Table of Contents

PROS & CONS OF powder coating process

Some of the key advantages of powder coating are its ability to produce thicker layers without running or sagging, resulting in a smooth and even finish. Moreover, powder coatings are typically more resistant to chipping, scratching, and fading than traditional liquid paints. Compared with other coating methods, powder coating produces few or no volatile organic compounds (VOCs). Furthermore, the excess powder can be collected and reused, reducing waste and lowering costs.

Powder coating has a few drawbacks, despite its many benefits. The powder coating process has a significant defect: the restricted selection of materials suitable for powder coating. Since the curing process requires exposure to high temperatures, only heat-resistant materials like metal can be coated with powder. Additionally, achieving skinny layers can be challenging with powder coating, and color changes during the process may be time-consuming.

We will explore powder coating in the following sections, including how it differs from other finishing methods, its materials, and how it is applied.

Understanding Powder Coating

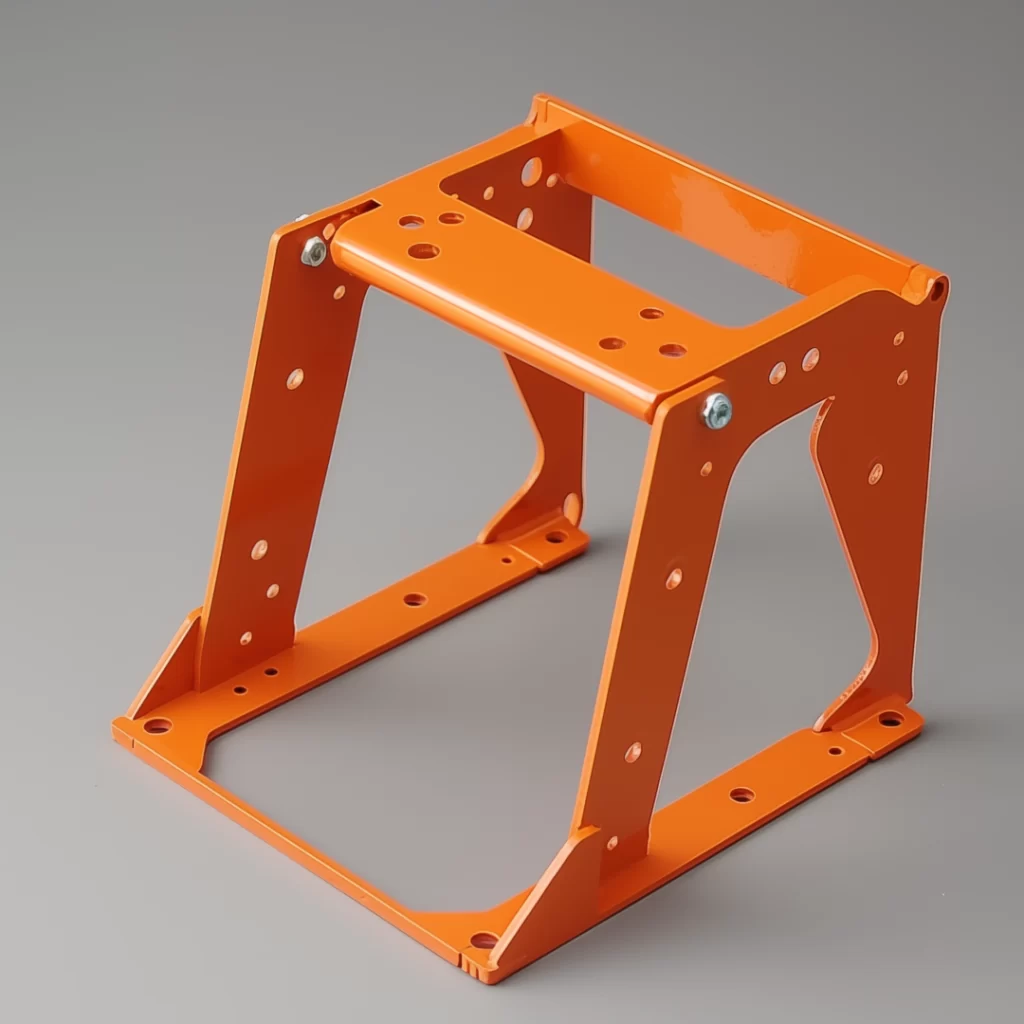

Powder coating is an advanced finishing method that involves the application of a dry, finely ground mixture of pigments and resins onto surfaces. This powder material, electrostatically charged by a powder coat gun, adheres to the electrically grounded surface, forming a smooth and continuous layer.

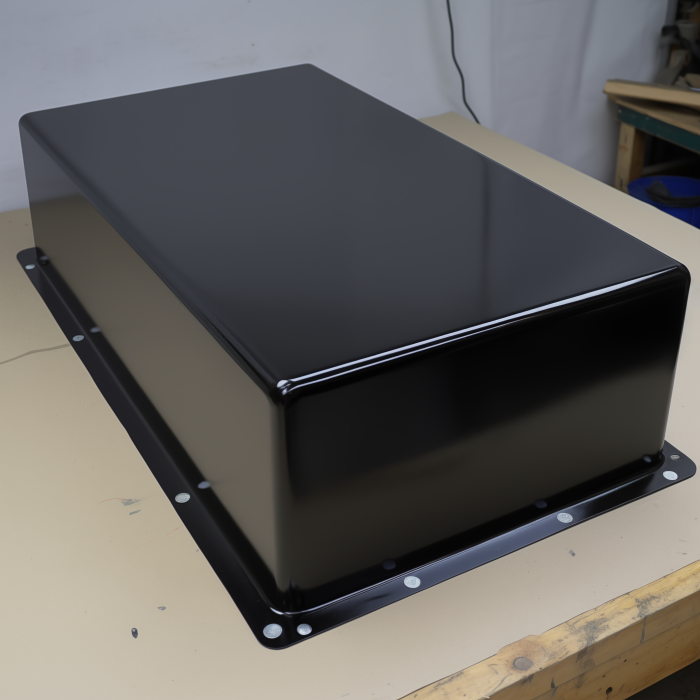

Post-application, the coated items are cured in a powder curing oven, where heat causes the powder to melt and flow into a hard, durable coating.

The difference between finish and coating

Distinguishing between the terms ‘finish’ and ‘coating’ can aid in comprehending powder coating. A ‘finish’ is applied during the final production stage to protect or decorate the product. On the other hand, a ‘coating’ refers specifically to this protective or decorative layer applied onto a surface. Powder coatings can therefore be considered both finishes and coatings depending on the context.

Metal finishing, a subset of the broader category of finishes, specifically refers to the processes used to alter the surface of a metal item for decorative or functional purposes. This can include cleaning, polishing, and applying protective layers like powder coatings. Metal finishing processes enhance metal products’ appearance, toughness, and rust resistance. Many industries use them, including automotive, aerospace, furniture, and jewelry.

Next, we’ll compare powder coating and more traditional liquid coatings, shedding light on why powder coating is increasingly becoming the preferred choice for many industries.

Powder Coating vs. Paint

When discussing finishes, it’s essential to distinguish between conventional liquid coatings, such as liquid paints, and powder coatings. Both serve a similar purpose – to provide a protective and decorative layer to a surface – but the methods of application and their properties differ significantly.

- A brush or spray gun helps apply liquid paint. These paints require a solvent to remain in a liquid state. On the other hand, powder coating is a solvent-free process that uses an electrostatic spray gun to apply the dry powder onto the surface. The powder coating heats in an oven after application which causes it to melt and create a resilient finish of superior quality.

- There are several reasons why powder coating often outperforms liquid paint. First, powder coating generally produces much thicker coats without runs or sags than liquid paint. The electrostatic spray deposition method ensures the coating is applied evenly, resulting in a smooth, uniform finish.

- Second, powder coatings are the way to go if you want a surface finish that can withstand harsh conditions or heavy use. They’re more durable and resist chipping, scratching, and fading better than other coatings.

- Third, powder coating is more environmentally friendly than liquid paint. Unlike liquid paint, it releases virtually no volatile organic compounds (VOCs), which can release these harmful chemicals during drying. Any excess powder overspray can also be collected and reused, minimizing waste.

- Fourth, in terms of economics, powder coating operations tend to be more cost-effective over time. While the initial equipment costs for powder coating might be higher, the long-term benefits of reduced waste, fewer reworks, and lower health and safety risks can lead to significant cost savings.

In short, while liquid paints still have their place in specific applications, powder coating offers compelling advantages in terms of finish quality, durability, environmental impact, and cost-effectiveness.

Powder Coating Material

An essential element to consider is the powder coating material to ensure successful powder coating. This is a dry, smooth-flowing mixture consisting of resin and pigment particles. Powder coating materials can be classified into two categories based on their chemical composition: thermoset and thermoplastic.

Thermoset and Thermoplastic

Thermoset powder coatings start as liquid resin combined with curatives, pigments, flow modifiers, and other additives. These ingredients undergo a chemical reaction in the curing oven during the curing process, creating a tightly crosslinked molecular structure. This irreversible reaction means thermoset coatings cannot be remelted or reshaped after curing.

The result is a high-performance coating that offers excellent durability, chemical resistance, and retention of color and gloss. Examples of thermoset powders include epoxy, polyester, and acrylic.

During the curing process, thermoplastic powder coatings do not experience any chemical reaction. Instead, the heat causes the powder to melt and flow into a smooth coating. When cooled, the coating hardens into a very durable and chemically resistant layer.

Thermoplastic coatings have the advantage of being able to be remelted and reshaped, unlike thermoset coatings. This property can be helpful in specific applications. Some examples of standard thermoplastic powders are polyethylene, polypropylene, and nylon.

Different applications require different types of powder coatings, such as thermoset and thermoplastic. Thermoset coatings are often preferred for their superior finish and resistance properties, while thermoplastic coatings stand out for their flexibility and impact resistance.

What materials can be powder coated?

- 1. Metals: This includes steel, aluminum, brass, and copper. These materials can withstand the high temperatures involved in the powder curing process and can be quickly grounded, which is essential for the electrostatic charge to attract powder particles during application.

- 2. Heat-Resistant Materials: Glass and certain types of ceramics can also undergo powder coating.

- 3. Wood and Medium-Density Fiberboard (MDF): With advancements in low-temperature curing powders, it’s now possible to powder coat these materials under specific conditions.

What materials can't be powder coated?

- 1. Plastic and Rubber: These materials cannot withstand the high curing temperatures used in the powder coating process and are typically unsuitable for it.

- 2. Certain Types of Wood: Some types of wood that cannot withstand the high curing temperatures are also unsuitable for powder coating.

- 3. Non-Conductive Materials: It is more difficult to powder coat non-conductive materials such as plastic and wood because they cannot be electrically grounded, an essential part of the powder coating process.

| Material | Can be Powder Coated | Details |

| Metal | Yes | steel alloys, stainless steel, galvanized steel, mild steel, aluminum, and electroplated steel. |

| Wood | Sometimes | Wood is tricky to powder coat due to its inability to withstand extreme temperatures and lack of electrical conductivity. However, some woods like MDF, which are electrostatic, can be powder coated using a low-temperature process. |

| Glass | Sometimes | Powder coating glass requires additional work and the object must be able to withstand the temperatures of the oven. Sometimes, putting a piece of metal on the other side of the glass will help the powder stick. |

| Plastics | Sometimes | Most plastics cannot withstand the heat of the ovens, causing them to melt. Plastic is also not naturally electrically charged. However, some durable plastics can be powder coated if the temperatures are kept low. |

| Fabric | NO | Fabric cannot withstand the extreme temperatures of the oven. |

| Non-electrically conductive materials | NO | If a material or surface doesn’t have electrical conductivity, it can’t receive powder coating. This includes certain metals that use fillers and are not electrically conductive. |

How powder coating is applied to metal

Powder coating application on metal involves several steps. Usually, the first step is to prepare the metal surface, which often includes cleaning and sanding to remove any oils, rust, or existing finishes. This process ensures that the powder coating will adhere properly to the metal surface.

Once the metal part is prepared correctly, it’s grounded, and the powder coating material is applied using an electrostatic spray gun. The grounded metal part attracts the powder particles by imparting a positive electric charge. The charged powder particles adhere to the metal surface, even on the edges and hard-to-reach areas, creating a uniform layer of powder across the part.

It is then placed in a curing oven after applying the powder. The heat causes the powder to melt, flow, and harden into a durable, smooth, attractive finish.

Next, we’ll discuss the different uses of powder coating in various industries, as it creates a final product with a durable finish that resists scratches, chipping, fading, and rust.

Preparing for Powder Coating

Proper surface preparation to be powder coated is essential in the powder coating process. The powder coat may adhere adequately to the correct practice, resulting in a good-quality finish that may chip or peel over time.

One of the key preparation steps is sanding. Sanding before powder coating helps to remove any surface imperfections such as rust, old paint, or mill scale.

It also helps to create a surface profile, or “roughness,” on the metal surface, which can enhance the adhesion of the powder coat. Achieving a smooth, high-quality finish and extending the lifespan of the powder coat depends on this step being completed correctly.

STEPS

To prepare bare metal for powder coating, follow these steps:

- Cleaning: First, clean the metal part to remove any oils, grease, or dirt. This can be done using a suitable degreasing solution. Make sure the part is arid before moving on.

- Sanding or Blasting: Next, sand or blast the metal surface to remove rust, scale, and old paint. This also creates a surface profile for better powder adhesion. Many tools are available, from sandpaper to power sanders or a bead blasting cabinet for larger or more complex parts. Remember to wear appropriate safety gear during this process.

- Chemical Pretreatment: A chemical pretreatment like phosphating (for steel) or chromatic (for aluminum) may be necessary depending on the metal type and the intended conditions for the part’s use. This step further enhances powder adhesion and provides additional corrosion resistance.

- Rinsing and Drying: Rinse the part thoroughly to remove any remaining debris or chemical residue after sanding and pretreatment. The piece must then be thoroughly dried before applying the powder. Any moisture left on the part can negatively affect the powder coating process.

Investing time in proper surface preparation can significantly enhance the quality and durability of your powder-coated finish.

The following section will provide a detailed guide on the powder coating process, covering the essential steps of application and curing.

Powder Coating Methods

Although the conventional powder coating process works well for numerous applications, customized techniques are also available for meeting specific requirements. These include powder dip coating, the 3-stage powder coating process, and advanced techniques like electrostatic spray deposition (ESD).

Powder Dip Coating

Powder dip coating is a variation of the fluidized bed method. In this process, the part to be coated is preheated and then dipped into a fluidized bed of powder material. The powder melts when heated and sticks to the surface, forming a coating.

The part is then post-cured in an oven to crosslink and harden the coating fully. This method is often used when a thicker coating is desired or when the part is complex and would be difficult to coat evenly using a spray gun.

3-Stage Powder Coating

A three-stage powder coating method applies three distinct layers of powder to produce a long-lasting and attractive finish.

- The first layer is a primer that enhances adhesion and corrosion resistance.

- The second layer is the base coat, which provides the primary color and texture.

- The third layer is a clear topcoat that adds gloss and additional protection.

Each layer is cured in an oven before the next layer is applied. This process is often used for high-end applications requiring superior performance and appearance.

Electrostatic Spray Deposition (ESD)

Electrostatic spray deposition is a key part of the powder coating process. During ESD, an electrostatic charge is applied to the powder particles on the part. The charged particles are attracted to the ground part, allowing the powder to stick to the surface.

The result is a uniform layer of powder that covers the whole piece, including hard-to-reach areas. ESD is highly efficient, allowing for excellent transfer efficiency and minimal waste. Furthermore, since the powder is dry, it does not emit volatile organic compounds (VOCs) like traditional liquid coatings.

These specialized methods demonstrate the versatility and adaptability of the powder coating process, proving it a valuable tool in the finishing industry. Let’s explore different ways powder coating works and how it outperforms traditional finishing methods regarding benefits.

The Powder Coating Process

Now that we understand the theory behind powder coating and the material preparation required let’s delve into the powder coating process itself. The final, high-quality finish can only be attained by following a series of crucial steps.

- Pretreatment: The first step is to prepare the surface for coating. This can involve cleaning, sanding, or blasting to remove oils, dirt, rust, or old paint. Chemical pretreatment is sometimes necessary to increase corrosion resistance and enhance powder adhesion.

- Powder Application: The next step involves the application of the powder coating material onto the prepared surface. This is usually done using an electrostatic spray gun, positively charging the dry powder particles. Electrostatic spray deposition (ESD) refers to adhering charged powder to grounded metal surfaces through electrostatic attraction (ESD). The result is a uniform layer of powder across the part, including the edges and hard-to-reach areas.

- Curing: After applying the powder, the part is placed in a curing oven. The heat causes the powder to melt, flow, and harden into a durable, attractive finish. The temperature and duration of the curing process depend on the type of powder coating material used.

The three-step coating process likely includes pretreatment, powder application, and curing.

Powder Coating in Various Applications

From automotive to architecture to furniture manufacturing, powder coating is popular because of its versatility and durability. Compared to traditional liquid paints, this process is environmentally friendly and can deliver superior finishes.

Powder Coating in the Production Process

In a typical production process, powder coating operations start after the parts are fabricated and surface-prepared.

The parts, whether large industrial components or small hardware, are hung on a conveyor system that moves them through the various stages of the powder coating process: pretreatment, powder application, and curing.

The powder coating materials used are carefully selected based on the expected use conditions of the parts, such as exposure to UV light, heated air, or harsh chemicals.

Application of Powder Coating to Springs, Leaf Springs, and Coil Springs

Finishing springs, including leaf and coil springs, is a unique powder coating application. These components often face harsh operating conditions and need a durable, corrosion-resistant finish. Powder coating fits the bill perfectly.

For example, leaf springs, critical components in vehicles’ suspension systems, can benefit significantly from powder coating. The process ensures an even, durable finish that protects the springs from rust and other environmental factors, helping to extend their lifespan. Similarly, coil springs, commonly found in mattresses and car seats, can also be powder coated for enhanced durability and aesthetics.

The process for powder coating springs is similar to other parts. The springs are thoroughly cleaned and pretreated; then, the powder is applied using an electrostatic spray gun. The coated springs are then cured in a powder-curing oven to form a durable finish.

Latest Trends in Powder Coating Technology

The powder coating industry is also evolving with continuous advancements in technology. Some new powder coatings available now have unique features, like being antimicrobial or tolerating extreme temperatures.

Another trend is using ultraviolet (UV) light to cure certain powder coatings. These UV-curable powders offer several advantages, including lower energy costs and faster curing times.

Many powder coating companies focus more on sustainability and strive to minimize environmental impact.

This includes developing powder coatings free of hazardous substances, improving process efficiency to reduce waste, and recycling excess powder overspray.

Overall, the potential of powder coating is vast, and its benefits are evident in more and more industries. New applications, materials, and techniques are constantly evolving to meet the changing needs of manufacturers and consumers. As a result, the process is continually evolving.

Conclusion

In this article, we have explored the fascinating world of powder coating, delving into its advantages, processes, and applications. As a recap, powder coating offers numerous benefits over traditional liquid paints, including:

- A durable and attractive finish that can withstand harsh conditions

- Improved corrosion resistance and longerlasting protection

- Greater environmental friendliness due to the absence of volatile organic compounds (VOCs)

- The ability to produce thicker coatings without runs or sagging

- A variety of colors, textures, and finishes

- Costeffectiveness and material efficiency, thanks to the ability to recycle excess powder

Powder coating is a critical finishing process in various industries, from automotive to furniture and architectural to consumer products. The process’s adaptability and versatility have allowed for the development of specialized methods, such as powder dip coating and 3-stage powder coating, as well as advancements in electrostatic spray deposition (ESD).

As for the future of the powder coating industry, we can expect continued growth and innovation. With ongoing research and development, we will likely see new powder coating materials, enhanced application techniques, and even more sustainable and environmentally friendly practices. The powder coating industry is set to grow due to the increasing need for long-lasting, superior quality, and environmentally friendly finishes. It will play a significant role in today’s manufacturing and finishing procedures.

Frequently Asked Questions

Fluidized powder material refers to the state of the powder during some application methods, such as the fluidized bed method. The powder is suspended, making it behave like a fluid. This fluid-like state allows even distribution and coating of the part when dipped into the bed.

There are two primary types of powder coating: thermoset and thermoplastic. Thermoset coatings chemically crosslink during curing, creating a durable and robust finish. Thermoplastic coatings, however, melt and flow when heated but can be remelted and reprocessed.

Powder coating finishes vary significantly in texture, gloss, and color. Some popular finishes include smooth, matte, glossy, metallic, and textured. The choice of finish depends on the desired appearance and specific application requirements.

During curing, a high temperature is applied to the part coated with powder. The heat causes the powder to melt, flow, and chemically crosslink (in the case of thermosetting powders), forming a continuous, durable finish.

Some specially formulated powder coatings can be cured using ultraviolet (UV) light. These UV-curable powders offer advantages like lower energy costs and faster curing times compared to a traditional oven

The powder coating work starts with preparing the part for coating, then applying powder using an electrostatic spray gun or other methods. It creates an even layer by adhering to the grounded part. As the powder melts and crosslinks, the finish becomes durable and attractive.

Liquid coating uses wet paint, while powder coating uses dry powder. The application methods and curing processes are also different. Compared to liquid coatings that contain volatile organic compounds (VOCs), powder coating typically produces a thicker, longer-lasting finish and is more eco-friendly.

No, powder coatings can vary in chemical composition depending on the specific application requirements and desired properties. Different resins, pigments, and additives are available to create a wide range of powder-coating products.

In a powder spray booth, the part to spray is hung or placed on a rack. An operator or an automated system applies the powder using an electrostatic spray gun. Excess powder is collected and recycled after the charged particles adhere to the part. The part is then transferred to a curing oven to complete the process.

Both vertically and horizontally coated surfaces can be powder coated effectively. The dry powder coating process and electrically charged powder particles allow for a uniform and consistent coating on any orientation.

Electrically charged powder particles in powder coating applications attract the powder to the grounded part. This results in a uniform and consistent layer of powder on the part, including hard-to-reach areas and complex geometries.