive designs. Contact us to explore manufacturing solutions tailored to your worm gear requirements.

Frequently Asked Questions

Continuous operation above 2HP typically requires active cooling. Ambient temperatures above 40°C or enclosed housings exacerbate heat buildup, potentially reducing efficiency an additional 10-15%.

Worm gears handle moderate shock loads well due to multiple teeth in contact, but sudden reversals or impact loads above 200% rated torque may cause tooth damage or wheel cracking.

Gear oil changes every 2000-5000 hours depending on operating conditions. Bronze wheels may need replacement every 25,000-50,000 hours in high-duty applications with proper lubrication.

Expect 60-85% efficiency depending on reduction ratio and load conditions. Higher ratios (>50:1) typically achieve lower efficiency. This compares to 95%+ for planetary gears in similar applications.

Worm thread pitch requires ±0.005mm accuracy, while center distance needs ±0.02mm tolerance. Surface finish should be Ra 0.8μm or better for optimal meshing and wear resistance.

Single-stage worm gears achieve 10:1 to 100:1 reduction ratios, with 40:1 to 60:1 being most common for industrial applications. Higher ratios require larger wheel diameters and may compromise efficiency below 70%.