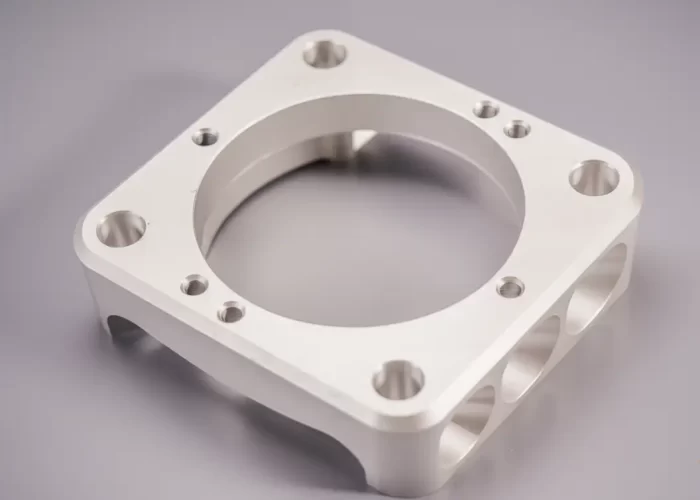

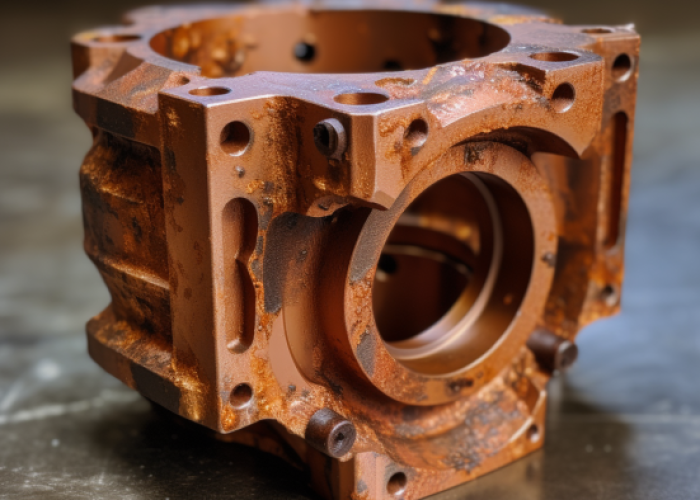

Designing for CNC machining isn’t just about geometry — it’s about preventing costly corrosion problems before they start. With decades of experience manufacturing parts for aerospace, medical, and industrial sectors, we’ve seen how smart material and design choices dramatically reduce rust risks while keeping costs reasonable.

Prevent rust on metal parts through three key strategies: choose corrosion-resistant materials like 316 stainless or 6061 aluminum with anodizing, modify geometry to eliminate moisture traps and overlapping joints, and apply protective coatings like powder coating or zinc plating based on your environment and electrical requirements.

Learn which materials rust in your environment, when coatings save more than alloys, and how geometry tweaks prevent moisture issues—backed by CNC insights.

Table of Contents

Will my material rust in this environment?

6061 aluminum naturally resists corrosion but may need anodizing for harsh outdoor applications. 304 stainless steel resists most corrosion but fails in chloride environments. Mild steel rusts rapidly in humid conditions and requires protective coatings for most applications.

Here’s how common materials perform in typical product environments:

Material Indoor Applications Outdoor/Humid Salt/Chemical Exposure Performance Timeline

6061-T6 Aluminum Excellent (no treatment needed) Requires anodizing above 70% humidity Poor (pitting within 12 months) 18 months outdoors unprotected

304 Stainless Steel Excellent Good for most climates Fails in chloride environments 6–12 months in salt spray

316 Stainless Steel Excellent Excellent Excellent (marine rated) 500+ hours ASTM B117 testing

Mild Steel Requires coating Rusts within weeks Rapid failure 3–5 years with quality powder coating

Environment Decision Tree:

- Salt exposure or coastal location? → Use 316 stainless steel (Phoenix outdoor parts perform well with 304, but Miami requires 316)

- Humidity above 70% or frequent condensation? → 6061 aluminum needs anodizing, stainless performs well

- Indoor controlled environment? → 6061 aluminum or coated mild steel work fine

- Chemical contact (cleaning agents, process fluids)? → Verify material compatibility or upgrade to 316 stainless

In our experience machining audio equipment housings, 6061 aluminum performs excellently in recording studio environments but required Type II anodizing for outdoor concert equipment after we documented surface pitting on unprotected parts in Seattle’s marine climate. Per ASTM B117 salt spray testing, properly anodized 6061 withstands 500+ hours before corrosion initiation.

Design Takeaway: Use this environment assessment to avoid over-specifying expensive materials. Match your specific conditions (geography, humidity, chemical exposure) to material limits rather than defaulting to the most expensive corrosion-resistant option.

Should I change my material or apply a surface treatment to prevent rust?

Choose material upgrades for high-volume production (>100 parts) and when tight tolerances can’t accommodate coating thickness. Choose surface treatments for prototypes, low volumes, or when you need specific colors—anodizing adds 0.0005-0.002″ thickness while powder coating adds 0.002-0.005″ thickness to all surfaces.

Quick Cost Decision Tool: If your mild steel part costs $50 to machine:

- 304 stainless version = $70 (+40%)

- Powder coating mild steel = $57.50 (+15%)

- Clear anodized 6061 aluminum = $54 (+8%)

Real Design Decisions:

- High-volume production (>100 parts): Material upgrade eliminates coating logistics

- Prototype/low-volume (<100 parts): Surface treatments offer cost and flexibility advantages

- Need colors or textures: Only coatings provide these options

- Tight tolerances or press fits: Material upgrades avoid coating thickness complications

In our experience with outdoor equipment brackets, switching from coated mild steel to 304 stainless eliminated coating logistics bottlenecks for 500-piece orders. Per ASTM A240 specifications, 304 stainless provides documented corrosion resistance without additional processing steps.

Design Takeaway: Use surface treatments for prototypes and low volumes where flexibility matters. Choose material upgrades for production volumes where coating logistics add complexity or when assembly requirements demand dimensional consistency.

Should I design blind holes or through-holes to avoid moisture trapping?

Use through-holes whenever structural and aesthetic requirements allow—they eliminate moisture trapping completely. When blind holes are necessary, limit depth-to-diameter ratios to 2:1 for holes under 6mm and add 1.5mm cross-drilled drain channels at the bottom to prevent corrosion.

Design Decision Rules:

- Use through-holes when: Structural loading allows, appearance isn’t compromised by visible holes on back side, assembly method can accommodate nuts or back-side access

- Use blind holes when: Through-holes would weaken thin walls, aesthetic requirements demand clean back surfaces, assembly space doesn’t allow back-side fastener access

Moisture Prevention Design Guidelines:

Hole Type & Diameter Maximum Depth Ratio Drainage Solution

Blind holes <6mm diameter 2:1 depth-to-diameter Add 45° chamfer at bottom

Blind holes >6mm diameter 3:1 depth-to-diameter* Cross-drill 1.5mm drain at bottom

Counterbored holes Any depth Design gasket groove or sealant channel

CAD Design Changes:

- Add drain channels: 1.5mm cross-drill at lowest point of blind features

- Taper hole bottoms: 45° chamfer prevents sharp moisture-trapping corners

- Relocate holes: Move to angled surfaces where possible for natural drainage

- Design escape routes: Connect deep pockets to part edges via shallow channels

In our experience with medical housings, adding 1.5mm cross-drilled drain channels eliminated moisture failures while maintaining IP65 sealing when combined with appropriate gaskets. We validate drainage effectiveness using accelerated humidity testing per ASTM D2247.

Design Takeaway: Default to through-holes unless structural or aesthetic requirements force blind holes. When blind holes are necessary, add drainage features in your CAD model now rather than hoping coatings will solve moisture problems later.

Should I avoid overlapping sheet metal joints?

Avoid overlapping sheet metal joints whenever possible—they create moisture traps that accelerate corrosion even with protective coatings. When overlaps are structurally necessary, design them with sealant channels, drainage gaps, or welded seams to eliminate moisture infiltration paths.

Full penetration welded butt joints maintain equivalent load capacity to overlapping designs, while butt joints with backing plates provide 90% strength with better corrosion resistance. For appearance-critical applications, flanged joints with gasket grooves eliminate moisture while maintaining clean aesthetics. When assemblies must be removable, mechanical fasteners through backing plates allow disassembly without joint damage.

Application-Specific Solutions: Structural brackets benefit from butt joints with 3mm backing plates that maintain strength while eliminating crevices. Enclosure panels work better with flanged edges and silicone gasket channels for clean aesthetics. Outdoor equipment requires full penetration welds to eliminate all moisture paths, while indoor assemblies can use mechanical joints with structural adhesive for adequate sealing.

Key CAD Changes:

- Replace lap joints: Use butt joints with backing plates for equivalent strength

- Add sealant channels: 1.5mm groove along joint perimeter for adhesive or gasket

- Design drainage gaps: 3mm minimum gap at bottom edge of vertical joints

- Specify weld-through: Full penetration welds eliminate crevice corrosion paths

Drawing Callout Examples:

- For backing plates: “3mm backing plate, full contact weld around perimeter”

- For sealant channels: “1.5mm x 1.5mm groove for structural adhesive, continuous around joint”

- For drainage gaps: “3mm min. gap at bottom edge, no sealant”

- For welded joints: “Full penetration weld, grind flush, no crevices”

Design Validation Check: Verify backing plate thickness equals 1.5x base material thickness for structural equivalence. Check that sealant channels don’t compromise load paths or create stress concentrations. Ensure drainage gaps don’t reduce structural performance below design requirements. Confirm welded joint access allows proper penetration without geometric interference.

In our experience with marine equipment housings, switching from overlapped corners to flanged joints with EPDM gaskets eliminated salt corrosion while improving IP65 sealing performance. We validate joint integrity using ASTM B368 testing combined with pressure decay testing per IP rating requirements.

Design Takeaway: Choose joint alternatives based on your strength requirements and aesthetic needs. Butt joints with backing plates solve most structural applications, while flanged designs work better when appearance matters more than maximum strength.

What surface finishes are most effective for rust protection?

Anodizing provides the best corrosion protection for aluminum parts, while powder coating offers superior protection for steel components. Hard anodizing (Type III) delivers excellent durability for harsh environments, while clear anodizing (Type II) provides adequate protection for indoor applications at lower cost.

Environment-Specific Finish Selection:

Environment Aluminum Choice Steel Choice Why This Finish

Indoor controlled (<50% humidity) Clear anodize Type II Black oxide + oil Cost-effective, adequate protection

Outdoor temperate (Seattle, Denver) Hard anodize Type III Powder coating Handles moisture, UV, temperature cycling

Coastal/marine (Florida, California) Hard anodize Type III Hot-dip galvanizing + powder coat Maximum salt spray resistance

Industrial/chemical Hard anodize Type III 316 stainless (no coating) Chemical compatibility critical

Anodizing requires machining threads oversize since post-coating machining isn’t possible, while powder coating allows masking of threaded features. Anodized surfaces preserve engraved text clearly, but powder coating may fill fine details depending on thickness. Anodizing blocks electrical conductivity completely, requiring separate contact areas for grounding, while powder coating allows design of specific grounding points.

Design Considerations:

- Threaded holes: Machine oversize for anodizing, mask for powder coating

- Electrical connections: Design separate contact areas for anodized parts

- Part markings: Use adequate depth for text that will be coated

Drawing Callout Examples:

- For anodized threads: “M6 x 1.0 TAP BEFORE ANODIZING, Type II clear anodize”

- For powder coated threads: “M6 x 1.0 thread, mask during powder coating”

- For electrical contacts: “Remove anodizing 5mm x 5mm area for electrical contact”

- For part markings: “0.1mm min. engrave depth, anodize over”

Design Validation Check: Verify thread engagement length remains adequate after anodizing thickness. Confirm electrical contact areas provide sufficient surface area for current requirements. Check that part markings remain legible after coating application. Ensure press-fit features account for coating build-up in tolerance stack-up calculations.

In our experience with outdoor audio equipment, Type III anodizing on 6061 aluminum faceplates maintains appearance and function after 5+ years in touring applications. We validate coating performance using ASTM B117 salt spray testing and document thickness measurements per ASTM B244 standards.

Design Takeaway: Match finish selection to your actual environment and functional requirements. Indoor parts rarely need expensive hard anodizing, while coastal applications justify the extra cost for long-term reliability.

Will coatings block my electrical connections?

Most protective coatings block electrical conductivity and require design modifications for grounding and electrical connections. Anodizing completely insulates aluminum surfaces, while powder coating creates a non-conductive barrier on all metals. Plan electrical contact areas during the design phase rather than removing coatings after manufacturing.

Contact Area Sizing Guide:

Current Requirement Contact Area Needed Coating Solution

Low current (<1 amp) 5 mm × 5 mm minimum Mask during coating

Medium current (1–5 amps) 10 mm × 10 mm minimum Mask during coating

High current (5–15 amps) 15 mm × 15 mm minimum Machine after coating

Grounding applications 10 mm × 10 mm minimum Mask or machine after

Design Solutions: Mask contact areas during coating application for clean, repeatable surfaces. Machine contact areas after coating when precise dimensions are critical. Design separate grounding studs that remain uncoated during manufacturing. Use conductive gaskets that penetrate coating thickness for EMI shielding applications.

Drawing Callout Examples:

- For masked areas: “MASK 10mm x 10mm area during anodizing for electrical contact”

- For machined contacts: “Machine contact surface after coating, Ra 3.2 μm max”

- For grounding studs: “M4 stud, machine threads after anodizing”

In our experience with audio equipment chassis, masking 15mm diameter areas around grounding studs during anodizing maintains proper electrical performance while preserving corrosion protection. We validate electrical continuity using standard resistance testing methods.

Design Takeaway: Size contact areas for your actual current requirements using 1 amp per cm² as a guideline. Plan electrical connections during the CAD design phase rather than trying to remove coatings later.

Will rust protection affect part tolerances or aesthetics?

All protective coatings add thickness that affects part dimensions and assembly clearances. Anodizing adds 0.0005-0.002″ per surface, while powder coating adds 0.002-0.005″ per surface. Plan for coating thickness during design to avoid interference fits, binding assemblies, or aesthetic problems.

Coating Thickness Reference:

Coating Type Thickness Added Tolerance Impact Minimum Wall Thickness

Clear Anodizing (Type II) 0.0005–0.001″ Minimal 0.040″

Hard Anodizing (Type III) 0.001–0.002″ Significant 0.060″

Powder Coating 0.002–0.005″ Major 0.080″

Zinc Plating 0.0003–0.001″ Minimal 0.020″

Tolerance Calculation Method:

- External surfaces: Subtract coating thickness from machined dimension

- Internal surfaces: Add coating thickness to machined dimension

- Clearance fits: Add total coating thickness from both mating parts

Example: 6.000mm hole with 0.05mm powder coating = machine to 6.05mm for final 6.000mm dimension.

Key Design Considerations:

- Corner radii: Use 0.5mm minimum to prevent coating pooling

- Threaded features: Machine oversized or mask during coating

- Press-fits: Reduce interference by coating thickness amount

- Surface finish: Coatings hide minor machining marks but reveal major defects

Drawing Callout Examples:

- Dimension control: “Machine Ø6.05mm hole, final Ø6.0mm after coating”

- Aesthetic specs: “RAL 7035 powder coat, 60-80 μm thickness”

- Thread protection: “Mask M6 threads during powder coating”

In our experience with medical device housings, accounting for anodizing thickness during design prevents binding in precision assemblies while maintaining proper fit tolerances. We validate dimensional compliance using CMM measurement per ISO 2768 standards.

Design Takeaway: Calculate coating impact on dimensions during initial design, not as an afterthought. Design for final coated dimensions to avoid assembly problems.

Conclusion

Effective rust prevention requires smart material choices, thoughtful geometry design, and appropriate surface treatments matched to your environment. Avoid moisture traps, plan for coating thickness, and design electrical connections early to prevent costly redesigns later.

Contact us to explore manufacturing solutions tailored to your corrosion-resistant part requirements.

Frequently Asked Questions

No, all coatings add thickness that affects dimensions. Anodizing adds 0.0005-0.002″ per surface, while powder coating adds 0.002-0.005″. Design parts undersize by coating thickness to maintain final dimensions, or specify larger clearances for mating parts.

Yes, anodizing and powder coating block electrical conductivity completely. Specify masked areas during coating or post-coating machining for grounding points. Use 10mm x 10mm minimum contact area for reliable grounding applications.

304 stainless steel can develop surface staining and pitting in chloride-rich environments like coastal or pool areas. Use 316 stainless steel for these applications, or stick with 304 for indoor and mild outdoor environments.

Butt joints with backing plates provide 90% strength of lap joints while eliminating moisture traps. This approach adds 10% material cost but eliminates expensive coating failures and warranty issues long-term.

0.080″ minimum wall thickness prevents distortion during powder coating cure cycles. Thinner sections may warp due to thermal stress, requiring fixture support or alternative coating methods like liquid paint.

Type II clear anodizing provides excellent protection for most outdoor applications at 8-15% additional cost. Hard anodizing (Type III) is only necessary for harsh coastal or industrial environments where the extra expense is justified by extended service life.