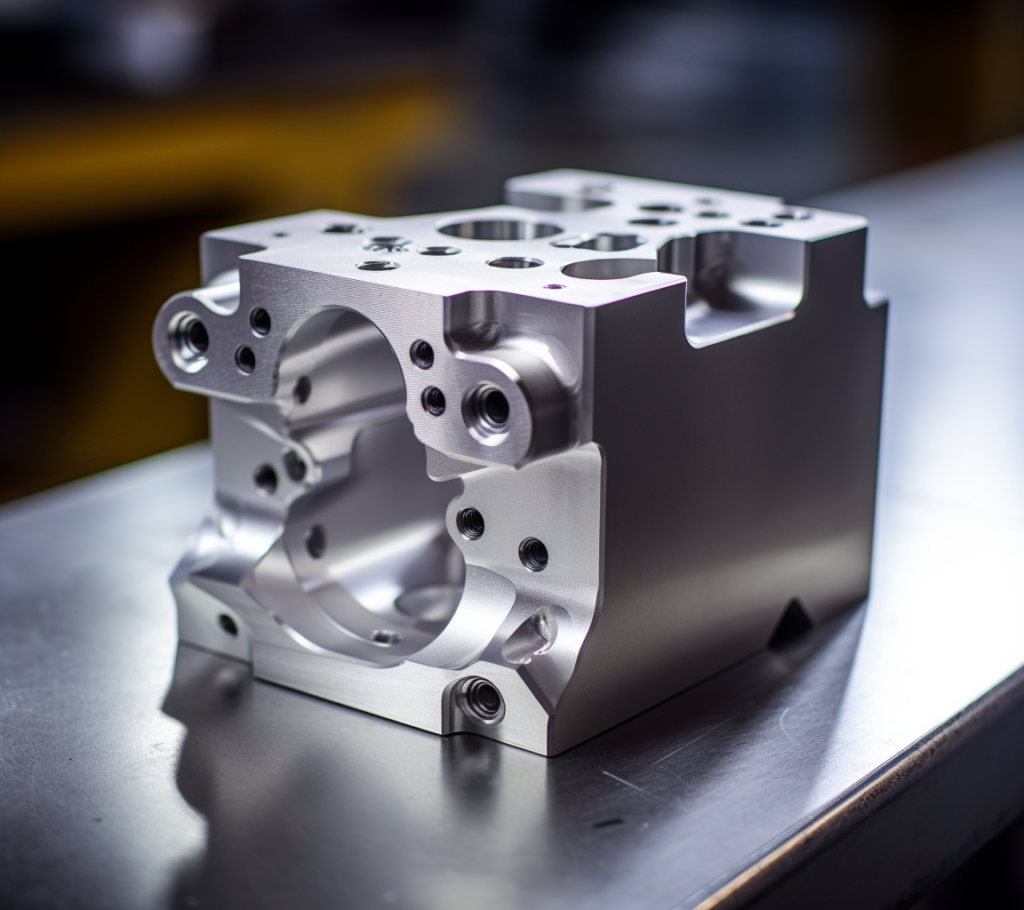

Quality Assurance

Looking for a reliable partner for your custom part manufacturing needs?

Discover okdor. We’re committed to precision, quality, and speed. Navigate the complexities of overseas production with our dedicated support and transparent pricing. Whether your project is big or small, we’ve got you covered. Start your journey towards hassle-free custom part manufacturing.

Quality You Can Trust

With okdor, quality isn’t just a promise, it’s a guarantee. Our commitment to excellence is reflected in our rigorous quality assurance process and adherence to global standards.

No matter where you are, you can trust in our comprehensive inspection methods to deliver custom parts that meet your exact specifications. Choose okdor, Choose Quality

Your Quality Partner

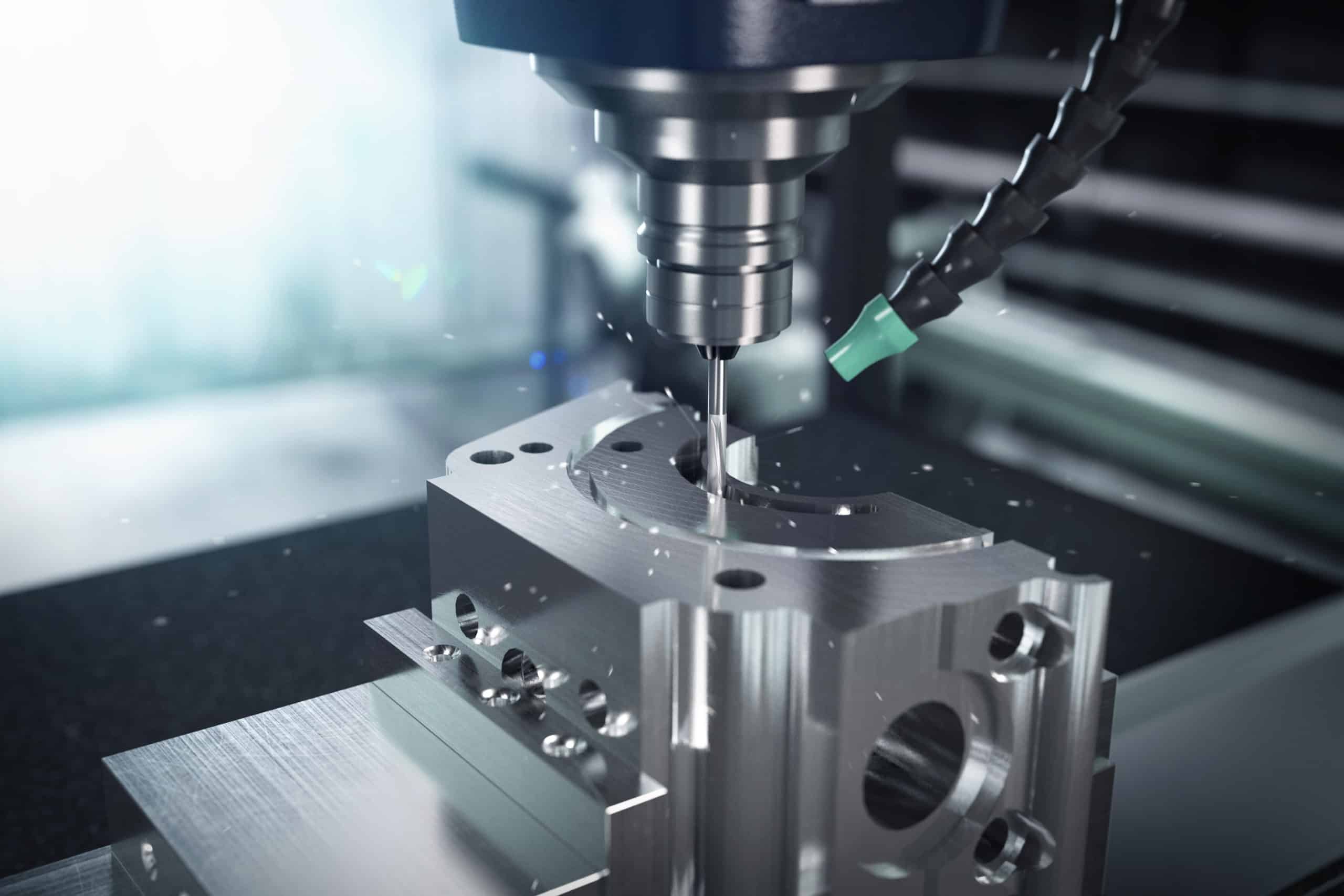

We use the latest machines and technology to check our parts. We watch every part of the process, from getting the materials to building the final product.

Delivering on Promises

We're not just committed to meeting your expectations - okdor aims to exceed them.

Our team of experienced quality control professionals works tirelessly to ensure that every part we produce is of the highest quality.

Quality Guaranteed

And our commitment to quality doesn't end when your parts leave our facility. okdor offers a one-year quality guarantee on all our custom parts. If anything goes wrong, we will fix it for free.

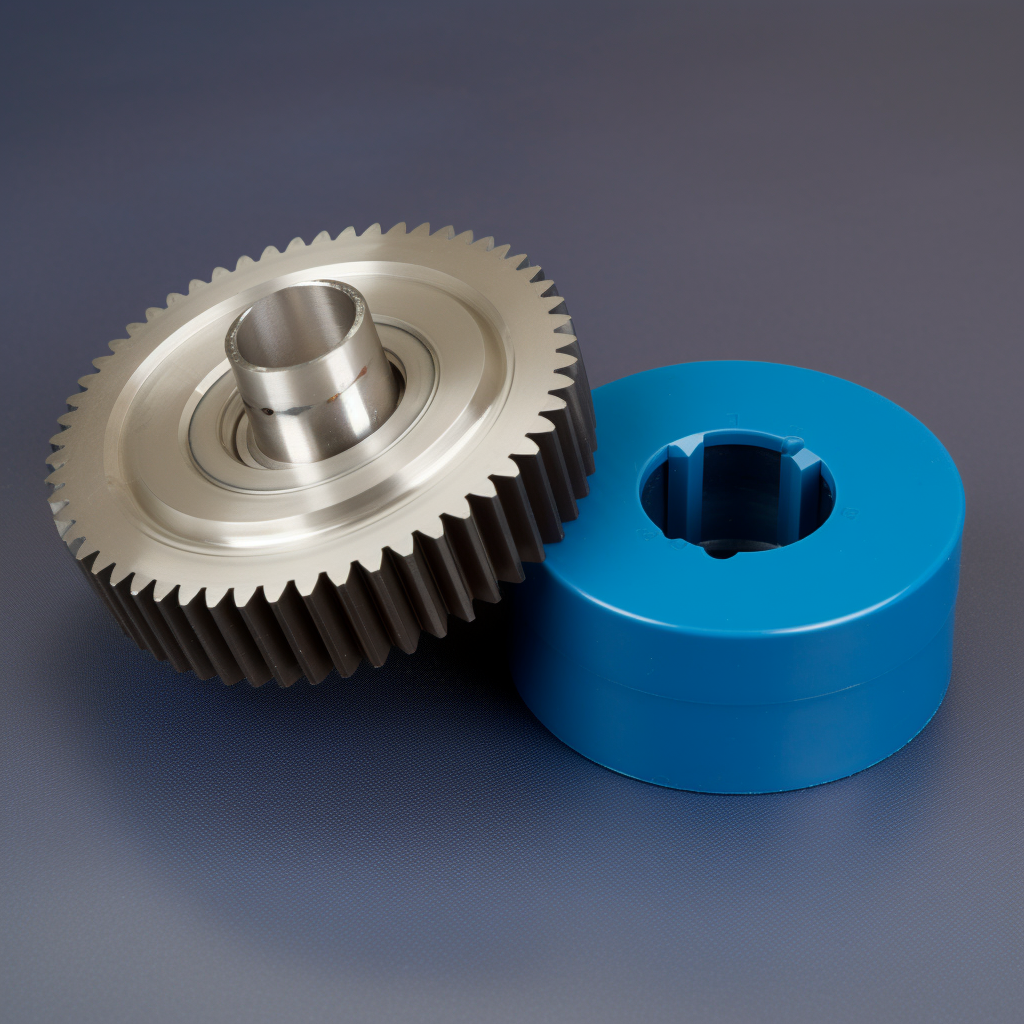

Unwavering Consistency, Every Time

We know how crucial consistency is in custom part manufacturing. That’s why we’ve invested in advanced CNC machining and stringent quality control processes. With Okdor, every part you order matches your specifications to the last detail, ensuring uniformity across all components. No variances, no surprises, just unwavering consistency. Choose Okdor, where precision and consistency meet.”

Standardized Processes

Implement standardized manufacturing processes to ensure each part is made the same way, including using the same equipment, settings, and procedures for each part.

Quality Materials

Use high-quality, consistent materials. The quality of the raw materials can significantly impact the consistency of the final product.

Advanced Technology

Utilize advanced manufacturing technology like CNC machining, which allows for precise control over the manufacturing process and can produce identical parts every time.

Equipment Maintenance

Regularly maintain and calibrate equipment to ensure it's always operating at its best. Even minor issues with equipment can lead to inconsistencies in the parts produced.

Quality Control

The quality control process include both automated inspections using technology like CMMs and manual inspections for aspects that require human judgment.

Detailed Documentation

Keep detailed records of each manufacturing run, including the materials used, equipment settings, and any issues encountered helping identify and correct any sources of inconsistency.

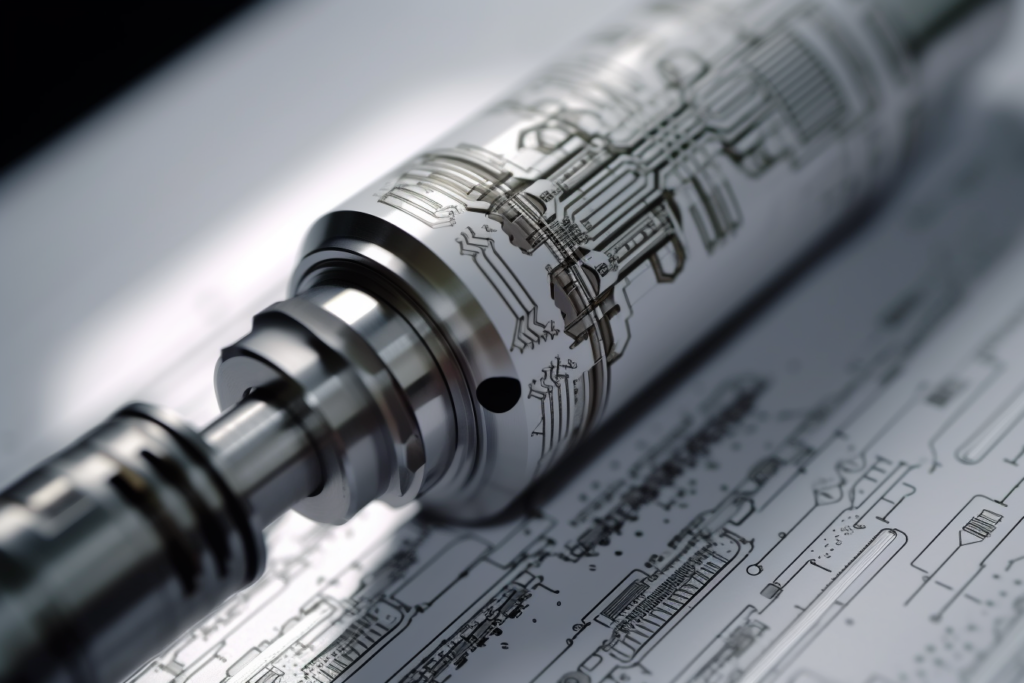

Precision to the Core

When it comes to custom part manufacturing, precision is not just a requirement, it’s an art. At Okdor, we’ve mastered this art. Our commitment to the ISO 2768 tolerance standard ensures that every part we produce meets your exact specifications, down to the smallest detail.

CNC Machining General Tolerances

- Following ISO 2768 for features of size and location, unless otherwise specified or mutually agreed upon in your quote.

- Sharp edges will automatically be broken and deburred. It is critical to indicate and describe critical edges that must remain sharp on a print.

- Surface Roughness as machined surface 125Ra or better.

- On any machined surface of plastic, there will be translucent swirl marks.

- If your quote doesn't specify otherwise, the following tolerances apply to orientation and form features. The features of a parallelogram are perpendicularity, cylindricity, straightness, flatness, and circularity.

Metals (ISO 2768-M)

| Nominal size | Linear Dimensions | Angular Dimensions | External Radius & Chamfer Heights |

| 0.5mm to 3mm | ±0.05mm | ±1° | ±0.20 |

| > 3mm to 6mm | ±0.05mm | ±0°30′ | ±0.50 |

| > 6mm to 30mm | ±0.10mm | ±0°20′ | ±1.0 |

| > 30mm to 120mm | ±0.15mm | ±0°10′ | |

| > 120mm to 400mm | ±0.20mm | ±0°5′ | |

| > 120mm to 400mm | ±0.30mm | / | |

| > 120mm to 400mm | ±0.50mm | / |

Nominal size

Linear Dimensions

Angular Dimensions

External Radius & Chamfer Heights

0.5mm to 3mm

±0.05mm

±1°

±0.20

over 3mm to 6mm

±0.05mm

±0°30′

±0.50

over 6mm to 30mm

±0.10mm

±0°20′

±1.0

over 30mm to 120mm

±0.15mm

±0°10′

over 120mm to 400mm

±0.20mm

±0°5′

over 400mm to 1000mm

±0.30mm

/

over 1000mm to 2000mm

±0.50mm

/

All parts are deburred. Tightest tolerance is available upon request.

Plastics (ISO 2768-M)

| Nominal size | Linear Dimensions | Angular Dimensions | External Radius & Chamfer Heights |

| 0.5mm to 3mm | ±0.10mm | ±1° | 0.02 |

| > 3mm to 6mm | ±0.10mm | ±0°30′ | 0.02 |

| > 6mm to 30mm | ±0.20mm | ±0°20′ | 0.05 |

| > 30mm to 120mm | ±0.30mm | ±0°10′ | 0.1 |

| > 120mm to 400mm | ±0.50mm | ±0°5′ | 0.2 |

| > 400mm to 1000mm | ±0.50mm | / | 0.3 |

| > 1000mm to 2000mm | ±0.80mm | / | 0.4 |

Plastics (ISO 2768-M)

Nominal size

Linear Dimensions

Angular Dimensions

Straightness & Flatness (T2)

0.5mm to 3mm

±0.10mm

±1°

0.02

over 3mm to 6mm

±0.10mm

±0°30′

0.02

over 6mm to 30mm

±0.20mm

±0°20′

0.05

over 30mm to 120mm

±0.30mm

±0°10′

0.1

over 120mm to 400mm

±0.50mm

±0°5′

0.2

over 400mm to 1000mm

±0.50mm

/

0.3

over 1000mm to 2000mm

±0.80mm

/

0.4

All parts are deburred. Tightest tolerance is available upon request.

Sheet Metal Fabrication General Tolerances

- Surface Roughness for blank material is Ra 125 max

- Sharp edges will automatically be broken and deburred. It is critical to indicate and describe critical edges that must remain sharp on a print.

- A manual quote will be requested for certain sheet metal designs that require custom toolings, such as hems, curled flanges, rolled sheets, stamped parts, and welded assemblies. Please allow us to review your part and provide you with an accurate cost and lead time if it contains these features.

| Process | Tolerance |

| Laser Cutting | ± 0.1mm |

| Bend to edge | ± 0.15mm |

| Bend to angle | ± 0.5° |

| Bend to hole | ± 0.25mm |

| Angularity | ±2° |

Precision Tailored to Your Needs

At okdor, we understand that your project’s success hinges on the precision of each part. That’s why we don’t just adhere to the ISO 2768 tolerance standard, we go beyond. We offer custom precision solutions, meticulously tailored to your unique specifications. With okdor, you’re not just getting a part, you’re getting a precision-crafted component designed to ensure the success of your project. Contact us to tailed your needs today.

Compliance with Standards

we go beyond just manufacturing custom parts. We ensure that every part we produce is a testament to our commitment to quality, precision, and environmental responsibility.

- ISO 2768: Okdor ensures all parts meet specified general tolerances.

- ISO 9001: We're certified for our commitment to high-quality products and services.

- AS9100: Okdor meets stringent aerospace industry requirements.

- REACH: We adhere to regulations for environmentally responsible manufacturing.

- RoHS: Okdor limits the use of specific hazardous materials in our products.

Inspection Services

Your parts are inspected to the degree that your projects require. Custom inspection is available if your part requires other inspection requirements.

- Material Test Reports

- Material Certificates

- CMM Inspection

- First Article Inspection Report Metals (AS9102)

- First Article Inspection Report Plastics (AS9102)

- Full Dimensional Report metals / plastic

Swift Turnaround

At Okdor, we understand that time is of the essence. That’s why we’re committed to delivering your CNC and sheet metal prototypes in as fast as 48 hours.

We’ve streamlined our processes to ensure quick turnaround without compromising on quality or precision. With Okdor, you can count on us to keep your projects on schedule

Resolving quality problems

Should your order not be as specified. Any issues with your parts can be raised within 5 business days after they are received. If these issues arise, we will resolve them as soon as possible, typically within 3 business days. Or you may contact us directly at sales@okdor.com

if you want to learn more about okdor’s quality assurance, please go and check out blog

FAQ's

As part of QA, the first step is to identify customer needs, after which further basic elements of QA are identified. It is therefore essential that we determine the purpose and size of your custom part. You may just need us to size and follow the drawing if that’s all you need.

Our equipment ensures the functional prototypes’ end-use parts are in proper working order which meets the client’s needs.

Depending on what kind of methods you need. We are happy to accommodate your custom requests for quality checking methods. Please contact us if you would like more information.

Our general tolerance standard is ISO 2786. We do accept tighter tolerance control on a case-by-case basis. Discuss alternative solutions by contacting us directly sales@okdor.com

Aside from the above methods, we can also offer some other options depending on each custom part’s quality assurance requirements.

Generally, we provide PDF files.

Generally, there is no charge for providing the report.