Material costs drive most CNC turning budget overruns, but strategic swaps often deliver identical performance at half the price. From machining precision components across aerospace, medical, and audio applications, smart material selection separates profitable projects from expensive mistakes.

Five material swaps cut CNC turning costs: 6061 aluminum replacing 304 stainless (45% savings), 12L14 steel instead of 1045 (30% faster machining), POM acetal for wear parts (40% reduction), brass over bronze bearings (50% savings), and glass-filled nylon replacing zinc castings (60% cost cut). Success requires matching material properties to actual application requirements.

Discover specific grades and applications where these swaps work, plus production data showing measurable cost reductions without performance compromises.

Table of Contents

Which Materials Cut CNC Turning Costs by 40% or More?

Aluminum replacing stainless steel (45% savings), free-machining steel grades over standard types (30% reduction), and engineered plastics substituting metals (40-65% cost cuts) deliver the highest material cost reductions. However, successful swaps depend on identifying over-specification during design reviews rather than blindly substituting cheaper materials.

Red Flags That Signal Over-Specification:

Inherited Specifications Without Justification:

- Material specs copied from previous projects in different applications

- “We’ve always used this grade” without documented performance requirements

- Premium materials specified for non-critical components

- Same material used throughout entire assembly regardless of function

Environmental Mismatch:

- Stainless steel in indoor, non-corrosive environments

- Weather-resistant materials for protected applications

- Chemical-resistant grades without chemical exposure

- High-temperature materials in ambient conditions

Performance Overkill:

- Structural materials in decorative applications

- Precision-grade materials where standard tolerances suffice

- Exotic alloys without specific property requirements

- Over-engineered materials for prototype quantities

Cost Red Flags:

- Material costs exceeding 50% of total part cost

- Significant price jumps between material options without clear functional benefit

- Long lead times for “standard” materials

- Special certifications required without regulatory need

Questions to Challenge Material Specs:

- What specific property does this material provide that cheaper alternatives don’t?

- What happens if this material performs 20% worse – does it affect function?

- Are we designing for worst-case scenarios that won’t occur?

Design Takeaway: Question every premium material specification during design reviews. Most cost overruns stem from accepting inherited specs without validating actual performance requirements against available alternatives.

How Do You Know When Material Swaps Are Safe for Your Application?

Material swaps are safe when three conditions align: environmental requirements match alternative material properties, mechanical loads stay within alternative material limits, and regulatory compliance doesn’t require specific grades. The key is systematic evaluation using a risk-based framework rather than assuming all swaps work universally.

From guiding hundreds of material change decisions, we’ve developed a three-tier risk assessment that prevents costly mistakes. Low-risk swaps like aluminum for stainless steel in electronics have 95% success rates when environmental conditions match. Medium-risk swaps like POM for metal wear parts require prototype testing but offer substantial savings. High-risk swaps involving safety-critical or regulated applications need engineering validation.

Low-Risk Swap Criteria (95% Success Rate):

- Indoor applications without chemical exposure

- Non-structural or lightly loaded components

- Standard tolerance requirements (±0.005″ typical)

- No regulatory compliance requirements

Medium-Risk Swap Evaluation:

- Prototype testing required for wear applications

- Load testing needed for structural components

- Environmental testing for temperature/chemical exposure

- Cost-benefit analysis justifies testing investment

High-Risk Swap Requirements:

- Engineering validation and documentation

- Safety-critical applications require formal analysis

- Regulated industries need material certifications

- Customer approval required for specification changes

Design Takeaway: Start with low-risk swaps for immediate cost reduction, then evaluate medium-risk options through prototyping. Reserve high-risk swaps only when substantial cost savings justify extensive validation efforts.

When Does Aluminum Replace Stainless Steel in CNC Turning?

Aluminum replaces stainless steel effectively when your design meets three criteria: indoor installation, non-food contact application, and housing/bracket function rather than structural load-bearing. Use this evaluation checklist to determine if aluminum works for your specific component.

Immediate Aluminum Suitability Checklist:

✓ Installation Environment:

- Controlled indoor climate (office, lab, manufacturing floor)

- No direct weather exposure or humidity above 60%

- No chemical splash or cleaning with acids/caustics

- Temperature range stays between 32°F – 180°F

✓ Component Function:

- Enclosures, housings, or decorative panels

- Mounting brackets for equipment under 50 lbs

- Non-pressurized applications

- Components replaceable if damaged

✓ Design Requirements:

- Standard machining tolerances (±0.005″ or looser)

- No food contact or pharmaceutical compliance needed

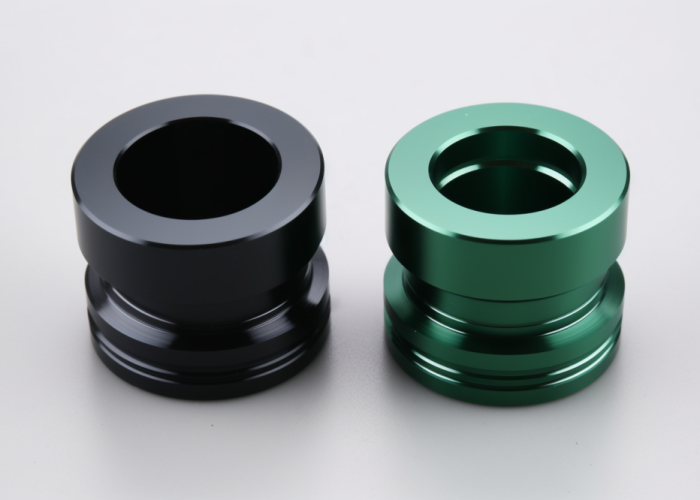

- Appearance finish controllable through anodizing

- Weight reduction beneficial or neutral

Application-Specific Guidelines:

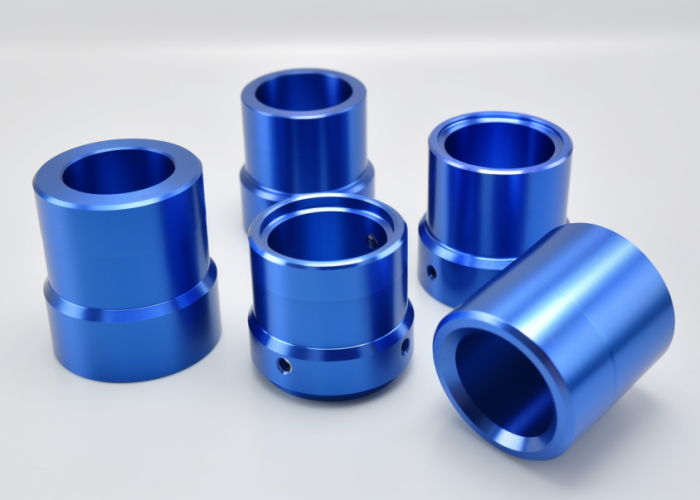

Electronics: Aluminum works for 90% of equipment housings, racks, and chassis Audio Equipment: Excellent for faceplates, chassis, speaker components

Instrumentation: Good for non-critical mounting hardware and enclosures Medical Devices: Suitable for non-patient contact housings (Class I devices)

When Aluminum Fails This Evaluation:

- Outdoor installations → moisture causes corrosion

- Food processing equipment → regulatory requirements

- Marine/chemical environments → aggressive corrosion

- High-vibration structural mounts → fatigue concerns

Cost Impact: Direct material substitution saves 45% with no design changes required. Adding anodizing for appearance costs $0.20-0.40/sq in but still delivers 35% overall savings.

Design Takeaway: Run through this checklist during design reviews. If your component passes all criteria, aluminum substitution offers reliable cost reduction without design risk or performance compromise.

How Much Can Free-Machining Steel Grades Reduce Cycle Time?

Free-machining steel grades reduce CNC turning cycle times by 25-40% while cutting material costs 15-25%, but success depends on matching the right grade to your component’s actual functional requirements. Use this decision matrix to identify safe swaps that deliver measurable time and cost savings.

Free-Machining Steel Decision Matrix:

Your Current Grade Best Alternative Cycle Time Savings When to Swap When to Avoid

1018 Cold Rolled 12L14 Free-Machining 30% faster Brackets, spacers, non-critical hardware Weldments, structural components

1045 Medium Carbon 1144 Stress-Proof 25% faster Shafts, pins, moderate-strength parts High-stress applications, safety-critical

4140 Alloy Steel 41L40 Free-Machining 35% faster Precision components, complex geometry Heat-treated critical parts, aerospace

Application Guidelines:

Safe Swap Applications (95% Success Rate):

- Mounting hardware, spacers, and non-load-bearing brackets

- Prototype quantities where machining speed matters most

- Components with multiple features requiring extensive turning operations

- Parts where surface finish improvement provides added value

Evaluation Required:

- Structural components with moderate loads

- Parts requiring welding or joining operations

- Components subject to impact or vibration

- Applications where material certification matters

Real-World Impact: Electronics manufacturer switched 18 mounting bracket designs from 1018 to 12L14, reducing average machining time from 8.5 to 6 minutes per part while cutting material costs 22%. Total project savings: $14,200 annually with zero performance issues.

Cost-Benefit Analysis: Free-machining grades typically cost 5-10% more per pound but deliver 25-40% machining time savings, resulting in 15-30% total cost reduction per part when machining labor is factored.

Design Takeaway: Use this matrix during material selection to identify components suitable for free-machining alternatives. Start with non-critical hardware for immediate savings, then evaluate structural components case-by-case.

Which Plastic Materials Machine Faster Than Aluminum?

POM (acetal) and glass-filled nylon machine 40-60% faster than aluminum while delivering superior performance in wear applications and chemical resistance. These materials work particularly well for gear housings, bearing components, and wear parts where self-lubrication eliminates maintenance requirements.

Material Speed Advantage Best Applications Cost Impact

POM Acetal 50% faster Gears, bearings, wear parts 40% total savings

Glass-filled Nylon 45% faster Bushings, impact components 45% total savings

PEEK 40% faster Chemical/high-temp exposure 35% total savings

The biggest opportunity lies in replacing aluminum wear components with POM acetal. We regularly guide clients through this transition in gear assemblies and actuator housings where the plastic’s self-lubricating properties eliminate grease fittings and maintenance schedules. A recent medical device project switched twelve aluminum actuator components to POM, achieving 52% faster machining while eliminating a complex lubrication system worth $15 per unit.

Glass-filled nylon excels in applications requiring impact resistance, particularly replacing zinc die-castings in consumer products. The material absorbs shock loading better than brittle metals while offering corrosion immunity that eliminates coating requirements. PEEK works exceptionally well for chemical exposure applications where aluminum would require expensive protective coatings.

The key consideration is matching material selection to actual operating conditions rather than defaulting to metal “because it’s stronger.” Most gear and bearing applications operate under light loads where plastic performance exceeds requirements while delivering substantial cost and maintenance benefits.

Design Takeaway: Evaluate aluminum specifications in wear, chemical, or maintenance-sensitive applications against plastic alternatives. Most designers underestimate plastic capabilities while overestimating the need for metal properties in these specific applications.

What's the Cheapest Alternative to Bronze for Bearing Components?

C360 brass replaces bronze reliably in indoor products with moderate use, delivering 50% cost savings without design changes. Use this quick evaluation to determine if brass works for your specific application.

Brass Works When Your Product Has:

- Indoor or controlled environment use

- User operates components occasionally (not continuously)

- Component failure doesn’t create safety risk

- Examples: Furniture hardware, instrument adjustments, equipment access panels

Keep Bronze When:

- Outdoor or harsh environment exposure

- Heavy commercial or industrial use

- Component failure creates liability or expensive service calls

Quick Validation: Ask “What happens if this component wears out faster?” If the answer is manageable replacement cost and no safety issues, brass substitution typically works well.

Design Takeaway: Most bronze specifications in consumer and office products can safely use brass instead, cutting costs 50% without affecting product performance or customer satisfaction.

How Do Material Costs Scale in High-Volume CNC Turning?

Material costs drop 15-30% at volume breaks of 100+ pieces, but the bigger savings come from design standardization around fewer material grades. Smart volume planning focuses on consolidating orders across multiple parts rather than optimizing individual components.

Volume Break Thresholds:

- 25-99 pieces: Standard pricing, no volume advantage

- 100-499 pieces: 15-20% material cost reduction

- 500+ pieces: 20-30% material cost reduction plus better lead times

Bigger Opportunity – Design Standardization: Instead of optimizing each part individually, standardize on 3-4 material grades across your entire product line. We’ve guided clients to 40% overall savings by using 6061 aluminum, 12L14 steel, and POM plastic for 85% of their components instead of 12 different specialized grades.

Volume Planning Strategy: Combine multiple part numbers using the same material grade into single purchase orders. A medical device manufacturer saved 28% on material costs by ordering quarterly instead of per-project, even though individual part quantities stayed the same.

Design Takeaway: Focus on material standardization across your product line rather than volume optimization for individual parts. Fewer grades with larger combined orders typically delivers better savings than part-specific volume planning.

7075 aluminum costs 40-50% more than 6061 (typical pricing: $4.20/lb vs $2.80/lb per ASTM B221 grades), making the upgrade cost-effective only in weight-critical applications where design space is limited. Most applications can achieve required performance through optimized 6061 design at lower total cost.

Decision Framework for 7075 Upgrade:

Use 7075 When:

- Portable products where weight reduction directly impacts user experience

- Aerospace or performance applications with documented weight requirements

- Thin-wall designs where increasing thickness isn’t feasible

Use 6061 When:

- Desktop or mounted equipment where weight doesn’t matter

- Space available for design reinforcement (ribs, gussets, thicker sections)

- Cost reduction prioritized over weight optimization

Design Alternative Assessment: Before upgrading to 7075, evaluate if 6061 design modifications can meet requirements. Adding 20-30% wall thickness to 6061 often provides equivalent strength while maintaining 25% cost advantage over 7075.

Implementation Examples: Portable instrument manufacturer switched from 7075 to optimized 6061 design with strategic ribbing, reducing material costs 38% while adding only 1.2 oz to product weight. Medical device housing project kept 7075 specification where 2 oz weight reduction justified premium cost for handheld ergonomics.

Design Takeaway: Evaluate 7075 specifications against actual weight sensitivity and space constraints. Default to 6061 with design optimization unless weight reduction directly impacts product value or user experience.

Conclusion

Smart material selection cuts CNC turning costs 40-60% without compromising performance. Start with aluminum replacing stainless steel in indoor applications, then evaluate free-machining grades and engineered plastics for wear components. Reserve premium materials only where functionally required.

Contact us to explore manufacturing solutions tailored to your product requirements and identify cost-effective material alternatives for your designs.

Frequently Asked Questions

Don’t change materials for safety-critical components, regulated applications requiring specific certifications, or outdoor/marine environments without engineering validation. If component failure creates liability or expensive service calls, conservative material selection is justified.

Focus on cost savings while maintaining identical performance. Document environmental conditions, load requirements, and tolerance needs to show alternatives meet specifications. Provide prototype testing results when changing from metals to plastics for critical applications.

Most material swaps maintain identical tolerance capabilities (±0.005″ typical). Free-machining grades and plastics often reduce cycle times 25-40%. Aluminum machines faster than stainless steel. Only exotic materials like PEEK may require adjusted machining parameters.

Look for stainless steel in indoor applications, bronze in light-duty bearings, or 7075 aluminum where weight isn’t critical. Most over-specification comes from copying previous project specs without questioning actual requirements. If material costs exceed 40% of part cost, alternatives likely exist.

Replace 304 stainless steel with 6061 aluminum in indoor electronics or equipment housings. This swap has 95% success rate, delivers 45% cost savings, and requires no design changes. Start here to build confidence before attempting more complex substitutions.

Start with prototype quantities using proposed materials. Test fit, function, and durability under actual use conditions. For bearing applications, run accelerated wear tests. Document results to build internal confidence and customer acceptance.