4-axis and 5-axis CNC Machining

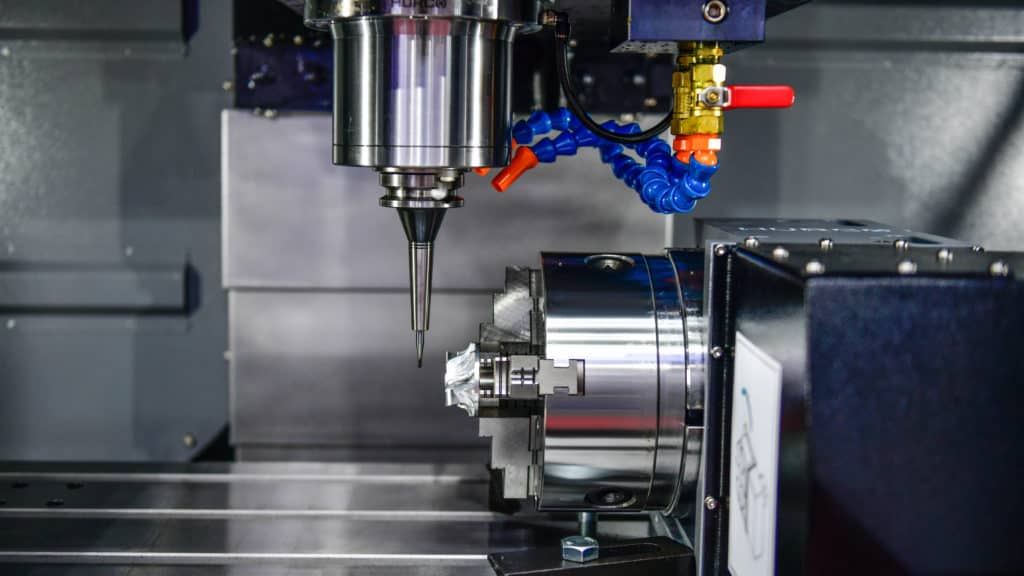

Are you an engineer or product developer considering CNC machining for your next project? If so, 4-axis and 5-axis CNC machining should be on your list. Projects can streamline production processes by utilizing 4-axis and 5-axis CNC machines to create manufacturing components while optimizing accuracy and precision in every job.

Table of Contents

4-Axis Machining

4-Axis Machining is a form of Computer Numerical Control (CNC) machining that utilizes four axes of motion to cut complex parts from various materials.

The four primary motions in 4-axis CNC machining are X, Y, Z, and A (or rotary). The X, Y, and Z axes are linear, allowing for precise positioning along three-dimensional planes. The A-axis is the rotary axis that allows for rotational movement of the machined cutting tool or part.

5-Axis Machining

5-Axis Machining is a CNC (Computer Numerical Control) machining type that uses five axes to move the cutting tool. A four-axis machine can provide greater flexibility and accuracy than traditional 3-axis Machining, as the additional two axes allow for more efficient cutting paths, resulting in faster and smoother cuts.

The term “5-axis” refers to the five directions – x, y, z, A, and B – controlling the cutting tool’s position and orientation. 5-Axis Machining also typically employs more extended tools than 3-Axis Machining and can be used on complex shapes with multiple surfaces.

Difference between 4-axis and 5-axis Machining

The main difference between 4-axis and 5-axis CNC machining is the number of directions in which the cutting tool can move. In 4-axis Machining, the cutting tool can move along four axes (X, Y, Z, and A), while in 5-axis Machining, it can move along five axes (X, Y, Z, A, and B).

- 4-axis Machining can move a cutting tool along three axes, while the 5-axis version can move the device along four linear axes and one rotational axis.

- In 4-axis Machining, you need to reposition the workpiece manually to access different sides of it. With a 5-axis machine, however, you can rotate the piece around its center without needing to reset it.

- 4-axis CNC machines are typically used for simpler operations such as drilling, milling, facing, or turning, whereas a 5th axis is better suited to trimming and 3D contouring complex shapes.

- 4-axis Machining usually has a smaller work area than 5-axis machines, making it less suitable for large parts and components.

- A 5th axis allows for complex multi-angle cuts that cannot be achieved with 4-axis machines, allowing for more intricate designs and faster production times.

- The versatility of the 5th axis also enables multiple parts to be cut simultaneously, improving efficiency and saving time.

- The additional axis in 5-axis Machining gives you more control over the cutting process, allowing for greater accuracy and smoother finishes on complex pieces.

- 5-axis Machining is more expensive than 4-axis due to the additional complexity of the machine, making it only cost-effective if you regularly produce complex parts.

- The higher cost and complexity of 5-axis Machining does, however, give you greater flexibility for cutting a wide range of shapes and materials with high accuracy.

In conclusion, 5-axis CNC machining allows for more complex shapes and higher precision than 4-axis CNC machining while also having faster cutting times due to its ability to access parts from all angles. Its nature makes it an excellent choice for any application that requires exact cuts or intricate designs.

CNC Machining: 4-axis or 5-axis?

When choosing between 4-axis and 5-axis CNC Machining, several factors are essential. Generally speaking, the choice ultimately comes down to the type of product created and its complexity.

4-axis CNC machining offers a lower cost option and is suitable for simpler or less intricate parts with fewer features. It can produce most standard shapes quickly and accurately, such as cylinders and slots. However, it offers a different level of accuracy than 5-axis CNC machining when making complex parts with multiple geometric operations.

On the other hand, 5-axis CNC machining allows for more complex geometries in a single setup by utilizing the five-dimensional movement of the cutting tool. Accordingly, this means that parts with complex features, such as those requiring high precision or tight tolerances, can be machined quickly and accurately on a 5-axis CNC machine.

In conclusion, choosing between 4-axis and 5-axis CNC Machining depends on the type and complexity of the product produced. If simple shapes are all needed, then 4-axis Machining is an economical option; however, if intricate parts require higher accuracy, then 5-axis CNC machining is recommended

Benefits of Using 4-axis and 5-axis Machining

For businesses that need complex parts made with precision and accuracy, 4-axis or 5-axis CNC machining is the ideal choice. With 4-axis and 5-axis machining, manufacturers can produce exact components in a fraction of the time required for traditional methods such as manual milling. The ability to move the tool head in two directions (4-axis) or three directions (5-axis) dramatically increases the flexibility and speed of production.

As a result of the higher level of control offered by these machines, intricate shapes can be achieved quickly and easily over traditional methods. This method can reduce costs significantly by eliminating secondary operations like hand finishing, which can be both time-consuming and expensive.

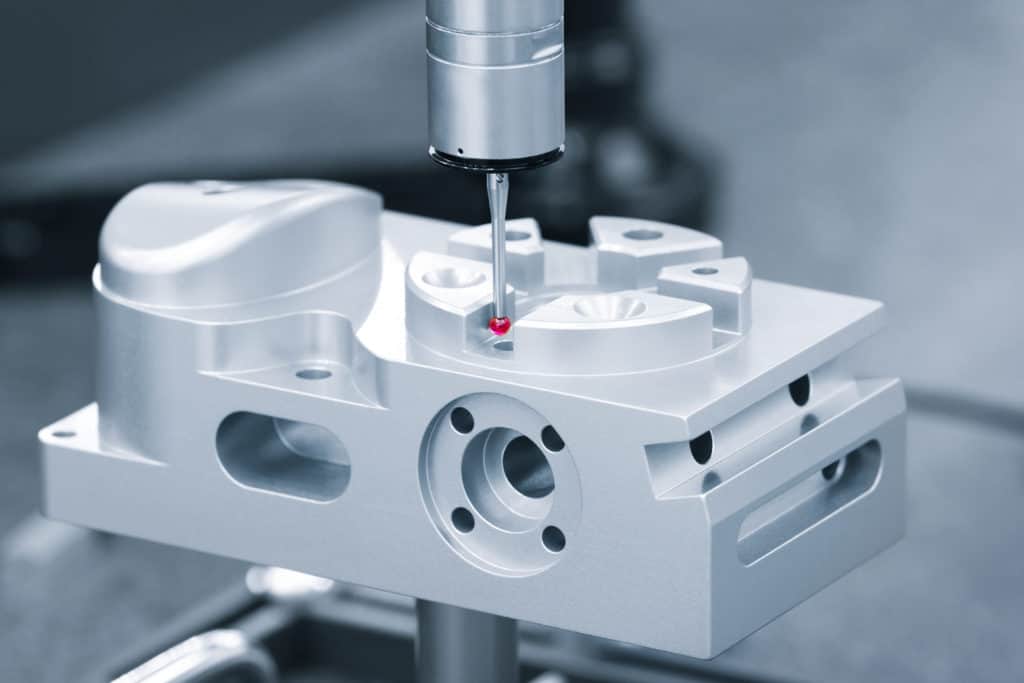

The improved accuracy of 4-axis and 5-axis machining also reduces scrap rates, allowing for more efficient production processes with little to no waste. By investing in a quality CNC machine, businesses can achieve an excellent return on their investment due to the cost savings from faster production times and lower material costs.

The okdor guarantee

Custom parts are provided One-year quality guarantees. If Your parts have issues in the rate instance, We’ll do whatever it takes to get it right without charge.

Our purpose is to provide a better and delightful manufacturing experience at competitive prices with a substantially lower total cost supported by an experienced team.

Applications of 4-axis and 5-axis Machining

4-axis and 5-axis machining have many applications. 4-axis Machining is primarily used for milling operations, such as side milling and face milling, while 5-axis Machining adds the ability to move around both planes and angles. The technology makes it possible to machine complex shapes in one setup, saving time and production costs.

Some examples of 4-axis CNC machining applications include: die molds, fixtures, small components with intricate features, and aircraft parts. Similarly, 5-axis CNC machining has become popular in aerospace components due to its precise accuracy and ability to work on complex shapes. It can also produce tool molds for plastic injection molding and, in the automotive industry, create turbine blades, valve bodies, and cylinder heads. Furthermore, 4-axis and 5-axis CNC machining enable the making of medical implants and prosthetics due to their high level of accuracy.

Manufacturing

CNC Machining on-demand

Is the current factory treating your business as if it is one of their top priorities? Is production proceeding according to plan? Can all parts and components be delivered promptly? Stunning custom parts demand special attention.

Conclusion: What is the Best Option for Your Project?

When considering both technologies, it is essential to consider factors such as the complexity of part geometry, precision needs and accuracy required, cost considerations, cycle times involved, and any additional processing needed.

Suppose a specialized function or increased accuracy is necessary for complex projects requiring intricate parts with tight tolerances. In that case, 5-axis CNC machining can be the best option due to its ability to access more axes. On the other hand, if tighter budgets and shorter lead times are significant considerations for your project, then 4-axis CNC machining may be the more cost-effective route.

Professional engineers and manufacturers who have experience with both 4-axis and 5-axis CNC machines are a good choice when choosing the right CNC machining solution for your project. The results will help you make the most informed decision and determine which technology best meets your needs.

Frequently Asked Questions

4-axis Machining refers to a process that involves four axes of motion (X, Y, Z, and A), while 5-axis Machining adds a rotary axis (B). Using either of these processes can create complex parts with curved surfaces in three dimensions. The fifth axis allows for more flexibility resulting in faster production times and increased accuracy.

These processes are standard in industries such as aerospace manufacturing, medical device manufacturing, automotive manufacturing, tool and die making, and many other fields where complex shapes are required.

These processes are compatible with various materials, including metals, plastics, and composites. The type of material used will depend on the application and intended use.

This process offers several advantages over other machining methods, including increased accuracy, faster production times, higher quality parts, improved repeatability, and reduced labor costs. Additionally, these processes allow for complex shapes to undergo minimal tool changes, which helps reduce setup time.

The main disadvantage of these processes is the cost associated with purchasing and maintaining the necessary equipment. Additionally, programming can be complex and requires specialized skills, which can add to overall costs. Additionally, the tooling used in these processes can be expensive. However, the advantages of using this process often outweigh the drawbacks.