You send your drawings, get a fast quote, and think production is on track—until your supplier stops replying or pushes delivery again. Missed deadlines don’t just “happen”; they usually follow the same early warning signs every time.

The clearest red flags are vague quotes, unrealistic lead times, slow replies, and sudden silence after PO submission. These usually mean the shop is overbooked, outsourcing work, or lacks in-house capacity—and your project is already slipping before machining begins.

Learn these warning signs your supplier will miss delivery—and how Okdor’s quoting and capacity systems prevent these failures to keep your parts on schedule.

Table of Contents

What Red Flags Should You Watch for in a Supplier’s Quote Response?

The biggest red flags are rushed replies, vague notes, and identical lead times across very different parts. These behaviors show the supplier hasn’t checked real capacity, fixture needs, or inspection load — meaning their delivery promise is built on assumption, not planning.

Most delayed projects reveal these signs early. A quick quote without tolerance details or surface-finish notes signals that the estimator didn’t coordinate with production. When you see “same-day quote” offers or no mention of setups, it often means they’re quoting to win business, not to verify feasibility. Once your PO arrives, the job competes with higher-priority work — and timelines start slipping.

We quote differently. Every schedule we send is based on confirmed spindle availability, material readiness, and process validation. Our team checks fixture feasibility and inspection slots before committing to delivery. That’s why our timelines hold under pressure — we quote from reality, not optimism.

You’ll also notice transparency: we flag coating lead times, secondary machining, or inspection bottlenecks up front, so expectations never shift mid-build.

Next Step: Before approving a quote, ask how the supplier verified machine time and inspection capacity. If they can’t answer confidently, your delivery risk is already high. Sharing your drawings with us ensures every lead time is validated before production begins.

Do Vague CNC Quotes Usually Lead to Delivery Problems Later?

Yes — vague quotes are the structural warning signs behind most missed deadlines. A quote that lists only price and lead time with no mention of setups, inspection, or secondary processes means the shop hasn’t connected estimating with actual production data. That disconnection creates chaos once machining begins.

The issue isn’t speed but planning depth. Many general CNC shops rely on rough spreadsheets or memory-based quoting. Without integrated CAM or capacity tools, they can’t see the true workload. When parts reach the floor, missing cutters, underestimated tolerances, or coating backlogs trigger stop-and-go scheduling that destroys momentum.

Our workflow eliminates that risk. Each estimate originates from verified CAM simulations and fixture planning. Lead times are confirmed only after checking spindle load, inspection queue, and finishing availability. We never quote blind or start until every dependency is locked in. That’s how schedule promises survive real-world pressure.

By quoting from verified process data, we prevent mid-project clarifications that drain time and trust. Engineers gain visibility into what’s been planned and what could extend lead time before a PO is issued.

Next Step: If a quote lacks process notes or inspection planning, it’s not validated. Request a feasibility review before committing. We’ll confirm manufacturability, capacity, and lead-time realism within 24 hours — helping you avoid the vague-quote cycle that turns two-week jobs into four.

Can You Trust a 2-Week Lead Time Quote for Complex Parts?

Only if the shop can prove how that two-week window was built. A short lead time means nothing unless it’s backed by verified spindle availability, tool setup, and inspection scheduling. Unvalidated “two-week” quotes routinely become four-week delays once machining starts.

Fast promises feel reassuring under pressure, but they often skip real planning. Many job shops issue quick quotes before checking fixture design, tooling readiness, or machine load. When the setup takes longer or cutters aren’t on hand, the job stalls — and you learn the truth through silence, not updates.

We quote differently: every delivery date comes after verifying spindle allocation, toolpath setup time, and inspection capacity. If a part involves multi-axis work or surface-critical features, that time is built in from the start. Because we confirm production readiness before committing, our timelines hold even under tight deadlines.

That process consistency saves engineers more than time — it prevents re-testing, missed integration windows, and cascading project slips.

Next Step: When a supplier quotes two weeks, ask what portion covers setup, machining, and inspection. If they can’t show a breakdown, the clock hasn’t started. Share your drawing with us for a capacity-confirmed schedule — so a two-week quote stays two weeks in reality.

Parts stuck in production?

Send your file now for an immediate re-quote and verified timeline you can activate if your current supplier misses again.

How to Spot Overbooked Shops Before They Take Your PO?

Overbooked shops expose themselves through vague scheduling, slow follow-ups, and identical lead times on every quote. These patterns mean the supplier is already running at or beyond capacity — and once your PO lands, your project joins a silent queue.

When estimators say, “we’ll confirm delivery after PO,” that’s your warning. They’re quoting to hold your slot, not because time exists on the floor. As new orders pile in, older ones slide. This is why many engineers face three-week “updates” that stretch into six.

We prevent that by linking quoting directly to live capacity data. Every quote reflects actual spindle availability on specific machines. If the window doesn’t exist, we say so before you commit. We also confirm machining start dates and inspection hand-offs before PO — eliminating the “we’ll fit it in later” problem.

That transparency keeps schedules predictable. Engineers know exactly when a part enters machining, and communication stays steady — not reactive.

Next Step: Before sending a PO, ask your supplier for the planned machining start date and available spindle count. If they hesitate or deflect, they’re already full. Upload your drawings to us for capacity-verified scheduling that keeps your delivery dates from disappearing into the backlog.

How to Verify That Your Supplier Actually Has a Machine Shop?

Ask for proof — photos, equipment lists, or inspection reports tied to their own facility. Many CNC suppliers online are brokers, not manufacturers, and every day they hold your PO adds 24 hours of uncertainty to your timeline.

Brokers relay your drawings to subcontractors, waiting for whichever responds first. Their quotes look generic, contact emails unbranded, and there’s no mention of machines or inspection gear. Once production starts, you get silent because they’re waiting on someone else’s schedule.

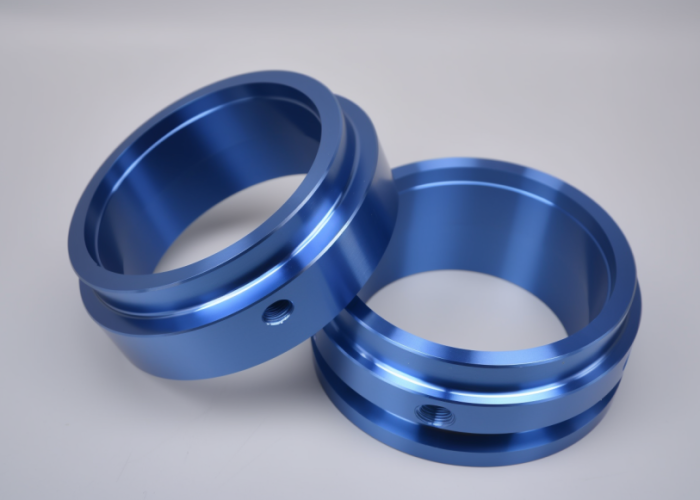

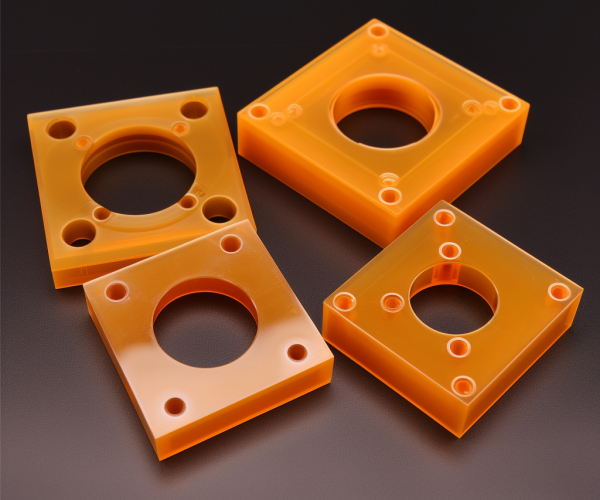

We work differently. All projects run in-house using verified equipment — from 5-axis centers to CMM inspection. Each quote is generated by our own engineers, and machining photos or setup confirmations are available upon request. We confirm who’s running your job and where, before you approve anything.

That visibility shortens risk chains and eliminates hidden mark-ups or communication gaps. It’s how engineers maintain control when quality and timing matter most.

Next Step: Before awarding a job, request direct evidence of in-house machining — equipment lists, operator photos, or inspection logs. If the supplier can’t show them, you’re dealing with a broker. Send your drawings to us for direct-manufacturer confirmation and a verifiable production plan from day one.

What Do Reliable CNC Suppliers Do Differently From Risky Ones?

Disciplined suppliers plan before they promise. They verify tooling, fixture design, and inspection timing before quoting — while reactive ones quote fast, plan late, and spend the rest of the job catching up. The difference isn’t cost; it’s consistency. Reliability is built through preparation, not optimism.

Reactive shops separate quoting from production reality. Estimators send numbers without confirming spindle availability or inspection load, assuming someone on the floor will “fit it in.” That gap leads to downtime, re-setups, and lost transparency — every hour of re-planning adds roughly half a day to your delivery window.

We quote from verified data. Before confirming price or lead time, we lock programming schedules, fixture prep, and inspection slots in the same system used for machining. That’s how our commitments hold — each quote represents a scheduled workflow, not a guess.

Structured suppliers also maintain predictable communication. They provide milestone updates at machining start, inspection release, and shipment confirmation. Disorganized shops only respond when issues surface, leaving engineers chasing information instead of tracking progress.

Next Step: When reviewing a quote, ask when programming starts, when machining begins, and when inspection is reserved. If your supplier can’t answer clearly, risk is already built in. Send your drawing to us for a schedule validated before the quote ever leaves our inbox.

Why Does Your Supplier Go Dark After You Send the PO?

Silence after a PO usually means production never started. Most suppliers go quiet because they’ve hit a scheduling wall, lost tooling, or depend on subcontractors who haven’t responded. Every week of silence typically adds three to five days to your real completion date.

Once the order arrives, quoting optimism meets shop reality. Programming overruns, missing materials, or overlapping projects push your job to the back. Without structured communication checkpoints, engineers hear nothing until the delay becomes irreversible — and recovery costs double.

We eliminate that risk by building communication into the process. Each job includes fixed updates — setup confirmation, first-article inspection, and shipping forecast — delivered automatically, not on request. If timing changes, notice arrives with recovery options, not excuses.

One early update can prevent weeks of downstream delay. A 24-hour tooling alert protects entire validation schedules, while silence multiplies cost across assemblies and testing.

Next Step: If you haven’t heard from your supplier within three business days of the PO, assume production hasn’t begun. Request an immediate progress timeline or move to a supplier with defined update checkpoints. Share your files with us to restore visibility and regain control of your schedule.

Why Do CNC Suppliers Keep Pushing Back Your Delivery Date?

Even when a silent supplier finally replies, another pattern often begins — constant delivery extensions. These rolling updates signal poor forecasting or overloaded subcontracting. After the second delay, 80 % of projects slip another 2–3 weeks because the underlying capacity problem remains unsolved.

Many shops quote from optimistic averages instead of verified schedules. They ignore fixture rework, inspection bottlenecks, or anodizing queues. When reality hits, they renegotiate time week by week to mask backlog pressure — a slow erosion of trust engineers recognize instantly.

We plan the entire chain — machining, finishing, and inspection — before accepting a job. Our live capacity tracker locks spindle and finishing schedules upfront. If workload changes mid-project, the system rebalances instantly and sends updated ship estimates within hours. You get data-backed adjustments instead of vague promises.

Predictable suppliers treat timeline accuracy as a deliverable. Updates arrive before you ask, and every change is explained with cause and recovery path. That’s the difference between schedule control and schedule drift.

Next Step: After two missed dates, stop waiting for a third. Ask to see the current queue and subcontract plan — or transfer the part to a shop that verifies capacity in real time. Upload your drawing to us for a turnaround plan that protects both your deadlines and credibility.

What Does “We’ll Update You Next Week” Really Mean?

It usually means your supplier doesn’t have real progress to report. “Next week” is a delay placeholder — a phrase suppliers use when they’re behind schedule, missing material, or waiting on subcontract updates they hope to resolve quietly. The moment you hear it, your delivery clock has already started slipping.

These vague promises hide deeper issues. When updates arrive in weekly loops with no data or photos, it’s not communication — it’s deflection. Each “next week” response costs 5–7 days of reaction time that you could’ve used to pivot or reallocate resources. Multiply that across assemblies, and one evasive phrase can derail an entire build schedule.

We approach updates as measurable deliverables. Every project milestone — programming, machining, finishing, inspection — is timestamped and tied to automated notifications. That’s why we never say “next week”; we give precise dates supported by current production data.

Predictable communication is a performance metric, not a courtesy. Engineers rely on visibility to plan integration and testing — and timely updates make supplier reliability measurable.

Next Step: The next time you hear “we’ll update you next week,” ask for a specific milestone, inspection photo, or toolpath timestamp. If they can’t show evidence within 24 hours, assume production hasn’t moved. Share your files with us for milestone-based tracking that replaces vague promises with verified progress.

When Should You Line Up a Backup Supplier (Before It’s Too Late)?

If you’re already hearing “we’ll update you next week,” it’s time to protect your schedule — not just hope for improvement.

The best time to qualify a backup supplier is when warning signs first appear, not after failure. Delayed quotes, shifting delivery dates, or repeated excuses are early indicators that capacity or capability is breaking down. Waiting until your current supplier collapses can cost two to four weeks of recovery time.

Engineers often hesitate to prepare a second source, but the cost of standby qualification is tiny compared to the downtime of a stalled build. Once your parts are trapped mid-production, re-quoting, fixturing, and setup easily double total project delay.

We maintain standby quoting and process validation for customers managing supplier risk. When a primary vendor misses, machining can begin within 24 hours because the groundwork is already verified. That’s not redundancy — it’s risk control.

A backup supplier isn’t about mistrust; it’s about maintaining delivery credibility when one link breaks. Engineers who prepare early never face total stoppage — they just redirect.

Next Step: Don’t wait for silence or repeated extensions. Qualify a backup while your current project still runs. Upload your drawings now for pre-assessed manufacturability and a validated quote on file — ready to activate the moment your supplier falters.

Conclusion

Most delivery failures start with vague quotes and silent updates — not machining difficulty. We specialize in rescuing delayed or rejected CNC projects with verified capacity and transparent scheduling. Upload your drawings now for an immediate assessment and revised quote within 24 hours — before another supplier setback costs you weeks.

Frequently Asked Questions

Yes. Send us the latest revision, partial parts (if any), and inspection data. We’ll evaluate what’s complete, confirm remaining work, and provide a revised quote and timeline within 48 hours. Most recovery projects restart machining in 3–5 days, depending on fixture reuse and material availability.

Upload your files through our portal. We’ll review manufacturability and provide a detailed quote within 24 hours, often the same day for urgent cases. If modifications are needed, we’ll suggest minimal design adjustments so your parts can move straight into production without another rejection cycle.

We’ll run a capability and cost breakdown to show what drives their pricing — tooling, setup, or margin protection. Our quoting system benchmarks against verified spindle time and process data, giving you a transparent comparison and alternative pricing within one business day for informed sourcing decisions.

Yes. We provide free DFM feedback within 24 hours of receiving your drawing. Our engineers flag tolerance, feature, or material risks that typically cause rejections elsewhere — so you know whether your current supplier’s claim of “not machinable” is valid or just a capacity excuse.

Every quote is tied to live spindle scheduling — machining starts only when capacity is confirmed. You’ll receive milestone updates (setup, inspection, shipment) automatically. For standard projects, we hold 95% on-time completion with immediate alerts if conditions shift, so you’re never left chasing updates again.

Yes. Upload your files and note your target date — our engineering team prioritizes emergency builds. You’ll receive a feasibility response within 12 hours and a full quote in 24. If material’s in stock, we can begin machining within 48–72 hours to recover lost schedule time.