Rapid Prototyping Service

Upload your CAD files, receive an instant Rapid Prototyping quote and get your parts done in hours.

All uploads are secure and confidential

CNC Machining · Sheet metal Fabrication · Rapid Tooling · Fast Lead Time

Rapid Prototyping Service

Upload your CAD files, receive an instant Rapid Prototyping quote and get your parts done in hours.

All uploads are secure and confidential

CNC Machining · Sheet metal Fabrication · Rapid Tooling · Fast Lead Time

What is Rapid Prototyping?

A rapid prototype, created using turnkey manufacturing technology, allows for swift testing and evaluation. Essentially, it’s a fast and affordable method, typically costing between $20 and $50, for producing parts for hands-on reviews. With CNC machining being a popular choice due to its affordability, prototypes are usually ready within 1-3 business days. Other common rapid prototyping processes include sheet metal fabrication and progressive stamping services.

Meeting Unique Manufacturing Needs

Delivering Custom Solutions for Prototype and Small-Scale Production Challenges

We understand that the production of custom parts, particularly for prototypes and small-scale orders, needs to be addressed due to the inherent challenges in the estimation, equipment configuration, and unique engineering processes. Our clients typically seek short-run custom parts for a multitude of reasons, such as

- Launching a limited number of their product.

- Facilitating end-of-life production in a cost-efficient manner.

- Initiating pilot production for product trials with an initial set of parts.

- Fulfilling their customers' varying demands for custom parts in a time-sensitive manner.

- Sustaining production with an early supply of parts while preparing their large-scale mold.

- Verifying the design, compatibility, and functionality of components in a developing product through a prototype.

Rapid Prototyping Processes

“Okdor accelerates product development cycles with rapid prototyping services for engineers and designers. We offer cost-effective rapid manufacturing for quick prototype creation. The choice of process and materials is tailored to each product, with CNC Machining as a popular option due to advancements in additive manufacturing. We fabricate parts using a wide range of metals and plastics.”

Instant Quotes , fast lead times

Our Rapid Prototyping quotes are instant and updated in hours according to your drawings.

· Upload drawings

· Integrate DFM instantly

· Quote price and lead time

Rapid Prototyping Service

No more back and forth. No more switching vendors. We have all the rapid prototyping services you need under one roof.

· CNC Machining

· Sheet Metal Fabrication

· Progressive Stamping

· Part Marking

· Hundreds of materials and finishing options

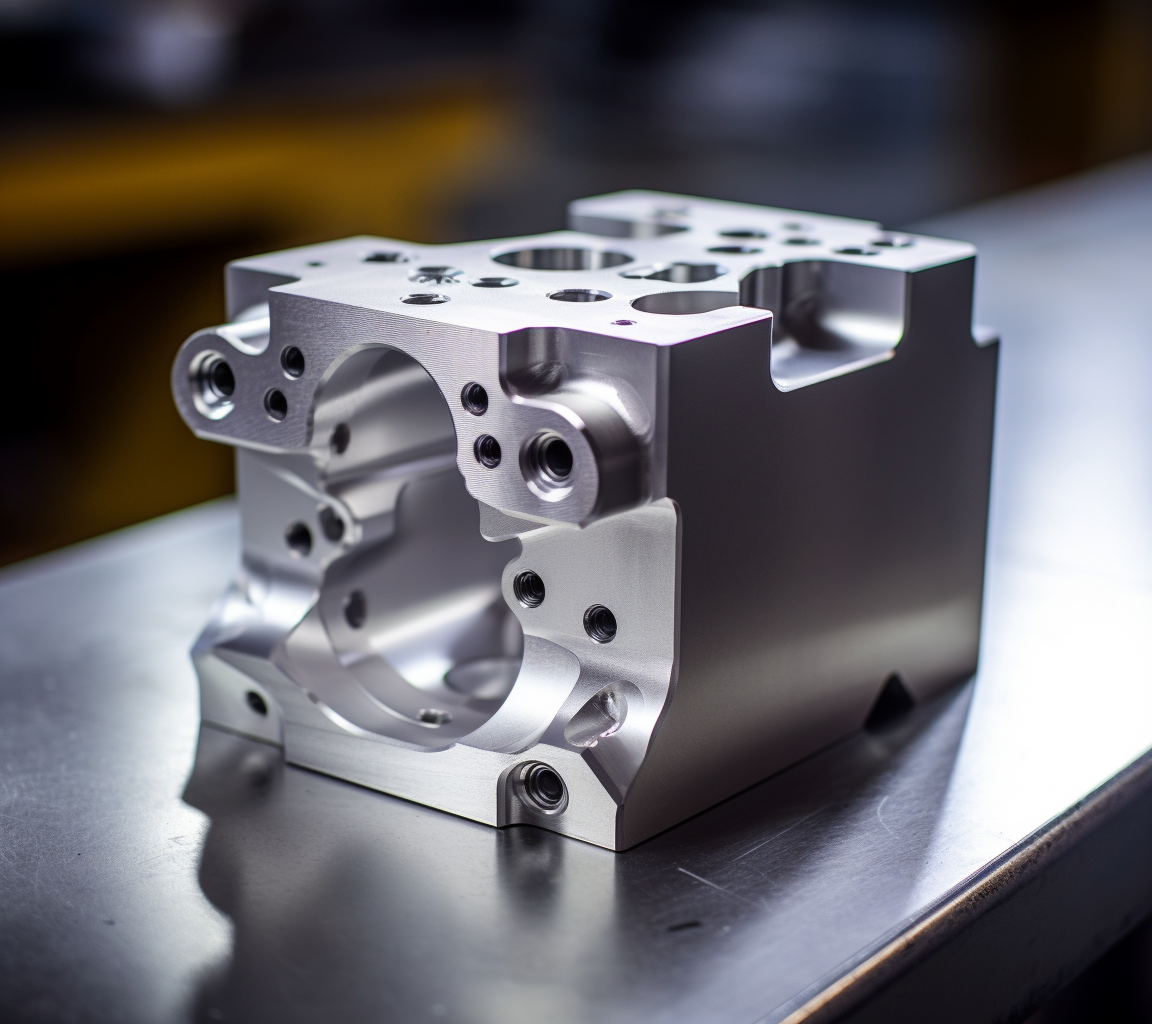

CNC Machining Prototyping

CNC Machining is the most accurate manufacturing option for plastic or metal parts.

| Capabilities | Description |

| Process | Turning and Milling ( 3, 4, 5-axis ) |

| Materials | 60 metals and plastics and more |

| Finishing | Anodized, powder-coated, brushed and more |

| Minimum order | 1 piece |

| Lead times | 24 to 72 hours |

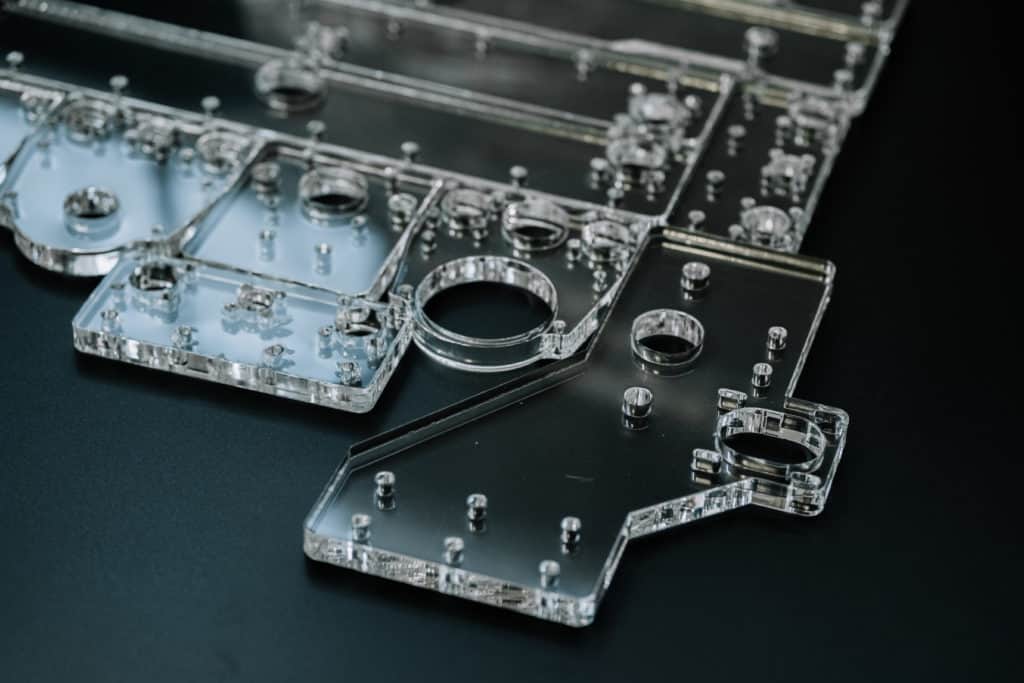

Sheet metal Prototyping

Sheet metal fabrication is great for function prototypes of metal parts requiring good mechanical properties.

| Capabilities | Description |

| Maximum Size | 3050 * 6100 * 60mm |

| Materials | 30 + metals |

| Finishing | Anodized, powder-coated, brushed, and more |

| Minimum order | 1 piece |

| Lead Times | 24 to 72 hours |

Available Surface Finishing for Rapid Prototyping

Surface Finishing generally apply after assemble which not only change the appearance but also provide much chemical resistance of the fine products

| Treatment | Material | Thickness | Color |

| Anodizing | Aluminum | 0.8-12 μm | RAL code, Pantone number |

| Nickel | All metals | 5-30μm | Silver appearance |

| Passivation | SS steel and Carbon Steel | 9~100 Å | Clear |

| Black oxide | Ferrous materials | 0.8μm | Black |

| Bead blasting | All metals | #100, #120 | Yellow or clear Iridescent |

| Powder Coating | All metals | 10-80μm | RAL code, Pantone number |

| Zinc-Nickel | All metals | 5-25 μm | Clear, Black , Iridescent |

| Chromate coating | Steel and Aluminum | 0.25-1.0μm | Yellow or clear Iridescent |

Quality Assurance

- Inspection report included in every order.

- Full dimensional inspection report available on request.

- Material and test reports are available on request.

- Strict NDA agreements are available.

- Surface Treatment report available on request.

FAQ's

Custom parts can be manufactured within 24 hours.

We offer fast turnaround manufacturing to product developers and engineers around the world who require a quick and cost-effective way to obtain their custom parts. This means we can produce low-volume CNC parts in 48 hours. Sheet metal parts can be made within 24 hours.

If use the material or process we recommend for your custom parts, of course, we will make sure the size and function are in good condition. in this way we can fast the CNC Machining process into 24 hours instead of 48 hours or even later.

Those more than 70 types of metals and plastics in stock are available for manufacturing same as other services.

Your custom part can be manufactured within 48 hours by rapid prototyping. Its purpose is to test the form, fit, and function of one or more components of a product under development. This may mean compromising the chemical surface treatment so that we can handle the prototypes to your hand ASAP.

We can handle the logistics by mutual agreement.

Depending on your specific parts. This will generally take more time to complete and deliver the custom part to you.

Machining Resources for engineers

CNC Machine Broke Down Before Deadline? What to Do Next

Your CNC supplier tells you a machine broke down, and your delivery is already close. At this stage, the explanation itself doesn’t change much—because even

CNC Supplier Outsourced Without Telling You — Parts Arrived Defective

Your CNC parts arrive defective, and only afterward do you discover the supplier outsourced the work without telling you. At that moment, the problem isn’t

When a CNC Supplier Goes Silent After a Deadline Change, What Now?

You told your CNC supplier the deadline changed. They acknowledged it—but responses slowed, updates became vague, and progress stopped moving. This isn’t a communication issue.

Get Started Today