Basics of Sheet metal fabrication

Metal sheet fabrication transforms flat metal sheets into various shapes and structures, such as panels, brackets, and enclosures. It involves different techniques to create custom and standardized components for diverse industries, including cutting, bending, and joining.

Sheet materials, such as stainless steel, mild steel, and aluminum, possess exceptional properties ideal for various applications. These properties include corrosion resistance, electrical conductivity, and good strength-to-weight ratios.

Table of Contents

Basics of Sheet Metal Fabrication

The importance of sheet metal fabrication is incalculable. Sheet metal fabrication is a manufacturing process that offers versatility and the capability to create complex shapes. This process helps manufacturers produce durable, high-quality, cost-effective parts for different industries. From automotive and aerospace to construction and electronics, sheet metal parts are essential for making multiple products and equipment.

Sheet Metal in Different Industries

Sheet metal plays a crucial role in numerous industries due to its adaptability and compatibility with various manufacturing processes. Some key industries that rely heavily on sheet metal fabrication include:

- Automotive: The use of sheet metal in the automotive industry is to create body panels, chassis components, and engine parts that help to enhance the structure and performance of vehicles.

- Aerospace: The aerospace industry requires lightweight, strong, and corrosion-resistant materials to produce aircraft components. Creating precise and high-quality parts in sheet metal fabrication heavily relies on essential processes like laser cutting and CNC machining.

- Construction: Sheet metal is an essential material in the construction industry for producing roofing, cladding, and structural components. With its high strength, durability, and weather resistance, sheet metal is an ideal choice for these applications.

- Electronics: Electronic devices often require custom sheet metal enclosures and components, which can be manufactured using sheet metal fabrication service. These parts provide protection, support, and functionality to various devices.

- HVAC: Ductwork and fittings used in HVAC systems transport air throughout buildings. Custom sheet metal fabrication ensures these components are tailored to specific requirements, providing efficient and effective air distribution.

The high demand for sheet metal fabrication across various industries demonstrates its significance and underscores the need for continued innovation and advancements.

Fabrication vs. Sheet Metal

Definition of Fabrication

Fabrication involves cutting, shaping, joining, and assembling products, parts, or metal, plastic, or wood structures. Metal fabrication transforms raw metal materials into finished pieces or products using various techniques, including cutting, bending, forming, and joining. The fabricated components are then applied to a variable and used in the automotive, aerospace, construction, and electronics industries.

Definition of Sheet Metal

Sheet metal refers to a flat and thin piece of metal that can range in thickness between 0.4 mm to 6 mm but may also be thicker or thinner depending on its use. It can be sourced from stainless steel, aluminum, brass, and copper. Due to its versatility, sheet metal finds application in numerous applications, such as automotive body panels, aircraft components, and electronic device enclosures.

Key Differences Between the Two

Although fabrication and sheet metal refers to the manufacturing of metal parts, they have distinctions that set them apart from each other :

- Scope: Fabrication is a broad term that encompasses various processes and materials, including metal, plastic, and wood. In contrast, sheet metal refers to the thin, flat metal sheets used in fabrication.

- Material form: Fabrication deals with materials in various forms, such as sheets, bars, rods, and tubes. Sheet metal, on the other hand, refers exclusively to flat sheets of metal that can be cut, bent, and formed into the desired shapes.

- Processes: Fabrication involves various techniques, including cutting, bending, forming, and joining. When working with sheet metal, specialized fabrication techniques, such as laser cutting, press brake forming, and welding, are used to create the desired shapes and structures.

- Applications: Fabrication can be applied to various industries and materials, creating multiple products and components. Industries like automotive, aerospace, and electronics use sheet metal because it is lightweight, durable, and versatile.

In summary, fabrication is a broad term that encompasses creating products, components, or structures using various techniques and materials, including metal. Thin, flat metal sheets used in fabrication to produce parts for multiple industries and applications are called sheet metal.

Types of Metal Fabrication

Metal Cutting Methods

Cutting is essential in sheet metal fabrication, as it shapes it into the desired forms. There are several cutting methods employed in the industry, each with its unique advantages and applications:

- Laser Cutting: This technique uses a high-powered laser beam to precisely cut through sheet metal materials. Laser cutting offers excellent accuracy, clean edges, and minimal material waste. It is perfect for making intricate designs and complex shapes, which makes it great for producing low-quantity prototypes and large-scale manufacturing.

- Plasma Cutting: Plasma cutting utilizes a high-velocity stream of ionized gas, known as plasma, to cut through metal sheets. The extreme heat generated by the plasma melts the metal, and the gas flow force blows the molten material away, creating a clean cut. Plasma cutting is beneficial for cutting thick metal sheets and larger components.

- Waterjet Cutting: A high-pressure jet of water mixed with abrasive particles is used to cut sheet metal using waterjets. This method generates no heat and minimal mechanical stress, making it suitable for cutting materials sensitive to high temperatures or those that might become distorted due to mechanical forces.

Bending and Forming

Bending and forming techniques shape sheet metal parts by applying force to change their geometry. Some of the most common bending and developing methods include:

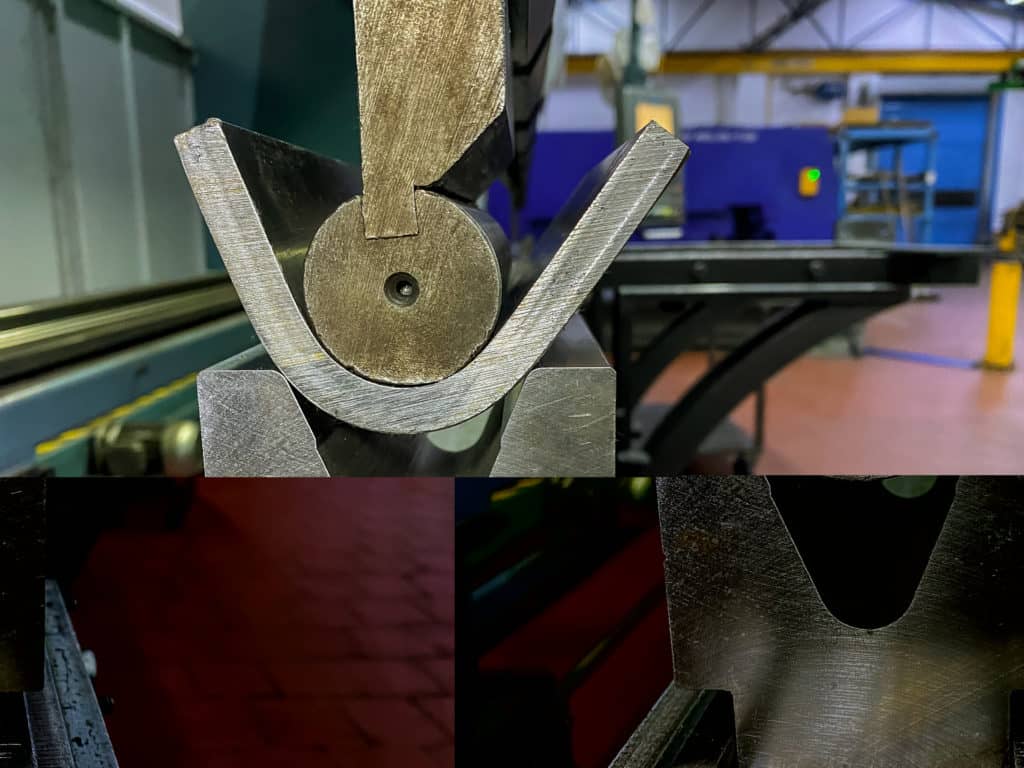

- Press Brake Forming: A press brake is a machine that exerts shearing force onto a metal sheet, causing it to bend along a specified axis. This method creates precise angles and complex shapes in sheet metal parts.

- Roll Forming: Roll forming is a continuous bending process that passes the sheet metal through a series of rollers to create a desired shape. This method is handy for producing long, uniform parts, such as channels and trim.

- Stamping: Stamping involves using a punch press to apply force on the sheet metal, creating impressions or shapes on its surface. Stamping can produce many forms, from simple bends to intricate designs, and plays a significant role in high-volume production.

| Laser Cutting Materials List | |||||

| Material Type | Model | Material Type | Model | ||

| Aluminum | 2024-T3 | Spring Steel | 1075 Annealed | ||

| 5052 H32 | 1075 Blue Tempered | ||||

| 6061 T6 | 1095 Annealed | ||||

| 7075 T6 | 1095 Blue Tempered | ||||

| Brass | 260 | Steel | 1045 | ||

| 353 H02 | A569/ASTM A1011 | ||||

| 464 H01 | A366/1008 | ||||

| 1018 | |||||

| Bronze | 220 H02 | 4140 | |||

| 510 H08 | 80CRV2 | ||||

| 932 M07 | A36 | ||||

| A572 | |||||

| Copper | 101 all series | G90 | |||

| 110, Annealed | Tool Steel D2 | ||||

| 110, H01 | Tool Steel O1 | ||||

| 110, H02 | |||||

| Material Type | Model | ||||

| Stainless Steel | 201 | ||||

| 202 | |||||

| 301 | |||||

| 304 / 304 hardened | |||||

| 316 / 316 annealed | |||||

| 410 annealed | |||||

| 430 | |||||

| 440C |

Assembling and Joining Techniques

Assembling and joining techniques are vital in metal fabrication, as they connect individual sheet metal parts to form complete assemblies. Some common assembling and joining methods include:

- Welding: Welding fuses two metal parts by melting their rough edges and allowing them to cool and solidify. This technique creates solid and permanent bonds between the joined parts, making it ideal for heavy-duty applications.

- Riveting: Riveting involves using a mechanical fastener, a rivet, to join sheet metal parts. Rivets create solid and durable connections commonly used in the aerospace and automotive industries.

- Adhesive Bonding: Adhesive bonding is a process that uses specialized adhesives to join sheet metal parts. This method offers a seamless appearance and is suitable for joining dissimilar materials, making it popular in applications where aesthetics are essential, such as consumer electronics.

By employing a variety of cutting, bending, and joining techniques, metal fabrication processes can create complex and functional sheet metal parts for a wide range of industries and applications.

Sheet Metal Fabrication Accuracy

Achieving precision and accuracy is crucial in the sheet metal fabrication industry, ensuring that the sheet metal design meets the specifications and functions as intended. The accuracy of fabrication techniques depends on several factors, such as the chosen method, equipment, and operator skill. Below, we discuss some popular sheet metal fabrication techniques and their accuracy levels:

- Laser Cutting: As previously mentioned, laser cutting is a highly accurate method of cutting sheet metal materials. The focused laser beam provides clean, precise cuts with minimal kerf width, resulting in intricate parts with tight tolerances. Advanced laser cutting machines, such as CNC-controlled systems, further improve accuracy by automating the cutting process and reducing the potential for human error.

- CNC Machining: CNC (Computer Numerical Control) machining is a subtractive manufacturing process that uses computer-generated machine code to control cutting tool movements. This method offers exceptional precision and repeatability, making it ideal for producing intricate sheet metal parts with tight tolerances. CNC machining can work with various materials, including stainless steel, aluminum, and brass.

- Press Brake Forming: Press brake forming is a highly accurate bending and forming technique that uses a press brake machine to apply force onto a metal sheet. The machine’s CNC control system ensures that the bending angle and depth are consistent, resulting in parts with precise dimensions. Press brake forming is especially suited for creating complex shapes and angles in sheet metal parts, such as brackets and enclosures.

- Waterjet Cutting: Waterjet cutting is another accurate sheet metal fabrication technique, as it uses a high-velocity stream of water and abrasive particles to make precise cuts without generating heat. This process is beneficial for cutting materials sensitive to thermal distortion or those with intricate designs that may be difficult to achieve using other cutting methods.

- Punch Press Operations: Punch press operations, such as stamping and punching, can achieve high levels of accuracy when using well-maintained and calibrated machinery. These processes are particularly well-suited for high-volume production runs, as they can rapidly create consistent, precise parts.

In summary, the accuracy of sheet metal fabrication techniques depends on the method, equipment, and operator skill. Advanced technologies, including CNC-controlled systems and high-precision cutting tools, have improved the precision of sheet metal fabrication processes. This has allowed manufacturers to produce high-quality intricate parts that meet different industries’ requirements.

Cost and Material Considerations

Raw Material Selection

The choice of raw material is vital in determining sheet metal parts’ quality, performance, and cost. Material selection is typically based on factors such as the part’s intended application, required properties, and compatibility with the chosen fabrication method. Some commonly used sheet metal materials include:

- Stainless Steel: Stainless steel is a good choice for items that need to withstand moisture or harsh conditions, like outdoor equipment and medical devices, because it is resistant to corrosion and quite strong.

- Mild Steel: With its lower carbon content, mild steel is more malleable and easier to form than stainless steel. It finds application in automotive components, construction, and various industrial applications.

- Aluminum: Aluminum is an excellent option for applications requiring a high strength-to-weight ratio, like aerospace and transportation, because it is lightweight and corrosion-resistant.

Factors Affecting the Cost of Sheet Metal Forming

Several factors influence the cost of sheet metal forming, including:

- Material cost: Fluctuations in the price of raw materials can considerably affect the final cost of sheet metal forming. Factors such as material type, grade, and market conditions can affect the cost of the chosen material.

- The complexity of design: More intricate designs often require advanced fabrication techniques, specialized equipment, and skilled operators, which can increase the cost of production.

- Production volume: The number of parts produced can influence the cost per unit. High-volume production runs can benefit from economies of scale, reducing the cost per part.

- Finishing processes: Additional processes, such as powder coating, chromate conversion coating, or painting, can add to the overall cost of sheet metal forming

Most Common Sheet Metal

Mild steel is generally considered the cheapest option among the commonly used sheet metal materials. Its low cost is because it is widely available and easy to produce. However, it’s essential to consider how well it performs, its corrosion resistance, and how long it will last when choosing the most cost-effective option for a particular use.

Best Forming Sheet Metal

The best-forming sheet metal depends on the final part’s specific application and desired properties. For example:

- Stainless steel is a great option when you need materials resistant to corrosion and high strength and durability.

- Aluminum is best used for lightweight applications like aerospace and transportation components because it has a high strength-to-weight ratio and is corrosion-resistant.

- Mild steel is a cost-effective option for general-purpose applications and can be transformed into various shapes.

The best forming sheet metal depends on the desired properties, application requirements, and fabrication method. By considering these factors, manufacturers can select the most suitable material for their sheet metal forming needs.

Surface Treatments

Corrosion Resistance Techniques

Corrosion resistance is a standard minimal post-processing aspect of sheet metal parts, especially when exposed to moisture, chemicals, or harsh environments. There are different ways to improve the ability of sheet metal parts to resist corrosion.

- Galvanization: To protect the sheet metal from corrosion, a thin layer of zinc is applied through a process called coating. Galvanization is a common process for steel components in construction, automotive, and other industries.

- Anodizing: Anodizing forms an oxide layer on aluminum sheet metal by electrochemical means. This layer provides increased corrosion resistance, improved wear resistance, and a decorative finish.

- Chromate Conversion Coating: This chemical process forms a corrosion-resistant layer on the surface of aluminum, magnesium, and zinc alloys. The conversion coating also improves adhesion for subsequent painting or bonding applications.

Sheet Metal Finishes

Sheet metal parts can be given different finishes to improve their appearance, durability, and performance. Some popular sheet metal finishes include:

- Powder Coating: Powder coating involves applying dry, powdered paint to the sheet metal surface, which is then cured under heat to form a hard, durable finish. This coating provides excellent resistance to wear, corrosion, and fade.

- Electroplating: The process of electroplating deposits thin layers of metal, such as chrome or nickel, onto the sheet metal surface. This process can enhance the part’s appearance, corrosion resistance, and good conductivity properties.

- Brushed Finish: To create a brushed finish on sheet metal, you need to use a series of abrasives to create a consistent texture on the surface. This will give the metal a uniform, textured appearance. This finish can provide a decorative and scratch-resistant surface.

| Finishing | Advantages | Disadvantages | Application |

| Anodizing | 1.Stylish and durable | 1.Non-Conductive | Enhances corrosion resistance and aesthetic appeal of aluminum, titanium, aluminum alloy, and magnesium. |

| 2.Easy to apply, even small parts. | 2.Comparatively brittle to powder coatings | ||

| 3.Smooth, almost matte texture | |||

| 4.Various colors available | |||

| Alodine | 1.Conductive | 1.Limited colors options | Functional parts only, not decorative purpose. |

| 2.Corrosion-free | 2.Easily abraded | ||

| 3.Increases durability | 3.Assembled parts cannot be alodined | ||

| Bead Blasting | 1.Deburrs | 1.Affect surface roughness | Surface preparation and visual purposes. Grit indicates the size of the pellets bombarded. Can be combined with anodizing. |

| 2.Tool marks free | 2.Affect critical dimensions | ||

| 3. Uniformly matte or satin surface | |||

| 4.Increases grip strength | |||

| Powder coating | 1.Decorated surface | 1.Doesn’t work well on internal surfaces | Applied to all metals for both protective and decorative purposes. |

| 2.Metal-compatible | 2.A lower degree of dimensional control | Can be combined with bead blasting or polishing processes. | |

| 3.Durability is greater than paint | 3.To powder coat, the part must be grounded. | ||

| 4.Corrosion- and weather-resistant |

Standard Painting Methods

Painting helps to apply a protective and decorative finish to sheet metal parts. Standard painting methods include:

- Spray Painting: Spray painting uses a spray gun to apply liquid paint to the sheet metal surface. This method can provide a uniform, durable finish suitable for large-scale production parts.

- Dip Coating: Dip coating involves immersing the sheet metal part in liquid paint, allowing the excess to drip off before curing. This method can provide a consistent and even coating for different shapes.

- Roll Coating: Roll coating uses rollers to paint the sheet metal surface. This method can provide a smooth, even finish, and works well for flat or gently curved parts.

By employing various surface treatments to achieve the desired aesthetic, manufacturers can enhance sheet metal components’ appearance, durability, and performance, ensuring they meet the demands of multiple industries and applications.

Conclusion

Recap of Key Points

Sheet metal fabrication has been discussed in various ways throughout this article, including:

- The definition and importance of metal sheet fabrication and its role in various industries.

- The different types of metal fabrication include cutting methods, bending and forming, and assembling and joining techniques.

- The accuracy of sheet metal fabrication techniques, such as laser cutting, CNC machining, press brake forming, waterjet cutting, and punch press operations.

- Cost and material considerations, including raw material selection, factors affecting the cost of sheet metal forming, and the cheapest and best-forming sheet metals.

- The distinction between fabrication and sheet metal, including their definitions and key differences.

- Surface treatments for sheet metal parts, including corrosion resistance techniques, sheet metal finishes, and standard painting methods.

Future Trends and Demand

The demand for sheet metal fabrication will continue to grow as industries innovate and require lightweight, durable, and versatile components. Sheet metal fabrication processes will be improved by technological advances such as increased use of CNC-controlled systems, automation, and additive manufacturing, leading to greater precision, efficiency, and capabilities. Additionally, the future of sheet metal fabrication will be influenced by sustainability and environmental concerns.

Manufacturers will likely enhance material efficiency, minimize waste, and utilize environmentally sustainable materials and procedures. Additionally, advancements in material science could result in the development of new sheet metal materials that possess better qualities, such as higher strength, reduced weight, or improved resistance to corrosion.

This further expands the possibilities for sheet metal fabrication process applications.

In conclusion, sheet metal fabrication is critical in manufacturing and various industries worldwide. The field of sheet metal fabrication will continue to experience growth in response to the increasing demand for precise and high-quality metal sheet parts, thanks to technological advancements and evolving industries. This growth will drive continued innovation and development in the field.

Frequently asked questions

Modern manufacturers possess various sheet metal fabrication capabilities, including laser cutting, CNC machining, bending, forming, welding, and assembling. They can also work with multiple materials, such as stainless steel, aluminum, and mild steel, to produce parts with intricate designs, high precision, and tight tolerances.

Sheet metal fabrication services often use advanced technology, such as CNC-controlled machines, automation, and 3D design software, to improve efficiency and precision. In contrast, traditional sheet metal shops may rely more on manual processes and techniques. Additionally, sheet metal fabrication services typically offer a broader range of capabilities, from prototyping to high-volume production.

Yes, modern metal fabrication work allows for creating complex structures using various techniques, such as press brake forming, stamping, and hydroforming. Manufacturers can design and produce intricate sheet metal parts to meet specific application requirements.

Sheet metal prototypes are initial, low-volume final sheet metal part versions. They are essential for testing and validating the component’s design, fit, and function before moving to full-scale production. Prototyping ensures that necessary adjustments are made before investing time and resources into large production volumes.

Yes, many sheet metal fabrication services offer online platforms for requesting quotes, submitting designs, and managing orders. These online services provide a convenient and efficient way to access manufacturing services, often with rapid turnaround times and competitive pricing.

Yes, sheet metal parts can be treated with various surface finishes, such as galvanization, anodizing, or chromate conversion coating, to enhance their corrosion resistance. Also, choosing corrosion-resistant materials, like stainless steel, can further improve the part’s longevity.

Selecting the appropriate sheet material depends on the intended application, desired properties, and fabrication method. Common sheet materials include stainless steel, aluminum, and mild steel, each offering different advantages in strength and weight.

Yes, laser cutters can be used for prototyping and production volumes. They offer high precision, fast processing times, and the ability to cut various materials and thicknesses. Laser cutting is ideal for creating intricate shapes, making it a versatile solution for different stages of the manufacturing process.