How to Choose the suitable Material for Your Sheet Metal Fabrication Project

Choosing sheet metal isn’t just about availability — the wrong material can drive up cost, delay production, or fail in service. At Okdor, we’ve supported aerospace, audio, and medical projects where early material choices determined whether designs scaled smoothly or hit costly setbacks.

Aluminum is best for lightweight enclosures, stainless steel for strength and corrosion resistance, and mild steel for cost-effective structures. Each material responds differently to bending, welding, and finishing, so selection must match performance, environment, and tolerance needs.

Learn how requirements, tolerances, and finishes impact sheet metal selection—and avoid common prototyping mistakes product developers often make.

Table of Contents

What performance requirements should guide material choice?

The best way to choose sheet metal is to start with performance — what the part must actually deliver in service. Most developers should evaluate five factors: strength, stiffness, corrosion resistance, weight, and conductivity. These criteria define how the part will function long before cost or finish are considered.

From our experience, aluminum alloys like 6061 are often chosen when weight reduction and machinability are critical, stainless steel 304 when corrosion resistance and durability are non-negotiable, and mild steel where strength is needed at the lowest cost. Copper and brass, while less common, offer excellent conductivity and are favored in electronic or decorative applications.

A frequent mistake we see is prioritizing raw strength while overlooking stiffness or corrosion behavior. For example, mild steel may look cost-effective, but in humid or sterilized environments it can fail prematurely, requiring redesign. By contrast, stainless steel may increase upfront cost but prevents downstream risks.

Design Takeaway: Start with the performance checklist — strength, stiffness, corrosion resistance, weight, and conductivity — then map materials against those needs. This ensures your choice supports both function and manufacturability, avoiding costly revisions later.

How does the environment affect sheet metal selection?

Environmental conditions are often the hidden driver of material choice. Parts exposed to moisture, chemicals, or temperature swings need alloys that won’t corrode, warp, or lose strength. Selecting only on price or strength often leads to early failures.

From our experience: stainless steel 304/316 is the safe choice for outdoor, marine, or sterilized applications where corrosion is constant. Aluminum alloys resist corrosion in general use but need anodizing or coatings in saltwater. Mild steel is acceptable indoors with painting or plating but will rust quickly if exposed. Copper and brass resist corrosion but may tarnish without a protective finish.

Environment–Material Fit Matrix

Environment Best-Fit Materials Notes on Use

Indoor, low humidity Mild steel, aluminum Use coatings for durability

Outdoor/general use Aluminum (anodized), 304 SS Resist UV and moisture

Marine/salt exposure 316 SS, coated aluminum Superior corrosion resistance

Sterilization/medical 304 SS, 316 SS Withstand chemicals, repeated cleaning

High temperature Stainless steels, Inconel Avoid aluminum if thermal creep is a risk

Low temperature Aluminum alloys Retains toughness better than some steels

Design Takeaway: Define humidity, temperature, and chemical exposure upfront. Pick materials proven to survive those conditions, then apply finishes as secondary protection. This prevents failures and warranty costs later.

Which sheet metals support tight tolerances?

Aluminum alloys and stainless steels are most reliable for tight tolerances, while mild steel and softer alloys often introduce variation. Material stability during machining and assembly directly affects how accurately dimensions can be held.

In practice, 6061 aluminum can hold ±0.01–0.02 mm with stable setups, and 304 stainless achieves similar precision despite being harder to cut. Mild steel, especially in thin gauges, tends to warp during machining or welding, making ±0.05 mm more realistic. Plastics like POM may expand or contract with heat, limiting achievable tolerances to ±0.05–0.10 mm.

We often see developers overspecify aerospace-level tolerances across every feature. For example, ±0.01 mm flatness on a cosmetic cover plate adds inspection cost without functional benefit. ISO 2768 provides general guidance, allowing looser tolerances on non-critical features.

Rule of Thumb for Tolerances:

- 6061 Aluminum & 304 Stainless → Stable for ±0.01–0.02 mm.

- Mild Steel → ±0.05 mm typical, risk of warping.

- Plastics (POM, ABS) → ±0.05–0.10 mm due to thermal expansion.

- Reserve tight specs only for functional features.

Design Takeaway: Use stable alloys when tolerances matter, but apply tight specs only where function demands it. This balances cost, manufacturability, and inspection time.

Need your parts within 2 days? We've got 2 days lead time

How do thickness and bend radius limit certain materials?

Minimum bend radius scales with sheet thickness and ductility — push too far and parts crack or distort. Aluminum typically tolerates bends at ~1× thickness, while stainless may need 1.5–2× due to lower ductility.

We’ve seen issues where designers specify sharp 90° bends in stainless without enough radius, resulting in edge cracking during forming. Grain direction also matters — bends made parallel to the rolling direction are more prone to failure. Mild steel is more forgiving, but even it can tear if the radius is too tight.

If you don’t know the exact temper or grain orientation, a safe default is to set bend radius ≥1× material thickness. This works for most ductile metals and avoids cracking during prototyping. For critical applications, consult forming data or run a sample bend before committing to production.

Rule of Thumb Table – Minimum Bend Radius

Material Typical Min. Bend Radius Notes

Aluminum (6061) ≥ 1× thickness T6 temper prone to cracking

Mild Steel ≥ 1× thickness Ductile, reliable

Stainless 304 ≥ 1.5–2× thickness Less forgiving, risk of cracking

Brass/Copper ≥ 0.5–1× thickness Excellent ductility

Design Takeaway: Default to ≥1× thickness if unsure, and scale up for less ductile alloys. It’s easier to adjust CAD fillets early than scrap cracked parts later.

Which sheet metals deliver the best surface finish?

Aluminum and stainless steels deliver the most consistent finishes, while mild steel usually requires coatings to achieve similar quality. Surface finish is influenced by both material and post-processing choices.

Aluminum is widely used in consumer and audio enclosures because it can be bead-blasted and anodized for Ra 1.6–3.2 µm matte finishes. Stainless steels can be machined to Ra ≤ 0.8 µm and polished further for medical or food applications. Mild steel, even when machined, often shows tool marks and needs powder coating or plating for corrosion resistance. Brass and copper polish well but tarnish without sealing.

Surface Finish Comparison – Typical Ranges

Material Machined Finish (Ra µm) Post-Processed Finish (Ra µm) Notes

Aluminum (6061) 1.6–3.2 ≤ 1.6 (bead blast, anodize) Excellent for cosmetic housings

Stainless 304 0.8–1.6 ≤ 0.4 (polished) Preferred for medical, hygienic use

Mild Steel 3.2–6.3 ≤ 1.6 (plated/coated) Needs finish for corrosion control

Brass/Copper 1.6–3.2 ≤ 0.8 (polished, lacquered) Aesthetic but prone to tarnish

One common pitfall is over-specifying ultra-low Ra for hidden brackets or structural parts — this adds machining and polishing time without functional benefit. In some cases, we’ve seen polishing requirements double lead time without improving performance.

Design Takeaway: Match finish requirements to function. Reserve Ra ≤ 0.8 µm for sealing surfaces or medical use, anodized aluminum for visible parts, and coatings for mild steel. Avoid premium finishes where they don’t impact performance.

How do weldability and joining methods affect selection?

Not all sheet metals join equally well—mild steel is the most forgiving to weld, austenitic stainless (304/316) welds readily, and 6xxx aluminum welds but loses strength in the heat-affected zone; copper/brass are usually better brazed or soldered.

Material → Joining quick guide

Material Weldability (summary) Good alternatives when welding isn’t ideal

Mild steel Easy with MIG/TIG; very forgiving in thin gauges Rivets, screws, spot welding, clinching

Stainless 304/316 Readily weldable with arc processes; no heat-treat needed Spot welding, clinching, mechanical fasteners

Aluminum 6061 Weldable but loses 30–50% strength in HAZ; needs care Rivets, screws, adhesives for mixed materials

Copper/Brass Difficult to weld cleanly; brazing/soldering preferred Brazing, soldering, mechanical fastening

Design Takeaway: When joints are cosmetic or high-volume, consider spot-welding or clinching to cut cycle time and heat distortion; use self-clinching fasteners or structural adhesives where serviceability or dissimilar materials matter.

Ready to get your parts?

How does material weight influence design trade-offs?

Weight impacts usability, shipping, and stiffness — aluminum reduces mass, while steel and stainless add durability but increase handling costs. Aluminum (~2.7 g/cm³) is about one-third the density of steel (~7.8 g/cm³), which makes it the natural choice for portable housings or assemblies where every gram counts.

In our projects, stainless and mild steel often prove more cost-effective for fixed or structural components where weight isn’t a constraint, but they can quickly make handheld or wearable devices impractical. Brass and copper, being even heavier, are chosen only when aesthetics or conductivity justify the penalty.

Use-Case Guide – Weight vs Material

Application Type Weight Priority Recommended Material

Portable / handheld High — minimize weight Aluminum alloys (e.g., 6061)

Stationary / structural Low — strength first Mild steel, Stainless 304

Large panels/enclosures Balance stiffness/weight Aluminum, thicker gauge if needed

Premium aesthetic parts Moderate — sometimes heavier feels “solid” Stainless, Brass

Design Takeaway: Treat weight as both an end-user and logistics factor. Use aluminum for portability, steel for budget strength, and stainless when durability outweighs mass concerns.

Which materials offer the best thermal or electrical conductivity?

For most sheet-metal parts, conductivity only matters if the component must manage heat or current — otherwise, it’s not a design factor. Aluminum offers the best balance: lightweight, machinable, and reasonably conductive. Copper is more conductive but heavier and costly, while stainless and mild steel are poor conductors.

From a manufacturability view:

- Aluminum machines cleanly, dissipates heat well, and works for housings that need some thermal relief (e.g., reducing hot spots in enclosures).

- Copper is highly conductive but heavy and expensive — we only see it specified when conductivity is the core function.

- Stainless and mild steel are selected for strength or corrosion resistance, not conductivity.

When to Consider Conductivity in Sheet Metal Parts

- Heat-sensitive enclosures where aluminum helps dissipate heat.

- Panels where reducing thermal buildup improves component lifespan.

- Cases where conductivity isn’t functionally needed → ignore it, and pick based on strength/cost.

Design Takeaway: Ask first: Does this part actually need to conduct heat? If yes, aluminum usually provides the best balance. If not, ignore conductivity and select materials for strength, finish, or cost instead.

How do cost and availability affect material choice?

Mild steel is usually the most affordable, aluminum sits in the middle, while stainless and copper alloys add cost and longer lead times. But availability can shift the picture just as much as price.

In practice, common grades like 6061 aluminum, 304 stainless, and cold-rolled mild steel are widely stocked and move quickly into production. By contrast, specifying a specialty grade — say duplex stainless — may push delivery out by weeks or force suppliers to buy at bulk MOQ levels. We’ve seen prototypes delayed simply because the chosen alloy wasn’t available in the needed thickness.

Sourcing Verification Checklist (before finalizing a spec):

- Is this alloy available in the required gauge/plate size?

- Do local suppliers stock it, or is it import-only?

- Can it be bought in small prototype quantities, or only in bulk?

- Is the lead time aligned with my project stage (prototype vs production)?

Relative Cost Guide (per kg, mild steel = 1.0 baseline):

- Mild steel → ~1.0×

- Aluminum → ~1.3–1.5×

- Stainless (304/316) → ~2–3×

- Copper/Brass → ~4–6×

Design Takeaway: Always check both price and stock reality. A well-chosen common grade avoids last-minute redesigns and keeps projects on schedule.

How do volume and lead time shape material decisions?

Material choice changes with quantity and timing — aluminum and mild steel are ideal for quick prototypes, while stainless or coated steels make sense in larger runs where durability offsets slower sourcing.

We often guide developers to switch alloys depending on stage: a prototype housing in 6061 aluminum might ship in 48 hours, while a stainless production run takes longer but cuts warranty risk. The trade-off is not just material performance but how fast you need parts in hand.

Volume vs Priority

Project Stage Typical Volume Priority Factor Best Material Approach

Prototype / early DFM 1–50 pcs Speed, machinability Common grades (6061 Al, mild steel)

Low-volume pilot 50–500 pcs Balance cost & durability Aluminum or stainless, stock-verified

High-volume production 500+ pcs Lifecycle durability & cost over time Stainless, coated steels, optimized alloys

Design Takeaway: Align material with stage and volume. Fast prototypes need stocked, easy-to-machine alloys; production runs can justify slower-sourcing materials if they reduce lifecycle cost.

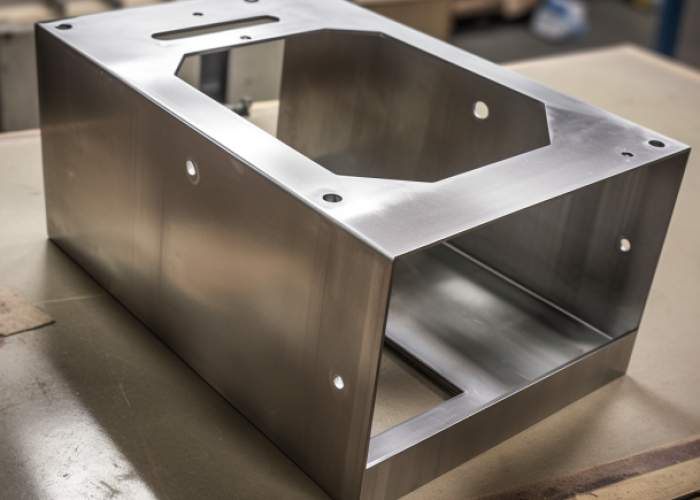

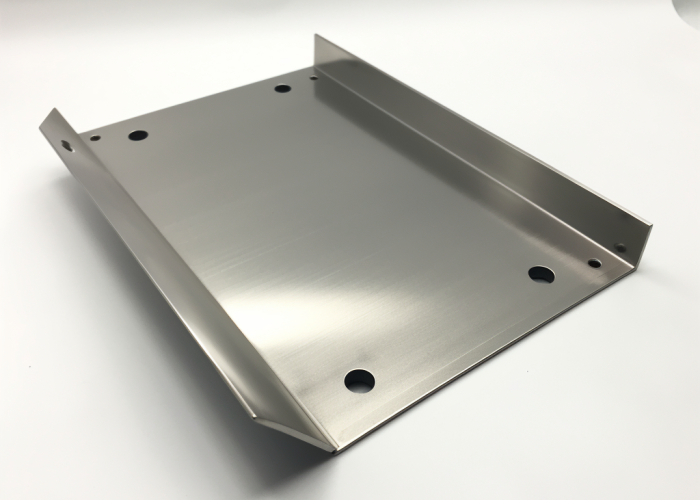

Which sheet metals work best for enclosures vs structural parts?

Aluminum alloys are preferred for lightweight, cosmetic enclosures, while stainless and mild steel are better for structural parts that must carry load. The choice depends on whether the part’s job is mainly to protect and look good or to support and withstand forces.

Application–Material Matrix

Application Type Best Materials Why It Works

Enclosures (audio, medical housings, electronics) Aluminum (6061, 5052) Lightweight, easy to machine, anodizes for premium finishes

Harsh-environment enclosures Stainless 304/316 Hygiene, corrosion resistance, durable in cleaning cycles

Structural supports, frames, brackets Mild steel, Stainless Strong, rigid, weldable, cost-efficient in thicker gauges

Aesthetic + structural (premium products, furniture) Stainless, Brass Strength + “solid” look and feel

Hybrid Cases: Some parts act as both enclosure and structure (e.g., medical housings that need appearance and strength). In those cases, stainless or thicker aluminum can balance durability with finish.

Design Takeaway: Match material to role: aluminum for light enclosures, stainless/mild steel for structural loads, and blend requirements thoughtfully for dual-role parts.

What mistakes should I avoid when choosing sheet metal materials?

The most expensive errors come from overspecifying or ignoring manufacturability limits. Avoiding just a few common pitfalls can save weeks of delay and thousands in rework.

Priority-Ranked Mistake Checklist

- Over-specifying alloys (critical) – Choosing 317 stainless when 304 would work, or 7075 aluminum when 6061 is sufficient. Raises cost and sourcing time without benefit.

- Ignoring forming limits (critical) – Designing bends tighter than material ductility allows, causing cracks or rework.

- Forgetting environment (common) – Using mild steel outdoors without coatings; leads to corrosion and warranty issues.

- Over-finishing (common) – Requiring Ra ≤ 0.8 µm on hidden brackets, adding cost with no performance gain.

- Not checking stock availability (common but costly late) – Specifying gauges/alloys suppliers don’t carry, forcing redesigns under deadline pressure.

Design Takeaway: Prioritize avoiding overspecification and unbendable designs first — these are the most costly mistakes. Then confirm environment, finish, and stock early to prevent avoidable delays.

Conclusion

Choosing the right sheet metal material means balancing performance, cost, and manufacturability. At Okdor, we help product developers avoid costly missteps and bring designs to production smoothly. Contact us to explore manufacturing solutions tailored to your sheet metal project requirements.

Frequently Asked Questions

For early samples, pick fast-to-machine materials like aluminum or mild steel. For production, switch to stainless or coated steel if durability is critical. Plan the changeover during design, not after testing.

Ask about equivalent stocked grades in the same family (e.g., 304 instead of 317 stainless). Sticking to common gauges avoids costly sourcing delays.

Tolerances or bends that don’t match the material’s limits. Always align specs with what the chosen alloy can realistically achieve — and confirm with your fabricator before release.

Finishes are part of the material system. Anodized aluminum adds wear resistance, powder-coated steel gains corrosion protection, and polished stainless meets hygiene needs. Factor these into durability expectations.

Build a prototype in the intended material. Even a single part verifies bend performance, finish, and weight feel — avoiding expensive redesigns later.

Share your CAD early and ask your fabricator to review bend radii, thickness, and tolerances. A quick DFM check often catches issues before you order prototypes.