How to Choose Materials for your CNC Parts?

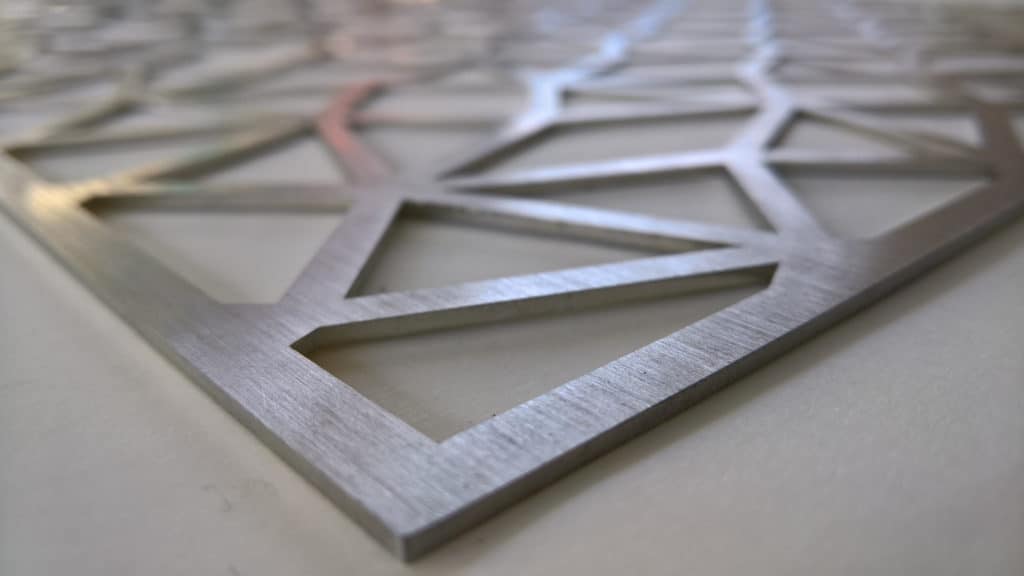

CNC machining is a popular manufacturing method due to its precision, versatility, and speed. This versatile process can be used in various automotive and aerospace industries. Additionally, it has become the go-to solution for custom parts manufacturing, allowing manufacturers to quickly and easily create high-quality components that meet their customers’ specifications.

Choosing a suitable material for your CNC machining project is essential to producing high-quality parts. Many different materials can be used in this process, such as wood, metal alloys, plastics, and composites. To ensure optimal results, it is essential to carefully consider the properties of each material, such as strength, durability, and workability. You can produce high-quality components that meet your exact specifications with the right choice of materials and a skilled team of CNC machinists.

This article gives tips on selecting materials for your custom CNC parts. Let’s explore together.

How to Choose Materials for your CNC Parts?

If you’re planning on running a CNC machining project, here are the most crucial factors to consider when choosing your materials.

- Material cost

- Material durability

- Material compatibility

- Material availability

- Material machinability

- Part precision

- Part application

- Working environment

Material cost

The cost is another crucial factor when selecting CNC parts materials. Different materials can vary widely in price, so finding a material that balances affordability and quality is essential. For example, steel or aluminum alloys might be more affordable than other materials, but they may need to be more durable and long-lasting. Ideally, consider a range of price points and compare the performance of different materials to find the best value for your applications.

Material durability

The material’s durability is one of the most critical factors when selecting materials for CNC parts. More durable materials will generally withstand more significant amounts of stress and wear without breaking down or becoming damaged over time. Consider different materials like metal alloys, composites, or plastics to find a material that will provide the best performance and longevity for your CNC parts.

Material compatibility

The compatibility of the material with CNC machining processes is another important consideration when selecting materials for CNC parts. In general, you should choose a material that will be easy and cost-effective to machine without requiring significant modifications or additional steps. For example, softer and more flexible materials may not be suitable for CNC machining if they are prone to deforming during processing or do not machine quickly or easily.

Material availability

The availability of the material is another critical factor to consider when selecting materials for CNC parts. In general, choose a material that is easy to find and purchase in the quantities you need for your applications. This can be incredibly challenging if you require specialized materials or materials from overseas suppliers, so it is essential to carefully evaluate your options and find a comprehensive and cost-effective material.

Material machinability

When selecting a material for CNC machining, it is vital to consider its machinability properties, as these can affect the productivity and quality of the finished part. For example, certain materials are more difficult to machine than others and may require additional time or specialized tools to achieve good results. Other materials may be more abrasive and result in faster tool wear, which can reduce cutting speeds or increase tool costs.

Some fundamental properties that affect machinability include the material’s hardness, strength, flexibility, and toughness. In general, softer materials tend to cut more easily than harder ones due to their lower cutting forces and excellent ductility. Hard materials like steel alloys may require high cutting speeds and lower feed rates to avoid overheating the tool. In addition, softer materials are often easier to machine using standard and specialized tools due to their lower strength and wear resistance.

Part precision

The precision required for CNC parts is another critical factor to consider when selecting materials. More complicated and rigid materials will provide better precision and accuracy for your parts. However, this may also come at a cost in terms of performance or manufacturing costs, so it’s essential to carefully weigh the different tradeoffs between these factors when selecting your material.

Part application

One of the primary factors that should be considered when selecting CNC machined materials is the application for which they will be used. For example, if a part needs to withstand high temperatures or aggressive chemicals, choosing a material that has good resistance to these conditions may be critical to its function and performance. In addition, if a part will be subjected to high stresses or if it will be exposed to impacts or repeated use, choosing a material that has good strength and durability can help ensure that the part will perform as intended.

Working environment

When selecting a material for CNC machining, it is crucial to consider the working environment in which the part will be used. Factors like temperature, humidity, and exposure to chemicals or other potential contaminants can affect the material’s durability and performance over time. For example, materials exposed to high temperatures or harsh chemical environments may require additional coatings or treatments to prevent corrosion or other degradation. Fabrics exposed to higher humidity levels may also be more susceptible to deformation or surface flaws, which can affect the accuracy and repeatability of the finished part. It is crucial to consider these factors when selecting a material for CNC machining to maximize part performance and longevity.

The considerations listed above are essential when selecting materials for CNC parts. Depending on your specific applications, you may need to prioritize one or more of these factors over others to find the best material for your needs. For example, suppose you require durable parts that withstand high-stress levels and wear. You may need to prioritize material durability over other factors, such as cost or part precision. Alternatively, suppose your applications do not require a high level of performance, and you are more concerned with affordability and manufacturing efficiency. In that case, you can focus on materials that are easy to machine and cost-effective instead. Ultimately, it is essential to carefully consider the different factors involved when selecting materials for CNC parts to find the best option that meets your needs.

The content below summarizes the most common CNC Materials used for machining and their key characteristics.

Aluminum

Aluminum alloy is your go-to material in creating aircraft and car parts. Its density ranges typically 2.65-2.80 g/cm3. They’re lightweight, durable, machinable, and affordable. Plus, it can effectively conduct heat and electricity.

Aluminum alloy is also popularly used in creating prototypes and similar products. Although it’s not as strong as steel, it can be anodized to compensate. Anodizing adds strength and creates a protective surface finish over the piece.

Types of Aluminum Alloys:

- Aluminum 7075 – best for aircraft engineering and on par with steels after heat treatment

- Aluminum 6061 – most commonly used type with outstanding machinability

- Aluminum 6082 – similar to aluminum 6061 but is often used in Europe

- Aluminum 5083 – best for construction, welding, and marine industries. Has high strength and moisture-resistance

Steel

The second most widely-used CNC material is steel. Those looking for something that could last decades without wear prefer steel. However, steels tend to be less machinable than aluminum and brass.

Types of Steels:

- Mild steel – is an economical type of steel that is used for everyday applications. Mild steels are machinable, weldable, and magnetic. However, it is not the most robust type and is prone to damage.

- Alloy Steel – tougher than mild steel, weldable, magnetic, and has high wear resistance. Alloy steels can be heat treated to add strength. However, it is still prone to chemical damage and wears over time.

- Tool Steel – used for manufacturing equipment such as stamps, knives, molds, and more. A tougher type of steel that is wear-resistant upon heat treatment.

- Stainless Steel – robust and wear-resistant. It also has high ductility and good machinability. Plus, some stainless steel can either be magnetic or non-magnetic.

Brass

Brass is the material often used in aesthetic and architectural applications. For example, you can use it for gold detailing and the like.

In addition, brass is highly machinable, making it ideal for high-volume production. It also has high electrical conductivity, is non-magnetic, and is naturally resistant to wear.

Thermoplastic

Last on this list is none other than thermoplastic. Thermoplastic is the most widely-used type of plastic in CNC machining.

Another name for it is ‘thermosoftening plastics.’ It is made out of resin plus other additives. Thermoplastics are commonly used to manufacture high-stress mechanical parts such as fluidic devices.

Types of Thermoplastic

- ABS – has a low density and is best applied for mass-producing lightweight custom parts. It has good mechanical characteristics, high impact power, and heat resistance.

- Polycarbonate – better than ABS in impact strength and primarily used in automotive glazing. Transparent in color but can be dyed in the preferred shade.

- Nylon – is famous in engineering because of its outstanding mechanical characteristics. It is also chemical resistant and scratch-proof. However, it is vulnerable to moisture.

- Delrin (POM) – is the most machinable out of all thermoplastics. Highly versatile and often used in engineering applications. Parts made out of Delrin are highly precise, tough, stable, and absorb little to no moisture.

- Teflon (PTFE) – is another engineering thermoplastic with high heat and chemical resistance. One of the few types of plastics that can withstand temperatures beyond 200°C.

- High-density Polyethylene – is best for outdoor purposes such as piping. Lightweight but has high wear resistance and impact strength.

- PEEK – a thermoplastic counterpart for steel. PEEK also offers medical grades, making it usable for biomedical purposes.

In summary, there are several key factors to consider when selecting materials for CNC parts, including the working environment, material performance and durability, machinability, and cost. Some of the most important considerations include the hardness and strength of the material and its susceptibility to corrosion or other degradation in high-temperature or chemical environments.

Additionally, it is crucial to consider factors such as part precision, manufacturing efficiency, and overall cost when selecting materials for CNC machining. Ultimately, the best material for your needs will depend on various factors and may vary depending on your specific applications and requirements. Therefore, it is essential to carefully consider the different aspects involved when selecting materials for CNC parts to find the best option that meets your specific needs.

Please contact us if you need help choosing suitable materials for your CNC machining project. The engineers at okdor will be more than happy to help you select the perfect materials for your needs.

Frequently asked questions

In regards to CNC Machining materials, this is one of the most frequently asked questions.

Depending on the application, this will vary. Although aluminum 6061 is often preferred for CNC machining because of its low cost and easy availability.

Plastics such as POM (Delrin) are the most cost-effective materials for CNC machining. Among the reasons for this are thermoplastics’ excellent machinability.

It will take a long list to answer this specific question, When choosing materials for machined parts, keep functionality in mind.

Our engineering team is here to solve the problem for you. Contact us directly at sales@okdor.com.

There are dozens of ways to speed up CNC manufacturing, like using recommended materials and surface treatments. Tolerances should be specified only when necessary. The fourth could employ a standard cutting tool for structure building.

Temperature, humidity, and exposure to chemicals or other contaminants can all impact the durability and performance of a material over time. For example, materials exposed to higher temperatures or harsher chemical environments may require additional coatings or treatments to prevent corrosion or other degradation. Similarly, fabrics exposed to higher humidity levels may be more susceptible to deformation or surface flaws, which can affect the accuracy and repeatability of the finished part.

To optimize material selection for CNC machining, it is essential to carefully evaluate the factors involved and their implications for your specific applications. Some possible considerations include assessing the properties of potential materials in terms of their performance, durability, and machinability. You may also need to consider factors such as part precision, manufacturing costs and efficiency, and material cost to select the best materials for your needs.

You can use various strategies to optimize material selection for CNC machining, including working with experienced engineering experts who can help you identify the best materials for your project. You should also conduct detailed research on different material properties and their implications for CNC machining. Finally, it is vital to collaborate with manufacturers to select optimized materials for both performance and cost. Ultimately, the key is carefully evaluating all the factors involved to find the best possible materials for your needs.

There are several types of materials that may not be suitable for CNC machining, including high-strength or heat-resistant materials. Such materials may require higher cutting speeds and feed rates to avoid overheating the tool and causing damage to the part. In addition, certain soft or pliable materials can be more difficult to machine using CNC tools, as they may be prone to deformation or other imperfections during the machining process. For these reasons, it is generally advisable to avoid materials such as high-strength alloys or overly soft polymers when making CNC parts. Instead, it would be best if you focused on selecting a material that is strong and durable enough for your needs but not so hard or brittle that it is difficult to machine with CNC tools. As always, the best way to choose a material for your project is by considering all of the different factors involved and selecting one that meets your specific needs and requirements.