Parts arrive, inspection fails, production stops — but your supplier insists everything was “within tolerance.” Now the clock is ticking and you must decide who’s actually at fault.

Tolerance failure is usually a supplier process issue — not a design mistake.

If the drawing clearly defines GD&T, material, and finish, failures typically come from poor fixturing, wrong measurement methods, or uncontrolled process variation — even when a shop claims the parts passed QC.

Before you scrap a batch or loosen specs, confirm the real cause — and whether it’s time to switch suppliers. Upload your drawing + failed measurements — we’ll diagnose whether it’s a supplier or design issue within 24 hours.

Table of Contents

How do you know whether tolerance failures are the supplier’s fault?

If your drawing is clear and fully defined, tolerance failure is almost always caused by supplier process errors — not design mistakes.

When GD&T callouts, finish requirements, and material specs are correct, the root causes usually include unstable setups, poor tool wear control, or measurement methods that can’t verify the tolerance you specified.

Most shops check only a few points with handheld gauges and hope the batch stays consistent. Parts “pass” at the factory but fail immediately when your QC enforces the actual tolerance limits. That’s not a design problem — that’s a capability gap disguised as confidence.

If you let the same supplier re-run the batch without changing their process, you’re guaranteeing the exact same failure a second time — just with more scrap.

We eliminate that risk by validating all critical dimensions during machining using calibrated fixturing and CMM inspection on geometries requiring precise fits or alignment — not just final checks after everything is already wrong.

Next Step

Before you approve another round, share your failed QC report + drawing — we’ll pinpoint whether the supplier or process was the issue within 24 hours so you can decide with data, not arguments.

How does your CNC supplier prevent measurement mismatches during QC?

Measurement mismatches are prevented when both sides use the same datums, fixturing, and calibrated equipment to verify parts.

Tolerance disputes happen when suppliers measure parts on the machine, reference different datums, or rely on tools like calipers for features that demand CMM accuracy. The part didn’t change — only the measurement truth did.

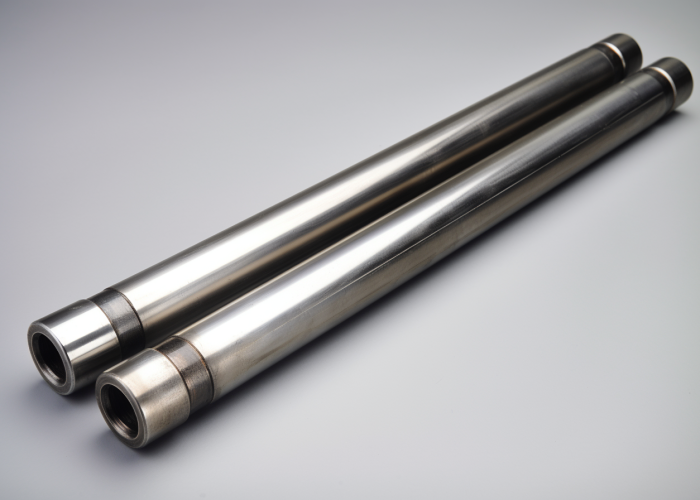

Shops without GD&T-aligned inspection fixtures routinely mis-locate reference features — especially on shafts, thin-wall housings, and multi-axis components — so their “pass” is your “fail.”

If a supplier cannot show how they’re measuring each critical feature before machining, they’re asking you to trust guesswork and hope for alignment later.

We verify the inspection plan upfront — same datums, same fixture strategy, same definitions your incoming QC will use — and share measurement method images so everyone is checking the same reality.

Next Step

Ask for the supplier’s measurement plan before machining starts.

If they can’t show exactly how they will verify tolerance, they can’t guarantee it.

Why do parts pass factory QC but fail your incoming inspection?

Because the supplier measured the wrong things, the wrong way, or at the wrong time.

When shops verify only basic dimensions with handheld tools, they miss function-critical features affected by clamping, stress relief, finishing, or environmental change. Parts appear fine at the factory — and fail once real inspection happens.

Shops often rely on spot checks to approve a batch. Incoming QC doesn’t test hope — they test risk.

If you accept “pass” at the factory without proving how it was validated, you’re only delaying the full cost of failure — scrapping parts at assembly is far more expensive than rejecting at source.

We prevent this by applying the right inspection tool to the right tolerance:

- CMM only where alignment or positional accuracy truly matters

- Go/No-Go gauges for repeatable mating features

- Profilometers for finish-critical surfaces

- Post-finish inspection before shipment

Next Step

Share before-shipment vs after-arrival data — we’ll pinpoint where dimensional drift entered the process so you prevent the same failure again.

Tolerance issues repeat when QC isn’t aligned

We review your drawing and failed measurements to prevent the same scrap twice

Which geometric features are most likely to drift out of tolerance?

Features that depend on alignment — not just size — fail the most.

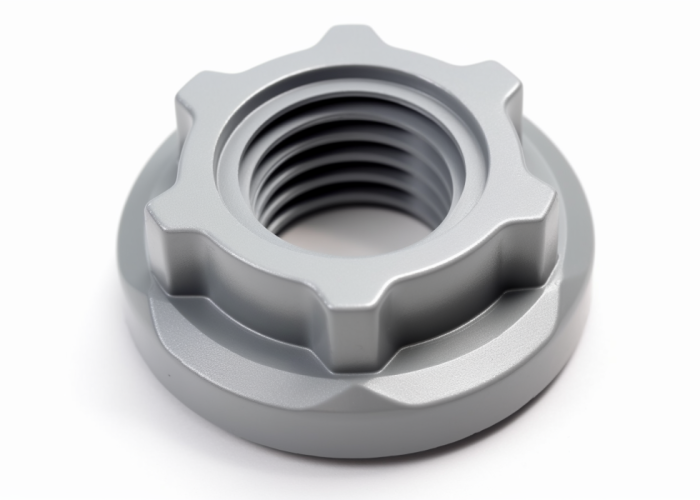

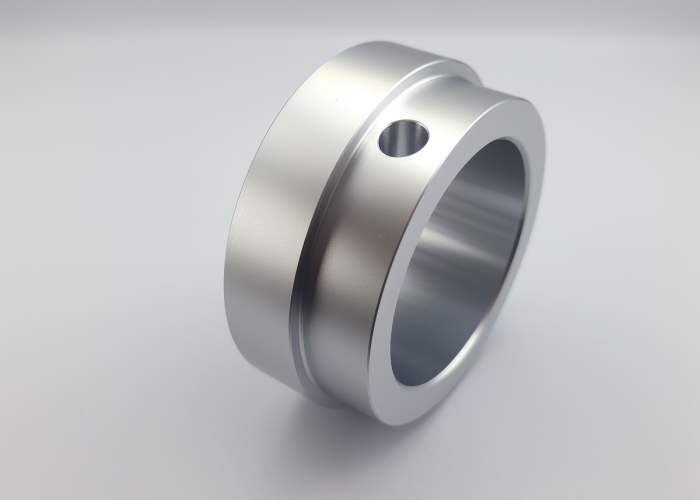

Straightness, concentricity, and hole patterns rely on fixturing stability and datum control — not just cutter precision. When suppliers don’t stabilize the setup, dimensions look right but function wrong.

High-risk areas engineers should flag early:

Feature Type | Why It Fails |

Bores & shafts | Datum misalignment + tool deflection |

Thin-wall sections | Clamping distortion + thermal expansion |

Keyways / slots | Cutter pull + uneven loading |

Hole arrays | Angular drift amplified across pattern |

Long stepped diameters | Runout accumulation |

If a supplier cannot prove stability on alignment-driven features, the batch may only show its failure once your product is fully assembled — doubling the cost instantly.

We run staged verification: fixtured measurement at rough, semi-finish, and finish cuts so variation is corrected while still fixable.

Next Step

Send your drawing — we’ll highlight your top-risk features and what must be controlled before releasing production.

How do you set tolerances that prevent scrap and avoid cost blowouts?

Prioritize tight tolerances only on features where function demands precision — not everywhere “just in case.”

Over-tightening tolerances drives two hidden costs:

- Higher scrap rate when the shop can’t repeat it

- More expensive inspection methods than the feature truly requires

Common over-spec behaviors that increase risk:

- Tight tolerances on aesthetic or non-mating surfaces

- GD&T controls without a functional purpose

- Surface finish specs that conflict with coating thickness

- “Default ±0.01 mm” applied across the entire drawing

When everything is “critical,” nothing actually gets controlled — and failure spreads invisibly across the part.

If tolerances aren’t reviewed against supplier capability before machining, your cost per good part increases every time a bad one is scrapped.

We reduce risk by mapping tolerances to:

- The mating function

- The assembly requirement

- The inspection plan that actually makes sense

Next Step

Upload your drawing — we’ll flag which tolerances drive 80% of your risk and spend so you cut failure, not corners.

What workholding mistakes commonly cause out-of-tolerance parts?

When the fixture introduces stress or shifts the datum, the machining path becomes irrelevant — the part will fail.

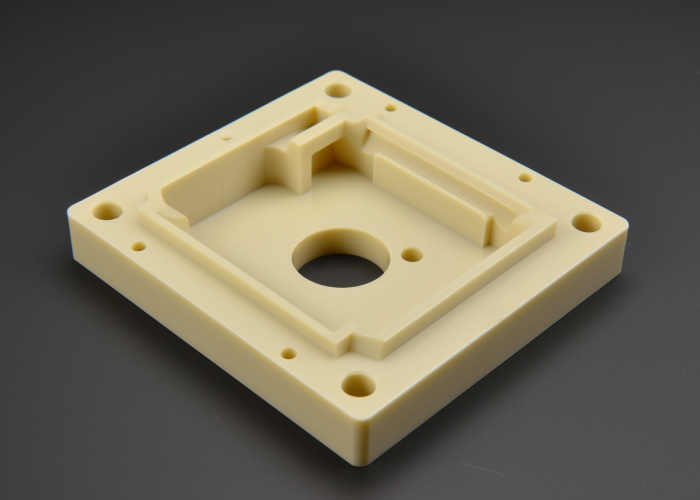

Thin walls, long parts, and asymmetric surfaces all react differently to clamping force. If the supplier relies on basic vises or generic soft jaws for precision features, the part relaxes into failure right after machining.

You’ll see diameters grow, flatness drift, or holes walk after release — because the geometry was artificially “correct” only while clamped.

Common red flags:

- Fixture references not aligned to the functional datum scheme

- No re-indication between machining operations

- Excessive clamping pressure on thin or hollow sections

If fixturing isn’t validated early, you pay full machining cost for parts that spring into non-conformance the moment they leave the jaws.

We prevent this by designing rigid, geometry-specific support, and verifying datum truth at each precision stage — so the part is accurate in use, not just in the fixture.

Next Step

Share your drawing — we’ll point out where fixturing could distort your most critical features before your next batch goes wrong.

How does tolerance stacking lead to assembly failure?

Each small locational error adds up — and the final assembly becomes the measurement that matters.

Suppliers often measure features in isolation: one hole here, one diameter there. But assemblies care about relationships, not isolated numbers.

Even a few microns of angular drift per feature becomes millimeters of mismatch over an array — suddenly, screws don’t align, shafts bind, and your fixture tech is widening holes on day one.

Watch for these stacking triggers:

- Hole patterns on large spans

- Runout on shafts that must spin true

- Multi-part locating features that must work together

When no one analyzes how errors accumulate, the assembly becomes the place where every mistake arrives at the same time — and the cost skyrockets.

We map functional datums early, inspect relationships (not just sizes), and verify fit using mating checks tailored to your assembly needs.

Next Step

Send us your drawing set — we’ll reveal the silent stack-up risks that destroy assembly tolerance before they show up on your production floor.

What process controls prove a supplier can maintain precision in production?

Precision isn’t what the first article looks like — it’s what part #50 and part #200 still look like.

If a supplier cannot explain how they maintain tolerances throughout tool wear, temperature changes, and operator shifts, the “good parts” stop as soon as the honeymoon tolerance ends.

A capable shop will show:

- Tool life monitoring — so cutter wear doesn’t push tolerances out gradually

- In-process checks — to stop drift before it becomes scrap

- CMM verification at intervals — especially on alignment-critical features

Without those controls, a job that starts in tolerance can slide into failure while nobody is looking — leaving your team to discover the problem at incoming QC or assembly.

We manage variation where it begins: on the machine, mid-run, not after the fact.

Next Step

Ask your current supplier for in-process control evidence.

If they only show the first article, they can’t prove repeatability — and the cost of learning that late is brutal.

When should you change geometry or material to improve tolerance stability?

When tolerance failures repeat even after fixing fixturing and inspection, the design needs a stability change — not more machining effort.

Long, thin, or cantilevered geometries amplify distortion. Soft or stress-prone materials shift during machining and again during finishing. If the supplier keeps “chasing tolerance,” but variability won’t settle, the part is fighting physics, not capability.

Typical triggers to modify the design:

- Thin walls that deform no matter the clamping approach

- Tall unsupported features that bend or vibrate under tool pressure

- Heat-sensitive alloys (like 6061) shifting after stress release

If you wait until assembly failure to rethink geometry, you’re paying twice — machining + emergency redesign under deadline.

We suggest minor stability enhancements that don’t alter form or function: thicker walls in non-visible areas, extra rib support, or switching to a more rigid alloy with the same finish capability.

Next Step

Share your tolerance-sensitive area — we’ll propose the smallest change that prevents recurring scrap and protects your schedule.

Production stops are expensive

Send your QC data — we’ll fix the tolerance source now

What documentation protects you when parts arrive out of tolerance?

Your best protection is documented alignment between design intent and manufacturing reality — before production begins.

When disputes start at delivery, you’re already in a weak position.

QC is not about trust — it’s about evidence.

Documents that eliminate “blame ping-pong”:

- First Article Inspection (FAI) tied to GD&T datums

- Measurement method confirmation with photos or fixture references

- Critical feature inspection plan signed off before machining

- Material certs + finish thickness data attached to each batch

If this foundation isn’t locked in, every failure becomes an argument — and arguments burn time and money faster than machining ever will.

With clear documentation, the supplier is accountable, not your production team — protecting your project timeline and internal reputation.

Next Step

Ask us for a pre-production QC alignment package — it gives you written proof of what will be controlled and how, before a single chip is cut.

How do you evaluate CNC suppliers who guarantee critical tolerances?

A supplier can only “guarantee tolerance” if they can prove process repeatability — not just confidence in the machinist.

Any shop can hold ±0.01 mm once.

Very few can hold it:

- On every part

- Through multiple setups

- After finishing

- In real assembly conditions

That is the difference between precision and luck.

Evaluation filters that expose weak suppliers fast:

- Ask for in-process control data — not just final checks

- Request a CMM report only on features that truly need CMM

- Confirm how they prevent drift during long runs

- Validate operator discipline — not tribal memory

If a supplier gets defensive or vague, they’re asking you to gamble your production schedule on hope instead of proof.

We win tolerance battles before they start — by showing how every critical feature will stay critical from first part to last.

Next Step

Send your drawing with tolerance priorities — we’ll show you exactly how we’ll keep every critical dimension in the green throughout production.

Conclusion

Out-of-tolerance parts stop production fast — and the cost multiplies every hour. Don’t wait for another bad batch to confirm the problem. Upload your drawings and failed QC data — we’ll pinpoint the root cause and secure a supplier that can keep your tolerances in the green.

Frequently Asked Questions

No — only alignment-critical and GD&T features. Others can use gauges or comparators if the method meets the feature’s precision and repeatability.

Only if the tolerance doesn’t affect function. If a supplier asks to loosen tolerances everywhere, they’re signaling capability limits, not engineering advice.

With failed QC data + drawing, root cause can often be identified in 24 hours — long before rework or delays escalate.

Confirm measurement alignment, fixturing approach, and in-process controls before releasing production. Without this, the same failure will return on the next batch.

Yes — if parts were checked while clamped, warm, or before finishing, the numbers shift after shipment. Only post-finish stable inspection is reliable.

Because they often use different datums, fixtures, or lower-accuracy tools. If measurement methods don’t match, tolerance results won’t match.