Quotes come back slow or overpriced. Some shops decline. Others say your tolerances look “too tight.” You start wondering—are you paying for precision that doesn’t matter?

Yes, many engineers over-specify gear quality and end up funding inspection time, tooling setups, and risk buffers that add no performance gain. Most shops price uncertainty, not capability. Matching gear grade to real functional need—and working with a vendor who holds precision efficiently—keeps cost and lead time under control.

Learn what slow or high gear quotes reveal about your specs, how capable suppliers quote tight tolerances faster, and how to control quality without overpaying.

Table of Contents

What Does a Slow or Expensive Quote Say About Your Gear Specs?

A slow or high quote usually means your drawing signals extra setup time, inspection effort, or scrap risk—not that it’s unmachinable.

Suppliers price uncertainty. When tolerances, finishes, or inspection notes go beyond their process limits, they expect longer CMM cycles and higher rejection probability—so they quote cautiously or delay replying.

Example: a ±0.01 mm flatness note across a non-mating surface can double inspection time for no performance gain. The shop reads that as “low profit, high risk.”

Specialized gear manufacturers interpret these drawings differently. They isolate which tolerances truly affect mesh or backlash and control them with focused setups instead of blanket precision. That keeps quote speed and cost consistent while holding quality where it matters.

If quotes arrive slow or inflated, treat it as capability feedback. Reviewing your drawing with a gear-focused machinist can clarify which specs drive cost—reducing re-quote cycles and keeping your supplier pipeline open without changing the design.

Why Do Some Suppliers Push Higher Gear Grades Than You Asked For?

Suppliers often recommend tighter gear grades to offset process variation or justify higher pricing—not because your gear requires them.

When alignment or runout control is marginal, quoting a stricter AGMA or DIN class gives the vendor a safety buffer. The upgrade sounds like quality assurance but usually hides process inefficiency.

Example: a Class 6 upsell on a moderate-speed spur gear rarely improves noise or wear, yet it can add hours of setup and full-profile inspection.

Experienced gear shops quote to functional requirement, not optics. They evaluate torque, backlash, and noise targets, then hold accuracy only where performance demands it. Consistent fixturing and calibrated gear analyzers remove the need for “safety-grade” markups, keeping cost proportional to true mechanical need.

If a supplier insists on a tighter grade “for safety,” ask for the performance data behind it. You can maintain reliability and avoid cost escalation by confirming that precision aligns with actual load or speed conditions—not with the shop’s comfort zone.

Are You Paying for Precision That Adds No Real Performance?

Many engineers unknowingly pay for micrometer-level precision that adds no functional benefit.

This happens when legacy tolerances carry over from prototypes or aerospace jobs into everyday production drawings. The result: every supplier assumes the entire part must be machined and inspected to the tightest possible limit, even if only one surface actually affects gear engagement.

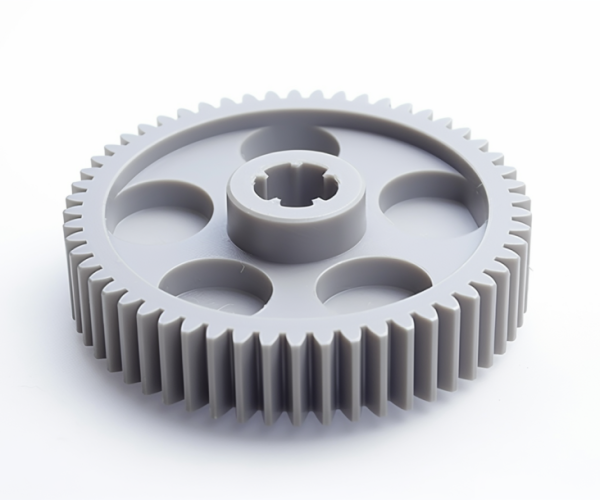

When a shop sees ±0.01 mm across all bores, faces, and hubs, it assumes extended cycle time, extra tool offsets, and full-profile CMM scans. Those requirements multiply inspection hours, not quality. One robotics developer saw a 20 % cost reduction after relaxing non-mating surfaces to ±0.05 mm while keeping the critical bore at ±0.01 mm—no change in backlash, torque transfer, or noise.

Efficient gear manufacturers focus precision where it matters: tooth profile, center distance, and bearing fits. They maintain normal shop tolerances on cosmetic or secondary features, using selective process control instead of blanket accuracy. That approach maintains identical mesh quality and smoothness while cutting machining time nearly in half.

Why it matters now: broad tolerances increase quoting hesitation and inspection bottlenecks. Reviewing which dimensions truly drive function shortens quote turnaround, prevents re-quotes, and gives you confidence you’re paying for performance—not for unnecessary precision hours.

When Does a Gear Drawing Look “High Risk” to a Machining Vendor?

A gear drawing looks high-risk when it demands high accuracy but leaves measurement intent unclear.

Suppliers price uncertainty; if datums, runout references, or tolerance stacking aren’t explicit, they assume rework risk and pad the quote. Even a perfect model can look dangerous when the 2D callouts leave room for interpretation.

Ambiguous notes like “runout ≤ 0.02 mm to center” without specifying which bore forces the machinist to guess setup order. Each guess means re-clamping, longer inspection, and potential rejection later. One customer cut a 30 % premium simply by defining two primary datums and noting “inspect runout to bore A.” That single clarification eliminated five hours of CMM setup time per batch.

Experienced gear producers interpret datums as process maps: they align measurement references with machining sequence, so inspection confirms—not contradicts—manufacturing intent. Clear definitions prevent them from over-guarding with extra setups or inflated contingency time.

Why it matters now: vague inspection structure delays every quote iteration. Tightening documentation before sending drawings reduces perceived risk, accelerates supplier response, and keeps your sourcing schedule predictable even under deadline pressure.

Need a second opinion on a slow or overpriced quote?

Upload your drawing for a capability check — get feedback and a new quote within 24 hours.

How to Spot When a Supplier Is Overcharging for “Precision Work”?

Overpriced “precision” quotes usually reflect inefficient processes, not superior capability.

Shops without temperature-controlled environments or repeatable fixtures must slow feeds, re-measure constantly, and rely on manual polishing to hit tight limits. Those extra hours appear on your quote as “precision surcharge.”

Watch for signs: excessive inspection fees, multi-day “CMM backlog,” or vague justifications like “manual finishing required.” These hint the shop is compensating for unstable setups. One automotive customer received two quotes for the same 60-tooth gear—one at $1,200 citing manual finishing, another at $650 from a facility using automated probing and thermal-stable tooling. Both promised ±0.01 mm accuracy; only one achieved it efficiently.

High-capability gear manufacturers treat micrometer control as standard practice. Closed-loop machining, in-process gauging, and calibrated gear analyzers maintain tolerance without re-setup. Because the process is stable, accuracy doesn’t inflate cost or lead time.

Why it matters now: catching inflated “precision” pricing early prevents budget surprises and missed launch targets. Ask each supplier how they verify tolerances—automated or manual, inline or offline. Precision should come from process control, not extra labor. Identifying that difference helps you lock in consistent pricing and supplier confidence before production starts.

What Does a Capable Gear Partner Do Before Quoting a Tight-Spec Job?

A capable gear manufacturer never guesses tolerance risk — they verify it before quoting.

Where general CNC vendors skim drawings for material and quantity, specialists run a full manufacturability check. They simulate tool access, verify datum flow, and confirm whether each tolerance can be held in one setup. That pre-quote analysis prevents both under-quoting and “surprise” cost revisions later.

Efficient suppliers follow a defined workflow:

- Review the 3D model for process sequencing and clamping points.

- Identify any tolerance clusters tighter than ±0.01 mm.

- Match inspection route — CMM or gear analyzer — to the critical feature.

- Provide quoting feedback within 24–48 hours, even on complex geometries.

Step | Typical Job Shop | Capable Gear Partner |

Drawing Review | Surface glance | Full DFM + risk map |

Quote Time | 3–5 days | 24–48 h |

Inspection Planning | After order | Before quote |

Setup Method | Manual offsets | Pre-qualified fixtures |

That structured review eliminates padding and earns faster approval.

Why it matters now: a pre-quote verification shortens RFQ cycles by several days and avoids costly “requote after review” emails. It’s the fastest way to tell whether a supplier truly understands tight-spec gear work.

Should You Relax Tolerances — or Find a Shop That Holds Them Efficiently?

Relaxing tolerances isn’t always cheaper — sometimes you just need a shop that can hold them without struggle.

Many engineers respond to high quotes by loosening specs, but that can create functional risk while barely changing price. The real cost driver is how efficiently a vendor achieves precision, not the tolerance number itself.

Typical job shops push price higher once limits drop below ±0.02 mm because they rely on manual measurement and single-point setup. A specialist with closed-loop probing holds ±0.01 mm routinely and quotes the same part at lower cost.

Example: two suppliers quoted a servo-gear shaft with identical tolerances. The first requested tolerance relaxation to ±0.03 mm; the second used thermal-stable tooling and completed inspection inline — same tolerance, 30 % lower cost and two-day faster lead time.

Capability Factor | Job Shop | High-Capability Vendor |

Measurement | Manual micrometers | In-process probing |

Temperature Control | Ambient | ±1 °C controlled |

Typical Lead Time | 4–6 weeks | 2–3 weeks |

Quote Consistency | Variable | Stable ±10 % |

Why it matters now: switching to a precision-efficient vendor maintains your design intent and cuts lead time without compromising accuracy. Use quote speed and confidence level as your first screening tools — not just the price column.

Why Experienced Gear Manufacturers Quote Faster — Even on Tight Specs?

Fast quotes aren’t guesswork — they’re proof of process readiness.

Shops familiar with complex gears already have pre-qualified tooling, standard fixture libraries, and inspection routines mapped to gear classes. That preparation lets them issue accurate quotes in hours instead of days.

Delays often signal missing capability data: a general CNC vendor must re-estimate setup time, source cutters, and check CMM availability. Each uncertainty adds review steps. An experienced gear shop simply loads parameters into its quoting system — gear diameter, module, face width — and retrieves validated cycle times.

Factor | General CNC Vendor | Experienced Gear Manufacturer |

Quoting Basis | Manual estimate | Verified process library |

CMM Scheduling | Shared queue | Dedicated gear analyzer |

Quote Turnaround | 3–5 days | 12–24 hours |

Cost Variation | ±40 % between runs | ±5 % repeatability |

Rapid quoting also reflects risk control: repeatable fixturing and documented inspection remove uncertainty.

Why it matters now: fast, confident quotes indicate genuine readiness — the supplier already knows how to hold your tolerance. Slow or hesitant replies usually mean capability gaps that won’t disappear after the PO. Switching early saves weeks of lost schedule.

What Separates True Gear Specialists From General CNC Vendors?

True gear specialists handle precision as routine — general CNC vendors handle it as risk.

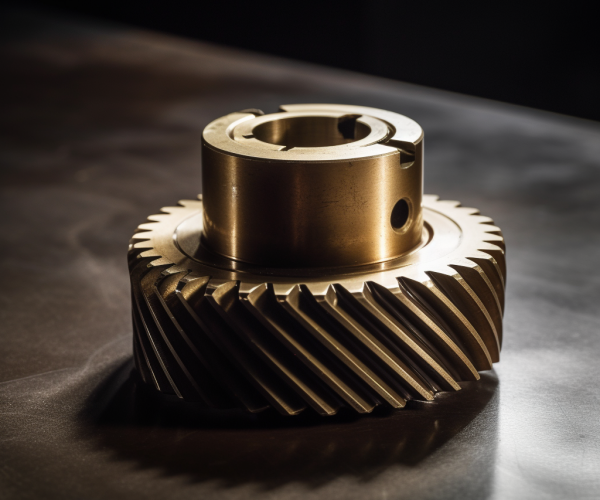

The real difference isn’t machine brand; it’s process readiness. Gear specialists follow ISO 1328 / AGMA 2015 standards daily, using dedicated gear analyzers, pre-qualified cutters, and environmental controls to stabilize every run. A general CNC vendor often treats gears as one-off parts, adapting milling setups that require trial alignment each time.

One sourcing manager compared quotes for a 40-tooth helical gear:

- The general shop needed 6 hours of setup and a 3-day quote window.

- The gear specialist reused proven fixturing, finished setup in 90 minutes, and quoted in 12 hours — with full lead/pitch/profile reports included.

Indicator | General CNC Vendor | Gear Specialist |

Primary Focus | General components | Gears & precision drives |

Setup Time per Gear | 5–6 h | 1–1.5 h |

Quote Turnaround | 3–5 days | 12–24 h |

Accuracy Stability | ±40 µm variation | ±10 µm repeatability |

Documentation | Basic CMM sheet | Full AGMA/ISO gear report |

That difference in preparation eliminates “learning curve” failures after order placement.

Why it matters now: the fastest, most data-backed quote usually comes from the shop best equipped to hold tolerance repeatably.

If you’re comparing suppliers this week, send one drawing for a capability-based quote review — you’ll see within 24 hours who’s truly ready.

How to Control Gear Quality Without Paying for Overkill?

Once you’ve identified a capable gear specialist, the next step is managing quality efficiently — not expensively.

Over-inspection and blanket high-grade specs inflate cost without improving reliability. The key is specifying what must be verified, how often, and to what limit.

Example: A customer machining servo gears required full CMM scans for every part. Switching to batch verification of composite error (one test per lot) maintained identical noise level but cut inspection time by 25 % and saved two days of lead per order.

High-capability suppliers use digital traceability to balance assurance with speed. Each lot logs pitch, runout, and surface data automatically, allowing batch-level proof instead of manual re-measurement.

Control Aspect | Over-Specified Practice | Efficient Quality Control |

Inspection Frequency | 100 % of parts | Critical features per batch |

Measurement Method | Full CMM each run | Inline probing + periodic CMM |

Cost Impact | +30 – 40 % inspection labor | Within baseline quote |

Lead Time | +2–3 days | Unchanged |

Why it matters now: effective control plans deliver the same performance with less downtime and fewer quote adjustments.

If your current supplier adds cost every time you request inspection data, request a side-by-side quality control proposal — you’ll see how process transparency replaces “precision premiums.”

Conclusion

Supplier quotes that feel inflated or delayed usually signal capability gaps, not design flaws. Okdor specializes in tight-spec gears other shops avoid—holding precision efficiently and quoting fast with verified process control. Upload your rejected or overpriced drawings today for a capability assessment and revised quote within 24 hours.

Frequently Asked Questions

We support audio, robotics, aerospace, and medical-device programs where documentation and repeatability are mandatory. Every quote includes traceable inspection data for lead, pitch, and profile accuracy, helping engineering and QA teams pass audits and approve parts faster than typical general-shop workflows.

Inspection frequency is scaled to function, not habit. Critical features receive full CMM or gear-analyzer checks; secondary fits are batch-sampled under statistical control. This balance maintains full traceability while cutting inspection time 25–40 % versus 100 % part-by-part checks — keeping quality assurance inside the quoted price.

Yes — for quoting, not machining. We maintain pre-qualified gear tooling, verified cycle-time data, and a dedicated quoting team for precision work. That’s why most drawings receive a manufacturability check and detailed quote within one business day. For urgent RFQs, same-day turnaround is available on request.

Precision comes from process control, not slower machining. In-process probing verifies each operation, and every part runs in a ±1 °C environment with automated CMM validation afterward. Because accuracy is built into the process, not added later, micrometer-level tolerances stay within baseline cost and lead time.

Often, yes. Provide the current drawings, inspection data, and any finished pieces. We review geometry, confirm datum integrity, and re-plan production within 48 hours. Most teams recover one to two weeks of lost schedule by transferring critical work this way — without restarting from scratch.

Send it anyway. Many parts get rejected because shops lack multi-axis fixturing or setup flexibility. We evaluate each feature through 5-axis simulation and modular fixture mapping, then issue a capability report and quote within 24–48 hours. You’ll see exactly which tolerances drive difficulty — and how they can be held efficiently.